Page 1

INSTALLATION

AND

OPERATING

R

INSTRUCTIONS

EASY-FILL HOT FOOD WARMER

Models:

SM50EZ, SHFWEZ-12D, SHFWEZ-1,

SHFWEZ-2D, -3D, -4D, -5D, -6D

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

UNIT MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughly before installing or servicing this equipment.

Initial heating of unit may generate smoke or fumes and must be done in a well ventilated area.

Overexposure to smoke or fumes may cause nausea or dizziness.

This equipment has been engineered to provide you with year-round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

P/N 70103009 3/06

Phone: +1

Fax: +1 (214) 565-0976

Toll Free: +1 (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

(214) 421-7366

APW WYOTT

729 Third Avenue

Dallas, TX 75226

!!

1

Page 2

TABLE OF CONTENTS

General Installation

Specifications:

SM50EZ

SHFWEZ-12D

SHFWEZ-1D

SHFWEZ-1D w/Shut-Off Valve

SHFWEZ-2, -3, -4, -5, -6

SHFWEZ-2D, -3D, -4D, -5D, -6D w/Shut-Off Valve

Warranty

2

A SM50EZ

B SM50EZ-12D 5

C SHFWEZ-1D 6

D SHFWEZ-2, -3, -4, -5, -6 7

Parts List & Exploded View

Wiring Diagram 9

Parts List & Exploded View

Wiring Diagram 11

Parts List & Exploded View

Wiring Diagram 13

Parts List & Exploded View 14

Parts List & Exploded View

Parts List & Exploded View 18

Wiring Diagram 20

4

8

10

12

16

22

GENERAL INSTALLATION

1. Always clean equipment thoroughly before use. (See general cleaning instructions.)

2. Check rating label for your model designation & electrical rating.

3. For best results, use stainless steel counter tops.

4. All dimensions in parenthesis in centimeters unless noted.

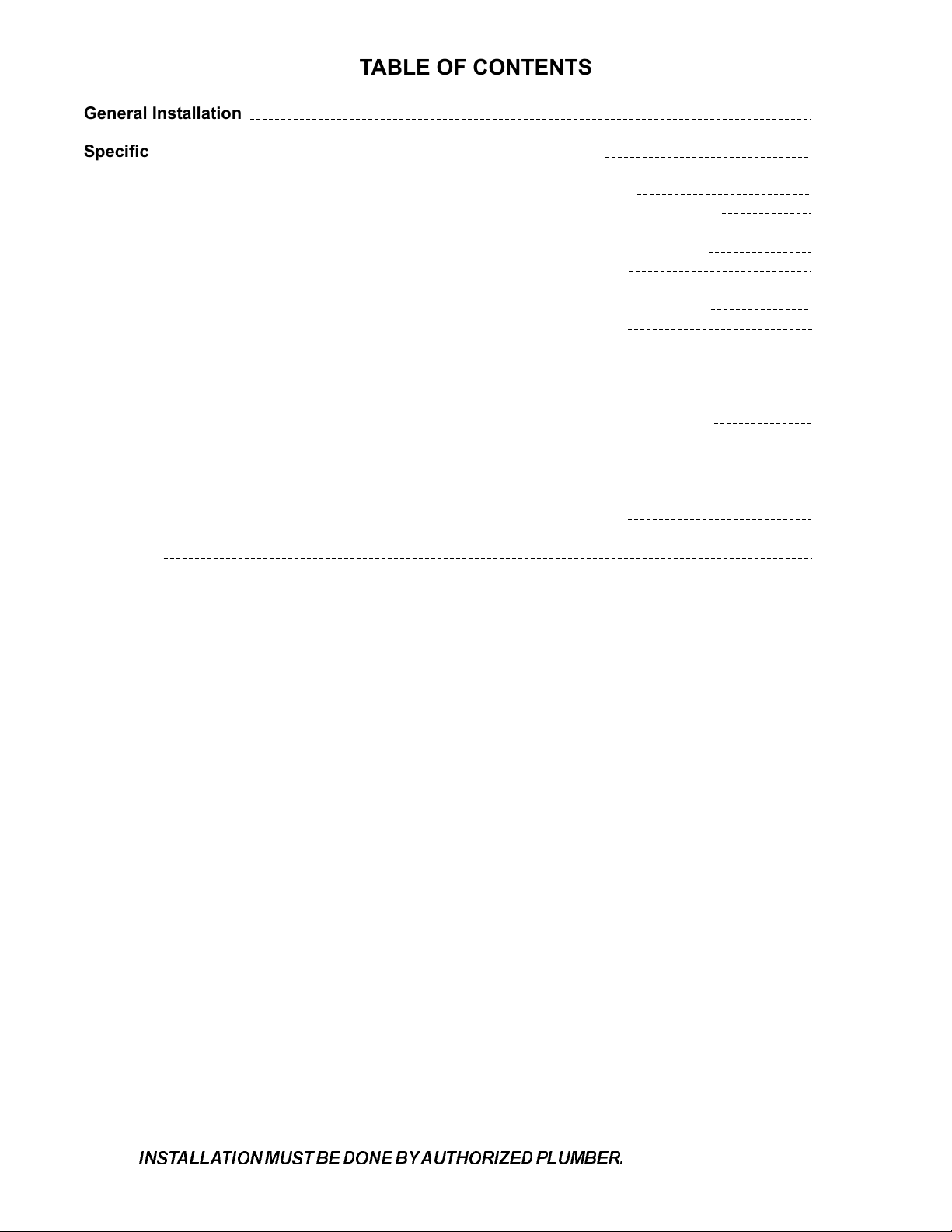

INSTALLATION INSTRUCTIONS FOR EZ WELL SUPPLY LINE

1. Install PIN 54508, brass fitting in each end of the solenoid using Teflon tape (not supplied).

2. Wrap the threads of the fitting as shown in the figure NO.1.

3. Remove the nut from the brass fitting and the sleeve from the inside of the fitting.

4. Place the sleeve and the nut, nut first, over the W copper tubing, PIN 54578, supplied with the

equipment.

5. Install the line into the solenoid and tighten the nut finger tight.

6. Using a wrench, tighten the nut far enough to crush the sleeve and attach the line.

NOTE:

7. Install the 3/8 x 1/4 adapter to the 3/8 stainless steel tube fitting using Teflon tape as shown in

figure NO.2.

8. Using the other end of the copper tube, install the line, nut, and sleeve to theadapter.

9. Tighten using the sameprocedure as before.

10. Turn on water supplyand look for leaks. If any leaks are found, tighten the nuts until leak is stopped.

NOTE:

To fill, turn one control to the first position and allow all wells to fill completely. After wells are full, set

controls to desired settings.

INSTALLATIONMUSTBE DONE BYAUTHORIZEDPLUMBER.

Do not over tighten nut. Just enough pressure is required to stop water leaks.

With EZ-fill multi-well units, turning on any of the controls will start water to fill all of the wells.

2

Page 3

FIGURE #1

Part Description: Brass Connector Male 1/8” NPT x 1/8” Tube

1/8 NPT

FIGURE #2

Inlet Tube

1.125

Sleeve

Teflon Tape APW

#89117, as Required

1/4” Copper Tube

Fitting Nut

Coupling

Teflon Tape

3/8” Female to

1/4” Tube Adaptor

GENERAL OPERATION INSTRUCTIONS

1 . All food service equipment should be operated by trained personnel.

2. Do not allow your customers to come in contact with any surface labeled "CAUTION HOT."

3. Do not cook, warm or hold food directly in liner pans (well pans). Always use steam table pans /

insets, etc. Steam table pan depth shouldnot exceed 6".

4. Never hold food below 150°F (66°C).

Wet set-up and operation procedures (Units with drains)

1. Turn thermostat control to "10" setting or if equipped with infinite controls to "7" or "HI". Preheat for

approximately 30 minutes. Pans will fill, to correct level,with water to white probe. . 2. Place covered

inset with preheated product into well. 3. Readjust control after another 30 minutes of operation to

the "6" setting depending on the amount and/or thickness of product. 4. Keep inset / steamtable

pan(s) covered to maintain ideal servingtemperature. 5. Water is automatically kept at correct level.

NOTE: Turning on any controlwill activate autofill.

GENERAL CLEANING INSTRUCTIONS

1. NEVER clean any electrical unit by immersing it in water. Turn off before surface cleaning.

2. Always clean equipment thoroughly before first use. Clean unit daily. Except where noted on charts:

Use warm, soapy water. Mild cleansers & PLASTIC scouring pads may be used to remove bakedon food & water scale.

3. Turn off electrical units before cleaning or servicing. All service should be performed by an APW

authorized agency.

GENERAL TROUBLESHOOTING

Always Ask & Check:

1. Is the unit connected to a live power source?

2. Check the circuit breaker.

3. Is power switch on & pilot light glowing?

4. Check rating label.Are you operating unit on proper voltage?

If the above checks out, and you still have problems, call an APW authorized service agency.

3

Page 4

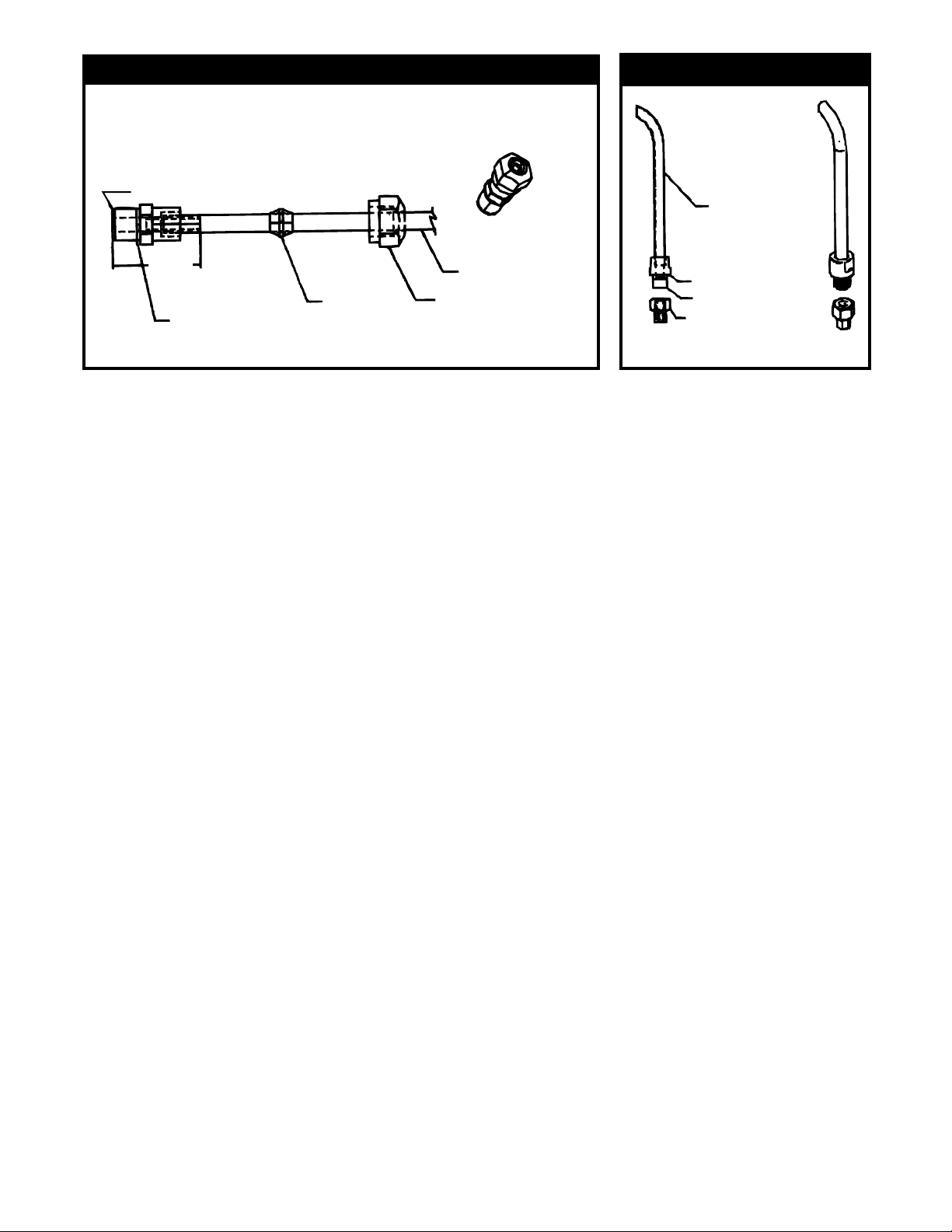

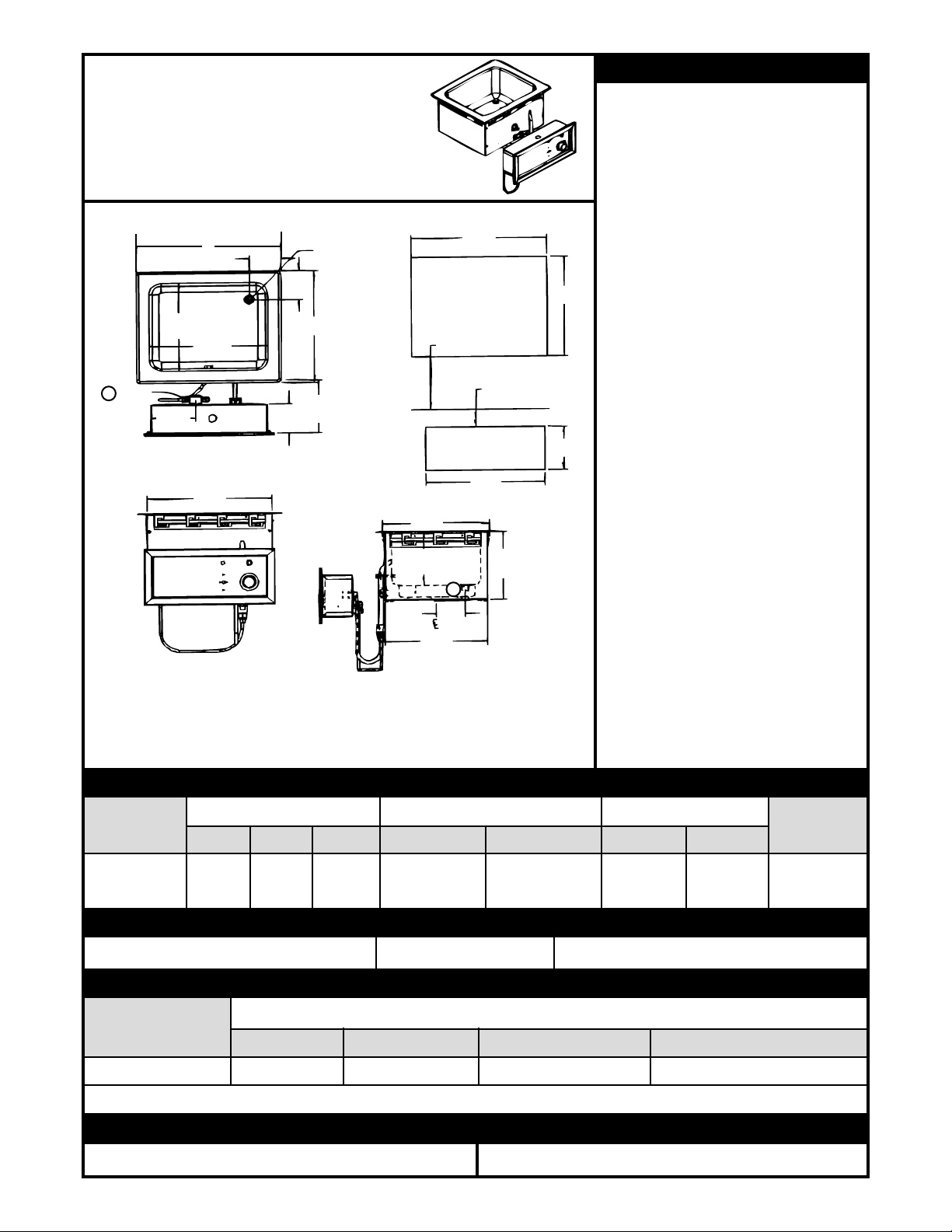

INSTALLATION

APW EZFILL HOT FOOD WELLS

Part Numbers Beginning with WHFW

D

Drain

6.0 (15.2) Minimum

From Counter Edge

E

7.78

(198)

12.02

(305)

7.55

(192)

4.19

(10.6)

10.69

(27.1)

C

1

B

8.12

(20.6)

Water

Inlet

A

610

(155)

2

1. Water fill is 3/8 (1.0) tubing connection on left back of left controls.

2. Main drain is ¾ female NPT.

Soup Well

Cut-out

2.0 (5.1) Minimum

From Counter Top

F

G

Control Cut-Out

1. Follow general installation

instructions on page 3.

2. Make applicable Cut-Out per above

table. Unit is designed for

Note:

installationin stainless steel tops.

Optional wood mounting kit available.

3. Apply putty tape to the underside

perimeter of the well rimouteredge.

4. Apply a 1/4" (.6) bead of silicone

sealant adjacent to the putty tape on

the well flange.

5. Drop well into opening from the top

and push down until entire

parameter of rim is flush with the

counter surface.

6. From below the counter surface

insert an 8" to10"(20to 25 cm) flat tip

screwdriver into the locking ring tab

slots and twist in a clockwise motion

to lock well in place.

7. Trim excess putty and sealant from

around well rim.

8. Mount control to front panel using

hardware. Maintain 4" (10.2)

clearance between well and front

panel.

9. Check nameplate for proper voltage.

Connect power.

10. Connect overflow tube on hot food

well to suitable tubing to handle

212°F water.Run to open drain.

Electrically connect units to

Note:

comply with local and NECcodes.

GENERAL SPECIFICATIONS (APW EZFILL HOT FOOD WELLS)

MODEL

OUTSIDE DIMENSIONS INSIDE DIMENSIONS

CUT-OUT CONTROL CUT-OUT

SHIP WT.

ABC E D F G

SM50EZ

WELL

10.34” 8.38” 6.44” 8.32” 10.875 5.0 12.5 13 Lbs.

(26.3) (21.3) (16.4) (21.1) (27.6) (12.7) (31.8) (5.9 Kg)

OPTIONS

Description: Lever Operated Drain Valve Stock Number: 56360 Drain Manifold: Fabricated to Unit, Required

ELECTRICAL SPECIFICATIONS

ELECTRICAL RATINGS 500 EA. @ 208V / 660 EA. @ 240V

MODEL

VOLTS WATTS AMPS (1 Phase) MAX AMPS (3 PHASE)

SM50EZ WELL 208/240 500/660 2.4/2.75 N/A

NOTE: CUT-OUT SIZES ARE DIFFERENT FROM STANDARD APW HOT FOOD WELLS (HFW’S)

OPERATION

1. Follow General Operating Instructions on page 3. 1. Follow General Cleaning Instructions on page 3

CLEANING

4

Page 5

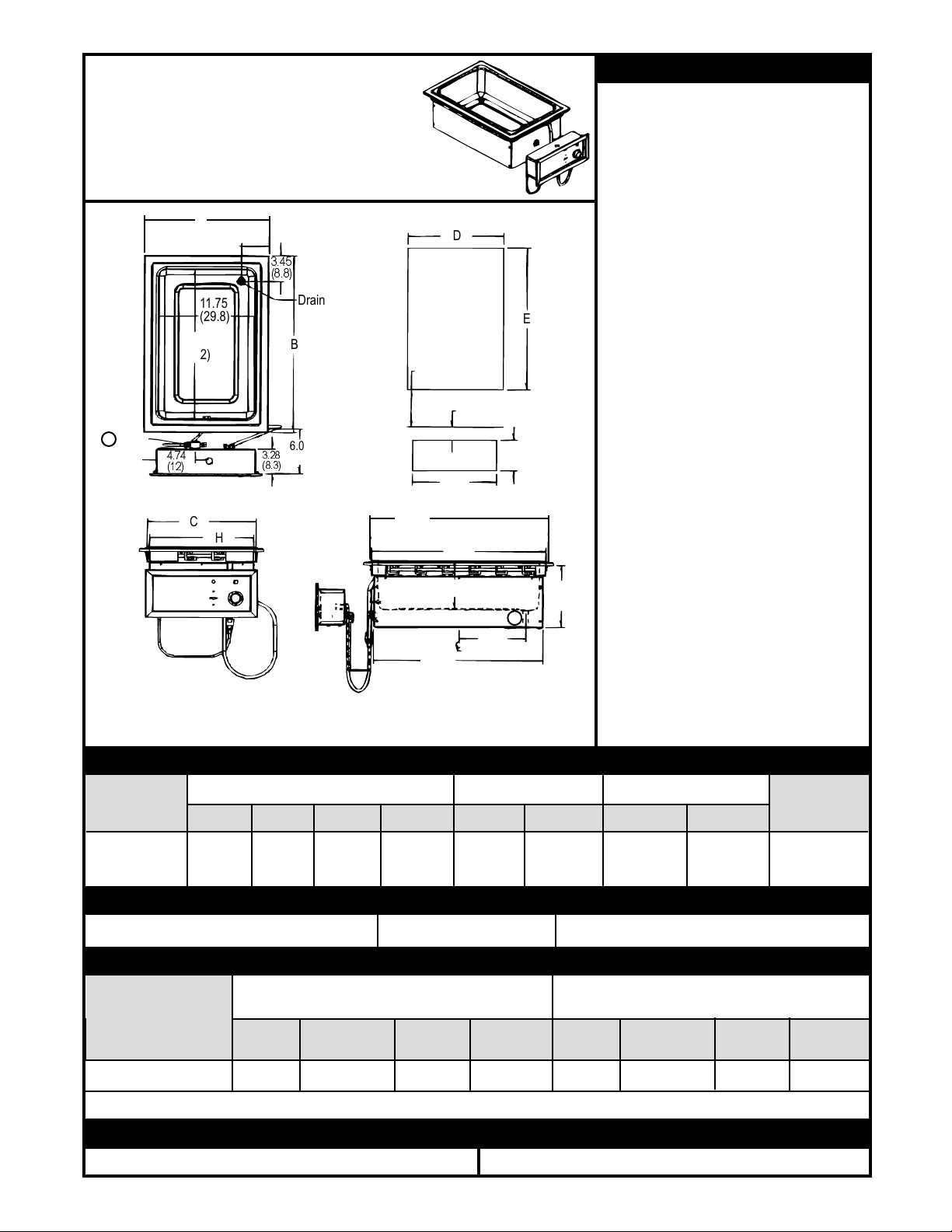

INSTALLATION

APW EZFILL HOT FOOD WELLS

Part Numbers Beginning with WHFW

3.29

3.29

(8.4)

3.28

(8.3)

(8.4)

Drain

B

Cut-Out

Front Edge

6.00

(15.2)

11.23

(28.5)

6.12

(15.6)

10.86

(27.6)

1

Water

Inlet

10.00

(25.4)

4.74

(12.0)

A

12.50

(31.8)

C

1. Water fill is 3/8 (1.0) tubing connection on left back of left controls.

2. Main drain is ¾ female NPT.

D

Hot Food Well

Cut-Out

6.00 (15.2) Minimum

From Counter Edge

2.00 (5.1) Minimum

From Counter Top

G

Control Cut-Out

7.72

(19.6)

2

3.07

(7.8)

1. Follow general installation

instructions on page 3.

2. Make applicable Cut-Out per above

table. Unit is designed for

Note:

installationin stainless steel tops.

Optional wood mounting kit available.

3. Apply putty tape to the underside

perimeter of the well rimouteredge.

4. Apply a 1/4" (.6) bead of silicone

sealant adjacent to the putty tape on

E

the well flange.

5. Drop well into opening from the top

and push down until entire

parameter of rim is flush with the

counter surface.

6. From below the counter surface

insert an 8" to10"(20to 25 cm) flat tip

F

screwdriver into the locking ring tab

slots and twist in a clockwise motion

to lock well in place.

7. Trim excess putty and sealant from

around well rim.

8. Mount control to front panel using

hardware. Maintain 4" (10.2)

clearance between well and front

panel.

9. Check nameplate for proper voltage.

Connect power.

10. Connect overflow tube on hot food

well to suitable tubing to handle

212°F water.Run to open drain.

Electrically connect units to

Note:

comply with local and NECcodes.

GENERAL SPECIFICATIONS (APW EZFILL HOT FOOD WELLS)

MODEL

OUTSIDE DIMENSIONS

CUT-OUT

CONTROL CUT-OUT

SHIP WT.

ABC E D F G

SM50EZ-12D

WELL

15.21 12.71 13.49 13.75 11.50 5.0 12.5 22 Lbs.

(38.6) (32.3) (34.3) (34.9) (29.2) (12.7) (31.8) (10.6 Kg)

OPTIONS

Description: Lever Operated Drain Valve Stock Number: 56360 Drain Manifold: Fabricated to Unit, Required

ELECTRICAL SPECIFICATIONS

ELECTRICAL RATINGS 500 EA. @ 208V / 660 EA. @ 240V

MODEL

VOLTS WATTS AMPS (1 Phase) MAX AMPS (3 PHASE)

SM50EZ-12D WELL 208/240 500/660 2.4/2.75 N/A

NOTE: CUT-OUT SIZES ARE DIFFERENT FROM STANDARD APW HOT FOOD WELLS (HFW’S)

OPERATION

1. Follow General Operating Instructions on page 3. 1. Follow General Cleaning Instructions on page 3

CLEANING

5

Page 6

INSTALLATION

APW EZFILL HOT FOOD WELLS

Part Numbers Beginning with WHFW

A

3.42

1

Water

Inlet

4.74

(12)

(8.7)

11.75

(29.8)

19.75

(50.2)

C

H

3.28

(8.3)

3.45

(8.8)

Drain

B

Cut-Out

Front Edge

6.00

(15.2)

21.80

(55.4)

1. Water fill is 3/8 (1.0) tubing connection on left back of left controls.

2. Main drain is ¾ female NPT.

D

Hot Food Well

Cut-Out

6.00 (15.2)

Minimum

From

Counter Edge

2.00 (5.1) Minimum

From Counter Top

G

Control Cut-Out

21.44

(54.4)

6.50 (16.5)

8.27

20.84

(52.9)

(21)

E

F

2

8.28

(21)

1. Follow general installation

instructions on page 3.

2. Make applicable Cut-Out per above

table. Unit is designed for

Note:

installationin stainless steel tops.

Optional wood mounting kit available.

3. Apply putty tape to the underside

perimeter of the well rimouteredge.

4. Apply a 1/4" (.6) bead of silicone

sealant adjacent to the putty tape on

the well flange.

5. Drop well into opening from the top

and push down until entire

parameter of rim is flush with the

counter surface.

6. From below the counter surface

insert an 8" to10"(20to 25 cm) flat tip

screwdriver into the locking ring tab

slots and twist in a clockwise motion

to lock well in place.

7. Trim excess putty and sealant from

around well rim.

8. Mount control to front panel using

hardware. Maintain 4" (10.2)

clearance between well and front

panel.

9. Check nameplate for proper voltage.

Connect power.

10. Connect overflow tube on hot food

well to suitable tubing to handle

212°F water.Run to open drain.

Electrically connect units to

Note:

comply with local and NECcodes.

GENERAL SPECIFICATIONS (APW EZFILL HOT FOOD WELLS)

MODEL

OUTSIDE DIMENSIONS

CUT-OUT CONTROL CUT-OUT

SHIP WT.

ABCHDE F G

SHFWEZ-1

WELL

15.38” 23.44” 13.80” 12.85” 14.25” 22.25” 5.0” 12.5” 12.4 Lbs.

(39.1) (59.5) (35.10) (32.6) (36.2) (56.5) (12.7) (31.8) (10.9 Kg)

OPTIONS

Description: Lever Operated Drain Valve Stock Number: 56360 Drain Manifold: Fabricated to Unit, Required

ELECTRICAL SPECIFICATIONS

ELECTRICAL RATINGS

1200 EA. @ 208V / 1600 EA. @ 240V

ELECTRICAL RATINGS

1600 EA. @ 208V

MODEL

VOLTS WATTS AMPS AMPS VOLTS WATTS AMPS AMPS

(1 Ph) (3 Ph) (1 Ph) (3 Ph)

SHFWEZ-1 WELL 208/240 1200/1600 5.8 / 6.7 N/A 208 1600 7.7 N/A

NOTE: CUT-OUT SIZES ARE DIFFERENT FROM STANDARD APW HOT FOOD WELLS (HFW’S)

OPERATION

1. Follow General Operating Instructions on page 3. 1. Follow General Cleaning Instructions on page 3

CLEANING

6

Page 7

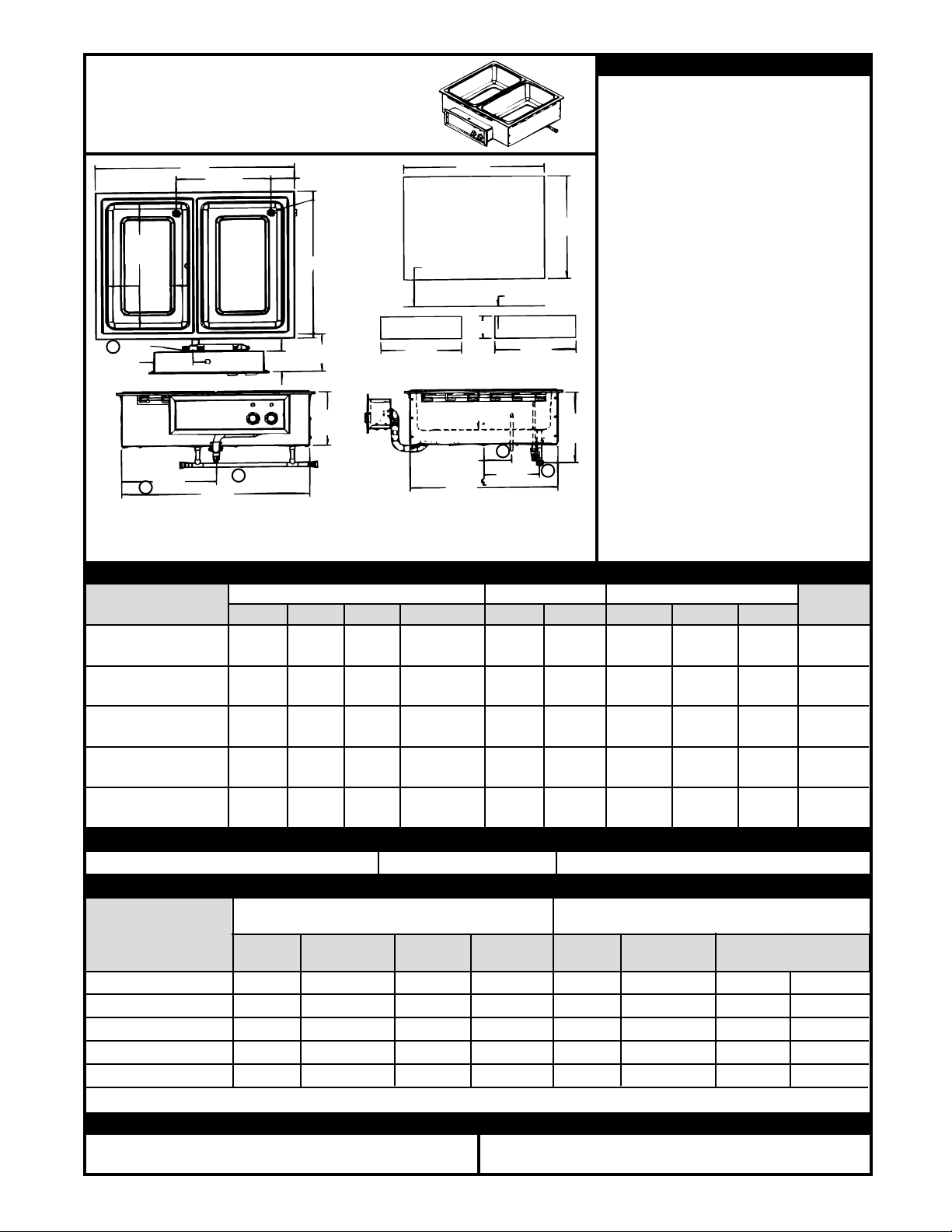

INSTALLATION

APW EZFILL HOT FOOD WELLS

Part Numbers Beginning with WHFW

D

Hot Food Well

Cut-Out

6.0 (15.2) Minimum

From Counter Edge

F

Control Cut-Outs

6.50 (16.5)

4.13

(10.5)

21.88

(55.6)

2

8.27

(21.0)

2.0 (5.1) Minimum

From Counter Top

1

19.75

(50.2)

Water

Inlet

11.74

(29.8)

2

Overflow

5.74

(14.6)

J

A

13.981

(35.51)

C

Manifold

3

3.284

(8.34)

3.434

(8.72)

Drain

B

6.0

(15.2)

(22.0)

Cut-Out

Front Edge

8.65

G

1. Water fill is 3/8 (1.0) tubing connection on left back of left controls.

2. Overflow drain is 1/2” (1.3) OD tube outlet

3. Main drain is ¾ female NPT.

H

3

1. Follow general installation instructions

on page 3.

2. Make applicable Cut-Out per above table.

Note:

Unit isdesignedfor inst allatio ni n

stainless steel tops. Optional wood

mounting kitavailable.

3. Apply putty tape to the underside

perimeter of the well rim outer edge.

4. Apply a 1/4" (.6) bead of silicone sealant

E

adjacent to the putty tape on the well

flange.

5. Drop wellintoopeningfromthetop a n d

push down until entire parameter of rim

is flush with the counter surface.

6. From below the counter surface insert

an 8" to 10" (20 to 25 cm) flat tip

screwdriver into thelocking ring tab slots

and twist in a clockwise motion to lock

well in place.

7. Trim excess putty and sealant from

around well rim.

8. Mount control to front panel using

11.27

(28.6)

hardware. Maintain 4" (10.2) clearance

between well and front panel.

9. Check nameplate for proper voltage.

Connect power.

10. Connect overflow tube on hot food well

to suitabletubing to handle212°F water.

Run to open drain. Electrically

connect units to comply with local and

NEC codes.

Note:

GENERAL SPECIFICATIONS (APW EZFILL HOT FOOD WELLS)

MODEL

OUTSIDE DIMENSIONS

A B C J Overflow D E F G H

CUT-OUT CONTROL CUT-OUT

SHIP WT.

SHFWEZ-2D WELL 29.42” 23.44” 27.79” 13.87” 28.5” 22.5” 5.0” 16.50” N/A 48 Lbs

(74.2) (59.5) (70.6) (35.2) (72.4) (57.2) (12.7) (41.9) (21.8 Kg).

SHFWEZ-3D WELL 43.46” 23.44” 41.83” 27.92” 42.5” 22.5” 5.0” 33.50” 12.50” 68 Lbs

(110.4) (59.5) (106.2) (70.9) (108) (57.2) (12.7) (85.1) (30.8 Kg)

SHFWEZ-4D WELL 57.50” 23.44” 55.87” 27.92” 56.5” 22.5” 5.0” 16.50” N/A 98 Lbs

(146.0) (59.5) (141.9) (70.9) (143.5) (57.2) (12.7) (41.9) (44.4 Kg)

SHFWEZ-5D WELL 71.54” 23.44” 69.92” 41.96” 70.05” 22.5” 5.0” 33.50” N/A 118 Lbs

(181.7) (59.5) (177.6) (106.6) (179.1) (57.2) (12.7) (85.1) (53.5 Kg)

SHFWEZ-6D WELL 85.59” 23.44” 83.96” 41.96” 84.50” 22.5” 5.0” 33.50” N/A 260 Lbs

(217.4) (59.5) (213.2) (106.6) (214.6) (57.2) (12.7) (85.1) (117.9 Kg)

OPTIONS

Description: Lever Operated Drain Valve Stock Number: 56360 Drain Manifold: Fabricated to Unit, Required

ELECTRICAL SPECIFICATIONS

ELECTRICAL RATINGS

1600 EA. @ 208V

MODEL

ELECTRICAL RATINGS

1200 EA. @ 208V / 1600 EA. @ 240V

VOLTS WATTS AMPS AMPS VOLTS WATTS AMPS AMPS

(1 Ph) (3 Ph) (1 Ph) (3 Ph)

SHFWEZ-2D WELL 208/240 2400/3200 12 / 14 10 / 12 208 3200 16 14

SHFWEZ-3D WELL 208/240 3600/4800 18 / 20 10 / 12 208 4800 23 14

SHFWEZ-4D WELL 208/240 4800/6400 24 / 27 16 / 18 208 6400 31 21

SHFWEZ-5D WELL 208/240 6000/8000 29 / 34 20 / 24 208 8000 39 27

SHFWEZ-6D WELL 208/240 7200/9600 35 / 40 20 / 24 208 9600 47 27

NOTE: CUT-OUT SIZES ARE DIFFERENT FROM STANDARD APW HOT FOOD WELLS (HFW’S)

OPERATION

1. Follow General Operating Instructions on page 3. 1. Follow General Cleaning Instructions on page 3

CLEANING

7

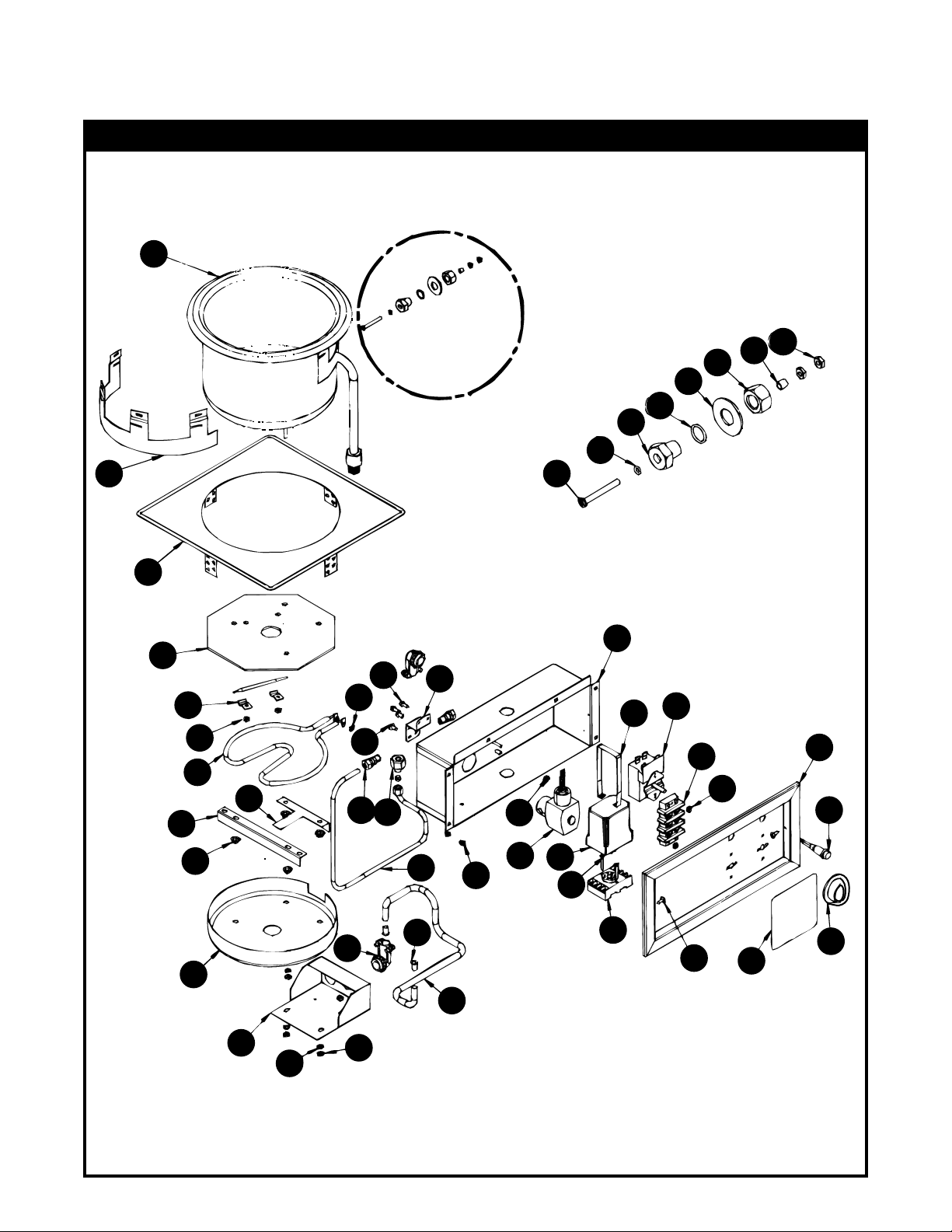

Page 8

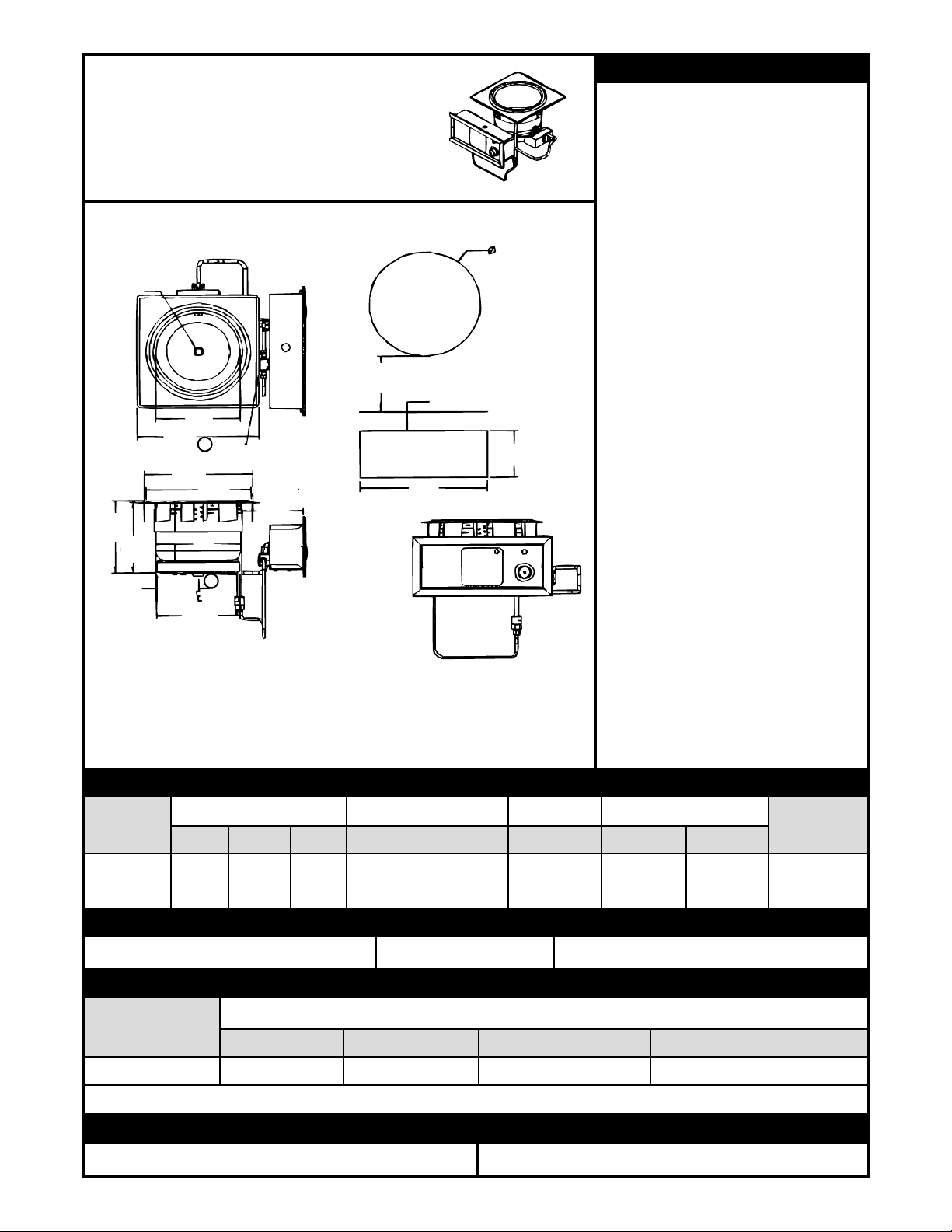

PARTS LIST & EXPLODED VIEW

SM50EZ Round Soup Well Drop-In with EZ Lock P/N EZSM50-7D 208/240V, 500/650W

EXPLODED VIEW SM50EZ

16

32

31

28

27

25

“B”

26

29

45

30

DETAIL “B”

44

17

20

41

22

24

18

21

19

8

23

36

15

37

1

10

13

3

14

2

35

6

7

40

35

34

11

12

43

9

42

33

5

4

39

38

23

24

8

Page 9

PARTS LIST SM50EZ EZ FILL MULTI WELLSPARTS LIST SM50EZ EZ FILL MULTI WELLS

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTIONITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

Washer 1/2-20 SS

1 54561 Control Box W/Assy 12.50 "

1 54561 Control Box W/Assy 12.50 "

2 54503 Bezel Control 12.50"

2 54503 Bezel Control 12.50"

3 56527 Thermostat 36" Capillary

3 56527 Thermostat 36" Capillary

4 56528 Knob, Black

4 56528 Knob, Black

5 63012 Indicator Light (56530)

5 63012 Indicator Light (56530)

6 54577 Adapter, 1/4" Tube To 3/8” Pipe

6 54577 Adapter, 1/4" Tube To 3/8” Pipe

7 54578 Tubing, Copper, 1/4”

7 54578 Tubing, Copper, 1/4”

8 55343 90° Conduit Connector

8 55343 90° Conduit Connector

9 54511 Octal Base Use With 54510

9 54511 Octal Base Use With 54510

10 54524 Bracket, Solenoid Valve

10 54524 Bracket, Solenoid Valve

11 54513 Water Solenoid Valve

11 54513 Water Solenoid Valve

12 54510 Liquid Level Control Octal Base

12 54510 Liquid Level Control Octal Base

XXXX Liquid Level Control Open Board

XXXX Liquid Level Control Open Board

13 54512 Hold Down Strap Use With 54510

13 54512 Hold Down Strap Use With 54510

14 30201 Terminal Block

14 30201 Terminal Block

15 54508 Brass Fitting 1/8 NPT x 1/4 Compression

15 54508 Brass Fitting 1/8 NPT x 1/4 Compression

16 54572 7 Qt. Round Well Pan W/Copper Tube

16 54572 7 Qt. Round Well Pan W/Copper Tube

17 50817 Plate, Heat Diffuser

17 50817 Plate, Heat Diffuser

18 55964 Heating Element 208/240V, 500W/660W

18 55964 Heating Element 208/240V, 500W/660W

19 55696 Bracket, Element Holder

19 55696 Bracket, Element Holder

20 55695 Bracket, Element Holder

20 55695 Bracket, Element Holder

21 89025 10-24 Speed Nut

21 89025 10-24 Speed Nut

22 55992 Bottom Cover

22 55992 Bottom Cover

23 89059 #10 External Lock Washer

23 89059 #10 External Lock Washer

24 89061 Nut, Hex 10-24

24 89061 Nut, Hex 10-24

25 54544 O-Ring For Probe Holder

25 54544 O-Ring For Probe Holder

26 54543 Probe Holder

26 54543 Probe Holder

27 54546

27 54546

28 54549

28 54549

29 54545

29 54545

30 88971

30 88971

31 54548

31 54548

32 89063

32 89063

33 56542

33 56542

34 88961

34 88961

35 89054

35 89054

36 88993

36 88993

37 89073

37 89073

38 51016

38 51016

39 55342

39 55342

40 55340

40 55340

41 89120

41 89120

42 88889

42 88889

43 88977

43 88977

44 55333

44 55333

45 55402

45 55402

56655 Drain Strainer

56655 Drain Strainer

54532 Wire Set Two Well

54532 Wire Set Two Well

54533 Wire Set Three Well

54533 Wire Set Three Well

54534 Wire Set Four Well

54534 Wire Set Four Well

54535 Wire Set Five Well

54535 Wire Set Five Well

54536 Wire Set Six Well

54536 Wire Set Six Well

Washer 1/2-20 SS

Nut, Hex 1/2-20

Nut, Hex 1/2-20

O-ring For Screw

O-ring For Screw

Screw 8-32 X 1-1/2 SS

Screw 8-32 X 1-1/2 SS

Spacer, Probe Holder

Spacer, Probe Holder

Nut, Hex 8-32

Nut, Hex 8-32

Plate, Dial-Wells

Plate, Dial-Wells

10-24 Hex Nut, Green-Ground

10-24 Hex Nut, Green-Ground

6-32 KEPS Nut

6-32 KEPS Nut

10-32 X 3/8 Truss Head Screw

10-32 X 3/8 Truss Head Screw

#8 X 1/2 Sheet Metal Screw

#8 X 1/2 Sheet Metal Screw

Cover, Terminal

Cover, Terminal

3/8" Conduit

3/8" Conduit

Anti-Short Bushing

Anti-Short Bushing

Jiffy Clip

Jiffy Clip

8 X 1/2 AB SMS, Phl Truss

8 X 1/2 AB SMS, Phl Truss

6-32 X 1.0 Slotted Pan Head

6-32 X 1.0 Slotted Pan Head

Wood Mount Kit SM-50-7

Wood Mount Kit SM-50-7

EZ Lock Clip 4 Tab

EZ Lock Clip 4 Tab

HARDWARE NOT SHOWNHARDWARE NOT SHOWN

Heating Element

SM-50 WIRING DIAGRAMS

Indicator Light

Heating Element

Robert Shaw

Thermostat

Indicator Light

Ranco

Thermostat

9

Page 10

PARTS LIST & EXPLODED VIEW

Small Frame Insulated Top Mount EZ Fill Hot Food Wells HFWEZ12D, P/N EZ12D4B-208/240V-500/660W

EXPLODED VIEW HFWEZ-12D

21

23

22

18

DETAIL “C”

DETAIL “D”

16

45

17

8

31

30

“C”

14

15

6

47

4

“D”

48

47

50

48

9

49

50

42

7

41

19

1

38

35

24

37

40

12

20

36

3

34

25

13

33

26

39

5

13

10

43

2

32

27

44

11

28

33

34

46

29

19

51

10

Page 11

PARTS LIST HFWEZ12D EZ FILL MULTI WELLS

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTIONITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

1 54561 ControlBox W/Assy 12.50"

2 55342 3/8" Conduit

3 55340 Anti-short Bushing

4 54578 Tubing, Copper, 1/4

5 88889 8 X 1/2 AB Sms, Phl Truss

6 54508 Brass Fitting 1/8 Npt X 1/4 Compression

7 56406 Wrapper, 1/2 Size Outer

8 54567 1/2 Size Well Pan W/Copper Tube

9 54571 Wrapper Outer End

10 30201 Terminal Block

11 56505 Knob, Black

12 88977 6-32 X 1.0 Slotted Pan Head

13 89054 6-32 KEPS Nut

14 54546 Washer 1/2-20 SS

15 54549 Nut, Hex 1/2-20

16 54543 Probe Holder

17 88971 Screw 8-32 X 1-1/2 SS

18 54548 Spacer, Probe Holder

19 89073 #8 X 1/2 Sheet Metal Screw

20 88993 10-32 X 3/8 Truss Head Screw

21 89063 Nut, Hex 8-32

22 54544 O-ring For Probe Holder

23 54545 O-ring For Screw

24 50817 Plate, Heat Diffuser

25 55964 Heating Element 208/240V, 500W/1660W

26 55695 Bracket, Element Holder

27 55696 Bracket, Element Holder

28 55992 Bottom Cover

29 56404 Bottom Cover

30 56655 Drain Strainer

31 88961

32 89025

33 89059

34 89061

35 55343

36 89120

37 54511

38 54524

39 54513

40 54510

XXXX

41 54512

42 54503

43 56527

44 56536

45 54577

46 56945

47 56412

48 56411

49 55305

50 56402

51 56388

56542 Plate, Dial-Wells

54532 Wire Set Two Well

54533 Wire Set Three Well

54534 Wire Set Four Well

54535 Wire Set Five Well

54536 Wire Set Six Well

10-24 Hex Nut, Green-ground

10-24 Speed Nut

#10 External Lock Washer

Nut, Hex 10-24

90° Conduit Connector

Jiffy Clip

Octal Base Use With 54510

Bracket, Solenoid Valve

WaterSolenoid Valve

Liquid Level Control Octal Base

Liquid Level Control Open Board

Hold Down Strap Use With54510

Bezel Control 12.50"

Thermostat 36" Capillary

Indicator Light (56530)

Adapter,1/4"TubeTo3/8”Pipe

Insulation 12x9x1/2

Insulation 12x9x1/2

Insulation 12x9x1/2

EZ Lock, 4 Tab

EZ Lock 1/2 Warmer

Plate, Hole Cover

HARDWARE NOT SHOWNHARDWARE NOT SHOWN

HFW-12 WIRING DIAGRAM

Thermostat

Indicator Light

Heating Element

11

Page 12

3

PARTS LIST & EXPLODED VIEW

37

27

EXPLODED VIEW HFWEZ-1D

17

32

DETAIL “B”

25

16

35

10

33

34

28

“B”

36

18

31

7

29

3

21

53

19

30

21

19

20

23

5

24

6

9

21

19

1

21

26

23

8

55

2

54

20

11

9

51

50

47

52

4

49

48

40

38

21

45

12

41

24

8

6

19

7

15

43

42

14

39

44

22

13

46

Small Frame Insulated Top Mount EZ Fill Hot Food Wells HFWEZ-1D SHFWEZ-1D P/N EZ1D2B-208V-1600W, SHFWEZ-1D P/N EZ1D4B-208/240V-1200/1600W

12

Page 13

PARTS LIST HFWEZ1D EZ FILL MULTI WELLS

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTIONITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

1 54551 Base

2 54555 Cover, Bottom

3 55308 E-Z Lock, 6 Tab

4 55340 Anti-Short Bushing

5 54554 Wrapper, End

6 54557 Bracket, Wrapper End

7 54556 E-Z Lock, 2 Tab

8 56515 Insulation,20-3/8x8x1/2

9 56516 Insulation,13x8x1/2

10 89063 Nut, Hex 8-32

11 56513 Insulation, 18x12x1

12 30201 Terminal Block

13 56505 Knob, Thermostat

14 88977 6-32 X 1.0 Slotted Pan Head

15 89054 6-32 KEPS Nut

16 54549 Nut, Hex 1/2-20

17 54545 O-Ring For Screw

18 89061 10-24 Hex Nut

19 56521 Rivet, Pop

20 89025 10-24 Speed Nut

21 89073 #8 X 1/2 Sheet Metal Screw

22 88889 8 X 1/2 AB SMS, Phl Truss

23 54552 Wrapper, Side

24 54558 Bracket, Wrapper Side

25 55789 Sealant, Permagum

26 54564 Hole Cover

27 54559 Well Pan W/Assy (w/Copper Tubes)

28 89120 Jiffy Clip

29 56039 Capillary Cover For Thermostats

30 56506 Reflector Pan

31 55441 Heating Element 208/240V,

1200W/1600W

32 54544 O-ring For (Probe Holder)

33 54543 Probe Holder

34 54546 Washer 1/2-20 SS

35 88971 Screw 8-32 X 1-1/2 SS

36 54548 Spacer, Probe Holder

37 56655 Drain Strainer

38 54561 Control Box W/assy 12.50”

39 54511 Octal Base Use With 54510

40 54524 Bracket, Solenoid Valve

41 54513 Water Solenoid Valve

42 54510 Liquid Level Control Octal Base

XXXX Liquid Level Control Open Board

43 54512 Hold Down Strap Use With 54510

44 54503 BezelControl 12.50”

45 54521 Bezel Control 16.50”

46 54529 BezelControl 33.50”

47 56527 Thermostat 36” Capillary

48 56536 Indicator Light (56530)

49 55343 90° Conduit Connector

50 88993 10-32 X 3/8 Truss Hd Screw

51 55342 3/8” Conduit

52 54553 Wrapper, Control End

53 54508 Brass Fitting 1/8 NPT x ¼ Compression

54 54578 Tubing, Copper, 1/4

55 89059 #10 External Lockwasher

56 54577 Adapter, 1/4” Tube To 3/8 Pipe

57 56388 Plate, Hole Cover

HARDWARE NOT SHOWNHARDWARE NOT SHOWN

88961 10-24Hex Nut, Green-Ground

56542 DialPlate

54532 WireSetTwoWell

54533

54534

54535

54536

Wire Set Three Well

Wire Set Four Well

Wire Set Five Well

Wire Set Six Well

HFW-1D WIRING DIAGRAM (THERMOSTATIC CONTROL CONFIGURATION)

Heating Elements

2

4

1

Probe

Common

7

7

8

1

5

2

6

5

4

3

8

9

3

6

10

Indicator Light

13

Thermostat

Page 14

PARTS LIST & EXPLODED VIEW

Small Frame Insulated Top Mount EZ Fill Hot Food Wells HFWEZ-1D

SHFWEZ-1D P/N EZ1D2B-208V-1600W, SHFWEZ-1D P/N EZ1D4B-208/240V-1200/1600W

EXPLODED VIEW SHFWEZ-1D w/SHUT-OFF VALVE

29

43

28

22

33

34

18

46

16

17

19

59

25

21

47

51

51

27

41

20

1

42

54

54

55

38

57

26

60

60

24

24

44

44

11

40

39

11

58

30

4

4

30

48

48

49

8

10

32

32

7

7

6

6

5

53

53

56

56

36

31

9

9

3

12

12

15

2

52

52

13

45

35

14

50

23

Note: When ordering, ALWAYS specify Part #, Model #, Serial #, Voltage & Phase. P/N 70103067 7/05

14

37

Page 15

PARTS LIST SHFWEZ1D w/SHUT-OFF VALVE

Item Item

10

11

12

13

14

1

2

3

4

5

6

7

8

9

P/N

54577

56542

56388

89073

89059

56513

52107

56360

89390

70101018

30201

54508

54510

54511

Description Description

Adapter, 1/4" To 3/8"

Plate, Dial-Wells

Plate, Hole Cover

Screw, #8 X 1/2 Hex Sht Mtl

Washer #10 External Lock

Insulation, 18 X 12 X 1

Nipple, 1/2" NPT X 3" Brass

Valve, Drain 1/2" Threaded

Label, Warranty Against Defects

Tubing, Brass 1/2" X 3" Long

Terminal Block, 600V, 50A

Connector, Male Brass

Control, Liquid Level Single Probe

Base, Liquid Level Control Socket

Quan Quan

1

34

1

35

1

36

32

37

2

38

2

39

1

40

1

41

1

42

1

43

1

44

2

45

1

46

1

47

P/N

88971

88977

88889

88993

89025

89054

89061

89063

89120

56521

54561

54512

70103066

54551

Screw, 8-32x1-1/2 Sl Pn Hd SS

Screw 6-32 X 1 Ph Pan Hd

Screw #8 X 1/2 AB Phl Truss

Screw 10-32x3/8 Trs Hd Phillips Nylk

Nut, Speed 10-24 Pal Zinc

Nut, KEPS 6-32

Nut, Hex 10-24

Nut, Hex 8-32

Clip, Jiffy

Rivet, Pop SS-42-D

W/Ass'y, Control Box

Strap, Hold Down

W/Ass'y, Ez1 Well Pan W/ Overflow

Base

1

2

2

2

16

4

4

2

2

12

1

1

1

1

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

54513

54543

54544

54545

54546

54548

54549

55308

55340

55343

55441

56039

56506

56515

56516

Valves, Water Solenoid

Holder, Probe

O-Ring, 1/2" ID. X 5/8" OD.

O-Ring, 5/32" ID. X 7/32" OD.

Washer, 1/2-20 S/S

Spacer, Phenolic

Nut, Hex 1/2-20 Plain

E-Z Lock, 6 Tab

Bushing, Anti-Short CCD, #1

Conduit Connector, 90° Flex

Element, 1200/1600W - 208/240V

Cover, Capillary

Plate, Reflector

Insulation, 20-3/8X8X1/2

Insulation, 13X8X1/2

1

48

1

49

1

50

1

51

1

52

1

53

1

54

2

55

2

56

2

57

1

58

1

59

1

60

2

2

54503

54578

54524

54556

55342

54564

54557

54554

54555

54558

54552

55789

70105017

Bezel

Tubing, Copper, 1/4 .032 Wall Refrig

Bracket, Solenoid Valve

E-Z Lock, 2 Tab

Conduit, 1/2"

Plate, Hole Cover

Bracket, Wrapper End

Wrapper, End

Cover, Bottom

Bracket, Wrapper Side

Wrapper, Side

Sealant, GS7500, 6.5 Ft. Lg.

Wrapper, Control End

1

1

1

2

1

1

2

1

1

2

2

1

1

30

31

32

33 56655

56541

60351

56536

Thermostat, Model 375°, 72"cap

Knob, Thermostat 375°F

S/A, Pilot Light Amber

W/Ass'y, Drain Strainer

Note: When ordering, ALWAYS specify Part #, Model #, Serial #, Voltage & Phase. P/N 70103067 7/05

1

1

1

1

15

Page 16

PARTS LIST & EXPLODED VIEW

Small Frame Insulated Top Mount EZ Fill Hot Food Wells HFWEZ-2, -3, -4, -5, -6

EXPLODED VIEW HFWEZ-2, -3, -4, -5, -6

4

8

5

10

3

2

MODEL P/N VOLTS WATTS

HFWEZ-2D EZ2D2B 208 1600

HFWEZ-2D EZ2D4B 208/240 1200/1600

HFWEZ-3D EZ3D2B 208 1600

HFWEZ-3D EZ3D4B 208/240 1200/1600

HFWEZ-4D EZ4D2B 208 1600

HFWEZ-4D EZ4D4B 208/240 1200/1600

HFWEZ-5D EZ5D2B 208 1600

HFWEZ-5D EZ5D4B 208/240 1200/1600

HFWEZ-6D EZ6D2B 208 1600

HFWEZ-6D EZ6D4B 208/240 1200/1600

23

24

6

1

7

9

13

14

16

11

12

15

17

18

19

20

21

22

23

34

35

36

37

38

39

40

41

25

23

31

30

32

42

43

44

45

46

26

33

16

47

50

52

49

48

51

23

28

53

29

24

27

24

23

25

Page 17

PARTS LIST HFWEZ-2, -3, -4, -5, -6 EZ FILL MULTI WELLS

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTIONITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

1 54575 Well Pan W/Assy (w/Copper Tubes)

2 55789 Sealant, Permagum

3 54518 Well Pan W/Assy (w/o Tubes)

4 56655 Drain Strainer

5 88971 Screw 8-32 X 1-1/2 SS

6 54545 O-ring For Screw

7 54543 Probe Holder

8 54544 O-ring For Probe Holder

9 89063 Nut, Hex 8-32

10 54548 Spacer, Probe Holder

11 54546 Washer 1/2-20 SS

12 54549 Nut, Hex 1/2-20

13 57264 Well Brace

14 54577 Adapter, 1/4” Tube To 3/8 Pipe

15 55441 Heating Element 208/240V,

1200W/1600W

54051 HeatingElement 208V/1600W

16 89059 #10 External Lockwasher

17 89120 Jiffy Clip

18 89061 10-24 Hex Nut

19 56039 Capillary Cover For Thermostats

20 56506 Reflector Pan

21 89025 10-24 Speed Nut

22 57252 2 Well Top Plate

57260 3WellTop Plate

57263 4WellTop Plate

57290 5WellTop Plate

57363 6WellTop Plate

23 89073 #8 X 1/2 Sheet Metal Screw

24 55308 E-Z Lock, 6 Tab

25 56050 End Cover

26 56048 Conduit Brace

27 57254 2 Well FrontOrBack Cover

57262 3WellFront Or Back Cover

57266 4WellFront Or Back Cover

57292 5WellFront Or Back Cover

57365 6WellFront Or Back Cover

28 60150 1" X7"X48" Insulation High Temp

29 56388 Hole Cover

30 54526 2 Well BottomCover

54538 3WellBottom Cover

54539 4WellBottom Cover

54540 5WellBottom Cover

54541 6WellBottom Cover

31 54524 Bracket, SolenoidValve

32 54508 Brass Fitting 1/8 NPT X ¼ Compression

33 54504 Control BoxW/assy12.50"

54522 ControlBox W/assy 16.50”

54529 Control Box W/assy 33.50”

34 54512 Hold Down Strap Use With 54510

35 54510 Liquid Level Control Octal Base

XXXX Liquid Level Control Open Board

36 88977 6-32 X 1.0 Slotted Pan Head

37 54511 Octal BaseUseWith 54510

38 54503 Bezel Control 12.50”

54521 Bezel Control 16.50"

54529 BezelControl 33.50”

39 88889 8 X 1/2 AB SMS, Phl Truss

40 56536 Indicator Light (56530)

41 56505 Knob, Thermostat

42 89054 6-32 KEPS Nut

43 54513 Water Solenoid Valve

44 30201 Terminal Block

45 56540 Thermostat 72" Capillary

46 56527 Thermostat 36" Capillary

47 55099 3/4" Conduit 24" Long

48 55058 90° Conduit Connector

49 88993 10-32 X 3/8 Truss Head Screw

50 55059 Anti-Short Bushing

51 87822 Washer Reducing1X3/4

52 89184 7/8" Hole Bushing

53 57258 2 Well DrainManifold

57273 3WellDrain Manifold

57267 4WellDrain Manifold

57293 5WellDrain Manifold

57366 6WellDrain Manifold

HARDWARE NOT SHOWN

88961 10-24 Hex Nut, Green-Ground

54578 Tubing, Copper

56542 Dial Plate

54532 Wire Set Two Well

54533 Wire Set Three Well

54534 Wire Set Four Well

54535 Wire Set Five Well

54536 Wire Set Six Well

17

Page 18

Small Frame Insulated Top Mount EZ Fill Hot Food Wells SHFWEZ-2D, -3D, -4D, -5D, -6D

EXPLODED VIEW SHFWEZ-2D, 3D, 4D, 5D, 6D w/SHUT-OFF VALVE

5 Well Model Shown

(SHFWEZ-5D)

10

10

50

50

PARTS LIST & EXPLODED VIEW

5

5

2

2

16

16

37

37

40

40

1

1

29

29

26

26

28

28

36

36

42

42

27

27

54

54

23

23

3

3

7

9

9

11

22

11

12

12

NA

NA

53

49

49

8

53

56

21

55

50

50

10

58

58

57

15

MODEL P/N VOLTS WATTS

SHFWEZ-2D 70109122 208/240 1200/1600

SHFWEZ-3D 70109132 208/240 1200/1600

SHFWEZ-4D 70109142 208/240 1200/1600

SHFWEZ-5D 70109152 208/240 1200/1600

SHFWEZ-6D 70109162 208/240 1200/1600

56

52

52

59

59

14

14

20

35

35

46

19

19

41

41

17

17

20

24

24

18

18

13

56

38

38

32

39

33

51

51

6

6

4

4

31

31

30

30

48

48

34

34

43

43

44

44

25

45

47

Note: When ordering, ALWAYS specify Part #, Model #, Serial #, Voltage & Phase. P/N 70103068 7/05

18

Page 19

PARTS LIST SHFWEZ-2D, -3D, -4D, -5D, -6D w/SHUT-OFF VALVE

Item Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

P/N

54579

56655

55789

56388

54580

55099

89120

56506

89061

88993

55441

89059

89390

88889

56541

54577

56542

30201

89054

56536

89073

56039

89025

60351

56360

54544

89063

54546

54543

55058

70101018

88977

54524

54578

54508

54549

88971

54510

XXXX

39

40

41

42

43

44

45

46

47

54513

54545

54512

54548

55059

87822

54511

88961

89071

Description Description

W/Ass'y, EZ Fill Well, 600 Pan

W/Ass'y, Drain Strainer

Sealant, Gs7500, 6.5 Ft. Lg.

Plate, Hole Cover

W/Ass'y, 600 Well Pan

Conduit 3/4" Length 24"

Clip, Jiffy

Plate, Reflector

Nut, Hex 10-24

Screw 10-32x3/8 Trs Hd Phillips

Element, 1200/1600W - 208/240V

Washer #10 External Lock

Label, Warranty Against Defects

Screw #8 X 1/2 AB Sms Phl Truss

Thermostat, Model 375°, 72"cap

Adapter, 1/4” Tube to 3/8” Pipe

Plate, Dial-Wells

Terminal Block, 600V, 50A

Nut, KEPS 6-32

S/A, Pilot Light Amber

Screw, #8 X 1/2 Hex Tapit Sht Mtl

Cover, Capillary

Nut, Speed 10-24 Pal Zinc

Knob, Thermostat 375°F

Valve, Drain 1/2" Threaded

O-Ring, 1/2" ID X 5/8" OD

Nut, Hex 8-32

Washer, 1/2-20 S/S

Holder, Probe

Conduit Connector, 90° Flex

Tubing, Brass 1/2" X 3" Long

Screw 6-32 X 1 Ph Pan Hd

Bracket, Solenoid Valve

Tubing, Copper, 1/4

.032 Wall Refrig

Connector, Male Brass

Nut, Hex 1/2-20 Plain

Screw, 8-32x1-1/2 Sl Pn Hd SS

Liquid Level Control, Octal Base

Liquid Level Control, Open Board

Valves, Water Solenoid

O-Ring, 5/32" ID X 7/32" OD

Strap, Hold Down

Spacer, Phenolic

Bushing, Antishort, 3/4", #4

Washer, Reducing1X3/4

Base, Liquid Level Control Socket

Nut, Hex 10-24, Green

Washer, #10 Flat

Quan

1

5

5

10

4

1

10

5

20

10

5

10

1

4

5

1

1

1

4

5

70

5

80

5

5

1

2

1

1

2

5

2

1

1

2

1

1

1

1

1

1

1

1

2

2

1

1

1

48

49

50

51

52

53

54

55

56

57

58

59

*60

P/N

57258

57273

57267

57293

57366

57252

57260

57263

57290

57363

57254

57262

57266

57292

57365

54526

54538

54539

54540

54541

56048

56050

57264

55308

60150

54503

54521

54528

54504

54522

54529

89184

54532

54533

54534

54235

54236

2 Well Drain Manifold

3 Well Drain Manifold

4 Well Drain Manifold

5 Well Drain Manifold

6 Well Drain Manifold

2 Well Top Plate

3 Well Top Plate

4 Well Top Plate

5 Well Top Plate

6 Well Top Plate

2 Well Cover, Front And Back

3 Well Cover, Front And Back

4 Well Cover, Front And Back

5 Well Cover, Front And Back

6 Well Cover, Front And Back

2 Well EZ Fill, Bottom Cover

3 Well EZ Fill, Bottom Cover

4 Well EZ Fill, Bottom Cover

5 Well EZ Fill, Bottom Cover

6 Well EZ Fill, Bottom Cover

W/Ass'y, Conduit Brace

Housing, End

Brace, Well Runner

E-Z Lock, 6 Tab

Insulation

Bezel Control 12.50"

Bezel Control 16.50"

Bezel Control 33.50"

Control Box W/Ass'y, 12.50"

Control Box W/Ass'y, 16.50"

Control Box W/Ass'y, 33.50"

Bushing, .875 Heyco 2126

2 Well Wire Set

3 Well Wire Set

4 Well Wire Set

5 Well Wire Set

6 Well Wire Set

*Not Shown

Quan

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

1

1

1

1

1

2

2

4

6

20

1

1

1

1

1

1

1

1

1

1

1

1

Note: When ordering, ALWAYS specify Part #, Model #, Serial #, Voltage & Phase. P/N 70103068 7/05

19

Page 20

HFWEZ-2, -3, -4, -5. 6 WIRING DIAGRAM (THERMOSTATIC CONTROL CONFIGURATION)

Heating Elements

15

14

21

L1

H1

28

4

5

6

7

8

34

22

29

19

23

H1

L1

33

33

28

22

L1

Indicator

Lights

H1

1

Probe

Common

2

18

13

3

23

17

7

8

1

2

6

5

4

3

16

L1

L2

20

L1

L2

H1

H2

19

26

27

29

Thermostat

Wire Nuts

Heating Elements

14

15

HFW-2

20

13

2

18

3

19

27

21

4

5

6

7

22

19

28

29

8

23

19

30

9

24

19

Indicator

Lights

10

31

11

12

25

19

1

Probe

Common

7

8

1

2

6

5

4

3

16

17

L1

L2

26

Thermostat

24

25

30

31

L1

HFW-3

L2

Single Phase

23

24

25

30

31

29

L1

HFW-4

L2

Single Phase

22

23

24

25

30

31

29

28

L1

HFW-5

L2

Single Phase

21

22

23

24

25

30

31

29

28

27

L1

HFW-6

L2

Single Phase

20

21

22

23

24

25

31

30

29

28

27

26

L1

L2

Single Phase

20

Page 21

Notes:

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or Parts, this information is required.

Model Number Serial Number Date Purchased

21

Page 22

Notes:

22

Page 23

APW WYOTT EQUIPMENT LIMITED WARRANTY

APW Wyott Foodservice Equipment Company warrants it's equipment against defects in materials and workmanship, subject to the

following conditions:

This warranty applies to the original owner only and is not assignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this warranty,at the option of

APW Wyott such product will be repaired or replaced by APW Wyott or its Authorized Service Agency.APW Wyott will only be

responsible for charges incurred or service performed by its Authorized Service Agencies. The use of other than APW Wyott

Authorized Service Agencies will void this warranty and APW Wyott will not be responsible for such work or any charges associated

with same.TheclosestAPWWyottAuthorized ServiceAgentmustbeused.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, metropolitan areas of Alaska and Canada. There

will benolaborcoverage for equipment located on any island not connected by roadway to the mainland.

Warranty coverage on products used outside the 48 contiguous United States, Hawaii, and metropolitan areas of Alaska and Canada

may vary. Contact the international APWWyott distributor,dealer, or service agency for details.

TimePeriod

One year for parts and one year for labor, effective from the date of purchase by the original owner.The Authorized Service Agency

may, at their option, require proof of purchase. Parts replaced under this warranty are warranted for the un-expired portion of the

original product warranty only.

Exceptions

Inallcases,partscovered by extended warranty will be shipped FOB the factory after the first year.

Portable Carry In Products

Equipment weighing over 70 pounds or permanently installed will be serviced on-site as per the terms of this warranty. Equipment

weighing 70 pounds or under, and which is not permanently installed, i.e. with cord and plug, is considered portable and is subject to

the following warranty handling limitations. If portable equipment fails to operate in its intended manner on the first day of

connection, or use, atAPWWyott's option or itsAuthorizedServiceAgency, it will be serviced on site or replaced.

From day two through the conclusion of this warranty period, portable units must be taken to or sent prepaid to the APW Wyott

Authorized ServiceAgency forin-warranty repairs. No mileage or travel charges are allowed on portable units after the first day of use.

If the customer wants on-site service, they may receive same by paying the travel and mileage charges. Exceptions to this rule: (1)

countertop warmers and cookers,which are covered under the Enhanced Warranty Program, and (2) toasters or rollergrills which have

instoreservice.

Exclusions

The following conditions are not covered by warranty:

If the equipment has been changed, altered, modified or repaired by other than an Authorized Service Agency during or after the

warranty period, then the manufacturer shall not be liable for any damages to any person or to any property,whichmay result from the

use oftheequipment thereafter.

This warranty does not cover services performed at overtime or premium labor rates. Should service be required at times which

normally involve overtime or premium labor rates,theownershallbechargedforthedifferencebetween normal service rates and such

premium rates.APWWyott does not assume any liability for extended delays in replacing or repairing anyitemsbeyonditscontrol.

Inallcases,theuseofotherthanAPWWyottAuthorized OEM Replacement Partswill void this warranty.

This equipment is intended for commercial use only.Warrantyis void if equipment is installed in other than commercial application.

WaterQuality Requirements

Water supply intended for a unit that has in excess of 3.0 grains of hardness per gallon (GPG) must be treated or softened before

being used. Water containing over 3.0 GPG will decrease the efficiency and reduce the operation life of the unit.

Note: Product failure caused by liming or sediment buildup is not covered under warranty.

THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES

AND CONSTITUTES THE ENTIRE LIABILITY OFAPW WYOTT. IN NO EVENT DOES THE LIMITED WARRANTY

EXTEND BEYOND THE TERMS STATED HEREIN.

*Gas/Electric Cookline:

component parts, except switches and thermostats. (2additionalyearsonpartsonly.No labor on second or third year.)

*BroilerBriquettes,

*Heat Strips:

*GlassWindows, Doors, Seals,Rubber Seals, Light Bulbs:

*Equipment failure relating to improper installation, improper utility connection or supply and problems due to

ventilation.

*Equipment that has not been properly maintained, calibration of controls, adjustments, damage from improper cleaning

and water damage to controls.

*Equipment that has not been used in an appropriate manner, or has been subject to misuse or misapplication, neglect,

abuse, accident, alteration, negligence, damage duringtransit,delivery orinstallation, fire, flood, riot or act ofgod.

*Equipment that has the model number or serial number removed or altered.

Models FD, FDL, FDD, FDDL. Two(2) YearWarranty on element only. No labor second year.

Models GCB, GCRB, GF, GGM, GGT, CHP-H, EF, EG, EHP. Three (3) Year Warranty on all

RockGrates, Cooking Grates, Burner Shields,Fireboxes:

90Day Material Only. No Labor.

90Day Material Only.No Labor.

9/05

23

Page 24

R

Phone: +1

(214) 421-7366

Fax: +1 (214) 565-0976

Toll Free: +1 (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

APW WYOTT

729 Third Avenue

Dallas, TX 75226

24

Loading...

Loading...