Page 1

INSTALLATION

AND

OPERATING

INSTRUCTIONS

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For Warranty

Service and/or Parts, this information is required.

Model Number

Serial Number

Date Purchased

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance.

WARNING: Improper installation, operation, service or maintenance can cause property

damage, injury or death. Read and understand these instructions thoroughly before

positioning, installing, maintaining or servicing this equipment.

WARNING: Instructions must be posted in a prominent location. All safety precautions

must be taken in the event the user smells gas. Safety information can be obtained from

your local gas supplier.

APW WYOTT Foodservice Equipment Company

P.O. Box 1829

Cheyenne, WY 82003

+1 (307) 634-5801 Phone

+1 (307) 637-8071 Fax

+1 (800) 752-0863 Toll Free

www.apwwyott.com

Gas Char-Broilers......................MODELS: GCB-18i, -24i, -36i, -48i

&

Gas CharRock Broilers........ MODELS: GCRB-18i, -24i, -36i, 48i

1

P/N 882201

Page 2

CAUTION: These models are designed, built, and sold for commercial use. If these

models are positioned so the general public can use the equipment, make sure that

cautions, warnings, and operating instructions are clearly posted near each unit so that

anyone using the equipment will use it correctly and not injure themselves or harm the

equipment.

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

WARNING: For your safety do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance. Keep the area free and clear of

combustibles. (See ANZI Z83. 14B, 1991).

NOTICE: Instructions to be followed if anyone smells gas should be posted in a prominent

place. These may be obtained from the gas supplier.

WARNING: A factory authorized agent should handle all maintenance and repair. Before

doing any maintenance or repair, contact APW Wyott.

GAS PRESSURE

The appliance and it’s individual shutoff valve (to be supplied by user) must be disconnected from the gas

supply piping system during any pressure testing of that system at test pressures in excess of ½ psi (3.45 kPa).

The appliance must be isolated from the gas supply piping system by closing it’s individual manual shut-off valve

during any pressure testing of the gas supply piping system at test pressures equal to or less than ½ psi

(3.45 kPa).

Congratulations on your purchase of APW Wyott commercial cooking or refrigeration equipment. APW Wyott

takes pride in the design and quality of our products. When used as intended and with proper care and

maintenance, you will experience years of reliable operation from this equipment. To ensure best results, it is

important that you read and follow the instructions in this manual carefully.

TABLE OF CONTENTS

ITEM PAGE ITEM PAGE

Safety Precautions ............................................. 3 Cleaning/Maintenance ............................................. 9

General Installation Instructions ......................... 4 Service/Repair ....................................................... 10

Specifications & Dimensions .............................. 4 Troubleshooting Guide .......................................... 11

Conversion ......................................................... 7 Replacement Parts Lists & Exploded Views ......... 12

Lighting Instructions ........................................... 7 Warranty................................................................. 21

Operation Instructions ........................................ 9

LOCATION OF DATA PLATE

The data plate is located on the rear panel.

2

Page 3

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

DANGER: This symbol warns of imminent hazard which will result in serious injury or

death.

WARNING: This symbol refers to a potential hazard or unsafe practice, which could result

in serious injury or death.

CAUTION: This symbol refers to a potential hazard or unsafe practice, which may result in

minor or moderate injury or product or property damage.

NOTICE: This symbol refers to information that needs special attention or must be fully

understood even though not dangerous.

NOTICE: This product is intended for commercial use only. Not for household use.

CAUTION: These models are designed, built, and sold for commercial use. If these

models are positioned so the general public can use the equipment make sure that

cautions, warnings, and operating instructions are clearly posted near each unit so that

anyone using the equipment will use it correctly and not injure themselves or harm the

equipment.

WARNING: Improper installation, operation, service or maintenance can cause property

damage, injury or death. Read and understand these instructions thoroughly before

positioning, installing, maintaining or servicing this equipment.

NOTICE: Local codes regarding installation vary greatly from one area to another. The

National Fire Protection Association, Inc., states in its NFPA96 latest edition that local

codes are "Authority Having Jurisdiction" when it comes to requirement for installation of

equipment. Therefore, installation should comply with all local codes.

All containers should be examined for damage before and during unloading. The freight carrier has assumed

responsibility for its safe transit and delivery. If equipment is received damaged, either apparent or concealed, a

claim must be made with the delivering carrier.

A) Apparent damage or loss must be noted on the freight bill at the time of delivery. It must then be signed by

the carrier representative (Driver). If this is not done, the carrier may refuse the claim. The carrier can supply

the necessary forms.

B) Concealed damage or loss if not apparent until after equipment is uncrated, a request for inspection must be

made to the carrier within 15 days. The carrier should arrange an inspection. Be certain to hold all contents

and packaging material.

Installation and start-up should be performed by a qualified installer who thoroughly read, understands and

follows these instructions.

If you have questions concerning the installation, operation, maintenance or service of this product, write

Technical Service Department APW Wyott Foodservice Equipment Company, P.O. Box 1829, Cheyenne,

WY 82003.

SAFETY PRECAUTIONS

3

Page 4

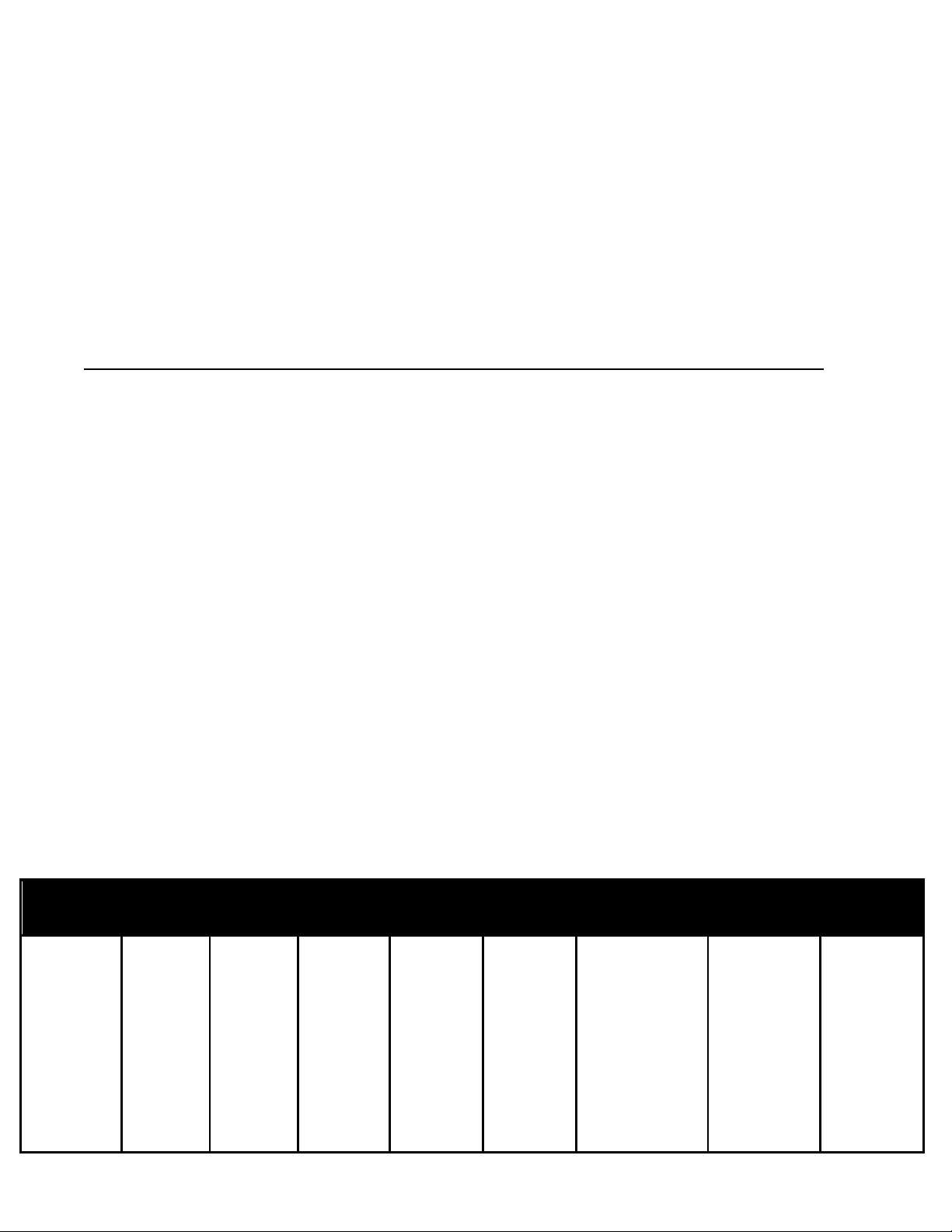

MODEL

A

IN. (MM)

B

IN. (MM)

C

IN. (MM)

D

IN. (MM)

# OF

BURNERS

BTU/kW PER

BURNER

NATURAL GAS

TOTAL

BTU/kW

HOUR

W.C.

IN.('Mbar')

GCB-18i

18 (457)

24.1 (639)

15.6 (396)

9.0 (229)

1

60,000/17.5

60,000/17.5

6/10(15/25)

GCB-24i

24 (610)

24.1 (639)

15.6 (396)

8.6 (219)

2

40,000/11.7

80,000/23.5

6/10(15/25)

GCB-36i

36 (914)

24.1 (639)

15.6 (396)

9.6 (243)

3

40,000/11.7

120,000/35

6/10(15/25)

GCB-48i

48 (1219)

24.1 (639)

15.6 (396)

10.6 (269)

4

40,000/11.7

160,000/46.8

6/10(15/25)

GCRB-18i

18 (457)

24.1 (639)

15.6 (396)

9.0 (229)

1

60,000/17.5

60,000/17.5

6/10(15/25)

GCRB-24i

24 (610)

24.1 (639)

15.6 (396)

8.6 (219)

2

40,000/11.7

80,000/23.5

6/10(15/25)

GCRB-36i

36 (914)

24.1 (639)

15.6 (396)

9.6 (243)

3

40,000/11.7

120,000/35

6/10(15/25)

GCRB-48i

48 (1219)

24.1 (639)

15.6 (396)

10.6 (269)

4

40,000/11.7

160,000/46.8

6/10(15/25)

GENERAL INSTALLATION INSTRUCTIONS

Ensure gas supply and gas type, as shown on unit nameplate, agree.

Unit installation must conform with the National Fuel Gas Code, ANSI Z223.1/NFPA 54, the National Gas

Installation Code, CSA-B149.1, or the Propane Installation Code, CSA-B149.2 as applicable and in accordance

with local codes.

Screw legs into the permanently fastened nuts on the four corners of the unit and tighten by hand. Level the unit

by turning the adjustment screw at the bottom of each leg. Do not slide unit with legs mounted, lift if necessary

to move unit.

Pipe threading compound must be resistant to the action of liquefied petroleum gases.

Caution: DO NOT use an open flame to check for leaks. Check all gas piping for leaks with a soap and water

solution before operating unit.

THESE UNITS ARE SUITABLE FOR INSTALLATION ON NON-COMBUSTIBLE SURFACES ONLY.

Noncombustible clearances:

0" sides (0 mm) 0" rear (0 mm) 4" floor (102mm)

Do not obstruct the flow of combustion and ventilation air, under the unit by the legs or behind the unit by the

flue.

Adequate clearance for air openings into the combustion chamber is required. Do not place objects between the

bottom of the unit and the counter top.

There must be adequate clearance for removal of the front panel. All major parts except the burners are

removable thru the front if the gas line is disconnected.

Unit must have adequate clearances for servicing. (Sides = 0", Rear = 0", Floor = 4").

European Community Installation Instructions:

"THIS APPLIANCE MUST BE FITTED BY A COMPETENT PERSON. IN THE UK, CORGI REGISTERED

INSTALLERS (INCLUDING THE REGIONS OF BRITISH GAS) UNDERTAKE TO WORK TO SAFE AND

SATISFACTORY STANDARDS. THIS APPLIANCE MUST BE INSTALLED IN ACCORDANCE WITH THE GAS

SAFETY (INSTALLATION AND USE) REGULATIONS AND THE RELEVANT BUILDING REGULATIONS / IEE.

REGULATIONS. DETAILED RECOMMENDATIONS ARE CONTAINED IN THE FOLLOWING BRITISH

STANDARD CODES OF PRACTICE -BS 6172, BS 5440 PART 2, BS 6891"

"THIS APPLIANCE MUST BE INSTALLED IN ACCORDANCE WITH THE RULES IN FORCE"

"MUST BE INSTALLED IN A WELL VENTILATED AREA. Ventilation requirements ie. B.S. 5440."

SPECIFICATIONS AND DIMENSIONS

4

Page 5

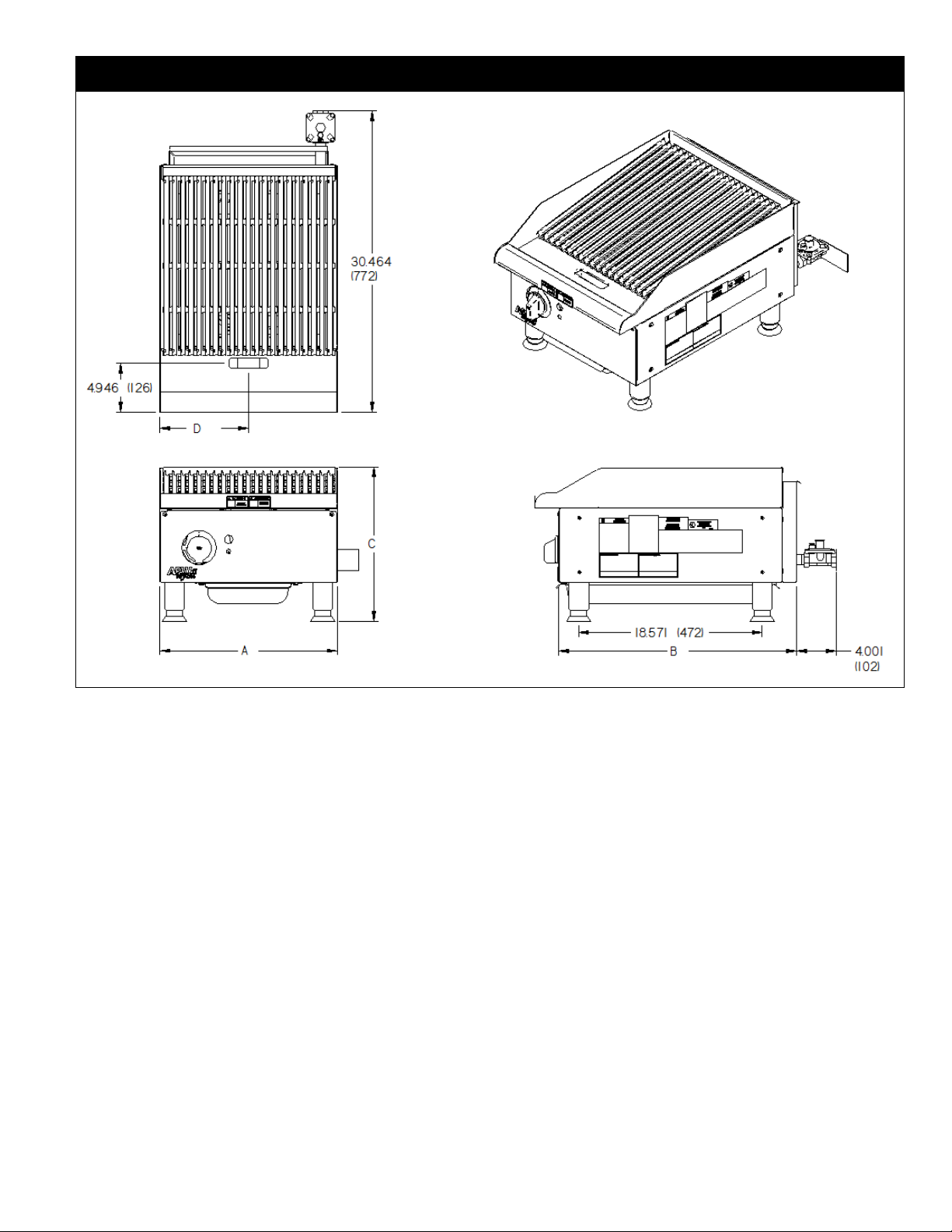

DIMENSIONS: GCB-18i & GCRB-18i

CONVERSION

Instructions are for conversion from Natural Gas to Propane (L.P.) on all models GCRB and GCB.

The conversion should be done before connecting the unit to the gas supply.

Units are shipped from the factory equipped for use on natural gas. Orifices necessary for LP (propane) are

provided in a bag tied to the valve on the front panel.

1. Remove the knobs and front panel.

2. Remove the orifice fittings from the valve. Change the orifices to the size recommended for propane (L.P.).

3. Replace the orifice fittings into the valve.

4. Remove cap, invert the insert and replace cap. NOTE: Marking on insert.

5. Continue with the installation.

LIGHTING INSTRUCTIONS

GCB and GCRB Broilers are furnished with either a pilot safety valve or a standing pilot (not available in the

European Community). Please follow the instructions for your unit.

Pilot Safety Valve Lighting Instructions

Lighting instructions are on the right side panel.

5

Page 6

If the pilot goes out, an automatic shutoff valve turns off the gas supply to the burners. To relight the pilot, follow

this procedure:

Turn the control valve to "OFF". Wait a sufficient length of time to allow gas, which may have accumulated in

the burner compartment, to escape (at least five minutes).

Turn on the main shutoff valve.

Depress and hold in the red button "A" on the automatic shutoff valve while lighting the pilot burner.

When gas at pilot has been burning for about 45 seconds, release the red button. If pilot does not remain lit,

repeat the operation, allowing more time before releasing red reset button. The button can be accessed

through an opening in the front panel.

To adjust the pilot flame, Rotate the knob clockwise to reduce the gas flow, and counterclockwise to

increase the gas flow; to provide a properly sized pilot flame (approximately 1/2" to 3/4" long). (12 to 19 mm)

All units are equipped with fixed orifices for use with natural gas, and no adjustment is necessary.

Units for operation on natural or propane gas, are also equipped with a factory preset pressure regulator

with an outlet pressure of 6.0" W.C. (15 'mbar') for natural gas supply, and 10" W.C. (25 'mbar') for propane

gas supply, and should not require further adjustment.

Standing Pilot Lighting Instructions (Not Available in the European Community)

The pilot lights on the broilers have been set at the factory. A screwdriver may be required for the first lighting to

adjust the flame for your elevation.

1. Turn off the manual shut off valve and wait 5 minutes to clear the gas.

2. Turn all knobs to the "OFF" position.

3. Turn the manual shut off valve on.

4. Hold an ignition source (match) at the pilot. When the flame is established, remove the ignition source.

5. Turn the burner knobs to "HI". If the burner does not ignite, promptly open the pilot valve more. If the pilot

flame appears larger than necessary, turn it down and reset burner ignition. The pilot flame should be as

small as possible but large enough to guarantee reliable ignition of the burners when the knobs are turned to

"HI".

RELIGHTING PILOT

If the pilot light should go out for any reason:

Promptly shut off all gas at the manual shut off valve.

Turn off all knobs and pilot valves; wait 5minutes to clear gas.

Relight following steps 4 through 6 under Standing Pilot Lighting Instructions.

LIGHTING MAIN BURNER:

Since the burner is lit from constantly burning pilot, turn knobs to "HI" to put the unit in operation; then adjust to

any desired position between "LO" and "HI".

To light burner, turn knob to "max". Then back off to the desired flame level. The range of adjustment is

virtually infinite between high and off. (At the small flame, there is a pre-set low).

When the broiler is first heated, it will smoke until oil used in manufacturing, preservation and dust from

storage and shipping are burned off. An hour at "max". On all burners is usually sufficient.

Turn knobs off and let cool.

For first cooking, set the grates at maximum tilt position and preheat before broiling. You will have to

experiment with knob settings and grate position for each particular item.

Keep the grease/water pan with sufficient water to cover the entire bottom.

6

Page 7

Clean regularly. Grates may be removed for washing in the sink. Brush out carbonized particles. Thoroughly

wash the grease/water pan.

CAUTION

Never attempt to move a grill section while cooking. An unexpected flare could cause severe injury. Turn off the

unit, let it cool and use potholders and/or gloves to reposition or remove. The space between the legs at the

bottom admits combustion air. DO NOT BLOCK THISS PACE.

Main burner air supply:

For efficient burner operation, a proper balance of gas volume and primary air supply must be maintained which

will result in complete combustion. Insufficient air supply results in a yellow streaming flame. Primary air supply

is controlled by an air shutter on the front of the burner.

Loosen the screws on the front of the burner, and adjust the air shutter to just eliminate the yellow tips of the

burner flame. Lock the air shutter in place by tightening the screws.

European Community

If adjustment becomes necessary in the field, it should be done by a factory authorized and trained

technician who should seal the screw after the adjustment to safeguard against unauthorized tampering

by the end user.

All burners are lit from constantly burning pilots. Turning the thermostat to the desired temperature is all that is

required to put the unit in service.

Do not permit fans to blow directly at the unit. Wherever possible, avoid open windows next to the units' sides or

back. Avoid wall type fans which create air cross-currents within a room.

It is also necessary that sufficient air should be allowed to enter the room to compensate for the amount of air

removed by any ventilating system. Otherwise, a subnormal atmospheric pressure will occur, which will effect

operation and cause undesirable working conditions.

A properly designed and installed hood will act as the heart of the ventilating system for the room or area in

which the unit is installed and will leave the unit independent of changing draft conditions.

All valves must be checked and lubricated periodically. This must be done by an authorized service

representative in your area.

OPERATING INSTRUCTIONS

OPERATION:

Turn the burners on about 15-20 minutes before cooking for preheating. Set the knobs to the desired flame

height or temperature. Each valve will control the gas flow to the burner to bring that area of the plate up to the

set temperature. If different temperature settings are to be used, adjoining areas should be set at progressively

higher temperatures using the lowest temperatures on the outside burners. A uniform and systematic approach

to the loading of the griddle will produce the most consistent product results.

RADIANTS

Place the radiant’s in their position as shown in Sketch 1. Make sure that the radiants are setting properly into

the slots on the front and rear supports. Radiants should be centered over straight section of the burners.

COOKING GRATES

Place the top cooking grates with the grid bars sloping toward the front as shown in Sketch 2.

NOTE: When cooking grates are placed sloping toward the front, the grooves on top will guide the excess fat

drippings into the grease trough.

7

Page 8

SKETCH 1

SKETCH 2

CLEANING / MAINTENANCE

INITIAL CLEANING:

Prior to operating your new broiler, thoroughly wash the exterior with a mild detergent or soap solution. Do not

use abrasive cleaners, since this might damage the cabinet finish. If the stainless steel surfaces become

discolored, scrub by rubbing only in the direction of the finished grain.

When the broiler is first heated, it will smoke until oil used in manufacturing, preservation and dust from storage

and shipping are burned off. An hour at "max." on all burners is usually sufficient.

CLEANING:

DAILY

Remove the grease pan, empty and wash it.

Grate "burn off'. The grease buildup on the grates should be cleaned daily (more often as needed).

A. Caution: When handling grates or radiants, always use insulated gloves to prevent burns.

B. Warning: Do not cover the top of the grid grates during a burn off operation. Restricting the airflow by

covering the grid grates may cause them to warp. It will also cause damage to the valves, the knobs and the

front panel decal.

C. Place grates on broiler, with grid bars horizontal, facing down.

D. Turn control knobs to "HI" for approximately 45minutes.

E. Turn off the broiler and allow it to cool for 20Minutes.

F. Clean top and bottom surfaces of grate with a wire brush to remove animal fats and carbonized grease.

G. Clean channels on grates with a scraper.

H. Remove grates from broiler. Clean top surface of radiant’s with the wire brush. They may be cleaned in

place.

WEEKLY

Thoroughly clean the exposed surfaces of broiler, sides, front and top grease trough, with a damp cloth, then

polish with a soft, dry cloth. A detergent may be used for cleaning. To remove discoloration, use a nonabrasive

cleaner.

After performing daily cleaning procedures, proceed with the following:

A. Remove the radiants. Clean reflecting drip shield of any dust or debris with a brush.

Note: Top grid grates and rock grates are heavy.

B. Burner air shutter openings must be kept clean.

8

Page 9

C. Burner ports must be kept clean. To clean burners, boil them in a strong solution of lye water for fifteen to

CAUTION: Clean the regulator at least once a month. Make sure the vent opening is open

and not blocked in any way. Failure to do so will cause variations in pressure. Your unit

will not function as well and it could shorten the life of the product

PROBLEM

POSSIBLE CAUSE

Heat does not come on when valve is turned

on.

Pilot burner not lit.

Gas valve is bad.

Pilot burner will not light.

Obstructed pilot orifice.

Pilot gas turned off at automatic pilot.

Automatic pilot valve is bad.

Pilot burner will not stay lit.

Thermocouple is bad.

Thermocouple is not hot enough.

Obstructed or wrong size pilot orifice.

Gas supply is not purged of air.

Air is blowing pilot light out.

Automatic pilot valve is bad.

Fat appears to smoke excessively.

Heat is set too high.

Moisture in the food may be turning into steam.

Food sticks to grates.

Heat is set too high.

Griddle surface needs cleaning and/or seasoning.

Surface under food may not have been covered with

enough cooking oil.

Food is undercooked inside.

Heat is set too high.

Food may not have been cooked for long enough time.

Food tastes greasy or has objectionable

off-flavor.

Food itself may have off flavor.

Food may have been stored improperly before cooking.

Too much griddle fat used.

twenty minutes. Then, either brush with a wire brush or clean gas ports with a sharp pointed metal

instrument to insure open ports.

EXTENDED SHUTDOWN:

Turn the manual shutoff valve to "OFF"; (field installed valve not supplied by the manufacturer); turn all control

knobs to the "OFF" position; and shut off the pilot flame by turning the adjustment on the pilot valve.

SERVICE / REPAIR

NOTE: THIS APPLIANCE MUST ONLY BE SERVICED BY AN AUTHORIZED AGENT.

NOTE: Parts protected by the manufacturer or his agent are not to be adjusted by the installer unless the

installer is an authorized service agent.

TROUBLE SHOOTING GUIDE

9

Page 10

Heat is set too low.

PLACE LAVA ROCKS WITH AIR SPACES BETWEEN THE ROCKS. DO NOT OVER LOAD ROCK GRATES.

Please Use The Following Amount of Lava Rock Per Model.

GCRB 18" = Approximately 3 LBS.

GCRB 24" = Approximately 4 LBS.

GCRB 36" = Approximately 7 LBS.

GCRB 48" = Approximately 9 LBS.

Notes:

10

Page 11

PARTS LIST: GCB-18i & GCRB-18i

Item

P/N

Description

Quan

Item

P/N

Description

Quan

1

218207-55

Weldment, 18" Bullnose

1

35

218212-16

Radiant Med Duty - H

2 2 218215-11

Body, 18" Firebox GGM

1

36

43813149

Label, Warning Hot Surface (French)

1

3

8431300

1/4-20 Flanged Hex Locknut

6

37

8706300

Knob, Metal Cook line .375 D Shaft

1

4

21813085

Spacer

4

38

8633700

Leg, HD 2” Diameter W/Foot Flange.

4 5 22011191

Baffle, 18" Front Heat

1

39

2425400

Pan, Grease Cook Line 18” Short Draw

1

6

8417100

Nut, Hex, KEPS 10-32

6

40

21813029

Grate Support

1

7

22030005

Support, Leg 18", i-Line

2

41

3103800

Grill Grate

3 8 218215-13

Bracket, Manifold GCRB/GCB/GGM-18

1

42

2067300

Regulator, Convertible 3/4 ½ PSIG

1

9

8153100

#8-32 X 3/8 Type T

11

43

8861000

Label, Spec

1

10

22011198

Manifold, 18" GCBi/GCRBi/GGMi

1

44

8809920

Decal, Improper Installation

1

11

2068200

Valve, Gas, On-Off

1

45

8832600

Label, Service Hotline

1

12

2066828

Orifice #28

1

46

8837130

Decal, Operating Instruction

1

13

2066841

Hood, Orifice #41

1

47

8825300

Decal, Leg

1

14

2092517

Plug, 1/8 NPTM

1

48

8822325

Decal, UL Sanitation, NSF Std. 4

1

15

2065643

Valve, 90° Pilot 1/8" NPT X 3/16

1

49

8837112

Label, Orifice Size

1

16

218207-28

Tube, Pilot

1

50

8837190

Tag, Orifice Location

1

17

218207-29

Bracket, Pilot GCRB/GCB/GGM-18

1

51

43813103

Label, Warning, Hot Surface

1

18

2066154

Pilot, Top

1

52*

2300100

Bags, Poly 36 x 27 x 44

1

19

218207-16

Side, Grease Chute

2

53*

2065847

Logo, APWWYOTT Casted

1

20

22011254

Side Panel, LH & RH, i-Line

2

54*

2901251

Carton, RSC 28.25 X 20.62 X 17, 275lbs

1

21

8170700

Screw, 10-32x1/2, Type AB

12

55*

29012-35

Pad Accessory

1

22

30047501

Guide, Grease Slide

2

56*

2901255

Post Corner

4

23

218207-57

Panel, Back

1

57*

8837201

Bag, Cloth, 4" x 6" w/Drawstring

1

24

218207-17

Support, Burner

2

58*

8838700

Manual, GCB-H/GCRB-H Champion II

1

25

81546-00

#8 X 3/8

4

59*

2900851

Skid, 21.75 X 29.5

1

26

218130-75

Burner "S?

1

60*

2901240

Pad

1

27

31007-12

U-Nut C7685 10A Tinnerman

4

61*

8837400

Box Label, APW/Wyott

1

28

22011195

Baffle, Front Panel 18”, i-Line

1

62*

3100001

Lava Rocks, 8lb Bag

1

29

22011196

Panel, Control 18” GCRBi/GCBi Safety

/IGN

1

63*

2901231

Carton, RSC 23-7/16 X 16-1/16 X 4 275DW

2

22011193

Panel, Control 18” GCRBi/GCBi/GGMi

64*

2300000

29 x 19 x 44 Poly

30

81973-00

T/S #10 X 1/2 TPB Tr Hd

4

65*

8899300

List Of Service Agencies

1

33

218207-53

Support, 18" Rock Grate, Rear

1

66

3102205

Grate, Rock

1

34

218207-22

Support, 18" Rock Grate, Front

1

67

218207-26

Guard, Burner

3

* = Not Shown

1

11

Page 12

EXPLODED VIEW: GCB-18i & GCRB-18i

12

Page 13

PARTS LIST: GCB-24i & GCRB-24i

Item

P/N

Description

Quan

Item

P/N

Description

Quan

1

218208-55

Weldment, 24" Bullnose

1

36

21813129

Grate Support

1

2

218208-51

Body, 24" Firebox GCRB-GGM

1

37

8706300

Knob, Metal Cook Line .375 D Shaft

2

3

8417100

Nut, Hex, KEPS 10-32

6

38

2425500

Pan, Grease 24" Shallow Draw

1

4

8153100

#8-32 X 3/8 Type T

14

40*

8834910

Decal, Dial Plate Manual Gas Valve

1

5

81546-00

#8 X 3/8

6

41

2067300

Regulator, Convertible 3/4 ½ PSIG

1

6

22030010

Support, Leg 24” i-Line

2

42

8825300

Decal, Leg

1

7

2068200

Valve, Gas, On-Off

2

43

43813149

Label, Warning Hot Surface (French)

1

8

21813085

Spacer 4 44

43813103

Label, Warning, Hot Surface

1

9

2066833

Hood, Orifice #33

2

45

8861000

Label, Spec

1

10

2092517

Plug, 1/8 NPTM

1

46

8832600

Label, Service Hotline

1

11

218208-17

Support, Burner

2

47

8837103

Label, Orifice Size

1

12

21820815

Manifold, 24" GCRB

1

48

8822325

Decal, UL Sanitation, NSF Std. 4

1

13

218208-18

Baffle, 24" Front Heat

1

49

8837130

Decal, Operator Instruction

1

14

22011198

Manifold, 18” GCBi/GCRBi/GGMi

2

50

8809920

Decal, Improper Installation

1

15

2068001

Pilot Valve

1

51

2066849

Hood, Orifice #49

2

16

8163100

M/S Pan Hd PH 10-32 X 1/4?

2

52

2092903

Pilot Natural@ 6" W.C.

1

17

22011254

Side Panel, LH & RH, i-Line

2

53*

2901255

Post Corner

4

18

30047501

Guide, Grease Slide

2

54*

2901252

Carton, HSC 28-1/4 X 26-5/8 X 17 275 Lbs

1

19

218208-25

Bracket, Pilot

1

55*

2901229

Pad, 21-13/16 X 23-3/16 200 Lbs

1

20

218212-16

Radiant Medium Duty - H

4

56*

29012-28

Cap, FTD 24.25 X 23.25 X 4 275 Lbs

1

21

2092800

Pilot, Broiler

1

57*

29012-27

Cap, FTD 23.43 X 22.06 X 4 275 Lbs

1

22

22011255

Baffle, Front Panel 24"

1

58*

29008-52

Skid, 27.75 X 29.5

1

23

218207-16

Side, Grease Chute

2

59*

2300000

29 x 19 x 44 Poly

1

24

31007-12

U-Nut C7685 10A Tinnerman

4

60*

3100001

Lava Rocks, 8 Lb Bag

1

25

8170700

Screw, 10-32 x 1/2, Type AB

12

61*

2901241

Pad, 26-1/4 X 27 200 Lbs

1

26

8431300

1/4-20 Flanged Hex Locknut

6

62*

8899300

List Of Service Agencies

1

27

21820727

Tube, Pilot Supply

1

63*

8837201

Bag, Cloth, 4" x 6" w/Drawstring

1

28

21813115

Panel, Back

1

64*

2300100

Bags, Poly 36 x 27 x 44

1

29

218208-52

Support, 24" Rock Grate Rear

1

65*

2065847

Decal, Front Panel GCB/GCRB/GGM-24

1

30

22011256

Panel, Control 24” GCRBi/GCBi Safety/IGN

1

66*

8837400

Box Label, APW/Wyott

1

22011253

Panel, Control 24” GCRBi/GCBi/GGMi

1

67*

8838700

Logo, APWWYOTT Casted

1

31

218208-22

Support, 24" Rock Grate Front

1

68*

218133-39

Pilot Shield

1

32

81973-00

T/S #10 X 1/2 TPB Tr Hd

4

69

3102205

Grate, Rock

4

33

3103800

Grill Grate

4

70

218207-25

Guard, Burner

2

34

8837190

Tag, Orifice Location

1

* = NOT SHOWN

35

8632000

Leg, HD 2” Diameter W/Foot Flange

4

13

Page 14

EXPLODED VIEW: GCB-24i & GCRB-24i

14

Page 15

15

PARTS LIST: GCB-36i & GCRB-36i

Item

P/N

Description

Quan

Item

P/N

Description

Quan

1

218209-55

Weldment, Bullnose 36"

1

37

218209-22

Support, 36" Rock Grate Front

1

2

218209-51

Body, 36" Firebox GGM

1

38

43813149

Label, Warning Hot Surface (French)

1

3

218209-52

Support, 36" Firebox Divider

1

39

218212-16

Radiant Med Duty - H

6

4

81546-00

#8 X 3/8

12

40

8633700

Leg, HD 2” Diameter W/Foot Flange.

4

5

218209-56

Divider, Firebox

1

41

2425400

Pan, Grease Cook Line 18” Short Draw

2

6

8431300

1/4-20 Flanged Hex Locknut

6

42

8706300

Knob, Metal Cook Line .375 D Shaft

3

7

21813085

Spacer 5 43

21813229

Weldment, Grate Support

1

8

218209-18

Baffle, 36" Front Heat

1

44

3103800

Grill Grate

6

9

8417100

Nut, Hex, KEPS 10-32

7

45

2067300

Regulator, Convertible 3/4 ½ Psig

1

10

218207-16

Side, Grease Chute

2

46

8861000

Label, Spec

1

11

218209-15

Manifold, 36" GCRB

1

47

8809920

Decal, Improper Installation

1

12

8153100

#8-32 X 3/8 Type T

20

48

8832600

Label, Service Hotline

1

13

2068200

Valve, Gas, On-Off

3

49

8837103

Label, Orifice Size

1

14

2066833

Hood, Orifice #33

3

50

8825300

Decal, Leg

1

15

2066849

Hood, Orifice #49

3

51

8822325

Decal, UL Sanitation, NSF Std. 4

1

16

2092517

Plug, 1/8 NPTM

1

52

8837130

Decal, Operating Instruction

1

17

218208-25

Bracket, Pilot

2

53

2065847

Logo, APWWYOTT Casted

1

18

2092800

Pilot, Broiler

2

54

8837190

Tag, Orifice Location

1

19

8163100

M/S Pan Hd Ph 10-32 X 1/4"

4

55

43813103

Label, Warning, Hot Surface

1

20

2092903

Pilot Natural@ 6" W.C.

2

56*

8837400

Box Label, APW/Wyott

1

21

2068001

Pilot Valve

2

57*

8838700

Manual, GCB-H/GCRB-H Champion II

1

22

21820727

Tube, Pilot Supply

2

58*

8837201

Bag, Cloth, 4" x 6" w/Drawstring

1

23

218209-17

Support, Burner

2

59*

8899300

List of Service Agencies

1

24

22011198

Manifold, 18” GCBi/GCRBi/GGMi

3

60*

2300000

29 x 19 x 44 Poly

1

25

22030015

Support, Leg 36”, i-Line

2

61*

2300100

Bags, Poly 36 x 27 x 44

1

26

22011254

Side Panel, LH & RH, i-Line

2

62*

29008-53

Skid, 40.5 X 29.5

1

27

8170700

Screw, 10-32 x 1/2, Type AB

12

63*

2901255

Post Corner

4

28

30047501

Guide, Grease Slide

4

64*

2901231

Carton, RSC 23-7/16 X 16-1/16 X 4 275DW

2

29

218209-57

Panel, Back

1

65*

29012-35

Pad Accessory

2

30

31007-12

U-Nut C7685 10A Tinnerman

4

66*

29012-42

Pad

1

31

22011375

Baffle, Front Panel 36", i-Line

1

67*

2901253

Carton, HSC 39.25 X 28.62 X 17 275lbs

1

32

22011376

Panel, Control 36" GCRBi/GCBi SAFTEY/IGN

1

68

3102205

Grate, Rock

6

22011373

Panel, Control 36” GCRBi/GCBi/GGMi

69

218207-25

Guard, Burner

3

33

81973-00

T/S #10 X 1/2 TPB Tr Hd

4

70*

218133-39

Pilot Shield

2

36

218209-53

Support, 36" Rock Grate Rear

1

* = NOT SHOWN

Page 16

16

EXPLODED VIEW: GCB-36i & GCRB-36i

Page 17

17

PARTS LIST: GCB-48i & GCRB-48i

Item

P/N

Description

Quan

Item

P/N

Description

Quan

1

218210-55

Weldment, 48" Bullnose

1

36

218210-22

Support, 48" Rock Grate Front

1

2

8417100

Nut, Hex, KEPS 10-32

7

37

22030020

Support, Leg 48”, i-Line

2

3

8153100

#8-32 X 3/8 Type T

20

38*

2065847

Logo, APWWYOTT Casted.

1

4

81546-00

#8 X 3/8

12

40

2066849

Hood, Orifice #49

4

5

218208-25

Bracket, Pilot

2

41

3103800

Grill Grate

8

6

2092800

Pilot, Broiler

2

42*

8837400

Box Label, APW/Wyott

2

7

8633700

Leg, HD 2” Diameter W/Foot Flange

4

43

218207-16

Side, Grease Chute

2

8

218209-56

Divider, Firebox

1

44

43813103

Label, Warning, Hot Surface

1

9

8163100 M/S

Pan Hd Ph 10-32 X 1/4"

4

45

2067300

Regulator, Convertible 3/4 ½ PSIG

1

10

2066833

Hood, Orifice #33

4

46

2092903

Pilot Nat @ 6" W.C.

2

11

2068200

Valve, Gas, On-Off

4

47

8832600

Label, Service Hotline

1

12

21813085

Spacer 5 48

8809920

Decal, Improper Installation

1

13

2092517

Plug, 1/8 NPTM

1

49

8861000

Label, Spec

1

14

218210-17

Support, Burner

2

50

8837103

Label, Orifice Size

1

15

21821015

Manifold, 48" GCRB/GCB/GGM

1

51

43813149

Label, Warning Hot Surface (French)

1

16

218210-18

Baffle, 48" Front Heat

1

52

8837130

Decal, Operator Instruction

1

17

2068001

Pilot Valve

2

53

8825300

Decal, Leg

1

18

22011198

Manifold, 18” GCBi/GCRBi/GGMi

4

54

8822325

Decal, UL Sanitation, NSF Std. 4

1

19

22011254

Side Panel, LH & RH, i-Line

2

55*

29012-27

Cap, FTD 23.43 X 22.06 X 4 275 Lbs

2

20

30047501

Guide, Grease Slide

4

56*

29012-28

Cap, FTD 24.25 X 23.25 X 4 275 Lbs

2

21

218212-16

Radiant Med Duty - H

8

57*

29012-43

Pad, 27 X 52.5 200lbs

1

22

218210-51

Body, 48" Firebox GGM

1

58*

2901229

Pad, 21-13/16 X 23-3/16 200lbs

2

23

81973-00

T/S #10 X 1/2 TPB Tr Hd

4

59*

2901254

Carton, HSC 2pcs 51.25 X 25.62 X 17 275lbs

2

24

8706300

Knob, Metal Cook Line .375 D Shaft

4

60*

2901255

Post Corner

6

25

22011495

Baffle, Front Panel 48” i-Line

1

61*

29008-54

Skid, 52.5 X 29.5

1

26

31007-12

U-Nut C7685 10A Tinnerman

4

62*

2300000

29 x 19 x 44 Poly

2

27

8170700

Screw, 10-32x1/2, Type AB

12

63*

8899300

List Of Service Agencies

1

28

2425500

Pan, Grease 24" Shallow Draw

2

64*

8837201

Bag, Cloth, 4" x 6" w/Drawstring

1

29

8431300

1/4-20 Flanged Hex Locknut

6

65*

8838700

Manual, GCB-H/GCRB-H Champion II

1

30

21820727

Tube, Pilot Supply

2

66

8837190

Tag, Orifice Location

1

31

218210-57

Panel, Back

1

67

218210-52

Support, 48" Firebox Divider

1

32*

8834900

Decal, Dial Plate Manual Gas Valve

1

68

3102205

Grate, Rock

8

33

218210-53

Support, 48" Rock Grate Rear

1

69

218207-25

Guard, Burner

4

34

21813329

Weldment, Grate Support

1

70*

3100001

Lava Rocks, 8 lb Bag

2

35

22011496

Panel, Control 48" GCRBi/GCBi/GGM SAF/IG

1

* = NOT SHOWN

22011493

Panel, Control 48” GCRBi/GCBi/GGMi

1

Page 18

18

EXPLODED VIEW: GCB-48i & GCRB-48i

Page 19

APW WYOTT EQUIPMENT LIMITED WARRANTY

APW Wyott Foodservice Equipment Company warrants it's equipment against defects in materials and workmanship, subject to the

following conditions:

This warranty applies to the original owner only and is not assignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this warranty, at the option of

APW Wyott such product will be repaired or replaced by APW Wyott or its Authorized Service Agency. APW Wyott will only be

responsible for charges incurred or service performed by its Authorized Service Agencies. The use of other than APW Wyott Authorized

Service Agencies will void this warranty and APW Wyott will not be responsible for such work or any charges associated with same. The

closest APW Wyott Authorized Service Agent must be used.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, metropolitan areas of Alaska and Canada. There will

be no labor coverage for equipment located on any island not connected by roadway to the mainland.

Warranty coverage on products used outside the 48 contiguous United States, Hawaii, and metropolitan areas of Alaska and Canada may

vary. Contact the international APW Wyott distributor, dealer, or service agency for details.

Time Period

One year for parts and one year for labor, effective from the date of purchase by the original owner. The Authorized Service Agency may,

at their option, require proof of purchase. Parts replaced under this warranty are warranted for the un-expired portion of the original

product warranty only.

Exceptions

* Gas/Electric Cookline: Models GCB, GCRB, GF, GGM, GGT, CHP-H, EF, EG, EHP. Three (3) Year Warranty on all

component parts, except switches and thermostats. (2 additional years on parts only. No labor on second or third year.)

* Broiler Briquettes, Rock Grates, Cooking Grates, Burner Shields, Fireboxes: 90 Day Material Only. No Labor.

* Heat Strips: Models FD, FDL, FDD, FDDL. Two (2)Year Warranty on element only. No labor second year.

* Glass Windows, Doors, Seals, Rubber Seals, Light Bulbs: 90 Day Material Only. No Labor.

In all cases, parts covered by extended warranty will be shipped FOB the factory after the first year.

Portable Carry In Products

Equipment weighing over 70 pounds or permanently installed will be serviced on-site as per the terms of this warranty. Equipment

weighing 70 pounds or under, and which is not permanently installed, i.e. with cord and plug, is considered portable and is subject to the

following warranty handling limitations. If portable equipment fails to operate in its intended manner on the first day of connection, or

use, at APW Wyott's option or its Authorized Service Agency, it will be serviced on site or replaced.

From day two through the conclusion of this warranty period, portable units must be taken to or sent prepaid to the APW Wyott

Authorized Service Agency for in-warranty repairs. No mileage or travel charges are allowed on portable units after the first day of use. If

the customer wants on-site service, they may receive same by paying the travel and mileage charges. Exceptions to this rule: (1)

countertop warmers and cookers, which are covered under the Enhanced Warranty Program, and (2) toasters or rollergrills which have in

store service.

Exclusions

The following conditions are not covered by warranty:

* Equipment failure relating to improper installation, improper utility connection or supply and problems due to ventilation.

* Equipment that has not been properly maintained, calibration of controls, adjustments, damage from improper cleaning and

water damage to controls.

* Equipment that has not been used in an appropriate manner, or has been subject to misuse or misapplication, neglect, abuse,

accident, alteration, negligence, damage during transit, delivery or installation, fire, flood, riot or act of god.

* Equipment that has the model number or serial number removed or altered.

If the equipment has been changed, altered, modified or repaired by other than an Authorized Service Agency during or after the warranty

period, then the manufacturer shall not be liable for any damages to any person or to any property, which may result from the use of the

equipment thereafter.

This warranty does not cover services performed at overtime or premium labor rates. Should service be required at times which normally

involve overtime or premium labor rates, the owner shall be charged for the difference between normal service rates and such premium

rates. APW Wyott does not assume any liability for extended delays in replacing or repairing any items beyond its control.

In all cases, the use of other than APW Wyott Authorized OEM Replacement Parts will void this warranty.

This equipment is intended for commercial use only. Warranty is void if equipment is installed in other than commercial application.

Water Quality Requirements

Water supply intended for a unit that has in excess of 3.0 grains of hardness per gallon (GPG) must be treated or softened before being

used. Water containing over 3.0 GPG will decrease the efficiency and reduce the operation life of the unit.

Note: Product failure caused by liming or sediment buildup is not covered under warranty.

"THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES AND

CONSTITUTES THE ENTIRE LIABILITY OF APW WYOTT. IN NO EVENT DOES THE LIMITED WARRANTY EXTEND

BEYOND THE TERMS STATED HEREIN."

9/05

19

Loading...

Loading...