Page 1

R

INSTALLATION

AND

OPERATING

INSTRUCTIONS

Models: FDC, FDDC, FDLC & FDDLC

CERAMIC OVERHEAD FOODWARMERS

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

UNIT MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and

liquids in thevicinity of thisor any otherappliance.

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughlybefore installing or servicing this equipment.

Initial heating of unit may generate smoke or fumes and must be done in a well ventilated area.

Overexposure to smokeor fumes maycause nausea ordizziness.

This equipment has been engineered to provide you with year-round dependable service when used

according to the instructions in thismanual and standard commercial kitchen practices.

!!

!!

*

NOTE: ONLY SINGLE UNITS AVAILABLE IN CANADA

*

P/N 70499001 Rev. 9/05

Phone:

Fax: (214) 565-0976

Toll Free: (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

(214) 421-7366

APW WYOTT

729 Third Avenue

Dallas, TX 75226

1

Page 2

TABLE OF CONTENTS

SECTION

1

2

3

4

5

6

7

8

9

ITEM

General Information

Electrical Requirements

Electrical Specifications

Overall Dimensions

Installation

Operation

Cleaning

Troubleshooting

Wiring Diagrams

A. FDC-120V

B. FDC-208/240

C. FDLC-120V

D. FDLC-208/240V

E. FDLC-120V w/Fuse

F. FDDC-120V

G. FDDC-208/240V

H. FDDLC-120V

I. FDDLC-208/240V

J. FDDLC-208/240 w/Fuse

K. Element Configuration - Chart A

PAGE

2

2

3

5

6

6

6

6

7

7

7

8

8

9

9

10

10

11

11

12

10

11

Parts List & Exploded View

Warranty

13

16

1. GENERAL INFORMATION

A. APW Wyott Overhead Foodwarmers are constructedfrom high quality stainless steel and available

in lengths from 18 to 72. Utilizing a ceramic heating element with a reflector, these units give

uniformheat over the entire holding surface.

2. ELECTRICAL REQUIREMENTS

A. Singlephase operation at120, 208, and 240 volts.

B. Field-wired units provided with ½ conduit knockout and terminal blocks easily accessed through

control box access plate. For supply connections, use minimum no. 14 AWG copper wires suitable

forat least 90°C.

2

Page 3

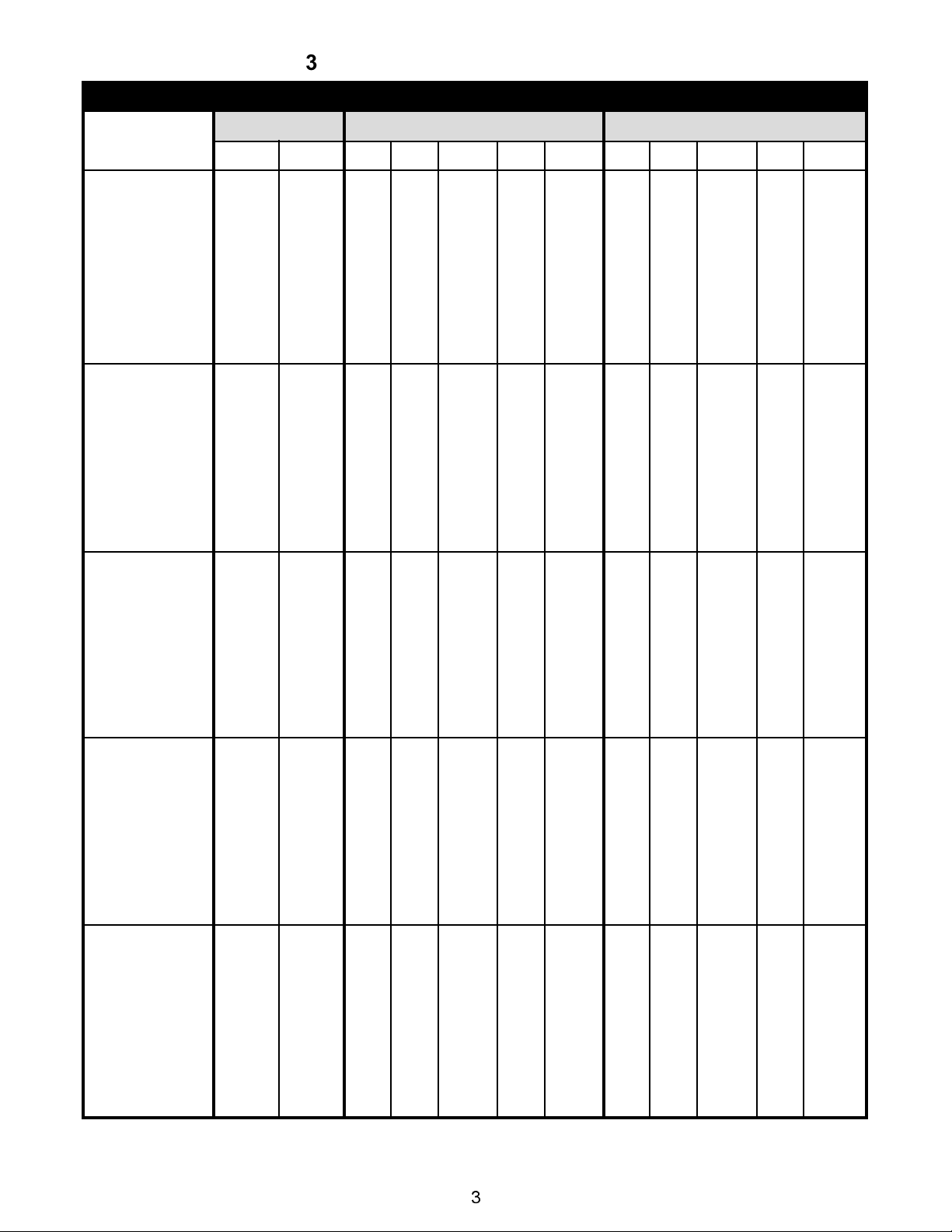

3. ELECTRICAL SPECIFICATIONS

STANDARD CERAMIC OVERHEADS ROCKER SWITCH CONTROL

MODEL

FDC-18

FDC-18

FDLC-18

FDLC-18

FDDC-18

FDDC-18

FDDLC-18

FDDLC-18

FDC-24

FDC-24

FDLC-24

FDLC-24

FDDC-24

FDDC-24

FDDLC-24

FDDLC-24

FDC-30

FDC-30

FDLC-30

FDLC-30

FDDC-30

FDDC-30

FDDLC-30

FDDLC-30

FDC-36

FDC-36

FDLC-36

FDLC-36

FDDC-36

FDDC-36

FDDLC-36

FDDLC-36

FDC-42

FDC-42

FDLC-42

FDLC-42

FDDC-42

FDDC-42

FDDLC-42

FDDLC-42

CIR-1

500

700

580

780

500

700

500

700

700

800

780

880

700

800

700

800

850

1150

930

1230

850

1150

850

1150

1000

1350

1160

1510

1000

1350

1000

1350

1200

1500

1360

1660

1200

1500

1200

1500

WATTS

CIR-2

~

~

~

~

500

700

580

780

~

~

~

~

700

800

780

880

~

~

~

~

850

1150

930

1230

~

~

~

~

1000

1350

1160

1510

~

~

~

~

1200

1500

1360

1660

VOLTS - RATINGS CIR-1

120

4.2

5.8

4.8

6.5

4.2

5.8

4.2

5.8

5.8

6.7

6.5

7.3

5.8

6.7

5.8

6.7

7.1

9.6

7.8

10.3

7.1

9.6

7.1

9.6

8.3

11. 3

9.7

12.6

8.3

11. 3

8.3

11. 3

10.0

12.5

11. 3

13.8

10.0

12.5

10.0

12.5

208

2.4

3.4

~

~

2.4

3.4

2.4

3.4

3.4

3.8

~

~

3.4

3.8

3.4

3.8

4.1

5.5

~

~

4.1

5.5

4.1

5.5

4.8

6.5

~

~

4.8

6.5

4.8

6.5

5.8

7.2

~

~

5.8

7.2

5.8

7.2

120/208

~

~

3.1

4.0

~

~

~

~

~

~

4.0

4.5

~

~

~

~

~

~

4.8

6.2

~

~

~

~

~

6.1

7.8

~

~

~

~

~

~

7.1

8.5

~

~

~

~

240

2.1

2.9

~

~

2.1

2.9

2.1

2.9

2.9

3.3

~

~

2.9

3.3

2.9

3.3

3.5

4.8

~

~

3.5

4.8

3.5

4.8

4.2

5.6

~

~

4.2

5.6

4.2

5.6

5.0

6.3

~

~

5.0

6.3

5.0

6.3

120/240

~

~

2.8

3.6

~

~

~

~

~

~

3.6

4.0

~

~

~

~

~

~

4.2

5.5

~

~

~

~

~

~

5.5

7.0

~

~

~

~

~

~

6.3

7.6

~

~

~

~

VOLTS - RATINGS CIR-2

120

~

~

~

~

4.2

5.8

4.8

6.5

~

~

~

~

5.8

6.7

6.5

7.3

~

~

~

~

7.1

9.6

7.8

10.3

~

~

~

~

8.3

11. 3

9.7

12.6

~

~

~

~

10.0

12.5

11. 3

13.8

208

~

~

~

~

2.4

3.4

~

~

~

~

~

~

3.4

3.8

~

~

~

~

~

~

4.1

5.5

~

~

~

~

~

~

4.8

6.5

~

~

~

~

~

~

5.8

7.2

~

~

120/208

~

~

~

~

~

~

3.1

4.0

~

~

~

~

~

~

4.0

4.5

~

~

~

~

~

~

4.8

6.2

~

~

~

~

~

~

6.1

7.8

~

~

~

~

~

~

7.1

8.5

240

~

~

~

~

2.1

2.9

~

~

~

~

~

~

2.9

3.3

~

~

~

~

~

~

3.5

4.8

~

~

~

~

~

~

4.2

5.6

~

~

~

~

~

~

5.0

6.3

~

~

120/240

~

~

~

~

~

~

2.8

3.6

~

~

~

~

~

~

3.6

4.0

~

~

~

~

~

~

4.2

5.5

~

~

~

~

~

~

5.5

7.0

~

~

~

~

~

~

6.3

7.6

3

Page 4

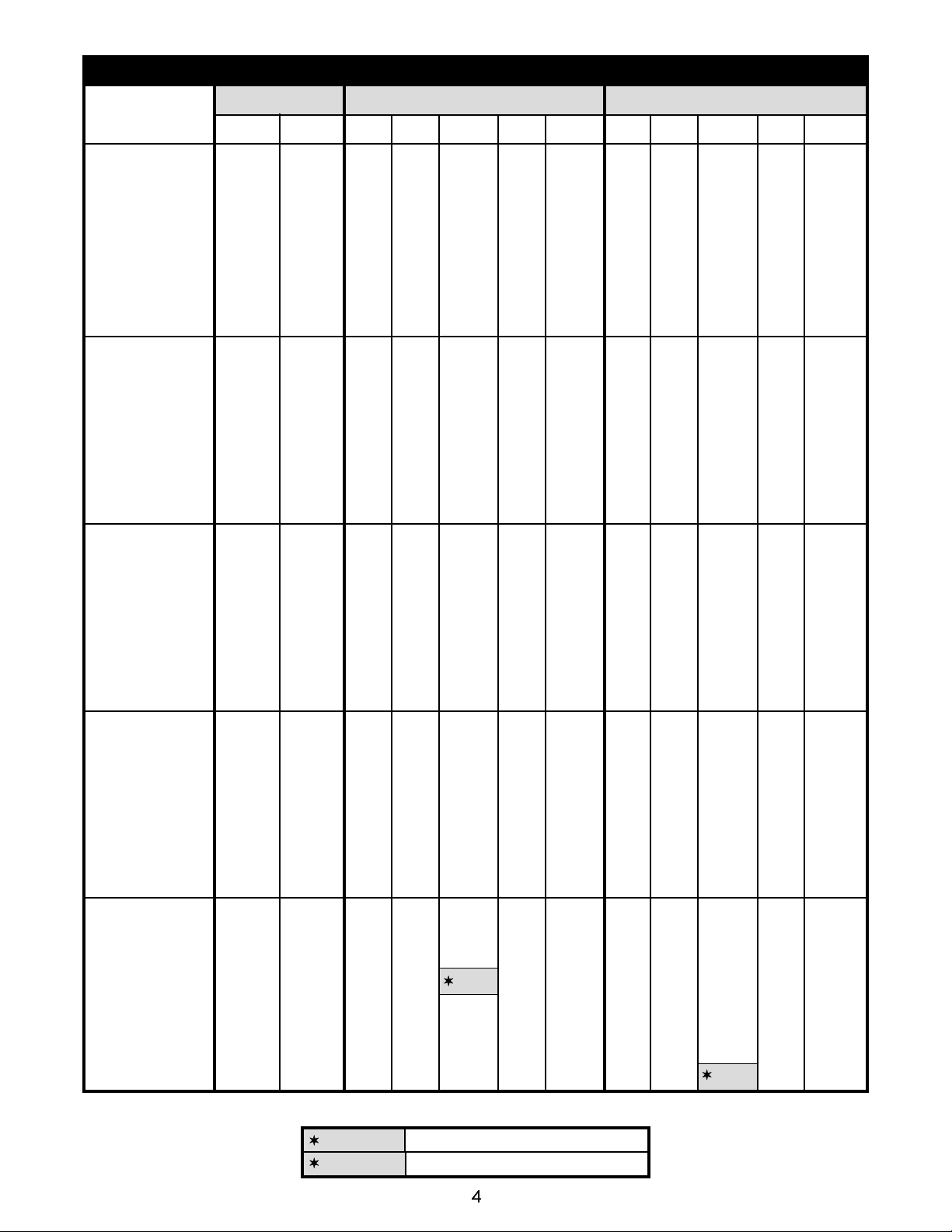

STANDARD CERAMIC OVERHEADS ROCKER SWITCH CONTROL

MODEL

FDC-48

FDC-48

FDLC-48

FDLC-48

FDDC-48

FDDC-48

FDDLC-48

FDDLC-48

FDC-54

FDC-54

FDLC-54

FDLC-54

FDDC-54

FDDC-54

FDDLC-54

FDDLC-54

FDC-60

FDC-60

FDLC-60

FDLC-60

FDDC-60

FDDC-60

FDDLC-60

FDDLC-60

FDC-66

FDC-66

FDLC-66

FDLC-66

FDDC-66

FDDC-66

FDDLC-66

FDDLC-66

FDC-72

FDC-72

FDLC-72

FDLC-72

FDDC-72

FDDC-72

FDDLC-72

FDDLC-72

CIR-1

1500

2000

1660

2160

1500

2000

1500

2000

1500

2200

1660

2360

1500

2200

1500

2200

2000

2700

2240

2940

2000

2700

2000

2700

2000

2700

2240

2940

2000

2700

2000

2700

2000

3000

2240

3240

2000

3000

2000

3000

WATTS

CIR-2

~

~

~

~

1500

2000

1660

2160

~

~

~

~

1500

2200

1660

2360

~

~

~

~

2000

2700

2240

2940

~

~

~

~

2000

2700

2240

2940

~

~

~

~

2000

3000

2240

3240

VOLTS - RATINGS CIR-1

120

12.5

~

13.8

~

12.5

~

12.5

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

208

7.2

9.6

~

~

7.2

9.6

7.2

9.6

7.2

10.6

~

~

7.2

10.6

7.2

10.58

9.6

13.0

~

~

9.6

13.0

9.6

12.98

9.6

13.0

~

~

9.6

13.0

9.6

12.98

9.6

14.4

~

~

9.6

14.4

9.6

14.42

120/208

~

~

8.5

10.9

~

~

~

~

~

~

8.5

11. 9

~

~

~

~

~

~

11. 6

15.0

~

~

~

~

~

~

11. 6

15.0

~

~

~

~

~

~

11. 6

16.4

~

~

~

~

240

6.3

8.3

~

~

6.3

8.3

6.3

8.3

6.3

9.2

~

~

6.3

9.2

6.3

9.2

8.3

11. 3

~

~

8.3

11. 3

8.3

11. 3

8.3

11. 3

~

~

8.3

11. 3

8.3

11. 3

8.3

12.5

~

~

8.3

12.5

8.3

12.5

120/240

~

~

7.6

9.7

~

~

~

~

~

~

7.6

10.5

~

~

~

~

~

~

10.3

13.3

~

~

~

~

~

~

10.3

13.3

~

~

~

~

~

~

10.3

14.5

~

~

~

~

VOLTS - RATINGS CIR-2

120

~

~

~

~

12.5

~

13.8

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

208

~

~

~

~

7.2

9.6

~

~

~

~

~

~

7.2

10.6

~

~

~

~

~

~

9.6

13.0

~

~

~

~

~

~

9.6

13.0

~

~

~

~

~

~

9.6

14.4

~

~

120/208

~

~

~

~

~

~

8.5

10.9

~

~

~

~

~

~

8.5

11. 6

~

~

~

~

~

~

11. 6

15.0

~

~

~

~

~

~

11. 6

15.0

~

~

~

~

~

~

11. 6

16.4

240

~

~

~

~

6.3

8.3

~

~

~

~

~

~

6.3

9.2

~

~

~

~

~

~

8.3

11. 3

~

~

~

~

~

~

8.3

11. 3

~

~

~

~

~

~

8.3

12.5

~

~

120/240

~

~

~

~

~

~

7.6

9.7

~

~

~

~

7.6

10.5

~

~

~

~

~

~

10.3

13.3

~

~

~

~

~

~

10.3

13.3

~

~

~

~

~

~

10.3

14.5

REQUIRES 3 AMP FUSE

REQUIRES 30 AMP CIRCUIT

4

Page 5

NOTE: TO AVOID BURNING OR CHARRING OF MATERIALS IN THE SURFACE

BELOW THE FOODWARMER USE ONLY ABOVE AN ALL-METAL STRUCTURE

SUCHASATABLE OR COUNTERTOP. SEE MINIMUM CLEARANCE CHARTABOVE.

REMOTE SWITCHES ARE RECOMMENDED FOR UNDER SHELF MOUNTING.

LONGER SWITCH LIFE WILL RESULT FROM COOLER SWITCH MOUNTING

LOCATIONS.

!!

WARNING:

INSTRUCTIONS IN THIS MANUAL COULD RESULT IN SERIOUS INJURY OR

!

DEATH.

ElectricalGround is requiredon this appliance.

Do not modify the power supply cord plug. If it does not fit into the outlet, have

theproper outlet installedby a qualifiedelectrician

Donot use an extensioncord with thisappliance.

Check with a qualified electrician if you are unsure as to whether the appliance

is properly grounded.

ELECTRICAL SHOCK HAZARD. FAILURE TO FOLLOW THE

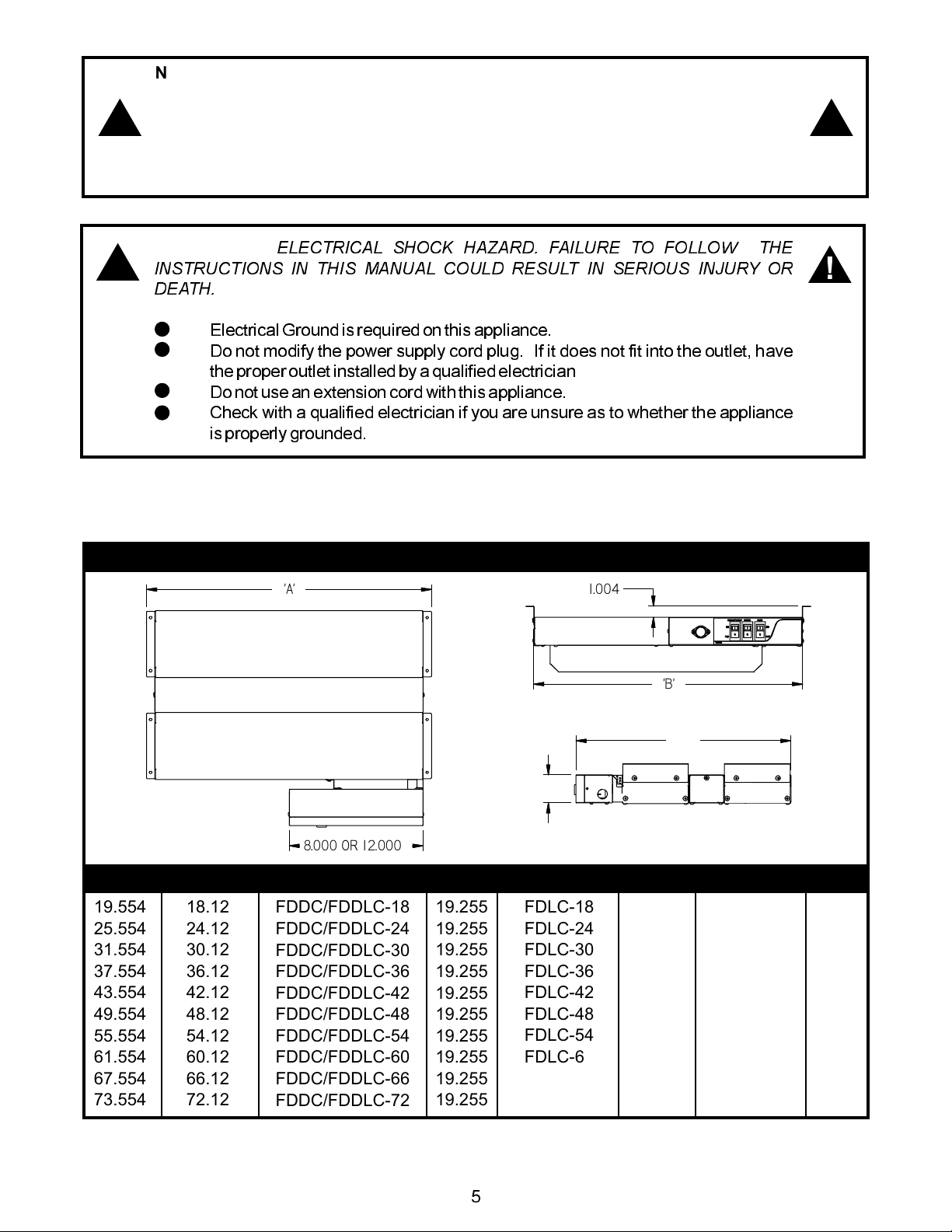

4. OVERALL DIMENSIONS

FDC / FDLC / FDDC / FDDLC MODELS

'A'

1.004

'B'

!

A”

19.554

25.554

31.554

37.554

43.554

49.554

55.554

61.554

67.554

73.554

B”

18.12

24.12

30.12

36.12

42.12

48.12

54.12

60.12

66.12

72.12

O

8.000 R 1 2.000

MODEL

FDDC/FDDLC-18

FDDC/FDDLC-24

FDDC/FDDLC-30

FDDC/FDDLC-36

FDDC/FDDLC-42

FDDC/FDDLC-48

FDDC/FDDLC-54

FDDC/FDDLC-60

FDDC/FDDLC-66

FDDC/FDDLC-72

C”

19.255

19.255

19.255

19.255

19.255

19.255

19.255

19.255

19.255

19.255

2.500

MODEL

FDLC-18

FDLC-24

FDLC-30

FDLC-36

FDLC-42

FDLC-48

FDLC-54

FDLC-60

FDLC-66

FDLC-72

C”

13.255

13.255

13.255

13.255

13.255

13.255

13.255

13.255

13.255

13.255

'C'

2.352

MODEL

FDC-18

FDC-24

FDC-30

FDC-36

FDC-42

FDC-48

FDC-54

FDC-60

FDC-66

FDC-72

C”

10.13

10.13

10.13

10.13

10.13

10.13

10.13

10.13

10.13

10.13

5

Page 6

5. INSTALLATION

A. Alwaysclean equipment thoroughly before first use (See cleaning instructions).

B. Providethe following clearancesaround foodwarmer:

1. Low watt minimum distance to non-combustible surface below: Single = 14, Double = 18.

Highwatt minimum distanceto non-combustiblesurface below: Single =18, Double = 24.

2. Minimumdistanceto non-combustible side (end)walls = 2

3. Minimumdistanceto non-combustible back wall= 2.

4. Minimumdistanceto non-combustible ceiling = 1

5. To avoid damage to overhead or surroundings never mount to combustible ceiling. All

surroundingback, sides and bottom surfaces to be non-combustible.

C. Consult foodwarmer rating label for model designation and correct operating voltage and

amperage.

D. Ceilingmountingbrackets areprovided with each foodwarmer for chain or shelf mounting. Remove

brackets from packaging and screws from ends of foodwarmer to attach brackets. Use four #10

screws or studs with locknuts for shelf mounting. For chain mounting, use #14 jack chain and S

hooks.

E. Remote switches are recommended. Longer switch life will result from cooler switch mounting

locations. Optional stainless steel remote box kits are available. Installation of remote box by

service personnel requires ½ conduit, and no. 14 AWG copper wire suitable for at least 90°C.

Mount remote box to flat surface with two #10 screws or studs with locknuts. All wires marked as

shown on wiring diagram. Whether supplying power to remote or control box remove control box

access plate Ref. exploded view item number 29. Fasten supply wires to terminal block marked t

erminals.To prevent damageto control box componentsre-install access plate item 29 after making

supplyconnections.

F. Optional tubular stands are available for permanently mounting foodwarmers to non-combustible

countertops.

G. Optionalportable legs are available for foodwarmers for use over non-combustible countertops.

6. OPERATION

A. Allfoodservice equipment should be operated by trained personnel.

B. Donot allow your customers to come in contact with any surface labeled CAUTION HOT.

C. Switchon unit. Place precooked product under heat source. Maximum heat coverage equivalent

to unit length.

D. Neverholdfood below 150°F.

WARNING: DO NOT TOUCH CERAMIC ELEMENTS WHILE UNIT IS ON OR

!

COOLING DOWN.

!

7. CLEANING

A. Neverclean any electricalunit by immersingit in water.

B. Neverclean any electricalunit using water jets.

C. Disconnectpowerbefore cleaningor servicing units.

D. Clean unit daily. Use warm, soapy water. Mild cleansers and non-abrasive pads may be used to

removebaked-on food.

8. TROUBLESHOOTING

A. Alwaysask and check:

1. Istheunit connected toa live power source?

2. Checkthecircuit breaker.

3. Ispowerswitch on andlight illuminating?

4. Checktherating label. Is the unitoperating on propervoltage?

B. If the above checks out, and problems still exist, call anAPWWyott authorized service agency.

C. Allserviceshould be performedby anAPW Wyottauthorized serviceagency.

6

Page 7

9. WIRING DIAGRAMS

A.

FDC-120V WIRING DIAGRAM

ELEMENT(S) - SEE ELEMENT CONFIG. CHART A

6

6

FDC-120V

NOTE: WIRE#'S 4, 5, AND 6 - 10GA. 450°C.

WIRE# 1 - 12GA. 105°C .

ALL OTHER - 12GA. 200 OR 250°C.

5

4

FOR REMOTE MODELS

LABEL LEAD WIRES AS SHOWN.

LEADS TO BE 6" FROM HOUSING.

FRONT HEAT-SW

1

4

2

8

A-LN

7

A-L1

5

6

3

2

3

1

GRN

CIR1-LN

CIR1-L1

B.

FDC-208/240V WIRING DIAGRAM

ELEMENT(S) - SEE ELEMENT CONFIG. CHART A

6

6

FDC-208/240V

NOTE: WIRE#'S 4, 5, AND 6 - 10GA. 450°C.

WIRE# 1 - 12GA. 105°C

ALL OTHER - 12GA. 200 OR 250°C.

5

4

FOR REMOTE MODELS

LABEL LEAD WIRES AS SHOWN.

LEADS TO BE 6" FROM HOUSING.

FRONT HEAT-SW

1

4

2

7

A-L1

A-L2

8

5

6

3

2

3

1

GRN

CIR1-L1

CIR1-L2

7

Page 8

C.

FDLC-120V WIRING DIAGRAM

TWO LAMPHOLDERSONE LAMPHOLDER

18,24,30 MODELS 60,66,72 MODELS

36,42,48,54 MODELS

THREE LA MP HOLDERS

FOR REMOTE MODELS

LABEL LEAD WIRES AS SHOWN.

LEADS TO BE 6" FROM HOU SING.

B-L1

D.

13

13

13

13

ELEMENT(S) - SEE ELEMENT CONFIG. CHART A

6

6

5

4

FDLC-120V

NOTE: WIRE#'S 4, 5, AND 6 - 10GA. 450°C.

WIRE# 1 - 12GA. 105°C

ALL OTHER - 12GA. 250°C.

FDLC-208/240V WIRING DIAGRAM

11

12

LIGHT-SW

9

B-LN

10

8

A-LN

7

A-L1

FRONT HEAT-SW

1

4

2

5

3

6

2

3

1

GRN

CIR1-L1

CIR1-LN

TWO LAMPHOLDERSONE L AMPHOLDER

TWO LAMPHOLDERSONE L AMPHOLDER

18,24, 30 MODELS 60,66, 72 MODELS

18,24, 30 MODELS 60,66, 72 MODELS

36,42, 48,54 MODELS

36,42, 48,54 MODELS

13

13

THREE L AMPHOLDERS

THREE L AMPHOLDERS

13

13

ELEMENT(S) - SEE ELEMENT CONFIG. CHART A

7

7

5

6

FDLC-208/240

NOTE: WIRE#'S 5, 6, AND 7 - 10GA. 450°C.

WIRE# 1 - 12GA. 105°C

ALL OTHER - 12GA. 250°C.

FOR REMOTE MODELS

LABEL L EAD WIRES A S SHOWN.

LEADS T O BE 6" FR OM HOUSING.

B-N

B-N

11

B-L1

B-L1

12

8

A-L1

A-L1

9

A-L2

A-L2

LIGHT-SW

FRONT HEAT-SW

FRONT HEAT-SW

1

4

1

4

2

5

2

5

6

6

3

3

10

2

3 4

1

GRN

CIR1-L1

CIR1-N

CIR1-L2

8

Page 9

E.

18,24, 30 MODELS 60,66, 72 MODELS

18,24, 30 MODELS 60,66, 72 MODELS

FDLC-208V w/FUSE WIRING DIAGRAM

TWO LAMPHOLDERSONE L AMPHOLDER

TWO LAMPHOLDERSONE L AMPHOLDER

36,42, 48,54 MODELS

36,42, 48,54 MODELS

THREE L AMPHOLDERS

THREE L AMPHOLDERS

B-N

B-N

FOR REMOTE MODELS

LABEL L EAD WIRES A S SHOWN.

LEADS T O BE 6" FR OM HOUSING.

14

FUSE

F.

13

13

13

13

ELEMENT(S) - SEE ELEMENT CONFIG. CHART A

7

7

5

6

FDLC-208V W/FUSE

NOTE: WIRE#'S 5, 6, AND 7 - 10GA. 450°C.

WIRE# 1 - 12GA. 105°C

ALL OTHER - 12GA. 250°C.

FDDC-120V WIRING DIAGRAM

11

B-L1

12

B-L1

8

A-L1

A-L1

9

A-L2

A-L2

LIGHT-SW

FRONT HEAT-SW

FRONT HEAT-SW

1

4

1

4

2

5

2

5

6

6

3

3

10

2

3 4

1

GRN

CIR1-L1

CIR1-N

CIR1-L2

ELEMENT(S) - SEE ELEMENT CONFIG. CHART A

14

14

ELEMENT(S) - SEE ELEMENT CONFIG. CHART A

14

14

FDDC-120V

NOTE: WIRE#'S 8, 9, 10, 11, AND 14 - 10GA. 450°C

WIRE# 1 - 12 GA. 105°C

ALL OTHER - 12GA. 250°C.

FOR REMOTE MODELS

LABEL LEAD WIRES AS SHOWN.

LEADS TO BE 6" FROM HOUSING.

BACK HEAT-SW

1

9

7

B-L1

13

11

B-L2

4

5

2

6

3

FRONT HEAT-SW

4

8

6

A-L1

12

10

A-L2

1

5

2

6

3

2

3

1

4 5

GRN

CIR1-L1

CIR2-L1

CIR1-LN

CIR2-LN

9

Page 10

G.

FDDC-208/240V WIRING DIAGRAM

ELEMENT(S) - SEE ELEMENT CONFIG. CHART A

10

10

ELEMENT(S) - SEE ELEMENT CONFIG. CHART A

10

10

FDDC-208/240V

NOTE: WIRE#'S 6, 7, 8, 9, AND 10 - 10GA. 450°C

WIRE# 1 - 12GA. 105°C

ALL OTHER - 12GA. 250°C.

FOR REMOTE MODELS

LABEL LEAD WIRES AS SHOWN.

LEADS TO BE 6" FROM HOUSING.

BACK HEAT-SW

1

13

8

9

B-L1

14

B-L2

4

2

5

3

6

FRONT HEAT-SW

1

11

6

7

A-L1

12

A-L2

4

2

5

3

6

2

3

1

4 5

GRN

CIR1-L1

CIR1-L2

CIR2-L1

CIR2-L2

H.

FDDLC-120V WIRING DIAGRAM

ELEMENT(S) - SEE ELEMENT CONFIG. CHART

10

10

TWO LAMPHOLDERSONE LAMPHOL DER

18,24,30 MODELS 60,66,72 MODELS

36,42,48,54 MODELS

19

19

THREE LA MPHOLDERS

19

19

ELEMENT(S) - SEE ELEMENT CONFIG. CHART

10

10

FDDLC-120V

NOTE: WIRE#'S 6, 7, 8, 9, AND 10 - 10GA. 450°C

WIRE# 1 - 12GA. 105°C

ALL OTHER - 12GA. 250°C.

8

9

6

7

13

14

16

15

11

12

B-LN

B-L1

C-L1

A-LN

A-L1

FOR REMOTE MODELS

LABEL LEAD WIRES AS SHOWN.

LEADS TO BE 6" FROM HOU SING.

BACK HEAT-SW

1

4

2

5

3

6

18

LIGHT-SW

FRONT HEAT-SW

1

4

2

5

3

6

1

GRN

17

2

3

4 5

CIR1-L1

CIR2-L1

CIR1-LN

CIR2-LN

10

Page 11

I.

FDDLC-208/240V WIRING DIAGRAM

ELEMENT(S) - SEE ELEMENT CONFIG. CHART

11

11

TWO LAMPHOL DERSONE LAMPHOLDER

18,24,30 MODELS 60,66,72 MODELS

36,42,48,54 MODELS

19

19

THREE LA MPHOLDERS

19

19

9

10

ELEMENT(S) - SEE ELEMENT CONFIG. CHART

11

11

7

8

FDDLC-208/240V

NOTE: WIRE#'S 7, 8, 9, 10, AND 11 - 10GA. 450°C

WIRE# 1 - 12GA. 105°C

ALL OTHER - 12GA. 250°C.

14

15

17

16

12

13

B-L1

B-L2

C-LN

C-L1

A-L1

A-L2

FOR REMOTE MODELS

LABEL LEA D WIRES AS S HOWN.

LEADS TO BE 6" FROM HOUSING.

BACK HEAT-SW

1

4

2

5

6

3

LIGHT-SW

FRONT HEAT-SW

1

4

2

5

3

6

1

GRN

18

2

3

4 5 6

CIR1-L1

CIR2-L1

CIR1-L2

CIR2-L2

CIR2-LN

J.

FDDLC-208/240V w/FUSE WIRING DIAGRAM

ELEMENT(S) - SEE ELEMENT CONFIG. CHART

11

11

TWO LAMPHOLDERSONE LAMPHOLDER

18,24,30 MODELS 60,66,72 MODELS

36,42,48,54 MODELS

19

19

THREE LA MPHOLDERS

19

19

ELEMENT(S) - SEE ELEMENT CONFIG. CHART

11

11

FDDLC-208V W/FUSE

NOTE: WIRE#'S 7, 8, 9, 10, AND 11 - 10GA. 450°C

WIRE# 1 - 12GA. 105°C

ALL OTHER - 12GA. 250°C.

FOR REMOTE MODELS

LABEL LEAD WIRES AS SHOWN.

LEADS TO BE 6" FROM HOUSING.

BACK HEAT-SW

1

4

2

14

9

10

15

B-L1

B-L2

C-LN

17

C-L1

16

20

3

5

6

18

FUSE

LIGHT-SW

FRONT HEAT-SW

1

12

7

8

13

A-L1

A-L2

4

2

5

3

6

2

3

1

4 5 6

GRN

CIR1-L1

CIR2-L1

CIR1-L2

CIR2-L2

CIR2-LN

11

Page 12

K.

CHART “A” - ELEMENT CONFIGURATION

FDC-18

FDDC-18

FDC-24

FDDC-24

FDC-30

FDDC-30

FDC-36

FDDC-36

FDC-42

FDDC-42

FDC-48

FDDC-48

FDC-54

FDDC-54

FDC-60

FDDC-60

FDC-66

FDDC-66

FDC-72

FDDC-72

WATTS

500

700

1000

1400

700

800

1400

1600

850

1150

1700

2300

1000

1350

2000

2700

1200

1500

2400

3000

1500

2000

3000

4000

1500

2200

3000

4400

2000

2700

4000

5400

2000

2700

4000

5400

2000

3000

4000

6000

CONFIGURATIONMODEL

(1F) 500

(1H) 500 + (1H) 200

(2F) 500

(2H) 500 + (2H) 200

(1F) 500 + (1H) 200

(1H) 500 + (2H) 150

(2F) 500 + (2H) 200

(2H) 500 + (4H) 150

(1F) 500 + (1H) 200 + (1H) 150

(2H) 500 + (1H) 150

(2F) 500 + (2H) 200 + (2H) 150

(4H) 500 + (2H) 150

(2F) 500

(2H) 500 + (1H) 200 + (1H) 150

(4F) 500

(4H) 500 + (2H) 200 + (2H) 150

(2F) 500 + (1H) 200

(3F) 500

(4F) 500 + (2H) 200

(6F) 500

(3F) 500

(2F) 500 + (2H) 500

(6F) 500

(4F) 500 + (4H) 500

(3F) 500

(4F) 500 + (1H) 200

(6F) 500

(8F) 500 + (2H) 200

(4F) 500

(2F) 500 + (3H) 500 + (1H) 200

(8F) 500

(4F) 500 + (6H) 500 + (2H) 200

(4F) 500

(4F) 500 + (1H) 500 + (1H) 200

(8F) 500

(8F) 500 + (2H) 500 + (2H) 200

(4F) 500

(4F) 500 + (2H) 500

(8F) 500

(8F) 500 + (4H) 500

MODEL

FDLC-18

FDDLC-18

FDLC-24

FDDLC-24

FDLC-30

FDDLC-30

FDLC-36

FDDLC-36

FDLC-42

FDDLC-42

FDLC-48

FDDLC-48

FDLC-54

FDDLC-54

FDLC-60

FDDLC-60

FDLC-66

FDDLC-66

FDLC-72

FDDLC-72

WATTS

580

780

1080

1480

780

880

1480

1680

930

1230

1780

2380

1160

1510

2160

2860

1360

1680

2560

3160

1660

2160

3160

4160

1660

2360

3160

4560

2240

2940

4240

5640

2240

2940

4240

5640

2240

3240

4240

6240

CONFIGURATION

(1F) 500

(1H) 500 + (1H) 200

(2F) 500

(2H) 500 + (2H) 200

(1F) 500 + (1H) 200

(1H) 500 + (2H) 150

(2F) 500 + (2H) 200

(2H) 500 + (4H) 150

(1F) 500 + (1H) 200 + (1H) 150

(2H) 500 + (1H) 150

(2F) 500 + (2H) 200 + (2H) 150

(4H) 500 + (2H) 150

(2F) 500

(2H) 500 + (1H) 200 + (1H) 150

(4F) 500

(4H) 500 + (2H) 200 + (2H) 150

(2F) 500 + (1H) 200

(3F) 500

(4F) 500 + (2H) 200

(6F) 500

(3F) 500

(2F) 500 + (2H) 500

(6F) 500

(4F) 500 + (4H) 500

(3F) 500

(4F) 500 + (1H) 200

(6F) 500

(8F) 500 + (2H) 200

(4F) 500

(2F) 500 + (3H) 500 + (1H) 200

(8F) 500

(4F) 500 + (6H) 500 + (2H) 200

(4F) 500

(4F) 500 + (1H) 500 + (1H) 200

(8F) 500

(8F) 500 + (2H) 500 + (2H) 200

(4F) 500

(4F) 500 + (2H) 500

(8F) 500

(8F) 500 + (4H) 500

Example: FDDLC-24 1480W has 2 full size 500 watt elements and 2 half size 200 watt elements

12

Page 13

10. PARTS LIST & EXPLODED VIEW

FDC / FDLC / FDDC / FDDLC-18 to 72 EXPLODED VIEW

2

9

3

7

6

8

22

4

34

5

20

33

11

11

12

13

14

17

21

10

16

14

13

12

1

16

19

15

26

28

25

29

35

13

23

24

27

18

30

31

32

Page 14

FDC / FDLC / FDDC / FDDLC-18 to 72 PARTS LIST

ITEM P/N DESCRIPTION QUAN

1

70476835

1

70476836

1

70476837

1

70476838

1

70476839

1

70476840

1

70476841

1

70476842

1

70476843

1

70476844

1

70476845

1

70476846

1

70476847

1

70476848

1

70476849

1

70476850

1

70476851

1

70476852

1

70476853

1

70476854

1

70476855

1

70476856

1

70476857

1

70476858

1

70476859

1

70476860

1

70476861

1

70476862

1

70476863

1

70476864

2

76802

3

76211

3

76212

3

76213

3

76214

3

76215

3

76216

3

76217

3

76218

3

76219

3

76220

4

75917

5

75916

6

46877

7

76159

8

76801

9

76865

10

70400146

10

70400147

11

70402028

V=QTY. VARIES S=SINGLE UNIT OR FDC/FDLC D=DOUBLE UNIT OR FDDC/FDDLC

HOUSING W/ASS'Y FD-18

HOUSING W/ASS'Y FD-24

HOUSING W/ASS'Y FD-30

HOUSING W/ASS'Y FD-36

HOUSING W/ASS'Y FD-42

HOUSING W/ASS'Y FD-48

HOUSING W/ASS'Y FD-54

HOUSING W/ASS'Y FD-60

HOUSING W/ASS'Y FD-66

HOUSING W/ASS'Y FD-72

HOUSING W/ASS'Y FDL-18

HOUSING W/ASS'Y FDL-24

HOUSING W/ASS'Y FDL-30

HOUSING W/ASS'Y FDL-36

HOUSING W/ASS'Y FDL-42

HOUSING W/ASS'Y FDL-48

HOUSING W/ASS'Y FDL-54

HOUSING W/ASS'Y FDL-60

HOUSING W/ASS'Y FDL-66

HOUSING W/ASS'Y FDL-72

HOUSING W/ASS'Y

HOUSING W/ASS'Y

HOUSING W/ASS'Y

HOUSING W/ASS'Y

HOUSING W/ASS'Y

HOUSING W/ASS'Y

HOUSING W/ASS'Y

HOUSING W/ASS'Y

HOUSING W/ASS'Y

HOUSING W/ASS'Y

FDD/FDDL-18

FDD/FDDL-24

FDD/FDDL-30

FDD/FDDL-36

FDD/FDDL-42

FDD/FDDL-48

FDD/FDDL-54

FDD/FDDL-60

FDD/FDDL-66

FDD/FDDL-72

COVER SMALL FD

LIGHT SUPPORT W/A DL-18

LIGHT SUPPORT W/A DL-24

LIGHT SUPPORT W/A DL-30

LIGHT SUPPORT W/A DL-36

LIGHT SUPPORT W/A DL-42

LIGHT SUPPORT W/A DL-48

LIGHT SUPPORT W/A DL-54

LIGHT SUPPORT W/A DL-60

LIGHT SUPPORT W/A DL-66

LIGHT SUPPORT W/A DL-72

LAMPHOLDER TWIN

LAMP 40W COATED

660W/250V

#40A15 120V

NIPPLE, 1/8-27 X 3/4 PLATED

COVER, END DL RH

CONTROL

COVER LARGE FD RH CTRL

COVER LARGE FD LH CTRL

INSULATION

INSULATION

INSULATION

OVRHD WRMR 18-72

OVRHD WRMR 18-72

OVRHD WRMR 18-72

S-1 D-2

ITEM P/N DESCRIPTION QUAN

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

V

V

V

1

1

1

V

V

V

12

13

14

15

16

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

18

19

20

20

20

21

22

22

22

22

22

22

22

22

22

23

23

24

24

24

24

25

26

27

27

76804

70402029

76803

70476803

76955

70400002

70400009

70400014

70400019

70400024

70400029

70400034

70400039

70400044

70400049

70400054

70400057

70400060

70400063

70400066

70400069

70400072

70400075

70400078

70400081

70444800

89184

95100006

94000028

94400003

95000028

70400084

70400149

70401149

70400085

70400150

70401150

70400083

70400148

70401148

70476314

70476316

70421275

70401275

70411275

70412275

70400005

70400006

70401281

70402281

SUPPORT ELEMENT FD

INSULATION 1/2X6X2-1/2

FD18-72

END PLATE FD

PLATE, FDB AND C END

BRACKET MOUNTING FD

REFLECTOR FD-18 LW

REFLECTOR FD-24 LW

REFLECTOR FD-30 LW

REFLECTOR FD-36 LW

REFLECTOR FD-42 LW

REFLECTOR FD-48 LW

REFLECTOR FD-54 LW

REFLECTOR FD-60 LW

REFLECTOR FD-66 LW

REFLECTOR FD-72 LW

REFLECTOR FD-18 HW

REFLECTOR FD-24 HW

REFLECTOR FD-30 HW

REFLECTOR FD-36 HW

REFLECTOR FD-42 HW

REFLECTOR FD-48 HW

REFLECTOR FD-54 HW

REFLECTOR FD-60 HW

REFLECTOR FD-66 HW

REFLECTOR FD-72 HW

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

(CERAMIC OVRHD)

SWITCH, ROCKER ON-OFF

BUSHING, .875 HEYCO 2126

ELEMENT, CERAMIC, 120V, 500W, FTE

ELEMENT, CERAMIC, 208V, 500W, FTE

ELEMENT, CERAMIC, 240V, 500W, FTE

RETAINER, CERAMIC ELEMENT

ELEMENT, CERAMIC, 120V, 200W, HTE

ELEMENT, CERAMIC, 208V, 200W, HTE

ELEMENT, CERAMIC, 240V, 200W, HTE

ELEMENT, CERAMIC, 120V, 150W, HTE

ELEMENT, CERAMIC, 208V, 150W, HTE

ELEMENT, CERAMIC, 240V, 150W, HTE

ELEMENT, CERAMIC, 120V, 500W, HTE

ELEMENT, CERAMIC, 208V, 500W, HTE

ELEMENT, CERAMIC, 240V, 500W, HTE

REMOTE ENCLOSURE,

REMOTE ENCLOSURE,

W/ASS'Y, REMOTE BOX

W/ASS'Y, REMOTE BOX COVER

W/ASS'Y, REMOTE BOX COVER

W/ASS'Y, REMOTE BOX COVER

SINGLE CONTROL 8"

SINGLE CONTROL 12"

COVER 12" W/FUSE

12"

8"

8"

BRACKET, CONTROL BOX

CONDUIT, ALUMINUM

LABEL, FDDLC CONTROL

LABEL, FDDC CONTROL

N/S=NOT SHOWNFTE=Full Size Ceramic Element HTE=Half Size Ceramic Element

S-2 D-4

S-2 D-4

S-1 D-3

1

S-2 D-4

S-1 D-2

S-1 D-2

S-1 D-2

S-1 D-2

S-1 D-2

S-1 D-2

S-1 D-2

S-1 D-2

S-1 D-2

S-1 D-2

S-1 D-2

S-1 D-2

S-1 D-2

S-1 D-2

S-1 D-2

S-1 D-2

S-1 D-2

S-1 D-2

S-1 D-2

S-1 D-2

V

S-1 D-2

CHART A

CHART A

CHART A

V

CHART A

CHART A

CHART A

CHART A

CHART A

CHART A

CHART A

CHART A

CHART A

1

1

1

1

1

1

1

1

1

1

14

Page 15

FDC / FDLC / FDDC / FDDLC-18 to 72 PARTS LIST

(Continued)

ITEM P/N DESCRIPTION QUAN

70403281

27

70404281

27

55102

28

70400007

29

70401007

29

70444700

30

85602

31

85601

32

33

70401011

34

70400011

70402042

35

35

70402043

V=QTY. VARIES S=SINGLE UNIT OR FDC/FDLC D=DOUBLE UNIT OR FDDC/FDDLC

LABEL, FDLC CONTROL

LABEL, FDC CONTROL

LOCKNUT, 1/2 INCH CONDUIT

PLATE, ACCESS

PLATE, 12 INCH ACCES

BLOCK, TERMINAL,

HOLDER, FUSE

FUSE, BUS SC3 AMP

SHIELD, FTE ELEMENT

SHIELD, HTE ELEMENT

INSULATION, 12”

INSULATION, 8”

3-POLE

CONTROL BOX

CONTROL BOX

ITEM P/N DESCRIPTION QUAN

N/S

1

N/S

1

N/S

2

N/S

1

N/S

1

N/S

V

N/S

1

N/S

1

V

N/S

V

N/S

N/S

1

1

46876

88961

89042

88889

88993

89071

89056

89039

88971

89063

88954

NUT HEX 1/8 -27 PLATED

NUT, HEX 10-24, GREEN

SCREW 8-32 X 1/2 PH SL SS

SCREW #8 X 1/2 AB SMS PHL TRUSS

SCREW 10-32X3/8 TRS HD PHL NYLK

WASHER, #10 FLAT

WASHER #8 INTERNAL LOCK, SS

SCREW, 8-32X5/16 PH PAN SS

SCREW, 8-32x1-1/2 SL PN HD SS

NUT, HEX 8-32

SCREW,8-32X3/16,PH,PH,SS

N/S=NOT SHOWNFTE=Full Size Ceramic Element HTE=Half Size Ceramic Element

V

1

2

V

V

V

V

1

4

V

4

Warranty Procedure

IFYOU NEED WARRANTYSERVICE FOR YOURAPW EQUIPMENT, FOLLOWTHESE STEPS:

1. Securethemodel and serialnumber from thedata tagof your unit.

2. Non-portable equipment- The serviceagency will dispatcha technicianto your location for repairs.

3. Portable equipment - If you request service at your location, you will be responsible for payment of

traveland mileage charges. You cantake the unitto the service agency to avoid thesecharges.

4. For the name of the closest authorized service/parts distributor consult the published list supplied

byAPWWyott or calltheAPW Wyott Service Hot Line, 1-800-733-2203

Notes:

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

WarrantyServiceand/or Parts, this information is required.

ModelNumber SerialNumber DatePurchased

15

Page 16

11.APW WYOTT EQUIPMENT LIMITED WARRANTY

APW Wyott Foodservice Equipment Company warrants it's equipment against defects in materials and workmanship, subject to the

following conditions:

This warranty applies to the original owner only and is not assignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this warranty, at the option of

APW Wyott such product will be repaired or replaced by APW Wyott or its Authorized Service Agency. APW Wyott will only be

responsible for charges incurred or service performed by its Authorized Service Agencies. The use of other than APW Wyott

Authorized ServiceAgencies will void this warranty and APW Wyott will not be responsible for such work or any charges associated

with same. The closestAPWWyottAuthorized Service Agent must be used.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, metropolitan areas of Alaska and Canada. There

will be no labor coverage for equipment located on any island notconnected by roadway to the mainland.

Warranty coverage on products used outside the 48 contiguous United States, Hawaii, and metropolitan areas of Alaska and Canada

may vary.ContacttheinternationalAPWWyottdistributor,dealer, or service agency for details.

TimePeriod

One year for parts and one year for labor, effective from the date of purchase by the original owner. The Authorized Service Agency

may, at their option, require proof of purchase. Parts replaced under this warranty are warranted for the un-expired portion of the

original product warranty only.

Exceptions

Inall cases, parts covered by extended warranty will be shipped FOB the factory after the first year.

Portable Carry In Products

Equipment weighing over 70 pounds or permanently installed will be serviced on-site as per the terms of this warranty. Equipment

weighing 70 pounds or under, and which is not permanently installed, i.e. with cord and plug, is considered portable and is subject to

the following warranty handling limitations. If portable equipment fails to operate in its intended manner on the first day of

connection, or use, atAPWWyott'soptionoritsAuthorizedServiceAgency, it will be serviced on site or replaced.

From day two through the conclusion of this warranty period, portable units must be taken to or sent prepaid to the APW Wyott

Authorized Service Agency for in-warranty repairs. No mileage or travel charges are allowed on portable units after the first day of use.

If the customer wants on-site service, they may receive same by paying the travel and mileage charges. Exceptions to this rule: (1)

countertop warmers and cookers, which are covered under the Enhanced WarrantyProgram, and (2) toasters or rollergrills which have

instore service.

Exclusions

The following conditions arenot covered by warranty:

If the equipment has been changed, altered, modified or repaired by other than an Authorized Service Agency during or after the

warranty period, then the manufacturer shall not be liable for any damages to any person or to any property, which may result from the

use of the equipment thereafter.

This warranty does not cover services performed at overtime or premium labor rates. Should service be required at times which

normally involve overtime or premium labor rates, the owner shall be charged for the difference between normal service rates and such

premium rates.APWWyottdoesnotassumeanyliability for extended delays in replacing or repairing any items beyond its control.

Inall cases, the use of other than APW WyottAuthorized OEM Replacement Parts will void this warranty.

This equipment is intended forcommercial use only.Warranty isvoid if equipment is installed inother than commercial application.

WaterQualityRequirements

Water supply intended for a unit that has in excess of 3.0 grains of hardness per gallon (GPG) must be treated or softened before

being used. Water containing over 3.0 GPG will decrease the efficiency and reduce the operation life of the unit.

Note: Product failure caused by liming or sediment buildup is not covered under warranty.

THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES

AND CONSTITUTES THE ENTIRE LIABILITY OF APW WYOTT. IN NO EVENT DOES THE LIMITED WARRANTY

EXTEND BEYOND THE TERMS STATED HEREIN.

*Gas/Electric Cookline:

component parts, except switches and thermostats. (2 additional years on parts only. No labor on second or third year.)

*BroilerBriquettes,

*Heat Strips:

*GlassWindows, Doors, Seals, Rubber Seals, Light Bulbs:

*Equipment failure relating to improper installation, improper utility connection or supply and problems due to

ventilation.

*Equipment that has not been properly maintained, calibration of controls, adjustments, damage from improper cleaning

and water damage to controls.

*Equipment that has not been used in an appropriate manner, or has been subject to misuse or misapplication, neglect,

abuse, accident, alteration, negligence, damage during transit, delivery or installation, fire, flood, riot or act of god.

*Equipment that has the model number or serial number removed or altered.

Models FD, FDL, FDD, FDDL. Two(2)YearWarranty onelement only. No labor second year.

Models GCB, GCRB, GF, GGM, GGT, CHP-H, EF, EG, EHP. Three (3) Year Warranty on all

RockGrates,CookingGrates,BurnerShields,Fireboxes:

90Day Material Only. No Labor.

90DayMaterialOnly.NoLabor.

9/05

16

Loading...

Loading...