Page 1

R

INSTALLATION

AND

OPERATING

INSTRUCTIONS

DROP-IN RACK DISPENSERS

Models:

DI-1014

DI-1020

DI-1418

DI-1216

DI-1620

DI-1622

DI-2020

RETAIN THIS MANUAL FOR FUTURE REFERENCE

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

WarrantyServiceand/or Parts,this informationis required.

ModelNumber SerialNumber DatePurchased

This equipment has been engineered to provide you with year-round dependable service when used

according to the instructionsin this manual and standard commercial kitchen practices.

P/N 88595/88632 9/05

Phone: +1

Fax: +1 (307) 637-8071

Toll Free: +1 (800) 752-0863

Website: www.apwwyott.com

E-mail: info@apwwyott.com

(307) 634-5801

APW WYOTT

P.O. Box 1829

Cheyenne, WY 82003

1

Page 2

Removalof Cables

A. Turnunit upside downon flat surface.

B. With a box end or hex socket wrench,loosen the two hex head boltsto relax the strap clamps

holding the power shaft. The power shaft will turn about one revolution when free of the

clamps-keep one hand on the power shaft while loosening the clamps so it will not spin

suddenlyand cause to "spill" offfrom the power drums.

C. With the aid of another person, unwind the cables from the power drums by pulling the

cables up evenly (allowing the power shaft to turn) until the cables are completely off the

drums. Do not allow the cables to "spill" off the power drums, as this puts an undesirable

twistin the cables.

D. Witha Phillips head screwdriver, remove screw Aand screw B from the power drum and put

in a safe place.Do on otherside.

E. With a box end or hex socket wrench, loosen (do not take apart) the carrier pulleys and tape

lockwashers on each side.

F. With needle nose pliers, pull out the ends of the cable, found in the centerof the power drum,

about 6" towards you. In back of the two cable ends, find the power drum key. With the

needle nose pliers, work the key up and out. Remove the cable through the hole the key

came out of. Remove the cable from the carrier pulleys and tape lock washers; discard

cable.Re peat on the other side.

InstallingNew Cables

GENERAL INFORMATION

A. Center 11 ft. cable between two bottom lock washers. Thread through lock washers and

through the guides just above. Bring cable towards the center of the unit, threading between

carrier pulley and carrier cable retainer.Tightenhex lock nut on carrier pulley as the retainer

is up against themetal flangeas far as it can go. Repeat on the other side.

B. Position the power shaft with the hole straight up and with the arrow pointing in the direction

of the limit cable. Align the hole on the power drum with the hole on the power shaft, showing

headsof screws towards you.

C. Place ends of the cable in the hole and pull on the ends with a pair of needle nose pliers,

bringing the ends out about 6". Do not twist the cables; make sure the right cable is on the

rightside and the left cableis on theleft side.

D. Take the power drum key and place in the hole in back of the cables. With a 1/4" punch

(screwdriverwill do) and a hammer,drive the key down into place making sure it has entered

throughboth holes.

E. Pull cables up as far as they will go, and replace screw Ain between the right and left cables.

Pull the cables inthe direction of the arrow and replace screw B over the cables.

F. Repeatsteps B through E on the otherside.

G. Hold the cables up, to hold them taut. There will be two loops on each side-use your thumb

andindex finger to support the loops on each side.

H. Have another person wind up the power shaft in the direction of the arrow stamped on the

powershaft, untilall of thecable is woundback into the power drums.

I. Once the cable is wound tight, continue to turn the power shaft an additional 3/4 to one turn

(for head load required to support the weight of the mechanism), and tighten the clamp bolt

to prevent the tube from turning.

J. Alignthe groove on the tape lock washers with the cable. Tightendown the tape lock washer

to prevent slippageof the cable in future use.

K. Place the unit back in the counter and depress the platform fully several times to allow the

cablesto attaintheir natural position on the power drums.

L. If the platform is level, the cable replacement is complete. If the platform is uneven, loosen

the four tape lock washers and allow the cables to shift into a balanced tension. To help

attain the condition, grip both power drums and apply torque in the direction of rotation that

will put additional tension on the cables. Tighten the four tape lockwashers and re-install the

unitin the counter.

2

Page 3

Adjustingthe Unit

A. Turnunit upside downon a flat surface.

B. Witha socket or box end wrench, loosen thetwo hex headbolts

to relax the strap clamps holding the power shaft. The power shaft will turn about one

revolution when free of the clamps keep one hand on the power shaft while loosening the

clampsso it will not spinsuddenly and cause the cableto "spill" offfrom thepower drums.

C. With the aid of another person, unwind the cables from the power drums by pulling the

cables up evenly (allowing the power shaft to turn) until the cables are completely off the

drums. Do not allow the cables to "spill" off the power drums, as this puts an undesirable

twistin the cables.

D. Removethe eight screws from each power drum. If the load rate is to be increased, re-install

the screws into a smaller circle of holes. If the load is to be decreased, re-install the screws

into the larger circle of holes. Be certain that the same circle of holes is used on both of the

power drums. Be certain that the cable emerges between the same relative screw locations

onboth power drums.

E. Loosenthe cable clamp hex nutsat the four corners underthe flange.

F. Hold the cables up to hold them taut. There will be two loops on each side-use your thumb

andindex finger to support the loops on each side.

G. Have another person wind up the torque tube in the direction of the arrow stamped on the

powershaft, untilall of thecable is woundback into the power drums.

H. Once the cable is wound tight, continue to turn the power shaft an additional 3/4 to one turn

(for head load required to support the weight of the mechanism), and tighten the clamp bolts

to prevent the tube from turning.

I. Tighten-the cableclamp hex nuts at thefour corners under the flange.

J. Place the unit back in the counter and depress the platform fully several times to allow the

cablesto attaintheir natural position on the power drums.

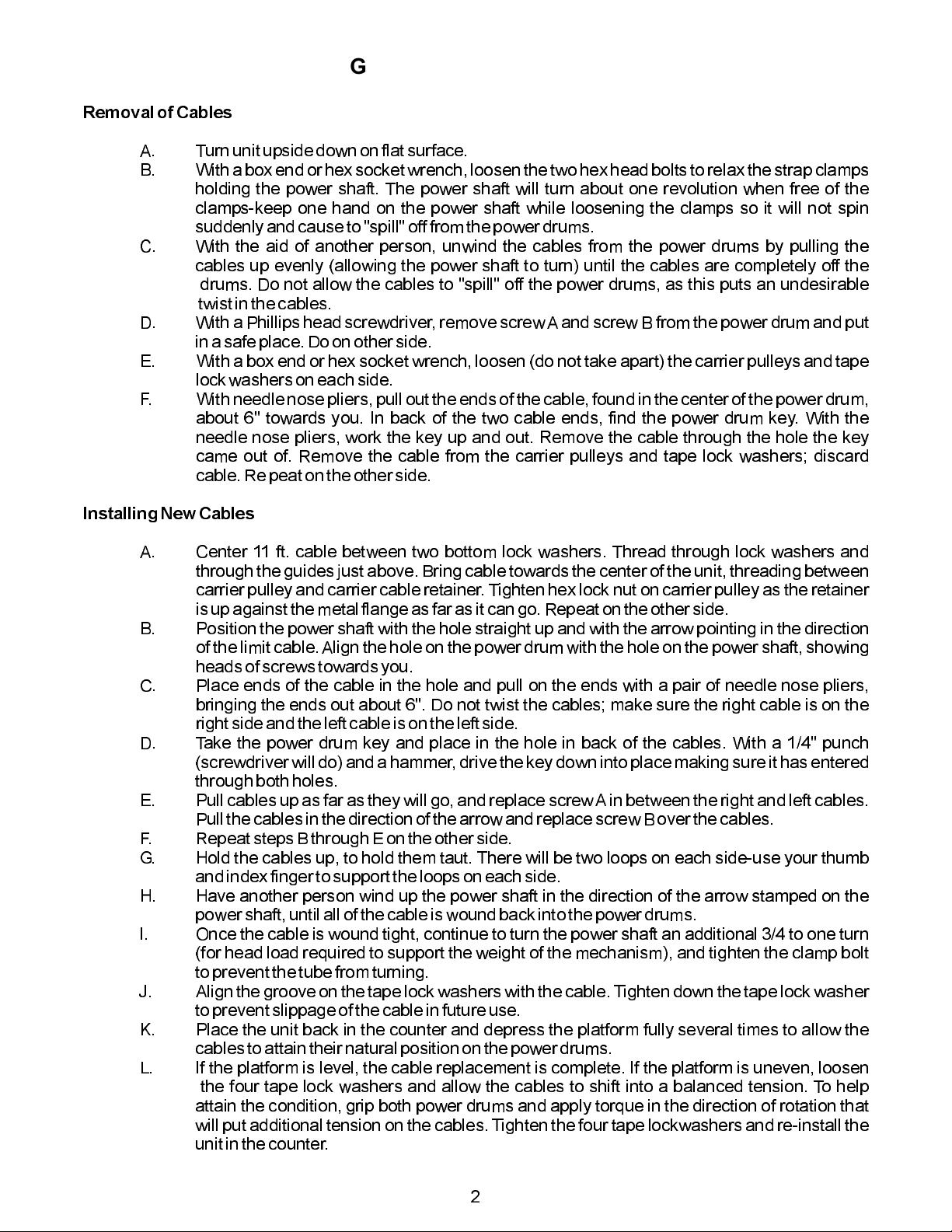

Materials Furnished

2 - (Two) Replacement Cables

2 - (Two) Power Drum Keys

Tools Needed

Needle Nose Pliers

Hammer

1/4: Punch (Screwdriver will do)

Phillips Head No.3 Screwdriver

Box End or Hex Socket Wrenches

CABLE REPLACEMENT KIT

Tape Lockwasher

(Cable Clamp)

Power Shaft

Carrier Pulley

Retainer

Limit

Cable

Shaft

Clamp

Flange

Weldment

Cable

Carrier

Weldment

Carrier

Pulley

Power

Drum

Screw “A”

Screw “B”

3

Page 4

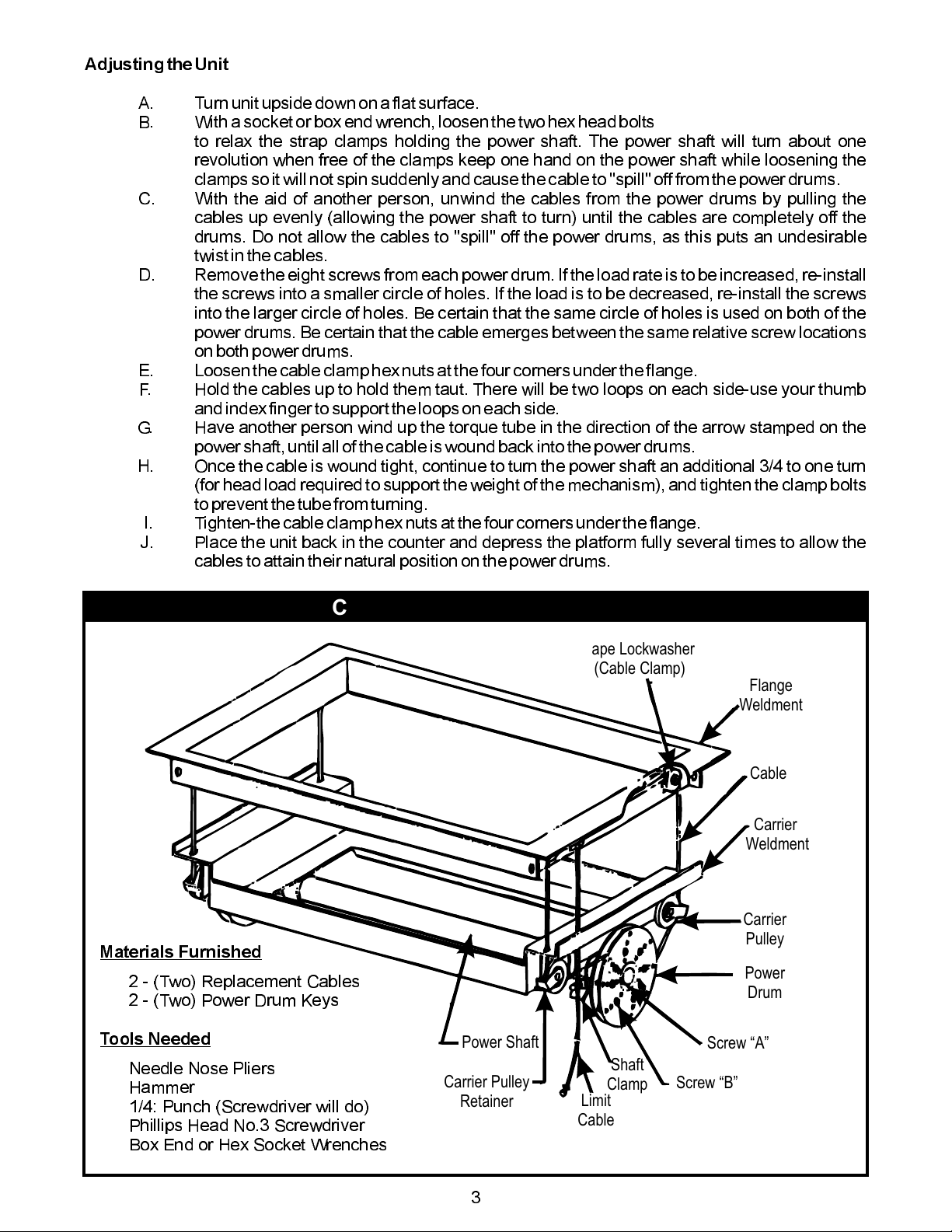

PARTS LIST & EXPLODED VIEW

57 SERIES IN-COUNTER DROP-IN LOWERATOR

9

1

2

3

4

5

8

7

ITEM DESCRIPTION DI-1014 DI-1020 DI-1418 DI-1620 DI-1622 DI-2020 DI-1216

1 Flange Weldment 202152 202151 202150 202149 202148 202147 21103600

2 Cable 30175 30175 30175 30175 30175 30175 30175

3 Carrier Weldment 202137 202136 202135 202133 202134 202132 21103200

4 Carrier Pulley 86020 86020 86020 86020 86020 86020 86020

5 Power Drum L.H. 202356 202356 202356 202356 202356 202356 20299700

Power Drum

6 Tube Clamp 202145 202145 202145 202145 202145 202145 202145

7 Cable Retainer 202357 202357 202357 202357 202357 202357 202357

8 Power Shaft 202168 202164 202165 202164 202166 202164 21103900

9 Tape Lock Washer 206535 206535 206535 206535 206535 206535 206535

*10 Limit Cable 30177 30177 30177 30177 30177 30177 30177

*11 Cable Repl. Kit 206853 206853 206853 206853 206853 206853 206853

*12 Power Drum Key 202358 202358 202358 202358 202358 202358 20299500

*13 Pulley Bushing 89666 89666 89666 89666 89666 89666 89666

*14 Cable Guide 86028 86028 86028 86028 86028 86028 86028

*15 Limit Cable Bushing 86029 86029 86029 86029 86029 86029 86029

*NOT SHOWN

R.H. 202355 202355 202355 202355 202355 202355 20299700

6

4

Page 5

NOTES:

5

Page 6

NOTES:

6

Page 7

APW WYOTT EQUIPMENT LIMITED WARRANTY

APW Wyott Foodservice Equipment Company warrants it's equipment against defects in materials and workmanship, subject to the

following conditions:

This warranty applies to the original owner only and isnotassignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this warranty, at the option of

APW Wyott such product will be repaired or replaced by APW Wyott or its Authorized Service Agency. APW Wyott will only be

responsible for charges incurred or service performed by its Authorized Service Agencies. The use of other than APW Wyott

Authorized Service Agencies will void this warranty and APW Wyottwill not be responsible for such work or any charges associated

with same. The closestAPWWyottAuthorized ServiceAgent must be used.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, metropolitan areas ofAlaska and Canada. There

will be no labor coverage for equipment located on any island not connected by roadway to the mainland.

Warranty coverage on products used outside the 48 contiguous United States, Hawaii, and metropolitan areas of Alaska and Canada

may vary.ContacttheinternationalAPWWyott distributor, dealer, or service agency for details.

TimePeriod

One year for parts and one year for labor, effective from the date of purchase by the original owner. The Authorized Service Agency

may, at their option, require proof of purchase. Parts replaced under this warranty are warranted for the un-expired portion of the

original product warranty only.

Exceptions

Inallcases, parts covered by extended warranty will beshipped FOB the factory after the first year.

Portable Carry In Products

Equipment weighing over 70 pounds or permanently installed will be serviced on-site as per the terms of this warranty. Equipment

weighing 70 pounds or under, and which is not permanently installed, i.e. with cord and plug, is considered portable and is subject to

the following warranty handling limitations. If portable equipment fails to operate in its intended manner on the first day of

connection, or use, atAPWWyott's option or its Authorized Service Agency,itwillbeservicedonsiteorreplaced.

From day two through the conclusion of this warranty period, portable units must be taken to or sent prepaid to the APW Wyott

Authorized ServiceAgency for in-warranty repairs. No mileage ortravel charges are allowed on portable units after the first day of use.

If the customer wants on-site service, they may receive same by paying the travel and mileage charges. Exceptions to this rule: (1)

countertop warmers and cookers, which are covered under the Enhanced WarrantyProgram, and (2) toasters or rollergrills which have

instore service.

Exclusions

The following conditions are not covered by warranty:

If the equipment has been changed, altered, modified or repaired by other than an Authorized Service Agency during or after the

warranty period, then the manufacturer shall not be liable for any damages to any person or to any property, which may result from the

use oftheequipment thereafter.

This warranty does not cover services performed at overtime or premium labor rates. Should service be required at times which

normally involve overtime or premium labor rates, the owner shall be charged for the difference between normal service rates and such

premium rates.APWWyott does not assume anyliability for extended delays in replacing or repairing any items beyond its control.

Inallcases, the use of other thanAPWWyottAuthorized OEM Replacement Parts willvoid this warranty.

This equipment is intended for commercial use only.Warranty is void if equipment is installed in other than commercial application.

WaterQualityRequirements

Water supply intended for a unit that has in excess of 3.0 grains of hardness per gallon (GPG) must be treated or softened before

being used. Water containing over 3.0 GPG will decrease the efficiency and reduce the operation life of the unit.

Note: Product failure caused by liming or sediment buildup is not covered under warranty.

THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES

AND CONSTITUTES THE ENTIRE LIABILITY OFAPW WYOTT. IN NO EVENT DOES THE LIMITED WARRANTY

EXTEND BEYOND THE TERMS STATEDHEREIN.

*Gas/Electric Cookline:

component parts, except switches and thermostats. (2 additional years on parts only. No labor on second or third year.)

*BroilerBriquettes,

*Heat Strips:

*GlassWindows, Doors, Seals, Rubber Seals, Light Bulbs:

*Equipment failure relating to improper installation, improper utility connection or supply and problems due to

ventilation.

*Equipment that has not been properly maintained, calibration of controls, adjustments, damage from improper cleaning

and water damage to controls.

*Equipment that has not been used in an appropriate manner, or has been subject to misuse or misapplication, neglect,

abuse, accident, alteration, negligence, damage during transit, delivery or installation, fire, flood, riot or act of god.

*Equipment that has the model number or serial number removed or altered.

Models FD, FDL, FDD, FDDL. Two (2)Year Warrantyonelementonly. Nolaborsecondyear.

Models GCB, GCRB, GF, GGM, GGT, CHP-H, EF, EG, EHP. Three (3) Year Warranty on all

RockGrates,CookingGrates,BurnerShields,Fireboxes:

90Day Material Only. No Labor.

90DayMaterialOnly.No Labor.

9/05

7

Page 8

R

Phone: +1

(307) 634-5801

Fax: +1 (307) 637-8071

Toll Free: +1 (800) 752-0863

Website: www.apwwyott.com

E-mail: info@apwwyott.com

APW WYOTT

P.O. Box 1829

Cheyenne, WY 82003

8

Loading...

Loading...