APW Wyott CHDT-3, CHDT-4, CHDT-6 General Manual

729 Third Avenue

Dallas, TX 75226

R

LISTED

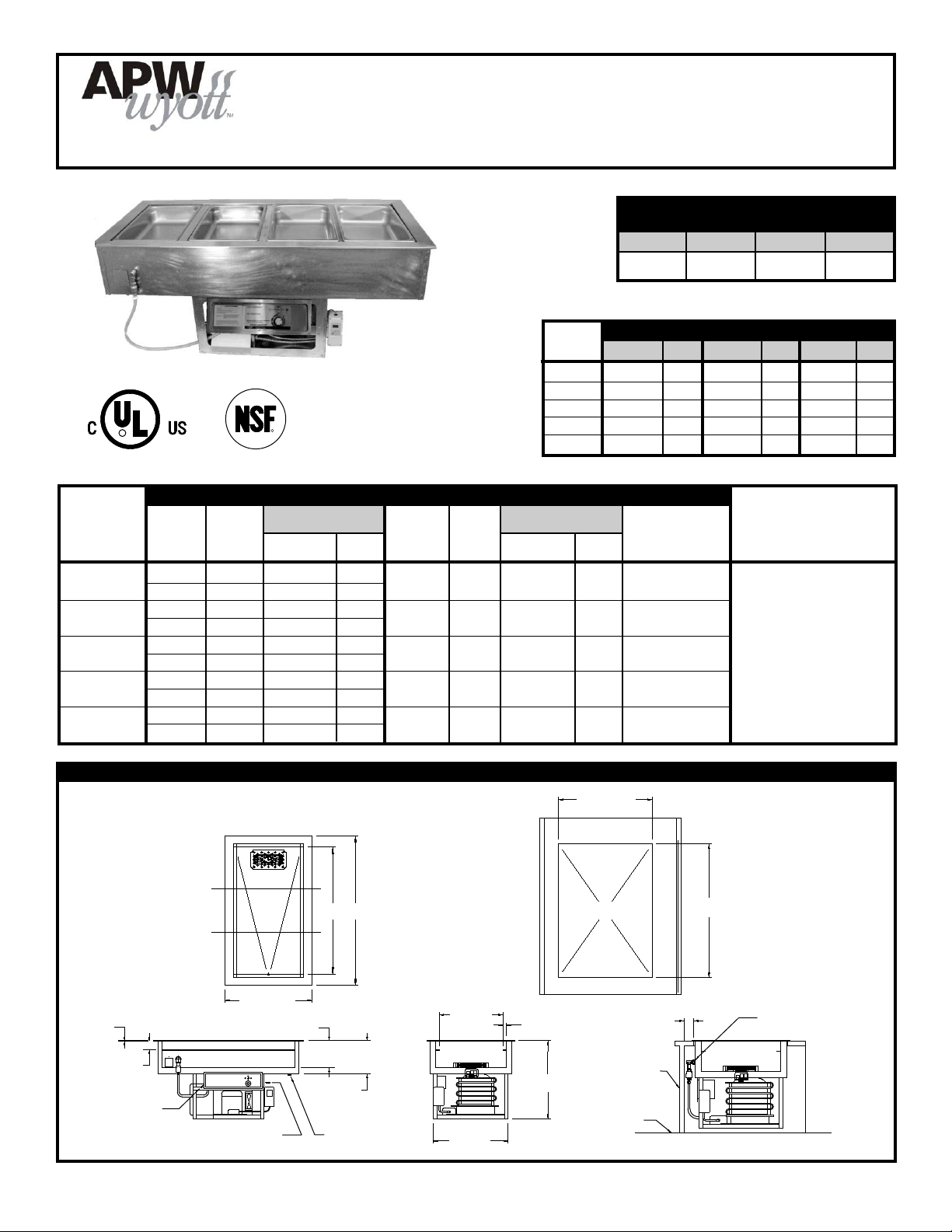

MODEL

CHDT-2

CHDT-3

CHDT-4

CHDT-5

CHDT-6

VOLTS

208

240

208

240

208

240

208

240

208

240

Phone:(214) 421-7366

Fax: (214) 565-0976

Toll Free:(800) 527-2100

Website: www.apwwyott.com

E-mail:info@apwwyott.com

(Model CHDT-4 Shown)

MEETS NSF STANDARD 7

PERFORMANCE REQUIREMENTS

AT 3" PAN RAIL DEPTH

R

STD. 7

WARMER REFRIGERATION

KW

1.9

2.5

3.0

4.0

3.8

5.0

6.0

8.0

6.0

8.0

AMPS (1 PHASE)

L1 - L2

9.0

10.4

14.4

16.7

18.1

20.8

28.9

33.3

28.9

33.3

N

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

VOLTS

120

120

120

120

120

ELECTRICAL

HP

1/4

1/3

1/2

3/4

3/4

INSTALLATION INSTRUCTIONS

TEMPERATURE WELL

Model Numbers: CHDT-2, -3, -4, -5 & -6

MODEL

CHDT-2

CHDT-3

CHDT-4

CHDT-5

CHDT-6

AMPS (1 PHASE)

L2 - N

5.5

7.0

7.5

15.3

15.3

L1

N/A

N/A

N/A

N/A

N/A

COLD HOT DUAL

MINIMUM CLEARANCE REQUIRED FROM

UNIT TO THE NEAREST SURFACE

Back

0” (0 mm)

A B C (CUTOUT)

INCHES MM INCHES MM INCHES MM

32 3/4

46

i1/2

60 1/4

74

87 3/4

REFRIGERANT

TYPE

R-134-A

R-404-A

R-404-A

R-404-A

R-404-A

Side

0” (0 mm)

DIMENSIONS

832

251/2

1181

1530

1880

2229

39 1/4

53

66 3/4

801/2

Bottom

N/A

648

i

997

1346

1695

2045

i

3” (76 mm)

311/2

i

45 1/4

59

72 3/4

861/2

i

Front

SINGLE PHASE SUPPLY

3 WIRE 120/208-240V

L1-L2 208-240V

L2-N 120VAC 60 HZ

ALL MODELS

PERMANENTLY

CONNECTED

800

1149

1499

1848

2197

5/16 (8)

3 (76)

1/4"NPT Water

Line Connection

1 1/8" Dia. Conduit K.O.

Terminal Block Connection

27 1/8 (689)

8 5/8 (219)

BA

10 3/8 (264)

1" NPT

Drain

MODEL CHDT-3 SHOWN

Top View

19 (505)

23 (584)

1 (25)

24 3/8 (620)

1

25 7/8 (657)

CUTOUT

3 (76) Minimum

Front Access

Required For

Floor

Level

C

Final Plumbing Assembly

Follow Instructions On Page 2.

Controls

Cross Section - Side View

P/N 79900404 1/08

INSTALLATION INSTRUCTIONS: COLD HOT DUAL TEMPERATURE WELL (Models CHDT-2 Thru CHDT-6)

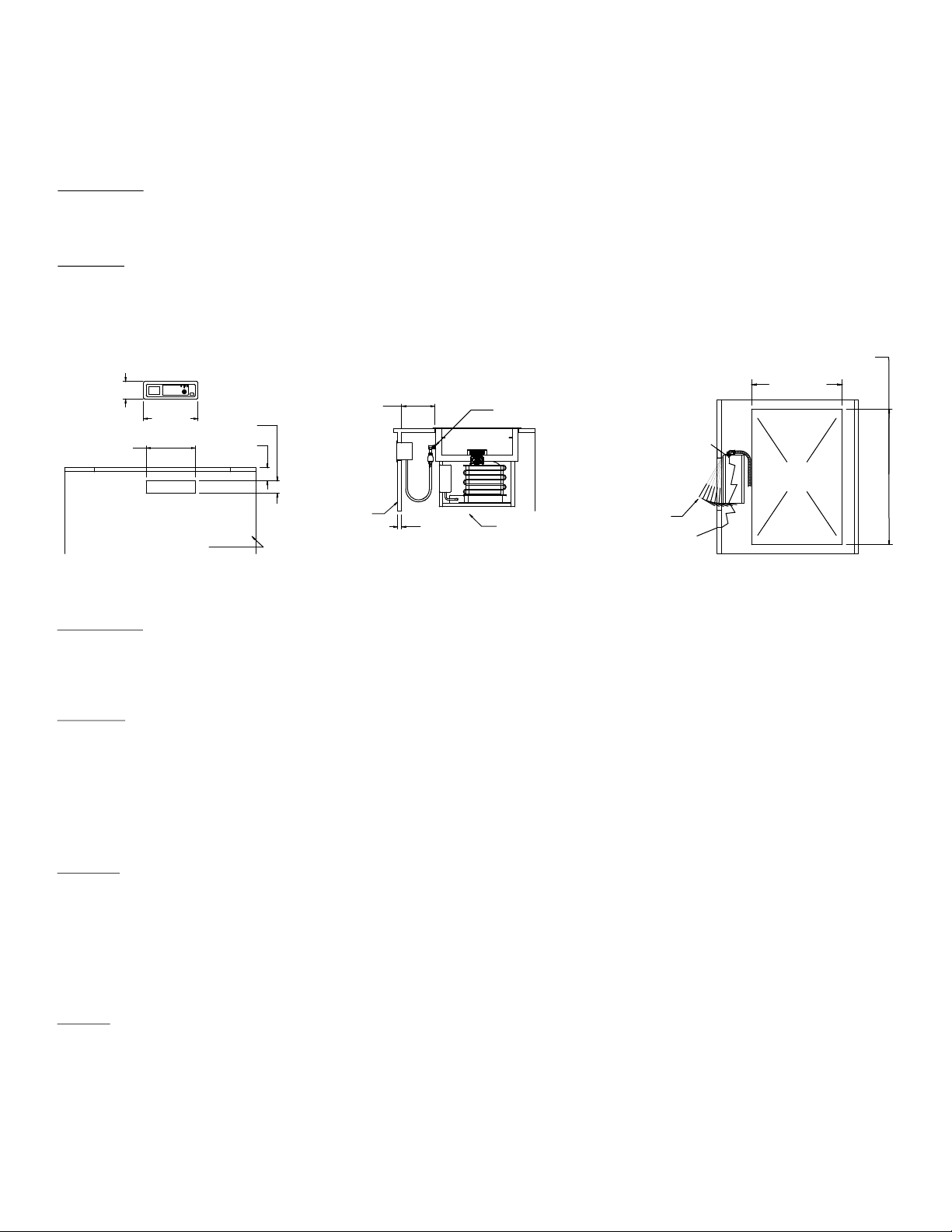

INSTALLER MUST MEET CONDITIONS OF ACCEPTABILITY OUTLINED BELOW UPON INSTALLATION:

1.This unit may be installed in stainless steel, wood, Formica, or Corian tables and countertops.

2. This unit requires drain connection. It also requires a 120/208-240 volt single phase power supply connection.

3. When installing the unit it is essential to provide front access for service and temperature adjustment. It should have openings to allow for proper air circulation.

Opening shall be at least twice the surface area of the condenser. Improper ventilation will cause compressor burnout and void the warranty.

TO FABRICATE :

1. Lay out 'cutout' dimensions on countertop or table.

2. Cut out hole. Make certain countertop is flat and level side to side and front to back before installing the unit.

3.Provide support from below to reduce load on countertop. For remote control panel mounting see below.

TO INSTALL:

1.Apply a generous bead of silicone sealant to underside of mounting flange before setting unit into cutout. Remove excess sealant from top flange and

countertop.

2. Remove thermostat knob and recessed control panel from control box for access to terminal block.

FOR PLUMBING AND WIRING PLEASE REFER TO THE BOTTOM OF THIS PAGE

Control Panel

6 1/4 (159)

18 (457)

17 (441)

FRONT VIEW

Provide Service Access

Below Control Panel

5 (127)

3 (67) Min.

9 (229) Min.

Provide Service

Access Panel

Below Control

Panel

Water Fill

Plumbing Assembly.

Follow Instructions

Below.

1 (25) Max.

Cross Section - Side View

Floor Level

Illustration Of

Electrical Box

Positioning And

Angle Of

Rotation

In Routing

Thru

Cutout

Top View

C (See Page 1)

25 7/8 (657)

CUTOUT

REMOTE CONTROL PANEL INSTALLATION INSTRUCTIONS

TO FABRICATE :

1. Lay out "cutout" dimensions on countertop or table.

2. Lay out control panel cutout in the front apron. Note: Control panel assembly is provided with extra length of flexible conduit and electric wiring. This option

allows for installation of the controls outside the enclosure for easy access. Provide louvered grills service access and temperature adjustment to the

refrigeration system.

TO INSTALL :

1. Apply a generous bead of silicone sealant to underside of mounting flange before setting unit into cutout.

2. Lower the unit into the counter cutout. Wipe clean excess sealant.

3. Remove thermostat knob and recessed control panel from control box.

4. Remove control box assembly from framework. Release wiring conduit from wire ties and retainers.

5.Install control box (Refer to Top View) by routing it thru the cutout.

6. Fasten control box by using six (6) screws provided.

PLUMBING AND WIRING INSTRUCTIONS

TO PLUMB :

Note: Plumbing connections must be completed after the unit is lowered onto the counter cutout. The water fill hose with check valve assembly is shipped

TO WIRE :

Note : MAKE CERTAIN POWER SUPPLY LINE IS DE-ENERGIZED BEFORE WIRING APPLIANCE.

disconnected from the tank for ease of setting unit into the cutout at installation.

1. Apply pipe sealant to the water fill tank fitting and attach the pre-assembled check valve assembly.

2. Attach water fill hose to hose fitting with hose clamp.

3. Connect 1/4NPT water supply and shut off valve to solenoid valve in control box. Note: Maximum pressure 120 psi. Maximim temperature 120°F.

4. A drain valve is supplied with the unit. It is the discretion of the installer to locate the position of the handle. Connect 1 inch drain to drain pan or floor drain. Valve

access must be provided for draining pan.

Unit operates on 120/208-240 volt single phase system. Use #8AWG minimum 60°C supply leads only. Make certain that 'L1 to L2' reads 208 to 240 VAC and 'L2 to N'

reads 120 VAC. Bring supply leads through 1 1/8" conduit K.O. to terminal block pre-installed in the electrical box.

Install control panel and control knob.

Note: INSTALLATION MUST MEET LOCAL PLUMBING AND ELECTRICAL CODES

A backflow preventer check valve is incorporated in unit between water fill solenoid and pan. Local codes may require additional vacuum break device.

2

Loading...

Loading...