Page 1

R

INSTALLATION AND OPERATING INSTRUCTIONS

COUNTER DECK OVEN

MODEL:

24 Hour Toll Free

Service Hot Line:

CDO-17

1-800-733-2203

WARNING:

property damage, injury or death. Read the installation, operating and maintenance instructions

!

thoroughlybeforeinstallingor servicing this equipment.

Improper installation, adjustment, alteration, service or maintenance can cause

!

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

WarrantyServiceand/or Parts,this information is required.

ModelNumber SerialNumber DatePurchased

P/N 88379-44 9-05

APW WYOTT Foodservice Equipment Company

P.O. Box 1829

Cheyenne, WY 82003

+1(307) 634-5801 Phone +1(800) 752-0863 TollFree

+1(307) 637-8071 Fax www.apwwyott.com

1

Page 2

GENERAL INFORMATION

THIS MANUAL SHOULD BE RETAINED FOR FUTURE REFERENCE

CAUTION:

trained and familiar with their proper use should operate them. They are not meant for operation by

!

thegeneral public under anycircumstances.

WARNING:

!

andfrequencylisted on thedata plate. Connect only to 1 or 3 phaseas listed on the data plate.

WARNING:

!

nationalelectricalcode and/or other localelectricalcodes.

WARNING:

!

powerplug, indicating that you are working on the circuit.

WARNING:

strongly recommend having a competent professional install the equipment.A licensed electrician

should make the electrical connections and connect power to the unit. Local codes should always

!

be used when connecting these units to electrical power. In the absence of local codes, use the

latestversionof the NationalElectricalCode.

WARNING:

property damage, injury or death. Read the installation, operating and maintenance instructions

!

thoroughlybeforeinstallingor servicing this equipment.

Maintenance & repair should be handled by a factory authorized agent. Before doing any maintenance or

repair, contactAPWWyottTechnicalService Departmentat (800) 752-0863 or (307) 634-5801.

These models are designed, built, and sold for commercial use only. Only persons

!

Checkthe data plateon this unit before installation.Connectthe unit only to the voltage

!

Electrical and grounding connections must comply with the applicable portions of the

!

Disconnect device from electrical power supply and place a Tag Out-Lockout on the

!

Installper the spacing requirements listed in the installationsection of this manual. We

!

Improper installation, adjustment, alteration, service or maintenance can cause

!

MAINTENANCE

WARNING:

!

surface.

Oncea week, or more often if necessary,cleanthe unit thoroughly.Turnoff the unit and allow it to cool.

STAINLESS STEEL:

water (with or without detergent) applied with a sponge or cloth. Dry thoroughly with a clean cloth. Never

usevinegar or corrosivecleaner.Do not use chlorine basedcleaners.

To remove grease and food splatter or condensed vapors that have baked on the equipment, apply

cleanersto a damp cloth or sponge and rub cleanser on the metal in the direction of the polished lines on the

metal. Rubbing cleanser as gently as possible in the direction of the polished lines will not mar the finish of

the stainless steel. NEVER RUB WITH A CIRCULAR MOTION. Soil and burnt deposits which do not

respond to the above procedure can usually be removed by rubbing the surface with SCOTCH-BRITE

scouringpads or STAINLESSscouringPads.

CAUTION:

!

NEVER USE

tools. Surfaces which are marred collect dirt more rapidly and become more difficult to clean. Marring also

increasesthe possibility of corrosive attack.

Never clean any electrical unit by immersing it in water. Turn off before cleaning

!

To remove normal dirt or product residue from stainless steel, use ordinary soap and

Donot use ordinarysteel wool as any particles left on the surface will rust.

a wire brush, steel or abrasive scouring pads (except stainless), scraper, file or other steel

!

NEVER

NEVER

!

useany corrosive cleaner.Use only cleanersapproved for stainless steel.

usecleaning solventswith a hydrocarbonbase.

WARNING: -

equipment.

SHOCK HAZARD

De-energize all power to equipment before cleaning the

2

!

Page 3

Congratulations on your purchase of APW Wyott Foodservice cooking or refrigeration equipment.

Wyott Foodservice takes pride in the design and quality of our products. When used as intended and with

proper care and maintenance, you will experience years of reliable operation from this equipment. To

ensurebest results,it is importantthat you read and follow the instructions in this manual carefully.

TABLE OF CONTENTS

Maintenance

Troubleshooting

SafetyPrecautions

Specifications

ReplacementParts

ElectricalConnections

Installation

Operation

Cleaning

WiringDiagram

Warranty

LOCATION OF DATAPLATE

Thedata plate for the deck oven is located on the back side of the unit.

IMMEDIATELYINSPECT FORSHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has

assumed responsibility for its safe transit and delivery. If equipment is received damaged, either apparent

or concealed, a claimmust be madewith the deliveringcarrier.

APW

2

3

4

4

5

5

6

6

6

7

8

A. Apparent damage or loss must be noted on the freight bill at the time of delivery. It must then

be signed by the carrier representative (Driver). If this is not done, the carrier may refuse the

claim.The carriercan supply thenecessary forms.

B. For concealed damage or loss, if not apparent until after equipment is uncrated, a request

for inspection must be made to the carrier within 15 days The carrier should arrange an

inspection.Be certainto hold all contents and packaging material.

Installation and start up should be performed by a qualified installer who thoroughly read, understands and

followsthese instructions.

GENERAL TROUBLESHOOTING

If the unit fails to operate, check the following.

1. Makesure the unit is connected to a live power source.

2. Checkthe circuit breakerto be sure it has not been tripped.

3. Checkif the power switch is on and the indicator light is glowing.

4. Checkthe data plate and make sure the unit is operating on the proper voltage.

If the above checks out and you still have problems, call an APW Wyott Foodservice authorized service

agency.

NOTICE:

knowledgeable with the operation of commercial gas, electric, steam cooking equipment. Contact the

Authorized Service Agency for reliable service, dependable advice or other assistance and for genuine

factoryparts.

Service work should be performed only by a qualified technician who is experienced in and

Warrantywillbe void and the manufacturer is relieved of all liability if:

A. Service work is performed by other than an APW Wyott Foodservice authorized Service

Agency;or

B. Otherthan GenuineAPWWyott Foodservicereplacement partsare installed.

A current listing of all authorized APW Wyott Foodservice authorized parts/service distributors is included

with this product manual at the time of shipment. In the absence of this list, you can call theAPW Wyatt 24-

hour Service Hot Line which gives access to the nearest Authorized APW Wyatt parts/service distributor.

Call1-800-733-2203.

3

Page 4

SAFETY PRECAUTIONS

Before installing and operating this equipment be sure everyone involved in its operation are fully trained

and are aware of all precautions.Accidents and problems can result by a failure to follow fundamental rules

andprecautions.

The following words and symbols, found in this manual, alert you to hazards to the operator, service

personnelor the equipment.The words are defined as follows:

DANGER:

!

WARNING:

!

seriousinjuryor death.

CAUTION:

moderateinjuryor product or propertydamage.

!

NOTICE:

eventhoughnot dangerous.

!

WARNING:

!

CAUTION:

positioned so the general public can use the equipment make sure that cautions, warnings, and

!

operating instructions are clearly posted near each unit so that anyone using the equipment will

useit correctly and not injure themselves or harm the equipment.

WARNING: -

!

WARNING:

property damage, injury or death. Read the installation, operating and maintenance instructions

!

thoroughlybeforeinstallingor servicing this equipment.

Thissymbolwarns of imminenthazardwhich will resultin serious injuryor death.

This symbol refers to a potential hazard or unsafe practice, which could result in

Thissymbol refers to a potential hazard or unsafe practice, which may result in minor or

This symbol refers to informationthat needs special attention or must be fully understood

Thisproductis intended forcommercialuse only.Notfor household use.

These models are designed, built, and sold for commercial use. If these models are

SHOCKHAZARD

Improper installation, adjustment, alteration, service or maintenance can cause

Donot open anypanelsthat require the use of tools.

!

!

!

!

!

!

!

!

NOTICE:

the absence of local codes, with the national electrical code ANSI/NFPA70- latest edition.

!

Canadian installation must comply with CSA-STANDARD C.22.2 Number 0 M1982 General

Requirements-CanadianElectrical CodePart II, 109-M1981-CommercialCookingAppliances.

NOTICE:

Fire Protection Association, Inc. states in its NFPA96 latest edition that local codes are Authority

Having Jurisdiction when it comes to requirement for installation of equipment. Therefore,

!

installationshouldcomplywith all local codes.

NOTICE:

!

WARRANTYWILL BE VOIDED..

The unit when installed, must be electrically grounded and comply with local codes, or in

!

Local codes regarding installation vary greatly from one area to another. The National

!

THESE PROCEDURES MUST BE PERFORMED BY QUALIFIED PERSONNEL OR

!

SPECIFICATIONS

Electrical:

DimensionsUnit:

Heating Elements:

underthe bottom shelf.Athermostatisprovided for selectingthe desired temperature.Afifteen-minutetimer

is provided for customerconvenience.

WARNING:

!

andfrequencylisted on thedata plate. Connect only to 1 or 3 phaseas listed on the data plate.

CDO-17 120Volts,50/60 Hz, 13 amps,1 Phase, 1.5 KW

208/240Volts,50/60 Hz, 7.7/9.0 amps,1 Phase, 1.6 KW/21.4 KW

21-3/4"W x 25" 0 x 18.75" H

Three metal sheath heaters; one over the top shelf, one under the top shelf, and one

Checkthe data plateon this unit before installation.Connectthe unit only to the voltage

!

4

Page 5

REPLACEMENT PARTS LIST

Item Part Number

1 Frame Assembly 1

2 Shelf/Heater Support Assembly 2

3 Shelf 2

4 Heater 3

5 Support Assembly Mounting Screw 4

6 Mica Washer 48

7 Flat Washer 18

8 Nuts 12

9 Door Assembly 1

10 Door Handle Bracket 1 ea

11 Handle 1

12 Handle Mount Screw 2

14 Door Hinge, LH 1

15 Door Hinge, RH 1

16 Hinge Mounting Screw 4

17 Control Panel 1

18 Control Thermostat 1

19 Indicator Light 1

20 Timer 1

21 Thermostat Control Knob 1

22 Timer Knob 1

23 Thermostat Mounting Screw 2

25 Timer Mounting Screw 1

27 Control Panel Mounting Screw 6

28 Chase Nipple 1

29 Chase Nipple Nut 1

30 Ground Screw 1

31 Wire Nut 2

32 Line Cord 1

33 Bottom Insulation 1

34 Side Insulation 2

35 Top Insulation 1

36 Rear Insulation 1

37 Case 1

38 Case Mounting Screw 14

39 Cover Plate 1

40 Romex Connector 1

41 Cover Plate Mounting Screw 2

42 Thermostat Sensor Mounting Clip 2

43 Mounting Clip Screw 2

825178-10

825755-01

31007-45

14044-15

81 058-00

Supplied w/Heater

Supplied w/Heater

841 04-00

300501-10

819764-01/02

819765-10

82499-00

825366-21

825366-20

81 058-00

825043-10

14798-07

15139-03

14994-05

87053-14

87053-15

81 034-00

Supplied w/Timer

81 058-00

20925-49

20925-50

81058-00

11964-04

15420-02

10180-21

10180-22

10180-20

10180-23

825753-00

81349-00

825048-01

16035-00

81349-00

825364-00

81058-00

Description

Quantity

ELECTRICAL CONNECTIONS

Checkthe data plate to determine for what voltagethis deck oven is wired andwhat voltage service to use.

WARNING:

!

is equipped with a three-prong (grounded) plug for your protection against shock hazard and

should be plugged directly into a properly grounded three-prong receptacle. Do not cut or remove

thegroundingprong from this plug.

WARNING:

!

unpreservedmeatsandsausages.

IMPROPERGROUNDINGCOULDRESULTIN ELECTRICALSHOCKThisappliance

!

This unit is not intended to hold potentially hazardous foods such as uncooked or

!

5

Page 6

INSTALLATION

The CDO-17 Bake Oven has been inspected and tested at the factory prior to shipment. The CDO-17 is

designedfor counter top operation.

EquipmentPreparation

Unpack the CDO-17 and remove all packing materials (make sure no parts are discarded with crating

material). Place it on a flat, horizontal surface at the desired location. Clean the deck oven before using

Wipebody and controlbox with a hot, wet cloth to remove any shipping dust or protective oil.

A power cord is provided for the 220 volt oven. If a suitable wall receptacle is not available, one must be

installed by a qualified electrician. These deck ovens have been provided with the appropriate cord and

plugset. Do not attempt to defeat its purpose by substituting a plug of a differentconfiguration.

1. All food serviceequipment should be operated by trained personnel.

2. Never hold food below 150°F or above 40°F.

3. Oven use is restricted to pizza and bread products only Oven may be used for cooking other

typesof food providedthe food is cooked in pansor other containers.

OPERATION

1. Plug deck oven in and turn thermostat to 500° F. The unit has been calibrated at the factory.

Wait about 45 minutes for the unit to heat up. This will burn off all protective oils from the

heatingelements.

2. Turn the thermostat clockwise to the desired temperature. The indicator light will come on.

The indicator light will go off when the desired temperature is reached. If you are unable to

set your deck oven to the desired temperature, contact your factory authorized service

agent for adjustment. Note: It requires 20-45 minutes for the oven to reach a desired

temperature.

3. When the indicator light goes out, place the product in the oven. Set the timer to the desired

time. When the time bell sounds, remove the product from the oven. If the oven is not to be

used again immediately, turn the thermostat counterclockwise to "OFF." Note: The timer is

notpart of the electrical circuit and does not turn the heaters off when it reaches zero.

CLEANING

1. Before cleaning, turn the oven off, open the door and allow the oven to cool. The outside of the oven

may be cleaned with any standard commercial cleaner. Shelves may be removed and cleaned.

Warning:

2. Liquids should never come in contact with the decks! Wipe clean with a dry cloth!

InstallationHintsfor Hearth Stones

1 To minimize warping and maximize the life of the stones, it is strongly recommended that the plates

be pre-dried. First, preheat the decks with the pilot burner on for one hour. Over a five-hour period,

gradually increase the temperature approximately 100'F every hour until your desired baking

temperatureis reached.

2. A slight odor and outgassing may occur during the initial heat up. This is normal as the stones are

adjustingto their environment.

3. The stones should be reversed periodically to equalizewear.

4. Do not subjectstones to thermalshock. Foods cannot be thawed directly on hearth stones.

Replacementof Heating Element

CAUTION: Unplug the line cord before beginningreplacement.

1. Unscrew the cover plate mounting screws (Item 41).

Donot clean deckswith high abrasionbrushing or wateras they may crack?

6

Page 7

2. Unscrew case mounting screws (Item38) and liftoff case(Item 37).

3. Unscrew the nuts (Item 8) from the rear of the heater to be replaced anddisconnect the wiring.

4. If top heater is being replaced, pry down the support tabs just far enough to slip the heater out.

Remove the old heater; replace it with a new one, and bend the tabs back in position. Go on the Step7.

5. If the heater under the shelf is being replaced, remove the shelf (Item 3) and unscrew the support

assembly mounting screws (Item 5). Pullout the support assembly (Item 2) and turn it over. Pry up

the support tabs just far enough to slip the heater out. Remove the old heater; replace it with the

newone, and bendthe tabs back into position.

6. Install the shelf support assembly. Be sure that the slot on the rear engages the table on the rear

wall.Install the support assembly mounting screw (Item 5) and the shelf (Item 3).

7. Connect the wiring to the new heater with the nuts (Item 8) and washers (Item 7). CAUTION: Take

carethat the mica washers are betweenthe electrical connections and the heaters.

8. Remount the case (Item 37) and reinstall thecase mounting screws (Item 38).

9. Remount the cover plate (Item 39) using the cover plate mounting screws (Item 41).

Replacementof Thermostat

CAUTION: Unplug the power cord before beginningthis procedure

.

1. Unscrew the cover plate mounting screws (Item 41).

2. Unscrew case mounting screws andlift offcase (Item 37).

3. Remove the thermostat sensor from the oven by unscrewing the mounting clips (Item 42) and

bendingthe sensor around. Push it back through the hole.

4. Unscrew the control panel mounting screws (Item 27) then lift the control panel (Item 17) forward

anddown.

5. Pull off the thermostat control knob (Item21).

6. Unscrew the thermostat mountingscrews (Item 23).

7. Disconnect the wires from

the thermostat (Item 18)

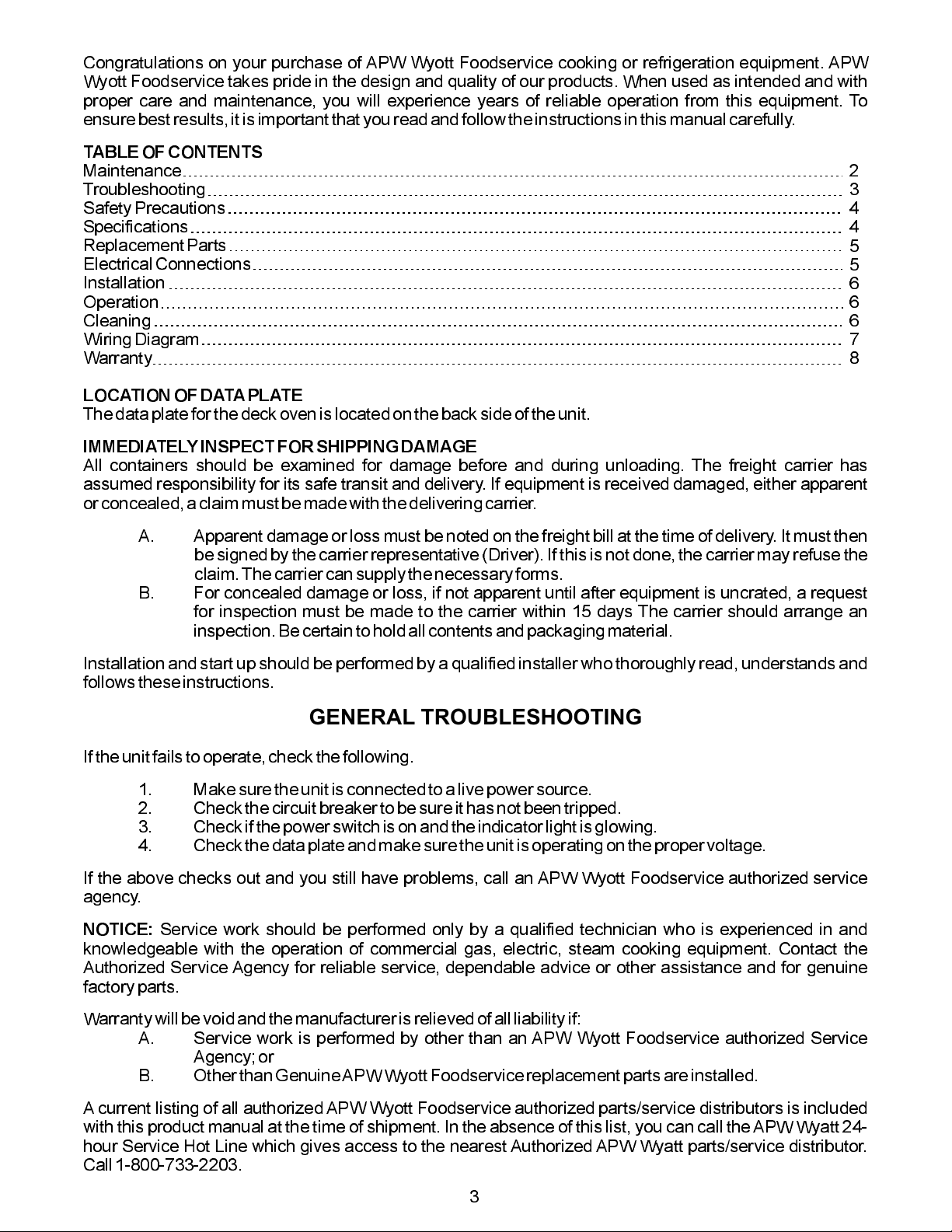

WIRING DIAGRAM

and install in the same

order on the new

thermostat. Remove the

Wire No. 1.

oldthermostat.

8. Mount the new thermostat

using the mounting screws

(Item23).

Wire No. 2.

Wire No. 3.

9. Remount the control panel

(Item 17) with mounting

screws(Item 27).

10. Press on the thermostat

Buss Bar

Pilot

Light

controlknob (Item 21).

11. Pull the sensor out far

Thermostat

enough to handle easily

then bend it around so it

lies along the rear wall.

Heating

Elements

Wire No. 4.

Mount with mounting clips

(Item 42) and screws (Item

43). Make

CAUTION:

certain the sensor

cable does not touch the

Buss Bar

Wire No. 5.

Wire

Nut

Wire

Nut

heater connections on the

backof the oven.

12. Remount the case (Item

37) and reinstall the

mounting screws (Item

38).

13. Reinstall the cover plate

White

Cordset

Black

Green

Ground

(Item 39) using the

mounting screws (Item 41).

7

Page 8

APW WYOTT EQUIPMENT LIMITED WARRANTY

APW Wyott Foodservice Equipment Company warrants it's equipment against defects in materials and workmanship, subject to the

following conditions:

This warranty applies to the original owner only and isnotassignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this warranty, at the option of

APW Wyott such product will be repaired or replaced by APW Wyott or its Authorized Service Agency. APW Wyott will only be

responsible for charges incurred or service performed by its Authorized Service Agencies. The use of other than APW Wyott

Authorized Service Agencies will void this warranty and APW Wyott will not be responsible for such work or any charges associated

with same. The closestAPWWyottAuthorized ServiceAgentmustbeused.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, metropolitan areas of Alaska and Canada. There

will be no labor coverage for equipment located on any island not connected by roadway to the mainland.

Warranty coverage on products used outside the 48 contiguous United States, Hawaii, and metropolitan areas of Alaska and Canada

may vary.ContacttheinternationalAPWWyott distributor, dealer,orserviceagency for details.

TimePeriod

One year for parts and one year for labor, effective from the date of purchase by the original owner. The Authorized Service Agency

may, at their option, require proof of purchase. Parts replaced under this warranty are warranted for the un-expired portion of the

original product warranty only.

Exceptions

Inallcases, parts covered by extended warranty will beshipped FOB the factory after the first year.

Portable Carry In Products

Equipment weighing over 70 pounds or permanently installed will be serviced on-site as per the terms of this warranty. Equipment

weighing 70 pounds or under, and which is not permanently installed, i.e. with cord and plug, is considered portable and is subject to

the following warranty handling limitations. If portable equipment fails to operate in its intended manner on the first day of

connection, or use, atAPWWyott's option or itsAuthorized ServiceAgency,itwillbeservicedonsiteorreplaced.

From day two through the conclusion of this warranty period, portable units must be taken to or sent prepaid to the APW Wyott

Authorized ServiceAgency for in-warranty repairs. No mileage or travel charges are allowed on portable units after the first day of use.

If the customer wants on-site service, they may receive same by paying the travel and mileage charges. Exceptions to this rule: (1)

countertop warmers and cookers, which are covered under the Enhanced WarrantyProgram, and (2) toasters or rollergrills which have

instore service.

Exclusions

The following conditions are not covered by warranty:

If the equipment has been changed, altered, modified or repaired by other than an Authorized Service Agency during or after the

warranty period, then the manufacturer shall not be liable for any damages to any person or to any property, which may result from the

use oftheequipment thereafter.

This warranty does not cover services performed at overtime or premium labor rates. Should service be required at times which

normally involve overtime or premium labor rates, the owner shall be charged for the difference between normal service rates and such

premium rates.APWWyott does not assume any liability for extended delays in replacing or repairing any items beyond its control.

Inallcases, the use of other thanAPWWyottAuthorized OEM Replacement Parts will void this warranty.

This equipment is intended for commercial use only.Warranty is void if equipment is installed in other than commercial application.

WaterQualityRequirements

Water supply intended for a unit that has in excess of 3.0 grains of hardness per gallon (GPG) must be treated or softened before

being used. Water containing over 3.0 GPG will decrease the efficiency and reduce the operation life of the unit.

Note: Product failure caused by liming or sediment buildup is not covered under warranty.

THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES

AND CONSTITUTES THE ENTIRE LIABILITY OF APW WYOTT. IN NO EVENT DOES THE LIMITED WARRANTY

EXTEND BEYOND THE TERMS STATEDHEREIN.

*Gas/Electric Cookline:

component parts, except switches and thermostats. (2 additional years on parts only. No labor on second or third year.)

*BroilerBriquettes,

*Heat Strips:

*GlassWindows, Doors, Seals, Rubber Seals, Light Bulbs:

*Equipment failure relating to improper installation, improper utility connection or supply and problems due to

ventilation.

*Equipment that has not been properly maintained, calibration of controls, adjustments, damage from improper cleaning

and water damage to controls.

*Equipment that has not been used in an appropriate manner, or has been subject to misuse or misapplication, neglect,

abuse, accident, alteration, negligence, damage during transit, delivery orinstallation, fire, flood, riot or act of god.

*Equipment that has the model number or serial number removed or altered.

Models FD, FDL, FDD, FDDL. Two(2)YearWarranty on element only. Nolaborsecond year.

Models GCB, GCRB, GF, GGM, GGT, CHP-H, EF, EG, EHP. Three (3) YearWarranty on all

RockGrates,CookingGrates,BurnerShields,Fireboxes:

90Day Material Only. No Labor.

90DayMaterialOnly.No Labor.

9/05

8

Loading...

Loading...