Page 1

R

INSTALLATION

AND

OPERATING

INSTRUCTIONS

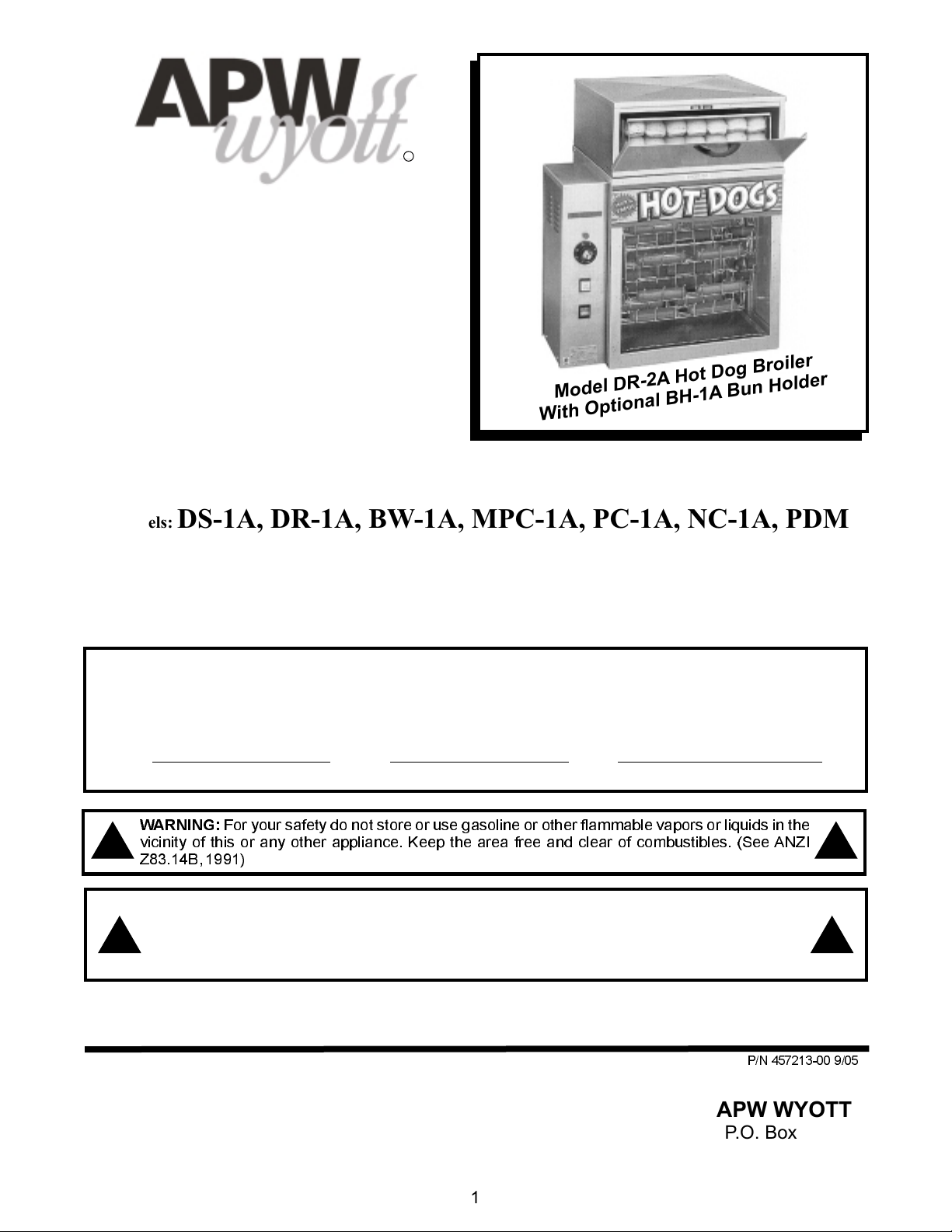

Model DR-2A Hot Dog Broiler

With Optional BH-1A Bun Holder

MERCHANDISERS

Models: DS-1A, DR-1A, BW-1A, MPC-1A, PC-1A, NC-1A, PDM

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

UNIT MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or Parts, this information is required.

Model Number Serial Number Date Purchased

WARNING:

vicinity of this or any other appliance. Keep the area free and clear of combustibles. (See ANZI

!

Z83.14B,1991)

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughly before installing or servicing this equipment.

This equipment has been engineered to provide you with year-round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

For your safety do not store or use gasoline or other flammable vapors or liquids in the

!

!!

Phone: +1

Fax: +1 (307) 637-8071

Toll Free: +1 (800) 752-0863

Website: www.apwwyott.com

E-mail: info@apwwyott.com

(307) 634-5801

P/N 457213-00 9/05

APW WYOTT

P.O. Box 1829

Cheyenne, WY 82003

1

Page 2

APW Wyott takes pride in the design and quality of our products. When used as intended and with proper

care and maintenance, you will experience years of reliable operation from this equipment. To ensure best

results, it is important that youread and follow the instructions in this manual carefully.

Installation and start-up should be performed by a qualified installer who thoroughly read, understands and

follows these instruction.

If you have questions concerning the installation, operation, maintenance or service of this product, write

Technical Service Department APW/Wyott Foodservice Equipment Company, P.O. Box 1829, Cheyenne,

WY 82003.

SAFETY PRECAUTIONS

Before installing and operating this equipment be sure everyone involved in its operation are fully trained

and are aware of all precautions.Accidents and problems can result by a failure to follow fundamental rules

and precautions.

The following words and symbols, found in this manual, alert you to hazards to the operator, service

personnel or the equipment. The words are defined as follows:

DANGER:

!

WARNING:

!

seriousinjuryor death.

CAUTION:

moderateinjuryor product or propertydamage.

!

NOTICE:

eventhoughnot dangerous.

!

CAUTION:

positioned so the general public can use the equipment make sure that cautions, warnings, and

!

operating instructions are clearly posted near each unit so that anyone using the equipment will

useit correctly and notinjurethemselvesorharm the equipment.

WARNING:

propertydamage,injury or death.Read the Installation, Operating and MaintenanceInstructions

thoroughlybeforeinstallingorservicingthis equipment.

WARNING:

strongly recommend having a competent professional install the equipment.Alicensed electrician

should make the electrical connections and connect power to the unit. Local codes should always

!

be used when connecting these units to electrical power. In the absence of local codes, use the

latestversionof the NationalElectricalCode.

Thissymbolwarns of imminent hazard whichwillresultin serious injury or death.

This symbol refers to a potential hazard or unsafe practice, which could result in

Thissymbol refers toa potential hazard orunsafe practice, which mayresult in minoror

This symbol refers toinformationthat needs specialattentionor must befully understood

These models are designed, built, and sold for commercial use. If these models are

Improper installation, adjustment, alteration, service or maintenance can cause

Installper the spacing requirements listed in the installationsection of this manual. We

!

!

!

!

!

!!

!

WARNING:

vicinity of this or any other appliance. Keep the area free and clear of combustibles. (See ANZI

!

Z83.14B,1991)

NOTICE:

Thesemaybe obtained from the gassupplier.

!

WARNING:

!

andfrequencylisted on the dataplate.Connectonlyto 1 or 3phaseas listed on thedataplate.

WARNING:

!

powerplug,indicatingthat you are workingonthe circuit.

CAUTION:

!

anymaintenanceor repair,contactAPW Wyott.

For your safety do not store or use gasoline or other flammable vapors or liquids in the

Instructions to be followed if anyone smells gas should be posted in a prominent place.

Checkthe data plate onthis unit before installation.Connecttheunitonly to thevoltage

Disconnect device from electrical power supply and place a Tag Out-Lockout on the

Maintenance & repair should be handled by a factory authorized agent. Before doing

2

!

!

!

!

!

Page 3

CONTENTS

Safety Precautions 2

General Information & Troubleshooting

DS-1A Mr. Frank Display Steamer 4

DR-1A Mr. Frank Display Broiler w/BW-1A Bun Warmer 4

MPC-1A Deluxe Popcorn Popper & PC-1A Deluxe Clearview Popcorn Popper 5

NC-1A Nacho Chip Cabinet 6

PDM Pretzel Display Merchandiser 6

Wiring Diagram 7

Parts List & Exploded View 8

Warranty

LOCATION OF DATA PLATE

The data plate for the warming shelf is located on the back of the unit.

IMMEDIATELYINSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has

assumed responsibility for its safe transit and delivery. If equipment is received damaged, either apparent

or concealed, a claim must be made with the delivering carrier.

A) Apparent damage or loss must be noted on the freight bill at the time of delivery. It must then be signed

by the carrier representative (Driver). If this is not done, the carrier may refuse the claim. The carrier can

supply the necessary forms.

B) Concealed damage or loss if not apparent until after equipment is uncrated, a request for inspection

must be made to the carrier within 15 days. The carrier should arrange an inspection. Be certain to hold all

contents and packaging material.

3

11

Installation and start-up should be performed by a qualified installer who thoroughly read, understands and

follows these instructions.

GENERAL INFORMATION & TROUBLESHOOTING

NOTICE:

the absence of local codes, with the national electrical code ANSI/NFPA70- latest edition.

!

Canadian installation must comply with CSA-STANDARD C.22.2 Number 0 M1982 General

Requirements-CanadianElectrical Code PartII,109-M1981-CommercialCookingAppliances.

NOTICE:

Fire ProtectionAssociation, Inc. states in its NFPA96 latest edition that local codes are Authority

Having Jurisdiction when it comes to requirement for installation of equipment. Therefore,

!

installationshouldcomplywithall local codes.

General Installation Instructions:

1. Always clean equipment thoroughly before first use. (See general cleaning instructions.)

2. Check rating label for your model designation and electrical rating.

3. Position equipment on level counter and plug into a grounded outlet so the plug is

The unit when installed, must be electrically groundedand complywith local codes, or in

!

Local codes regarding installation vary greatly from one area to another. The National

!

accessible. (See individual description for electrical loads.) On units bearing the CE

marking, the appliance must be connected by an earthing cable to all other units in the

complete installation and, hence, to an independent earth connection.

3

Page 4

General Operating Instructions:

1. All foodservice equipment should be operated by trained personnel.

2. Do not allow your customers to come in contact with any surface labeled “CAUTION HOT.”

3. Where applicable, never pour cold water into dry heated units.

4. Where applicable, do not cook, warm or hold food directly in liner pans (well pans). Always

use steam table pans/insets, etc.

5. Never hold food below 150°F (66°C).

General Cleaning Instructions:

1. NEVER clean any electrical unit by immersing it in water. Unplug unit before surface

cleaning.

2. Always clean equipment thoroughly before first use. Clean unit daily. Except where noted

on charts, use warm, soapy water. Mild cleansers and PLASTIC scouring pads may be used

to remove baked-on food and water scale.

3. Unplug all units before cleaning or servicing. All service should be performed by an APW

authorized service agency.

4. Do not use chlorides or chloride-based products in this unit. Always clean equipment before

first use. Clean unit daily. Use warm, soapy water. Rinse thoroughly to remove all residue.

Chlorides, chloride-based products and improper cleaning may cause corrosion and pitting.

Failure to comply with these instructions may void unit warranty.

General Troubleshooting—Always ask and/or check:

1. Is the unit plugged in?

2. Check circuit breaker.

3. Is power switch on and pilot light glowing?

4. Check rating label.Are you operating unit on proper voltage?

5. If the supply cord is damaged, it should only be replaced by an identical supply cord.

If the above checks out and you still have problems, call an APW authorized service agency.

DS-1A—MR. FRANK DISPLAY STEAMER

Installation:

1. Follow general installation instructions on page 3.

2. The operator must slide basket in over support pins and support flange.

Operations:

1. Follow general operation instructions on page 4.

2. Pour 3 quarts of hot water, 120°-140°F (50°-60°C), into lower pan. Cap on drain pipe must

be finger tight.

3. Place perforated hot dog tray into lower compartment. Load with up to 150 hot dogs.

4. Heat up time will depend on size and temperature of the hot dogs. Place bun basket into

upper cabinet, slide drip shield on top of bun basket, load up to 60 buns. Buns may be stored

in plastic bag for prolonged holding periods.

5. Turn on unit. Setinfinite control to “HI” position to begin steaming.

6. For holding, readjust control to “4” or “5” setting after 15 minutes (or when water steams).

7. Add water to unit if level is low.

Cleaning:

1. Follow general cleaning instructions on page 4.

2. Turn off unit and allow cabinet to cool.

3. Unscrew drain cap and drain water from cabinet.

4. Remove trays, baskets and support shelves from cabinet. Clean thoroughly

DR-1A—MR. FRANK DISPLAY BROILER WITH BW-1A BUN WARMER

Installation:

1. Follow general installation instructions on page 3. The broiler is labeled “Caution Hot.” Do

not allow customers to come in contact with the hot surface.

2. Insert basket holder assembly into cabinet by placing shaft end into spring loaded fitting.

Connect slotted coupling end over motor shaft by compressing spring loaded fitting.

3. Place individual baskets into support holes on hold assembly. Open side of basket should

4

Page 5

always face operator.

4. Slide drip pan into cabinet under the basket assembly.

5. If optional bun warmer is used, place warmer into opening on top of broiler.

Operations:

1. Follow general operating instructions on page 4.

2. Switch on unit. Set infinite control to “HI” position to begin broiling.

3. Load each basket with up to 4 hot dogs. Use “Load/Unload” push button.

4. Heat up time will depend on the size and temperature of the hot dogs when loaded into the

baskets.

5. For holding, readjust control to “5” or “6” setting after 15 minutes. If control is left on “HI,” hot

dogs will blister. To display hot dogs for several hours without shriveling or flavor loss, Do

Not Pierce Casings.

6. If optional bun warmer is used, pour 1 quart of hot water, 120°-140°F (50°-60°C), into pan.

Load up to 36 buns. Attach drip shield. Buns may be stored in plastic bag for prolonged

holding periods.

7. Use LOAD/UNLOAD push button to remove hot dogs from unit.

8. Add water as necessary to maintain moist buns.

Daily Cleaining:

1. Follow general cleaning instructions on page 4 .

MPC-1A—DELUXE POPCORN POPPER

PC-1A—DELUXE CLEARVIEW POPCORN POPPER

Installation:

1. Follow general installation instructions on page 3.

2. Install heat lamp in lamp holder at top rear of cabinet.

3. Slide drawer into slot at base of cabinet.

4. Install kettle by inserting locking hinge pin through holes in support bracket and kettle.

5. Insert kettle plug into ceiling mounted receptacle. Twist plug to lock.

6. Install kettle hinged covers by inserting tabs into support bracket slots.

7. Install acrylic doors.

Operations:

1. Follow general operating instructions on page 4.

For 6-8 oz. (170-230 gm) Popper Only:

2. Raise kettle to support bracket and latch by turning handle clockwise..

3. Turn on POWER/DISPLAY and KETTLE STIRRER switches to preheat kettle for 8 minutes.

4. Raise hinged kettle cover with lifting knob and add 1/4-1/3 cup (.06-.08 liter) popcorn oil, 3/4

5. Leave KETTLE/STIRRER switch on until popping is completed. Unlatch kettle. Gradually

6. Additional batches of popcorn can be popped immediately.

7. Always turn off KETTLE/SITRRER switch when not popping corn.

8. Do not leave popper unattended when in use.

For 10 oz. (284 gm) Popper Only

2. Raise kettle to support bracket and latch by turning handle clockwise.

3. Turn on POWER/DISPLAY and KETTLE switches. Preheat kettle for 10 minutes.

4. Raise hinged kettle cover with lifting knob and add 1/3 cup (.08 liter) popcorn oil, 1 1/3 cup or

5. Turn on STIRRER switch until popping is complete. Unlatch kettle. Gradually lower kettle to

6. Additional batches of popcorn can be popped immediately.

7. Always turn off KETTLE and STIRRER switches when not popping corn.

8. Do not leave popper unattended when in use.

to 1 cup or 6 oz. (.08 to .24 liter or 170 grams) popcorn and desired salt. Close cover. Avoid

spilling oil on exterior of kettle.

lower kettle to dump all popcorn. Do not allow kettle to drop abruptly .

CAUTION: “CAUTION HOT.”

CAUTION:

10 oz (.32 liter or 284 gram) popcorn, and desired amount of salt. Close cover. Avoid spilling

oil on exterior of kettle.

dump all pop-corn. Do not allow kettle to drop abruptly.

CAUTION: “CAUTION HOT.”

CAUTION:

Kettle is marked Do not touch kettle, use insulated handle.

Kettle is marked Do not touch kettle, use insulated handle.

5

Page 6

Suggestions:

1. Keep access doors open when popping to reduce cabinet moisture.

2. Use POWER/DISPLAY switch to warm and display popped corn.

Cleaning/Daily Cleaning:

1. Follow general cleaning instructions on page 4.

2. To prevent build-up of excess oil and salt, clean daily when kettle is still warm.

CAUTION:

immerse kettle in water.

3. Pull spring clip to remove stirrer from drive shaft. Align hole in stirrer and drive shaft to

reinstall clip.

4. Lift off kettle cover. A mild abrasive cleaner and PLASTIC scouring pad may be used to

remove oil build-up on any of the kettle parts.

5. Remove all un-popped corn from drawer and wipe out entire cabinet. Clean cabinet and

doors with mild soap and water, dry with soft towel.

Installation:

1. Follow general installation instructions on page 3.

2. Insert deflector into slot oninside of cabinet.

Operations:

1. Follow general operating instructions on page 4 .

2. Switch on unit

3. Load from top with up to 12 pounds (5.5 kg) of chips. Maintain level below indicating label.

4. To maintain product freshness, do not turn off unit until cabinet is empty.

Allow sufficient cool down time before removing kettle for cleaning. Do NOT

NC-1A—NACHO CHIP CABINET

Cleaning:

1. Follow general cleaning instructions on page 4.

Installation:

1. Unpack unit and remove protective material from display rack and reflector lamps.

2. Follow general installation instructions on page 3.

Operations:

1. Follow general operating instructions on page 4.

2. Place preheated food product on display rack.

3. To turn on reflector lamps and rotate display rack, presspower switch to “ON” position.

Cleaning:

1. Follow general cleaning instructions on page 4.

PDM—PRETZEL DISPLAY MERCHANDISER

(120 volt outlet - 1.75 amp load) (230 volt - 0.8amp load)

Note:

then swing lower end of shaft towards the front of unit.

to remove display rack for cleaning, grip center shaft and lift up as far as it will move

6

Page 7

LAMPS

WIRING DIAGRAM DR-1A, DR-2A

240V

SINGLE

PHASE

HEATING ELEMENT

LAMPS

INDICATOR

LIGHT

GEAR

MOTOR

TERMINAL BLOCK

P

L1

L2

INFINITE

H1

H2

CONTROL

LOAD/UNLOAD

SWITCH

ON/OFF

SWITCH

240V

SINGLE

PHASE

7

Page 8

P.O. Box 1829

Cheyenne, WY 82003

DR-1A, DR-2A, BH-1A

R

Display Hot Dog Broiler

HOT DOG ROASTER DR-1A & DR-2A

Phone:

Fax:

Toll Free:

Website:

E-mail:

+1 (307) 634-5801

+1 (307) 637-8071

+1 (800) 752-0863

www.apwwyott.com

info@apwwyott.com

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Part No.e

44685200

44685400

44680200

44680100

8967200

44686600

44687000

1506000

2002300

2000300

44687800

44683100

1505800

1196100

Description

Wrapper Assembly

Control Housing

Large Glass

Small Glass

1/2 Inch Hole Bushing

Top Cover

Reflector Assembly

Lamp Holder,

Nipple, Lamp Holder

Nut, Lamp Holder

Heating Element 120V

Heating Element 240V

Lamp Bulb

Wire Nut

Item

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Part No.e

44683800

83006-00

48914500

48521000

1301608

1301602

45582500

48940600

44687500

45653000

44689500

44689100

44685000

44685600

Description

Conveyor Motor 240V

Motor Drive Roll Pin

Terminal Block

Conveyor Idler Bearing

Infinite Control 120V

Infinite Control 240V

Knob, lnfinite Control

On-Off Switch

Load Push Switch

Indicator Light

Inspection Panel

Conveyor Carousel

Basket (each)

Drip Pan

15

16

17

18

Item

36

37

38

39

40

41

42

47255900

1547000

8968900

48609300

Part No.e

44688100

44688500

47253300

44689000

44680300

8705000

44674900

Cord 120V

Cord 240V

Strain Relief Bushing

Conveyor Motor 120V

BUN HOLDER BH-1A

Description

Wrapper & Top Assembly

Door Assembly

Handle, Door

Bun Basket

Drip Shield

Magnet Door

Magnet Plate, Door

33

34

35

36

Item

44687400

44681200

45576800

21766800

Part No.e

Top Hole Cover

Bottom Cover

Foot (each)

Marketing Label

Description

8

Page 9

P.O. Box 1829

Cheyenne, WY 82003

DR-1A, DR-2A, BH-1A

R

Display Hot Dog Broiler

Phone:

Fax:

Toll Free:

Website:

E-mail:

+1 (307) 634-5801

+1 (307) 637-8071

+1 (800) 752-0863

www.apwwyott.com

info@apwwyott.com

BUN HOLDER BH-1A

40

36

42

37

41

38

39

HOT DOG ROASTER DR-1A

33

6

12

11

30

7

10

9

8

13

31

Page 3 of 4

5

14

3

19

24

18

23

2

28

25

29

21

17

16

15

Note: When ordering,ALWAYSspecify Part #, Model #, Serial #, Voltage & Phase.

27

26

35

22

1

32

34

P/N 467111-00 Rev. 6/05

4

9

Page 10

NOTES:

10

Page 11

APW WYOTT EQUIPMENT LIMITED WARRANTY

APW Wyott Foodservice Equipment Company warrants it's equipment against defects in materials and workmanship, subject to the

following conditions:

This warranty applies to the original owner only and is not assignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this warranty,at the option of

APW Wyott such product will be repaired or replaced by APW Wyott or its Authorized Service Agency.APW Wyott will only be

responsible for charges incurred or service performed by its Authorized Service Agencies. The use of other than APW Wyott

Authorized Service Agencies will void this warranty and APW Wyott will not be responsible for such work or any charges associated

with same.TheclosestAPWWyottAuthorized ServiceAgentmustbeused.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, metropolitan areas of Alaska and Canada. There

will benolaborcoverage for equipment located on any island not connected by roadway to the mainland.

Warranty coverage on products used outside the 48 contiguous United States, Hawaii, and metropolitan areas of Alaska and Canada

may vary. Contact the international APWWyott distributor,dealer, or service agency for details.

TimePeriod

One year for parts and one year for labor, effective from the date of purchase by the original owner.The Authorized Service Agency

may, at their option, require proof of purchase. Parts replaced under this warranty are warranted for the un-expired portion of the

original product warranty only.

Exceptions

Inallcases,partscovered by extended warranty will be shipped FOB the factory after the first year.

Portable Carry In Products

Equipment weighing over 70 pounds or permanently installed will be serviced on-site as per the terms of this warranty. Equipment

weighing 70 pounds or under, and which is not permanently installed, i.e. with cord and plug, is considered portable and is subject to

the following warranty handling limitations. If portable equipment fails to operate in its intended manner on the first day of

connection, or use, atAPWWyott's option or itsAuthorizedServiceAgency, it will be serviced on site or replaced.

From day two through the conclusion of this warranty period, portable units must be taken to or sent prepaid to the APW Wyott

Authorized ServiceAgency forin-warranty repairs. No mileage or travel charges are allowed on portable units after the first day of use.

If the customer wants on-site service, they may receive same by paying the travel and mileage charges. Exceptions to this rule: (1)

countertop warmers and cookers,which are covered under the Enhanced Warranty Program, and (2) toasters or rollergrills which have

instoreservice.

Exclusions

The following conditions are not covered by warranty:

If the equipment has been changed, altered, modified or repaired by other than an Authorized Service Agency during or after the

warranty period, then the manufacturer shall not be liable for any damages to any person or to any property,whichmay result from the

use oftheequipment thereafter.

This warranty does not cover services performed at overtime or premium labor rates. Should service be required at times which

normally involve overtime or premium labor rates,theownershallbechargedforthedifferencebetween normal service rates and such

premium rates.APWWyott does not assume any liability for extended delays in replacing or repairing anyitemsbeyonditscontrol.

Inallcases,theuseofotherthanAPWWyottAuthorized OEM Replacement Partswill void this warranty.

This equipment is intended for commercial use only.Warrantyis void if equipment is installed in other than commercial application.

WaterQuality Requirements

Water supply intended for a unit that has in excess of 3.0 grains of hardness per gallon (GPG) must be treated or softened before

being used. Water containing over 3.0 GPG will decrease the efficiency and reduce the operation life of the unit.

Note: Product failure caused by liming or sediment buildup is not covered under warranty.

THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES

AND CONSTITUTES THE ENTIRE LIABILITY OFAPW WYOTT. IN NO EVENT DOES THE LIMITED WARRANTY

EXTEND BEYOND THE TERMS STATED HEREIN.

*Gas/Electric Cookline:

component parts, except switches and thermostats. (2additionalyearsonpartsonly.No labor on second or third year.)

*BroilerBriquettes,

*Heat Strips:

*GlassWindows, Doors, Seals,Rubber Seals, Light Bulbs:

*Equipment failure relating to improper installation, improper utility connection or supply and problems due to

ventilation.

*Equipment that has not been properly maintained, calibration of controls, adjustments, damage from improper cleaning

and water damage to controls.

*Equipment that has not been used in an appropriate manner, or has been subject to misuse or misapplication, neglect,

abuse, accident, alteration, negligence, damage duringtransit,delivery orinstallation, fire, flood, riot or act ofgod.

*Equipment that has the model number or serial number removed or altered.

Models FD, FDL, FDD, FDDL. Two(2) YearWarranty on element only. No labor second year.

Models GCB, GCRB, GF, GGM, GGT, CHP-H, EF, EG, EHP. Three (3) Year Warranty on all

RockGrates, Cooking Grates, Burner Shields,Fireboxes:

90Day Material Only. No Labor.

90Day Material Only.No Labor.

9/05

11

Page 12

R

Phone: +1

(307) 634-5801

Fax: +1 (307) 637-8071

Toll Free: +1 (800) 752-0863

Website: www.apwwyott.com

E-mail: info@apwwyott.com

APW WYOTT

P.O. Box 1829

Cheyenne, WY 82003

12

Loading...

Loading...