Page 1

Built to Last

• X*WAV™ Ceramic heaters are made of a stronger material that

maintains a moderate material temperature. They last significantly

longer than Quartz elements and do not have the issue of shattered

glass in your operation.

• Bottom heat is provided by a specially placed elements that can

easily handle drippings and grease. Competitive units use quartz

elements that can shatter with grease drippings.

• Brushless DC conveyor motor is long lasting.

Reliability backed by APW Wyott’s Warranty

• Certified by the following agencies:

Model: X*WAV 1422 EZ SS

Designed Smart

APW Wyott Design Features

Options

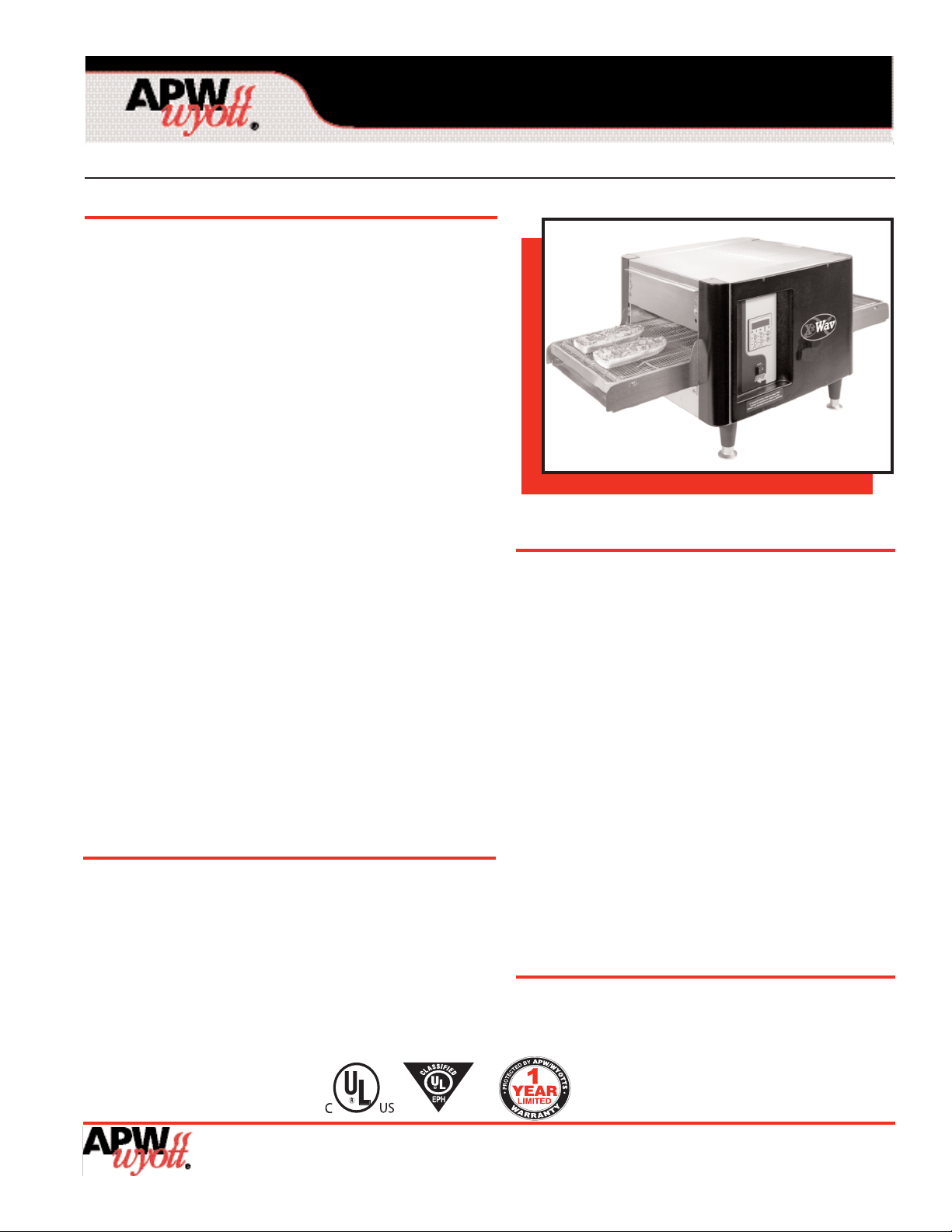

X*WAV™ 1422 EZ SS

Pass-Through Conveyor Toaster

APW Wyott Foodservice Equipment Company · 729 Third Ave., Dallas, TX 75226

(800) 527-2100 · (214) 421-7366 · Fax (214) 565-0976 · www.apwwyott.com · info@apwwyott.com

Rev. 1/03/2008

X*WAV™ 1422 EZ SS PASS THROUGH CONVEYOR TOASTER

Developed for high output!

• X*WAV™ Radiant Pass Through Conveyor Oven uses a series of

cutting edge controls and infrared heat systems that are focused at

your food, delivering an “extreme” level of heat energy for Broiling,

Toasting, Baking and Warming.

Heat Systems…the X*Treme Difference!

• X*WAV-EZ SS

®

ceramic heat system has over 31% more efficiency

in its InfraRed Energy vs. Quartz based units.

• X*WAV-EZ SS

®

heat system is a concentrated, focused source of

radiant energy that consistently sends InfraRed evenly toward the

conveyor belt...at both high and low temperature levels…InfraRed

efficiency is 96%!

• Hot toasted sandwiches in 45seconds; Perfect pizza in 5-8 mintues!*

X*Treme Control!

• X*WAV-EZ SS

®

cooking control system utilizes a programmable Solid

State Digital Control for a variety of menu options.

• Choosing a menu option will automatically adjust the heat settings,

both top and bottom, and the conveyor speed.

Operations that are X*Tremely Easy & Efficient!

• Conveyor speed can be set between speeds that are maximum

(10 minutes) to a minimum speed of 30 seconds.

• Conveyor direction can be reversed with switch on side of conveyor.

• Crumb trays are provided on either end of the toaster. 12” Extended

Conveyor shelves are supplied for both “entrance or exit” areas...

allowing easy loading and off-loading of products.

• Fully insulated top and sides provide “Cool to the Touch” exteriors...

Thermostatically controlled fan keeps exterior surface cool even

when unit is turned off.

• X*WAV-EZ SS

®

control panel is recessed vs. the “exposed” control

panel on the competition…reducing inadvertent bumps on control

buttons that change the performance speed or temperature

• X*WAV™ ovens are designed to Toast, Broil, Bake and Warm a

variety of menu items while minimizing countertop space.

• Ceramic InfraRed heaters located on the top provide the most

efficient and effective radiant energy to the cooking area.

• X*WAV™ bottom heat is provided by a specially placed

metal sheathed elements that direct a concentrated level of

energy to the food.

• X*WAV™ solid state digital controls provide the maximum

amount of control to top and bottom heat.

• Conveyor belt direction switch to reverse flow of food.

• Thermostatically controlled fan cooling system keeps the

conveyor oven “Cool to the Touch” and extends the life of

critical components.

• Conveyor belt speed control and top & bottom heat control

enables different menu items to be cooked in the same oven...

provides superior flexibility.

• Product entry and exit openings are adjustable to 3” high.

• Removable extended load/unload shelf area for ease of

product removal.

• Removable crumb tray for fast and easy clean-up.

• Stacking Kit (94000189)

• End stop (94000151)

• 3 Phase

See reverse side for product specifications.

*Times depend on crust thickness- Thawed pizza only

Built Solid

Page 2

X*WAV™ 1422 EZ SS

Pass-Through Conveyor Oven

PRODUCT: QUANTITY: ITEM #:

Model: X*WAV 1422 EZ SS

APW Wyott Foodservice Equipment Company · 729 Third Ave., Dallas, TX 75226

(800) 527-2100 · (214) 421-7366 · Fax (214) 565-0976 · www.apwwyott.com· info@apwwyott.com

Rev. 1/2008

# 1716

Ovens are constructed of stainless steel, painted aluminum

extrusions, and polycarbonate material. Range of belt

speeds should be 30 seconds to 12 minutes and is controlled

by a Solid State Digital System.

Conveyor belt is reversable

with a flip of a switch.

Single oven furnished with 4” adjustable

legs. Infrared ceramic radiant heaters and on/off heat switch

for heat control are standard. Product opening adjustable

from 1” to 3 3/4”, motors are permanently lubricated. Units

are UL listed, UL Sanitation, and Canadian UL approved.

PRODUCT SPECIFICATIONS

Construction:

X*WAV™ 1422 EZ SS external top, back, sides and base

are made of 18 gauge stainless steel. Front control side is

made of high temperature polycarbonate material.

Conveyor belt is made of non-corrosive steel. Internal

Chamber is made of 18 gauge Stainless Steel. 4” High

Temperature Polycarbonate and steel legs. High

temperature insulation used around cooking chambers.

Electrical Information:

X*WAV™ 1422 EZ SS is equipped with a 6ft., 4 wire

grounded power cord which terminates with a 15-30P plug.

Power cord exits out the back of the unit.

Electrical Specifications:

X*WAV™ 1422 EZ SS: 208V, 7000W, 19.45amps 3ph

204V, 7000W, 19.45amps 3ph

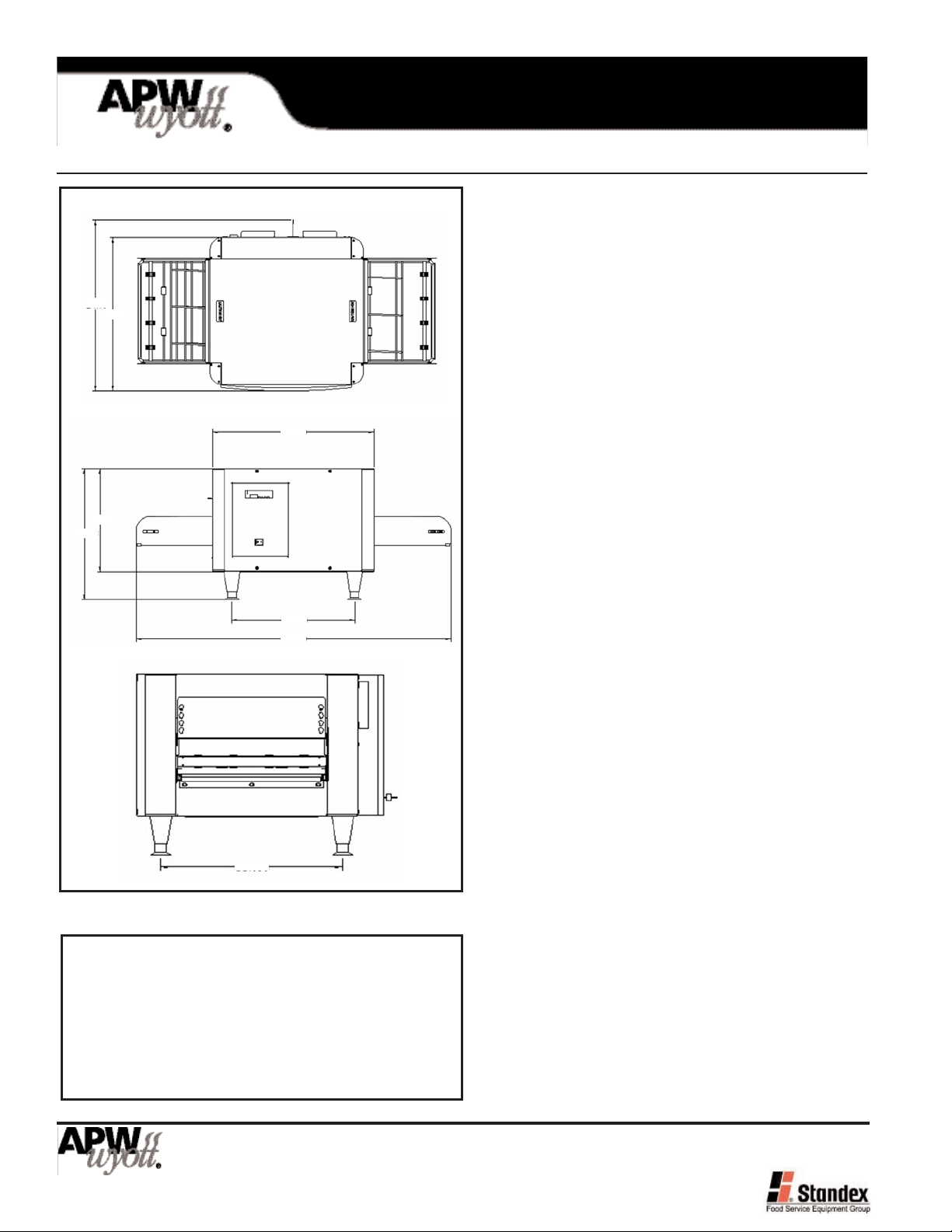

Overall Dimensions:

X*WAV™ 1422 EZ SS External:

Length with conveyor: 43” (109.2 cm)

Length with entrance

and exit shelves: 67” (170.2 cm)

Length of conveyor

belt outside of chamber

(for exit/entrance): 10” (25.5 cm)

Width: 24 1/2” (62 cm)

Height with 4” legs: 18” (46 cm)

Height of work deck: 10” (25.5 cm)

Height of 2 stacked: 34 1/6" (91.86 cm)

Height of 3 stacked: 50 1/4" (127.64 cm)

X*WAV™ 1422 EZ SS Footprint Leg placement

Length: 16 3/4” (42.5 cm)

Depth: 18” (46 cm)

Oven Cooking Chamber:

Length: 22” (56 cm)

Depth: 14” (35.5 cm)

Height (Max): 3 7/8” (9.6 cm)

Shipping Weight:

X*WAV™ 1422 EZ SS: 166 lbs (75.5 kg)

Freight Class: 100

F.O.B. Dallas, TX

Consultant Specifications

24.49

21.95

22.00

14.14

17.91

16.75

43.00

*APW Wyott reserves the right to modify specifications

or discontinue models without incurring obligation.

18.00

Loading...

Loading...