HARDWARE TECHNICAL REFERENCE

XEN

apricot

MITSUBISHI ELECTRIC

HARDWARE TECHNICAL REFERENCE

i486 and OverDrive are trademarks of Intel Corporation.

Duracell and D389 are registered trademarks of Duracell Inc.

Irwin is a trademark of Irwin Magnetic Systems Inc.

MS-DOS is a registered trademark of Microsoft Corporation.

Maxtor is a trademark of Maxtor Corporation.

Panasonic is a trademark of Matsushita Communication Industrial Co. Ltd.

Archive is a registered trademark of Archive Corporation.

Adaptec is a registered trademark of Adaptec Inc.

AT and IBM are registered trademarks of International Business Machines Corporation.

Quantum and ProDrive are trademarks of and DisCache is a registered trademark of Quantum Corporation.

National Semiconductor is a registered trademark of National Semiconductor Corporation.

Cirrus Logic is a registered trademark of Cirrus Logic Inc.

Information contained in this document is subject to change without notice and does not represent a commitment on the part of

Apricot Computers Limited. The software described in this manual is furnished under a license agreement. The software may be used

or copied only in accordance with the terms of this agreement.

It is against the law to copy any disk supplied for any purpose other than the

purchaser’s personal use.

All rights reserved; no use or disclosure without written consent.

Copyright © Apricot Computers Limited 1993

Published by

Apricot Computers Limited

3500 Parkside

Birmingham Business Park

Birmingham B37 7YS

MITSUBISHI ELECTRIC

Printed in the United Kingdom

Part no. 15092231

Preface

The Apricot XEN Technical Reference Manual is intended for:

• Programmers and engineers involved in hardware and software design for XEN.

Contents

Preface

• Service personnel involved in fault diagnosis and repair.

All computers in the Apricot XEN range using system boards with the identifier

PC/235 are covered.

The manual is divided into a number of sections and appendices as described below:

1. Introduction This is a brief overview of the Apricot XEN which describes the options and major

components of the system.

2. System unit This section describes the system unit. It also includes, disassembly instructions for

servicing and replacing major components of the system, and instructions for the

installation of add-ons and upgrades. Pinouts of the connectors which appear at the

rear of the system unit are provided.

3. System board This section provides an overview of the function of the system board, and more

detailed descriptions of the circuitry on the board. Sub-sections provide a description

of each area of the board.

4. Peripheral This section describes each of the system components which attach to either the

items system board e.g. floppy disk drive, or system unit e.g. keyboard. Also included is brief

information on the KeyLOC card. Sub-sections describe each component.

Chapter 1

Chapter 2

Chapter 3

5. Memory and This section provides information on the usage of Memory and I/O space by the system

I/O space board, and programming information for each part of the system.

Appendices Four appendices are included:

Appendix A

Contains specifications for each component of the XEN.

Appendix B

This appendix describes the differences between the revision D and E system boards

and the revision F system board described in section 3.

Appendix C

A list of error beep codes.

Appendix D

This appendix contains information on the interrupt and DMA usage of the system

board, its memory map and I/O port usage.

Chapter 3

Chapter 5

XEN HARDWARE TECHNICAL REFERENCE 1

Preface

Associated Publications

Preface

ContentsChapter 1

Chapter 2

The following publication may be of general use to engineers and programmers.

IBM Personal Computer AT Technical Reference Manual.

The following manufacturers data sheets give information on specific devices:

Intel i486

82077 Floppy disk controller

82596 Ethernet coprocessor

VLSI VL82C486

VL82C425 cache controller

VL82C113A

Cirrus CL-GD542X video controller

National Semiconductor NS16450 Serial communications controller

LMC1982

LMC835

Yamaha YMZ263

YMF262

YAC512

Chapter 3

Chapter 5 Chapter 3

2 XEN HARDWARE TECHNICAL REFERENCE

CONTENTS

Contents

1 INTRODUCTION

General....................................... 1/2

Variants....................................... 1/2

System unit ................................ 1/3

System board............................. 1/3

Power supply............................. 1/4

Drive bays .................................. 1/4

Keyboard.................................... 1/4

Monitors..................................... 1/4

Expansion cards ........................ 1/5

2 SYSTEM UNIT

2.1 Introduction ............................2/2

2.2 System unit description ....2/3

Construction ............................. 2/3

External layout.......................... 2/3

Internal layout ........................... 2/4

2.3 Dismantling instructions ..2/5

Servicing level............................ 2/5

Warnings and cautions............ 2/5

Anti-static precautions............ 2/5

Equipment required ................. 2/5

System board connectors.......2/6

Dismantling and reassembly... 2/7

2.4 Installing add-ons ...............2/18

Introduction.............................2/18

Expansion cards ......................2/18

Memory .................................... 2/20

Processor upgrades ...............2/22

5.25" drives ..............................2/28

3.5" hard disk drive................ 2/31

2.5 System unit connectors ..2/33

3 SYSTEM BOARD

3.1 Introduction ............................3/2

General....................................... 3/2

Description ................................ 3/4

3.2 Processor system .................3/5

3.3 VL82C486 ................................3/6

Interrupt structure................... 3/6

Direct Memory Access ........... 3/8

System timers............................ 3/9

Contents

3.4 System memory ...................3/9

General....................................... 3/9

Read only memory (ROM).....3/9

Random access memory

(RAM) .......................................3/10

3.5 Video controller .................3/10

General.....................................3/10

3.6 Floppy disk controller ......3/12

3.7 Hard disk and SLC

interfaces ...............................3/13

General.....................................3/13

Interface signal descriptions.3/13

3.8 Peripherals controller ......3/14

Serial ports...............................3/14

Parallel port ............................. 3/15

3.9 82C113A .................................3/15

Real time clock (RTC) RAM 3/15

Keyboard port ........................3/19

3.10 LOC Technology ................3/20

3.11 Ethernet port .......................3/20

General.....................................3/20

3.12 Professional audio ..............3/22

General.....................................3/22

3.13 System board

connectors .............................3/24

Hard disk drive connector ...3/24

SLC interface connector.......3/24

Floppy drive connectors.......3/25

Audio data................................3/25

System board power

connector.................................3/26

Front panel connector .......... 3/26

VESA connector ..................... 3/26

Battery jumper........................3/27

4 PERIPHERAL ITEMS

4.1 Power supply ..........................4/3

Output connectors .................. 4/4

Chapter 1

Contents

Contents

Chapter 2

Chapter 3

Chapter 3

Chapter 5

XEN HARDWARE TECHNICAL REFERENCE 1

Contents

Contents

Contents

Chapter 1

Chapter 2

Chapter 3

Chapter 5 Chapter 3

4.2 Hard disk drives ....................4/4

Introduction............................... 4/4

Quantum ProDrive ELS .......... 4/5

Maxtor 7213A........................... 4/6

Quantum ProDrive LPS

240AT ......................................... 4/7

Quantum LPS525A .................. 4/8

IDE interface............................4/10

4.3 Floppy drives ........................4/12

3.5" floppy drive......................4/12

5.25" floppy drive ...................4/13

Interface signals.......................4/17

4.4 Tape drives ............................4/18

DAT drive ................................4/18

Archive SCSI tape drives ......4/20

Irwin 285 .................................. 4/23

4.5 CD-ROM drives ...................4/25

SLC CD-ROM drive .............. 4/25

SCSI CD-ROM drive ............. 4/27

4.6 Adaptec AHA-1510 SCSI

controller ...............................4/28

Introduction.............................4/28

Configuration ..........................4/28

SCSI bus....................................4/29

4.7 Monitors .................................4/31

Introduction.............................4/31

Maintenance.............................4/31

Video signal.............................. 4/32

Apricot SVGA colour

monitor.....................................4/32

HiVision Low Emission 14"

colour........................................4/33

HiVision Low Emission 17"

colour........................................4/35

Connector ............................... 4/36

4.8 Keyboard ................................4/37

Introduction.............................4/37

Operation.................................4/37

Scan codes ...............................4/40

Connector ............................... 4/46

4.9 KeyLOC card ........................4/47

5 MEMORY AND I/O USAGE

5.1 Introduction ...........................5/2

5.2 Memory usage .......................5/2

5.3 I/O space ..................................5/4

DMA I/O address map............ 5/5

Interrupt controllers ............... 5/6

System timers............................ 5/6

Keyboard controller................ 5/6

Port B.......................................... 5/7

RTC RAM/NMI mask .............. 5/8

Port A ....................................... 5/13

Chipset......................................5/13

Apricot ports...........................5/15

Hard disk drive controller

registers.................................... 5/19

Joystick port ............................5/20

Serial port controller

registers.................................... 5/20

Ethernet controller................ 5/20

SLC CD-ROM controller.....5/22

Professional audio .................. 5/22

Floppy disk controller ...........5/24

Parallel port controller .........5/24

Video DAC ..............................5/26

VGA registers .........................5/26

CL-GD542X Extension

registers.................................... 5/31

APPENDICES

A: Specifications

B: Revision D and E system boards

C: Error beep codes

D: Configuration

2 XEN HARDWARE TECHNICAL REFERENCE

INTRODUCTION

Chapter 1

Contents

1 INTRODUCTION

General........................................1/2

Variants........................................1/2

System unit.................................1/3

System board..............................1/3

Power supply..............................1/4

Introduction

Drive bays...................................1/4

Keyboard.....................................1/4

Monitors......................................1/4

Expansion cards.........................1/5

Contents

Chapter 2

Chapter 1

Chapter 3

Chapter 3

Chapter 5

XEN HARDWARE TECHNICAL REFERENCE 1/1

Chapter 6

Introduction

General

The XEN family is a range of ISA compatible desktop computers.

Contents

Chapter 2

Chapter 1

Variants

The main features of the range are:

• i486 processor running at external clock speeds of up to 33MHz.

• 4 to 64 Mbytes of RAM.

• One parallel and two serial ports.

• Mouse port.

• Floppy disk controller on system board.

• ATA (IDE) compatible hard disk interface on system board.

• SLC CD-ROM interface on system board.

• Three ISA compatible expansion slots.

• Full ISA functional compatibility.

• On-board enhanced VGA controller.

• On-board local bus Ethernet coprocessor (optional).

• LOC technology sub-system (optional).

• On-board professional audio sub-system (optional).

• On-board numerics coprocessor (i486DX variants only)

• Secondary 256kbyte cache (optional)

• Processor upgrade socket.

Chapter 3

Chapter 5Chapter 6 Chapter 3

The basic system unit may be fitted with:

• 4 to 64 Mbytes of RAM.

• 3.5" floppy disk drive.

• 1 or 2 3.5" hard disk drives.

• One half height 5.25" device. Apricot supply the following options:

5.25" floppy drive.

Irwin FTD tape drive

150 or 525 Mbyte tape drive.

DAT drive.

CD-ROM drive.

• Apricot Professional Audio

• 82596 Ethernet coprocessor based Ethernet interface

• LOC Technology security subsystem.

A VGA monitor will be required.

1/2 XEN HARDWARE TECHNICAL REFERENCE

Introduction

System unit

The system unit contains: the system board, drives, power supply and up to three

expansion cards.

All the interface circuitry is on the system board.

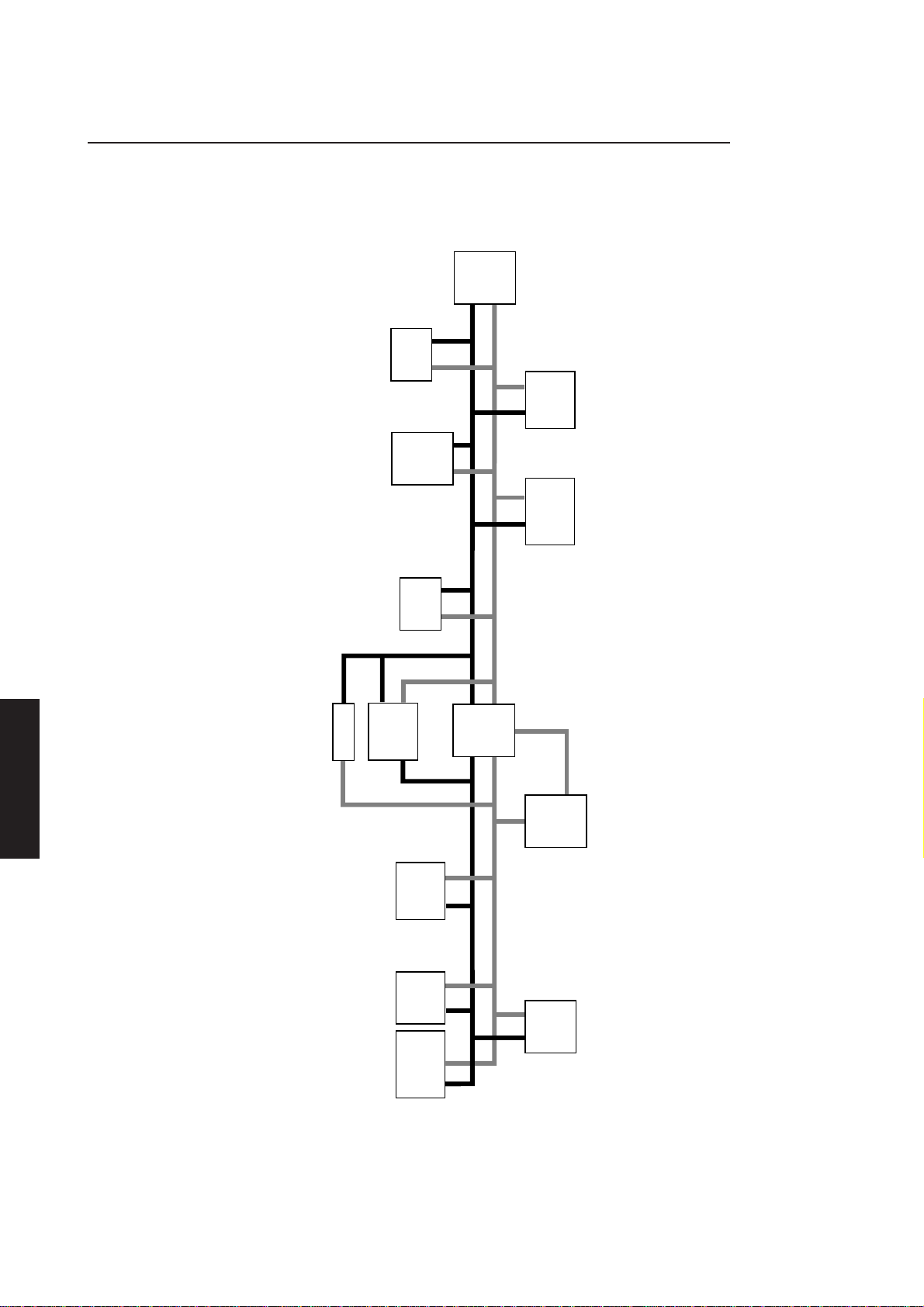

A block diagram of the system unit is shown at the end of this section. It shows the

components of the system and the functions implemented on the system board.

System board

The XEN system board is an extremely compact custom design using highly integrated

components. It utilizes carefully selected components to combine excellent performance

and reliability.

Processor The XEN can be fitted with any i486 processor with external clock speeds between

16 and 33 MHz.

Note

Contents

Chapter 2

Chapter 1

Systems equipped with the on-board Ethernet interface have a minimum clock speed of

25MHz.

A processor upgrade socket is provided on the system board. The socket can be

configured to suit a wide range of Intel processors.

Some models are fitted with a 256 Kbyte external cache to further boost performance.

Memory System memory can be expanded to a total of 64 Mbytes using two SIMM sockets on

the system board.

Ethernet interface The XEN system board may be fitted with an Ethernet interface.

An Intel 82596 Ethernet coprocessor forms the basis of this interface. The 82596 is a

high performance component which uses the processor’s local bus to maximise the

throughput of data to and from the network.

Audio The XEN system board may be fitted with the Apricot Professional Audio subsystem.

This system includes a mixer, MIDI port and joystick, and is AdLib compatible.

Security The XEN system board contains Apricot’s LOC Technology security sub-system

which, when used in conjunction with a KeyLOC card and LOC Technology software,

provides a sophisticated security system.

Chapter 3

Chapter 3

Chapter 5

XEN HARDWARE TECHNICAL REFERENCE 1/3

Chapter 6

Introduction

Power supply

Contents

Drive bays

Keyboard

Chapter 2

Chapter 1

The XEN is fitted with a 145W power supply capable of powering a fully configured

system. The power supply can be set to operate from either a 240V or 110V AC mains

supply.

Two drive bays are incorporated in the system unit.

The 3.5" bay is at the front right of the system unit. The 3.5" floppy drive is mounted

on the top of the bay. One or two 1" high, or one 1.6" high, 3.5" hard disk drives may

be mounted in the bay.

The 5.25" bay is in the centre of the system unit behind the door. This bay can hold one

standard half height 5.25" device. Apricot supplies a variety of floppy, tape and CDROM drives which may be fitted in this bay.

The keyboard is a full QWERTY typewriter keyboard and numeric keyboard together

with editing keys. The layout of the 102 key UK keyboard is compatible with the IBM

AT enhanced keyboard.

Chapter 3

Monitors

Chapter 5Chapter 6 Chapter 3

Any compatible keyboard can be plugged into the system unit.

The system board is fitted with a VGA video interface which will drive any suitable

monochrome or colour analogue monitor. Higher resolution video modes are also

supported. These require software specific display drivers and a suitable highresolution monitor.

The video output on the rear of the system unit may be connected to Apricot VGA

or HiVision monitors. Other manufacturers' VGA monitors may also be used.

1/4 XEN HARDWARE TECHNICAL REFERENCE

Expansion cards

The system unit provides three ISA expansion slots.

PARALLEL

PORT

KEYBOARD

PORT

MOUSE

PORT

MIDI

PORT

AUDIO

IN

AUDIO

OUT

EXPANSION

CARDS

SERIAL

PORT

MONITOR

THICK

TWISTED

VIDEO

PORT

PROCESSOR: MEMORY:

SYSTEM CONTROLLER:

FLOPPY AND HARD DISK

SERIAL AND PARALLEL

PORTS: AUDIO SYSTEM:

INTEGRATED PERIPHERALS

ETHERNET INTERFACE:

ETHERNET

PAIR

ETHERNET

UPGRADE SOCKET:

SECONDARY CACHE:

LOC TECHNOLOGY:

PORT

SYSTEM BOARD

INCLUDING

VIDEO ADAPTER:

CONTROLLERS:

CONTROLLER:

OPTIONS

AUDIO SYSTEM

THIN

ETHERNET

PORT

Introduction

AC

AC

INLET

OULET

POWER SUPPLY

3.5" DRIVEBAY

CASELOCK

Contents

Chapter 2

Chapter 1

Chapter 3

Chapter 3

LOUDSPEAKER

5.25" DRIVE BAY

3.5"

FLOPPY DRIVE

LOUDSPEAKER

FRONT BEZEL

MOUSE

KEYBOARD

XEN HARDWARE TECHNICAL REFERENCE 1/5

Chapter 5

Chapter 6

SYSTEM UNIT

Chapter 2

Contents

2 SYSTEM UNIT

System unit

Contents

2.1 Introduction ............................2/2

2.2 System unit description ....2/3

Construction ............................. 2/3

External layout.......................... 2/3

Internal layout ........................... 2/4

Power supply......................... 2/4

3.5" drive bay......................... 2/4

3.5" floppy drive.................... 2/4

5.25" drive tray ..................... 2/4

System board......................... 2/4

2.3 Dismantling instructions ..2/5

Servicing level............................ 2/5

Warnings and cautions............ 2/5

Anti-static precautions............ 2/5

Equipment required ................. 2/5

System board connectors.......2/6

Dismantling and reassembly... 2/7

Removing the top cover ..... 2/7

5.25" drive tray ..................... 2/8

5.25" drive.............................. 2/8

Expansion cards .................... 2/9

Backplane................................ 2/9

Card guide support............2/10

System board.......................2/10

3.5" drive bay.......................2/11

3.5" floppy drive..................2/12

3.5" hard disk drive ............2/13

Front bezel........................... 2/13

PSU ........................................ 2/14

LED board............................ 2/16

Loudspeakers.......................2/16

System unit lock..................2/17

Side panels............................2/17

2.4 Installing add-ons ...............2/18

Introduction.............................2/18

Expansion cards ......................2/18

Installation ............................2/18

Memory .................................... 2/20

Configurations.....................2/20

Installation ............................2/21

Processor upgrades ...............2/22

Installation ............................2/25

Configuring the system

board..................................... 2/26

5.25" drives ..............................2/28

Generic .................................2/28

5.25" floppy or Irwin FTD 2/30

SLCD CD-ROM..................2/30

SCSI drives ...........................2/31

3.5" hard disk drive................ 2/31

Preparation ..........................2/31

Drive configuration ............2/32

Installing the drive .............. 2/32

2.5 System unit connectors ..2/33

VGA.......................................2/33

Serial port.............................2/33

Parallel port .........................2/34

Keyboard/mouse

connectors ...........................2/34

Ethernet................................ 2/35

Audio.....................................2/36

Chapter 1

Chapter 2

Chapter 2

Chapter 3

Chapter 3

Chapter 5

XEN HARDWARE TECHNICAL REFERENCE 2/1

System unit

2.1 INTRODUCTION

ContentsChapter 1

Chapter 2

The main components of the system unit are:

• chassis

• top cover

• front bezel

• system board

• power supply

The top cover is easily removed without any tools and allows access to all major

components.

The system board contains all the processing and interface circuitry and up to 64

Mbytes of system RAM. 4 Mbytes of RAM is soldered to the system board and SIMMs

can be fitted to increase the total amount of system RAM to 64 Mbytes.

Chapter 2

Chapter 3

Chapter 5 Chapter 3

2/2 XEN HARDWARE TECHNICAL REFERENCE

2.2 SYSTEM UNIT DESCRIPTION

Construction

System unit

Contents

External layout

A metal chassis and powder coated metal top cover form the basic structure to which

other components are attached. Separate plastic front bezel and side panels attach to

the front and either side of the chassis providing the distinctive appearance of the XEN

range.

The front panel of the system unit contains: 3.5" floppy drive, door to 5.25" drive tray,

the power switch, the volume control, slots for three LEDs and the IR detector for the

KeyLOC card.

POWER

SWITCH

INFARED

SENSOR

LEDS

VOLUME

CONTROL

LOUDSPEAKER

5.25" DRIVE BAY

3.5" FLOPPY DRIVE

LOUDSPEAKER

CASELOCK

Chapter 1

Chapter 2

Chapter 2

Chapter 3

The top cover lock is on the right hand side of the system unit.

The rear panel of the system unit contains: serial and parallel ports, video port, Ethernet

connectors, blanking plates for expansion cards and AC power inlet and outlet

connectors.

EXPANSION SLOTS

THUMBSCREW

POWER

IN

POWER

OUT

SECURITY LOOP

ETHERNET

CONNECTORS

VIDEO

PORT

SERIAL

PORT

THUMBSCREW

PARALLEL

PORT

CONNECTOR

KEYBOARD

CONNECTOR

MOUSE

CONNECTORS

MIDI PORT

AUDIO

Connectors for the keyboard and mouse and the audio subsystem are on the left side

of the system unit.

Illustrations and pinouts of the connectors are given at the rear of this section.

Chapter 3

Chapter 5

XEN HARDWARE TECHNICAL REFERENCE 2/3

System unit

Internal layout

ContentsChapter 1

Chapter 2

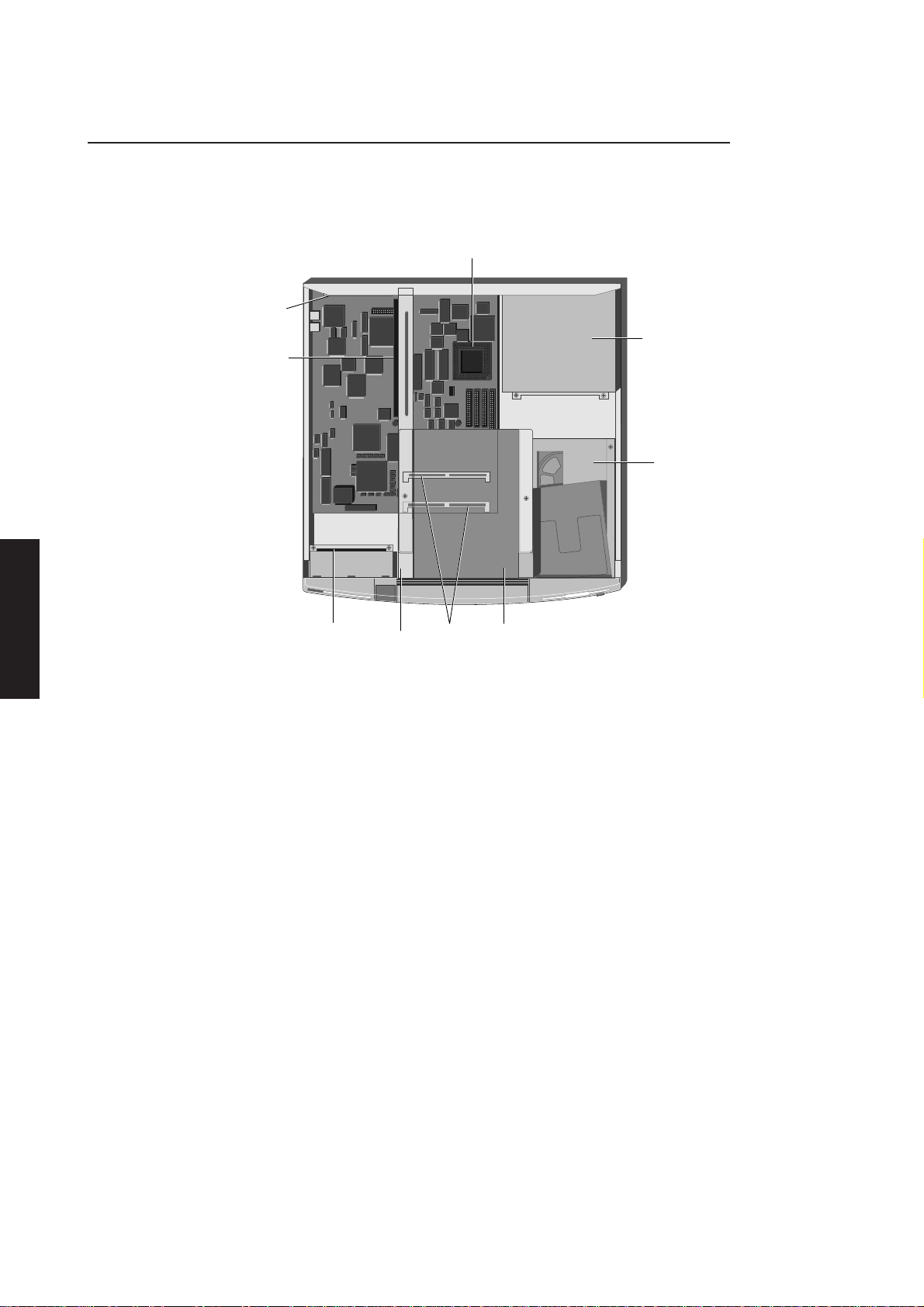

The layout of the inside of the system unit is shown in the following illustration.

PROCESSOR

UPGRADE SOCKET

BLANKING

PLATES

EXPANSION

CARD

CONNECTORS

POWER

SUPPLY

3.5"

DRIVE BAY

Chapter 2

Chapter 3

3.5" floppy drive A 3.5" floppy drive is always fitted. The drive is mounted to the top of the 3.5" drive

5.25" drive tray The 5.25" drive tray supports one half height 5.25" device.

Chapter 5 Chapter 3

CARD

GUIDES

BRACE

SIMM

SOCKETS

5.25"

DRIVE BAY

Power supply The power supply satisfies all the power requirements of the system unit. The system

unit cooling fan is incorporated in the power supply.

3.5" drive bay The 3.5" drive bay supports one or two 1" high, or one 1.6" high, 3.5" hard disk drives.

bay.

System board The system board is a high performance ISA compatible board that provides all the

processing and interface circuitry and up to 64 Mbytes of system RAM.

2/4 XEN HARDWARE TECHNICAL REFERENCE

2.3 DISMANTLING INSTRUCTIONS

Servicing level

The level of information in this section is intended to enable suitably qualified personnel

to remove and replace major components of the system unit, and access components

for option selection.

Warnings and cautions

The XEN range has been designed to meet all international safety standards.

To ensure safety and continued compliance with these standards, observe the following

precautions.

• It is recommended that modifications are carried out by an authorized dealer.

Unqualified users should not normally dismantle the equipment.

• Replacement parts should be of the type and rating specified by the manufacturer.

• All earth connections must be maintained to the original specification.

System unit

Contents

Chapter 1

Chapter 2

• Ensure that all personnel concerned are familiar with the action to be taken in

the event of electric shock.

Warning

Before removing any part of the system it must be powered down and disconnected from the

AC power supply.

Anti-static precautions

All electronic components and equipments are sensitive to static electricity. Even small

electrostatic discharges can render components useless or severely shorten their

working life, therefore preventive measures should always be taken.

No work should be carried out on any item unless it is in a Special Handling Area (SHA)

as defined in BS CECC 00015:Part 1. In general this involves:

• a common earth point

• an earthed bench or bench mat

• an earthed wrist strap

Equipment required

Chapter 2

Chapter 3

Chapter 3

Chapter 5

The following tools are required to dismantle the system unit.

• Cross-head screwdriver

• Flat bladed screwdriver

• Nut spanner set

• Pliers

XEN HARDWARE TECHNICAL REFERENCE 2/5

System unit

System board connectors

ContentsChapter 1

Chapter 2

Many of the dismantling/reassembly procedures that follow involve the disconnection

and reconnection of system board plugs and sockets. The following table gives, for each

socket, the connector number that identifies it. This number is printed on the system

board next to each connector.

Connector Label

Hard disk drive PL43

3.5" floppy disk drive PL40

5.25" floppy disk drive PL38

SLC CD-ROM PL36

System board power PL30

LED board PL16

CD-ROM audio PL4

Video disable jumper PL50

VESA PL21

ISA backplane PL31

CMOS discharge PL29

Chapter 2

Chapter 3

Chapter 5 Chapter 3

PL4

PL21

PL31

PL50

PL30

SW4

PL43

PL40

PL38

PL36

PL16

2/6 XEN HARDWARE TECHNICAL REFERENCE

SW1

PL29

Dismantling and reassembly

Removing the 1. Turn off both the system unit and the monitor.

top cover

2. If your AC power outlets have switches, set them to their Off positions.

3. Unplug all power cords from the rear of the system unit.

4. Turn the caselock key to the unlocked position.

5. Loosen the two casing screws.

6. Slide the top cover rearwards slightly, then lift it off.

CASELOCK

System unit

Contents

Chapter 1

Chapter 2

CASING SCREW

CASING SCREW

Take effective anti-static precautions while the top cover is off.

Refitting the cover is the reverse of removal.

Note

Four spring metal clips are fitted to the rear panel of the system unit and six to the front of

the top cover. They ensure good contact between the chassis and the cover and are necessary

for compliance with international RFI emission standards. If any of the clips is damaged during

removal or replacement of the top cover the system may no longer comply with these

regulations.

Chapter 2

Chapter 3

Chapter 3

Chapter 5

XEN HARDWARE TECHNICAL REFERENCE 2/7

System unit

ContentsChapter 1

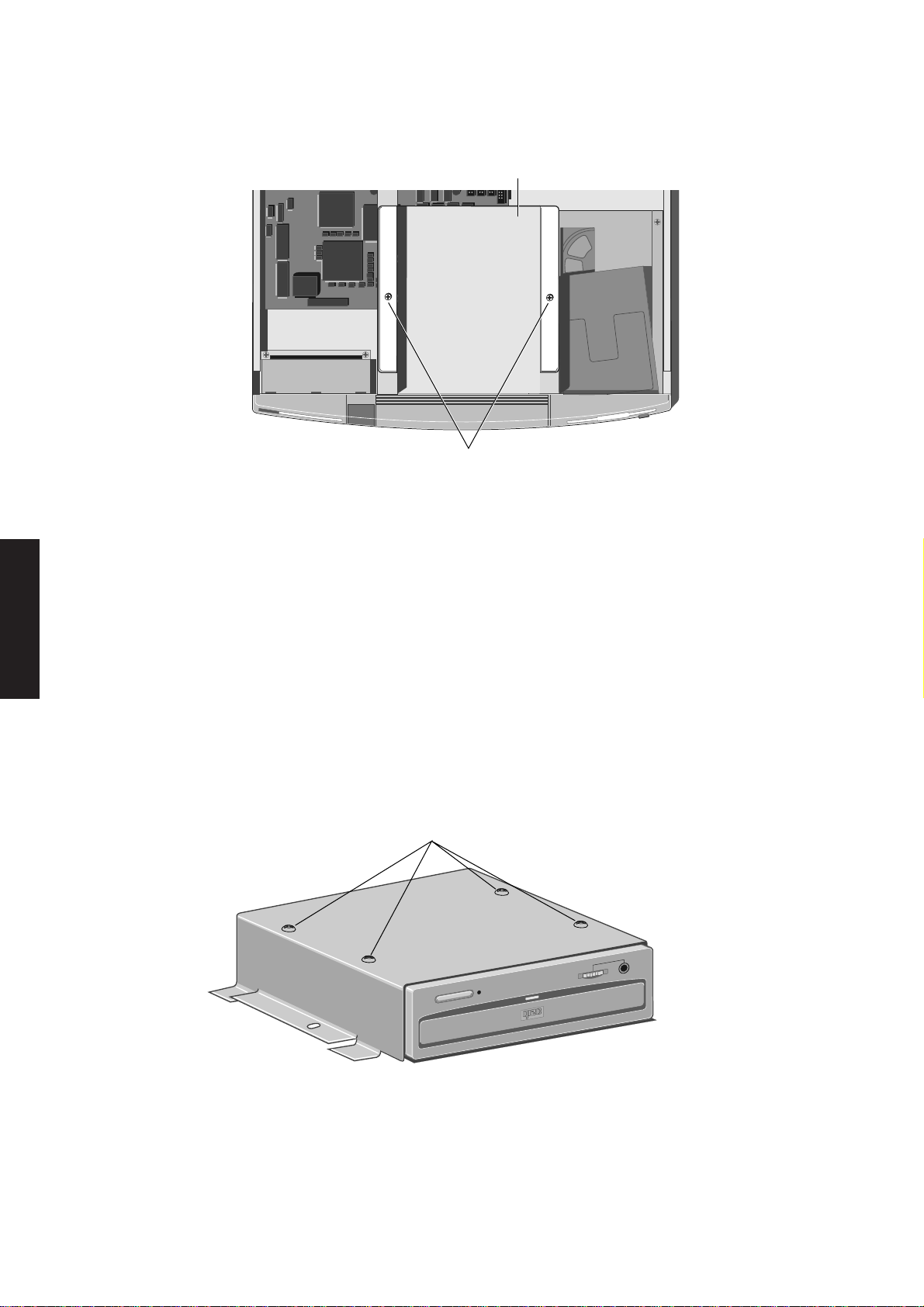

5.25" 1. Remove the system unit top cover and identify the 5.25" drive tray from the

drive tray following illustration.

5.25" BAY

SECURING SCREWS

2. If a drive is fitted, disconnect the power and signal cables from the drive.

Chapter 2

Chapter 2

Chapter 3

Note

Some systems without a 5.25" drive may have the unused drive power cable secured to

the tray with a cable clip.

3. Remove the two screws that secure the drive tray.

4. Slide the tray backwards to clear the front of the system unit.

5. Lift the tray out of the system unit.

Replacement is simply the reverse of removal.

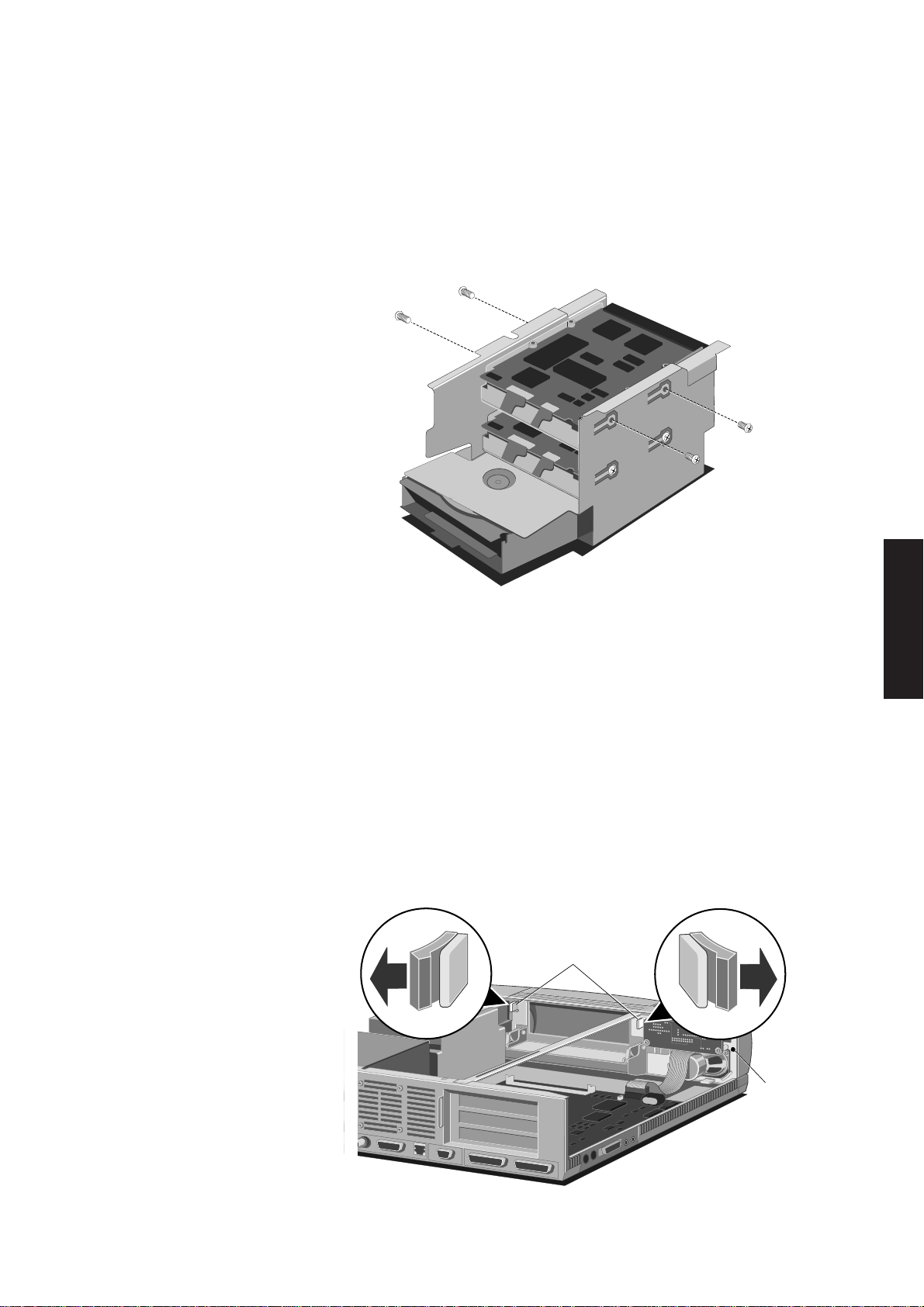

5.25" drive 1. Remove the 5.25" drive tray.

2. Turn the tray upside down and rest it on a flat surface.

SECURING SCREWS

Chapter 5 Chapter 3

2/8 XEN HARDWARE TECHNICAL REFERENCE

COMPACT

3. From the illustration above, identify the four screws which secure the drive and

remove them.

4. The tray can now be lifted clear.

Replacement is simply the reverse of removal.

System unit

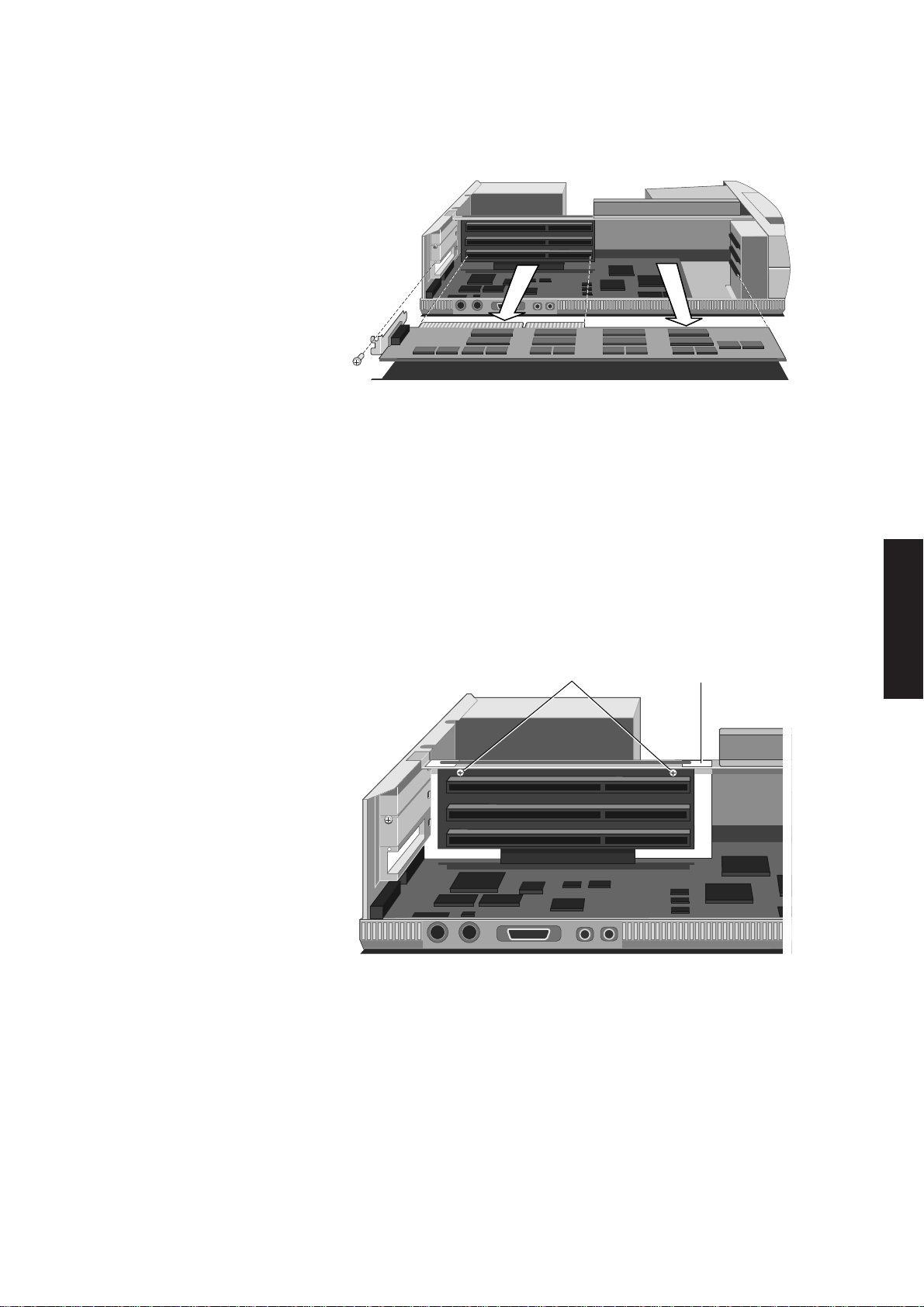

Expansion cards 1. Remove the system unit top cover and identify the expansion card area from the

following illustration.

2. Identify the card you wish to remove, and disconnect all cables from it.

3. Remove the screw which secures the rear of the card to the system unit.

4. Pull the card horizontally out of the slot.

Contents

Chapter 1

Chapter 2

Replacement is simply the reverse of removal. A fuller description of installing

expansion cards is given in Installing add-ons later in this section.

Backplane 1. Remove all expansion cards.

2. Unclip the white plastic air baffle from the system unit brace and remove the baffle.

SECURING SCREWS

AIR BAFFLE

Chapter 2

Chapter 3

Chapter 3

Chapter 5

3. Identify and remove the two screws that secure the backplane to the system unit

brace.

4. Align the backplane with the slot in the brace and lift the backplane out of its

connector.

5. Tilt the bottom of the backplane to the left and lower it down through the brace.

With the bottom of the backplane to the left of the connector on the system board

the backplane can be lowered far enough to be removed.

Replacing the backplane is simply the reverse of removal.

XEN HARDWARE TECHNICAL REFERENCE 2/9

System unit

Card guide The card guide support at the front of the expansion card slots is secured to the base

support of the system unit by two screws. To remove the card guide support:

ContentsChapter 1

Chapter 2

1. Remove all expansion cards.

2. Remove the screw (or screws) that secure the card guide support to the base of

the system unit.

SECURING SCREWS

3. Lift the card guide support to free it from the locating lug at the front left of the

system unit and remove it from the system unit.

Replacement is simply the reverse of removal.

Chapter 2

Chapter 3

Chapter 5 Chapter 3

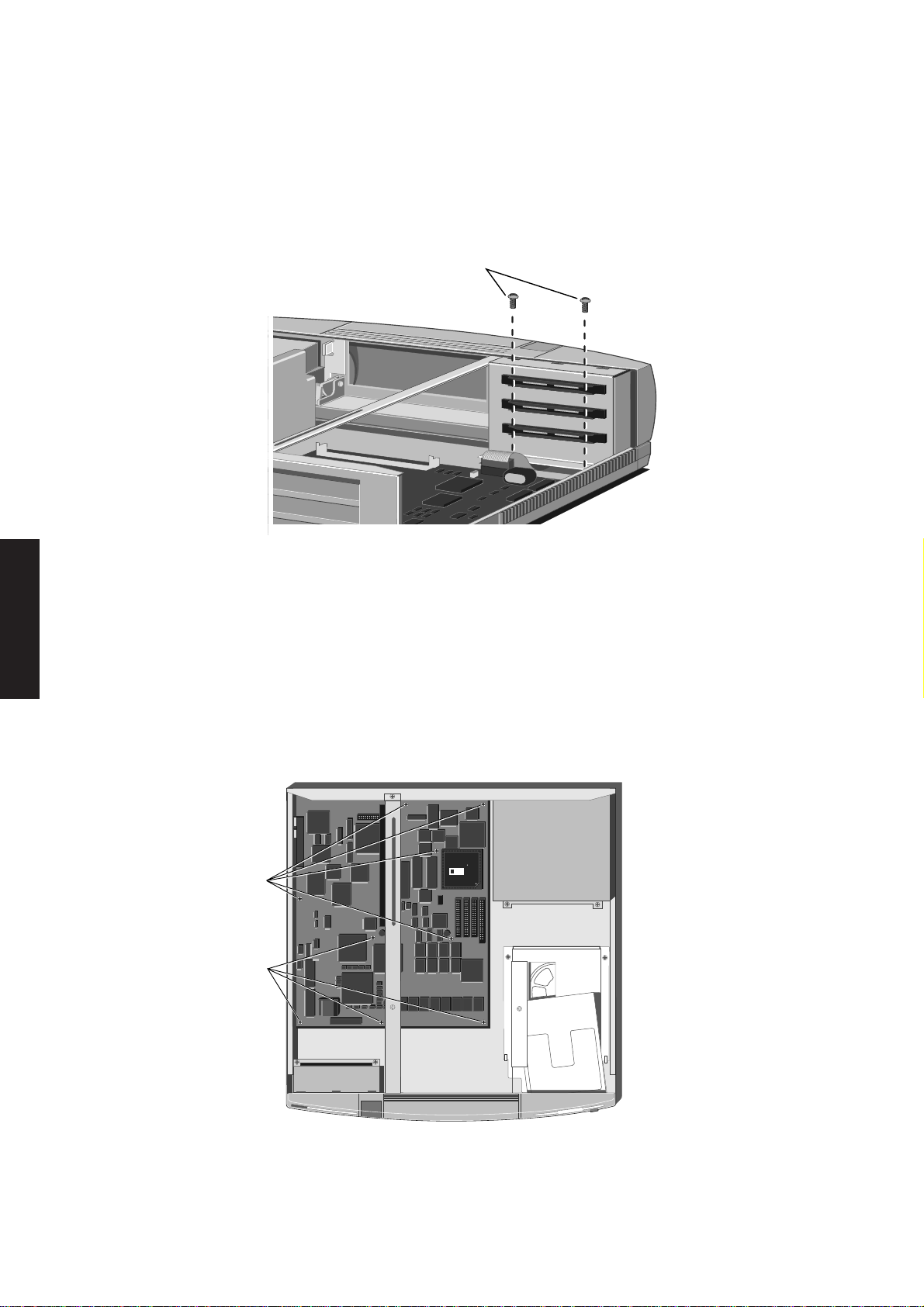

System board 1. In order to remove the system board you must first remove the: 5.25" drive tray,

expansion cards and backplane.

2. Disconnect all system board cables.

3. Remove the nine screws that secure the system board.

int l

e

TM

DX

486

SECURING

SCREWS

SECURING

SCREWS

i

4. Remove the screwlocks on the ports on the rear of the system unit.

2/10 XEN HARDWARE TECHNICAL REFERENCE

System unit

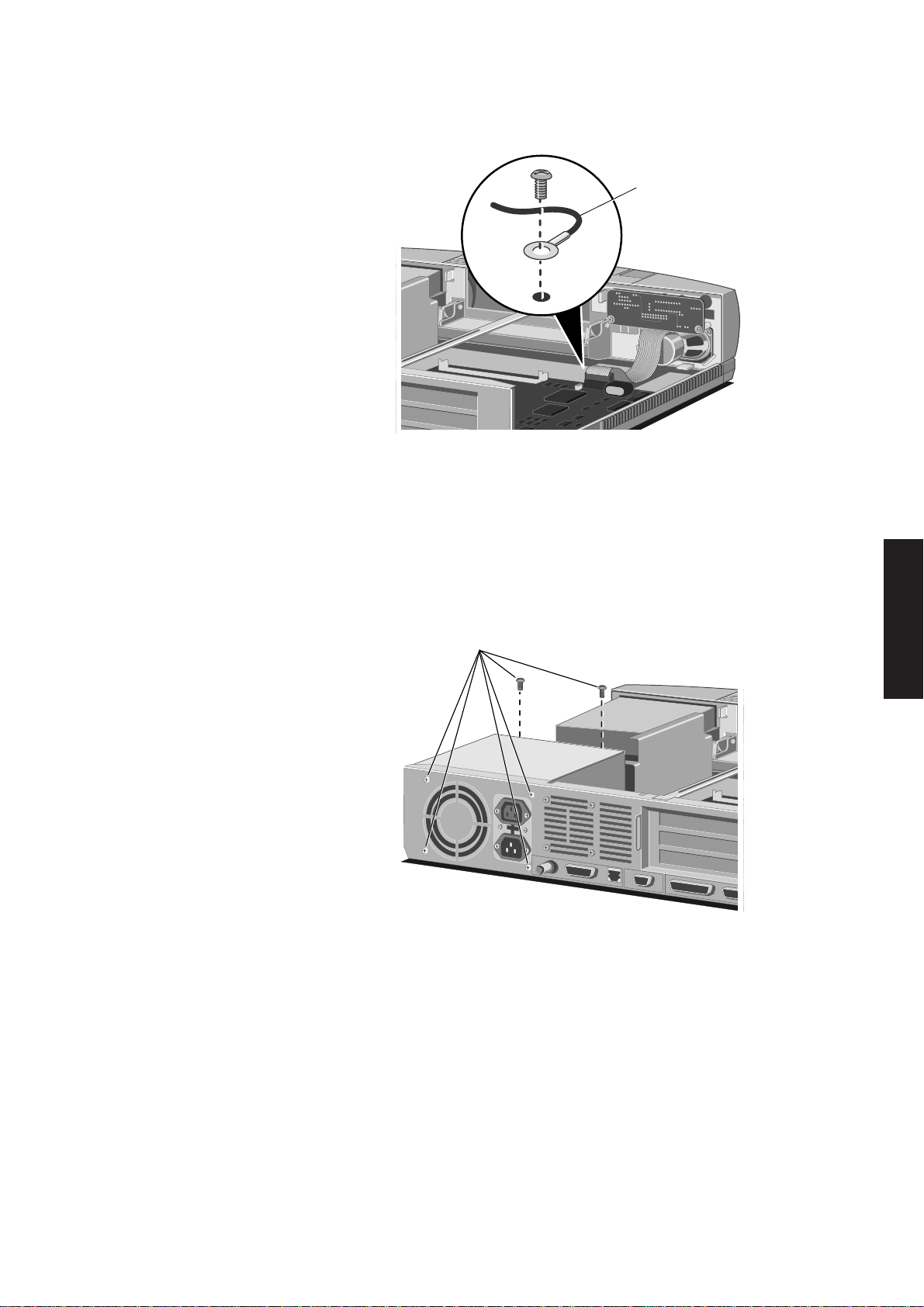

5. If the system board is equipped with on-board Ethernet:

remove the two screws that secure the thick Ethernet connector slidelock, and

remove the slidelock

Contents

remove the nut that secures the thin Ethernet connector.

6. If the system board is fitted with Apricot Professional Audio remove the screwlocks

on the MIDI connector on the left side of the system unit.

7. The system board can now be removed. In order for the connectors on the rear

left edges of the board to clear the chassis the board must move forward and right.

To remove the system board, carefully hold the front corners of the board between

thumb and forefinger, taking care to avoid touching any components. Then gently

move the front of the board to the right towards the 3.5" drive bay, and pull the

board towards the front of the system unit.

8. Once the connectors are clear of the chassis carefully pick the board up by its edges

and move it sideways out of the chassis.

9. Put the system board down on a suitable antistatic surface.

Replacing the system board is simply the reverse of removal. Care should be taken

when replacing the board in the system unit, do not force the board into position, it

should move into position easily. If it does not, remove the board and try again.

Note

If the system board being inserted is a replacement make sure that the audio escutcheon plate

is fitted to the new board before you install it. The plate is secured by a screw and nut at the

left rear corner of the board, the screw must be inserted from beneath the board.

Chapter 1

Chapter 2

Chapter 2

Chapter 3

Chapter 3

3.5" drive bay The 3.5" drive bay is secured to the base of the system unit by two screws and two lugs. To remove the bay:

int l

e

TM

DX

486

i

SECURING

SCREWS

Chapter 5

XEN HARDWARE TECHNICAL REFERENCE 2/11

System unit

1. Remove the top cover and the 5.25" drive tray.

2. Disconnect the power cables from any hard disk drives in the 3.5" drive bay.

ContentsChapter 1

3.5" floppy drive The 3.5" floppy drive is secured to the top of the 3.5" drive bay by three screws. To

Chapter 2

3. Disconnect the drive signal cables at the system board.

4. Identify and remove the two screws that secure the drive bay.

5. Slide the drive bay backwards to free it from the lugs in the base of the system unit.

6. Lift the drive bay out of the system unit and place it on a suitable antistatic surface.

Replacement is simply the reverse of removal, however you must make sure that the

3.5" floppy drive signal cable is connected to the correct connector on the system

board, refer to the label on the inside of the top cover.

remove the floppy drive:

1. Remove the 3.5" drive bay.

2. Carefully place the bay upside down on a suitable antistatic surface.

SECURING SCREWS

Chapter 2

Chapter 3

Chapter 5 Chapter 3

3. Remove the three screws that secure the 3.5" floppy drive.

4. Lift the drive bay off the floppy drive.

Replacement is simply the reverse of removal. If the drive being installed is a

replacement you must ensure that the drive select switch is in the same position as the

old drive.

Warning

Make sure you use screws of the correct length. If you use longer screws you may do irreparable

damage to the drive.

2/12 XEN HARDWARE TECHNICAL REFERENCE

System unit

CLIPS

SCREW

3.5" hard disk The 3.5" hard disk drives are secured to the 3.5" drive bay by four screws, two in each

drive side. To remove a hard disk drive:

1. Remove the 3.5" drive bay.

Contents

2. Carefully place the bay upside down on a suitable antistatic surface.

3. Remove the four screws that secure the drive.

4. Slide the drive out of the bay.

Replacement is simply the reverse of removal. If the drive being installed is a

replacement you must ensure that the jumpers on the drive are correctly configured.

Chapter 1

Chapter 2

Chapter 2

Chapter 3

Front bezel Two variants of the front bezel have been used in the XEN range. Initial shipments were

with a bezel which was secured by clips and double-sided tape, later units use a bezel

secured by clips and two screws. To remove the front bezel:

1. Remove the top cover and any expansion cards.

2. Identify the clips, and whether the bezel is secured by screws. The clips and screws

are located inside the system unit. The clips are on either side of the 5.25" drive tray

and the screws are at either end of the front panel.

Chapter 3

Chapter 5

XEN HARDWARE TECHNICAL REFERENCE 2/13

System unit

ContentsChapter 1

Chapter 2

3. If the bezel is secured by screws, remove the screws.

4. Using a flat-bladed screwdriver, free each of the clips in turn, and ease the top of

the bezel away from the system unit until there is a gap wide enough to get your

thumb and forefinger between the bezel and the front of the system unit.

On systems where the bezel is secured using double sided tape applying pressure

with your thumbs to either end of the top edge of the bezel will help free the bezel

from the tape. The tape will remain on the top of the front of the system unit chassis.

Chapter 2

Chapter 3

Chapter 5 Chapter 3

5. The volume control switch on the left side of the bezel is connected, by a membrane

cable, to an LED board inside the front of the system unit. Identify the cable, then

reach between the bezel and the system unit and carefully disconnect it from the

system unit.

6. Rotate the bezel forward to an angle of approximately 45° to free the two clips at

the bottom of the bezel from the system unit, and lift the bezel away.

Replacing the front bezel is simply the reverse of removal, but you must be very careful

when reconnecting the volume control switch cable and rotating the bezel back into

position.

Make sure that the volume control switch connector is correctly plugged in to the LED

board. As you rotate the bezel back into position ensure that the cable passes through

the slot in the rear of bezel, and does not get trapped between the bezel and the front

of the system unit.

PSU The XEN power supply is secured by four screws in the rear of the system unit and

two inside the system unit.

1. To remove the power supply you must first remove the 5.25" drive tray, the card

guide support and the front bezel.

2/14 XEN HARDWARE TECHNICAL REFERENCE

System unit

SECURING SCREWS

2. Remove the screw that secures the earth lead to the system unit base.

EARTH LEAD

3. Remove the two screws that secure the system unit power switch to the front of

the system unit.

4. Remove the switch, and free the cable from the channel behind the 5.25" drive bay

aperture.

Contents

Chapter 1

Chapter 2

Chapter 2

Chapter 3

5. Disconnect the system board and hard disk drive power cables.

6. Remove the six screws that secure the power supply.

7. Remove the power supply.

Replacement is simply the reverse of removal. If the PSU you are installing is a

replacement and the old PSU on/off switch is fitted with a plastic case, you may have

to remove the plastic case from the old on/off switch and attach it to the new switch.

Chapter 3

Chapter 5

Warning

You must remember to reconnect the PSU earth lead to the chassis.

Ensure that the system meets the following electrical safety tests:

Earth bond resistance <0.1ohm excluding mains lead resistance

Earth leakage current <3.5mA total

Insulation resistance >2Mohms @ 500Vdc

Dielectric strength 2.2kV for 6 seconds

XEN HARDWARE TECHNICAL REFERENCE 2/15

System unit

LED board The LED board is secured to the front of the chassis by two screws. To remove the

LED board:

ContentsChapter 1

Chapter 2

1. To remove the power supply you must first remove the 5.25" drive tray and the

card guide support.

2. Remove the two screws that secure the LED board.

SECURING SCREWS

3. Carefully move the LED board backwards taking care not to knock any of the LEDs

against the chassis.

4. Disconnect the loudspeaker cables and the cable to the system board.

Chapter 2

Chapter 3

Chapter 5 Chapter 3

5. Lift the LED board out of the system unit.

Replacement is simply the reverse of removal. Text on the rear of the LED board,

behind the loudspeaker connectors, indicates which loudspeaker should be plugged

into each connector. Systems with one loudspeaker use the left channel as viewed

from the front.

Loudspeakers The XEN system unit provides mountings for two loudspeakers, one at each end of the

front of the system unit. The left loudspeaker is mounted in front of the card guide

support, the right one in front of the 3.5" drive bay. To remove the loudspeakers:

1. Remove the 3.5" drive bay and the card guide support.

2. Disconnect the loudspeaker cables from the LED board.

SECURING SCREWS

2/16 XEN HARDWARE TECHNICAL REFERENCE

System unit

3. Remove the screw (or screws) that secure the top of each loudspeaker.

4. Lift the loudspeakers out of the system unit.

Replacement is simply the reverse of removal. Text on the rear of the LED board,

behind the loudspeaker connectors, indicates which loudspeaker should be plugged

into each connector. Systems with one loudspeaker use the left channel as viewed

from the front.

System unit lock The system unit lock is secured by a clip. To remove the lock simply pull the clip up

with a pair of pliers.

Contents

Chapter 1

Chapter 2

Side panels The plastic panels along the bottom of each side of the system unit are not intended

to be removed. Under normal circumstances there should be no reason to remove

them.

The panels are each secured by four clips and can be removed by pushing the front of

the four clips outwards with a small screwdriver and sliding the panel backwards. In

order to remove the right panel you must first remove the system unit lock.

Chapter 2

Chapter 3

Chapter 3

Chapter 5

XEN HARDWARE TECHNICAL REFERENCE 2/17

System unit

2.4 INSTALLING ADD-ONS

Introduction

ContentsChapter 1

Expansion cards

This section contains instructions on installing add-ons and upgrades in the XEN range.

The areas covered include:

• expansion cards

• additional memory

• processor upgrades

• additional drives

While you are installing add-ons you must take effective anti-static precautions as

described earlier in this section.

Chapter 2

Chapter 2

Chapter 3

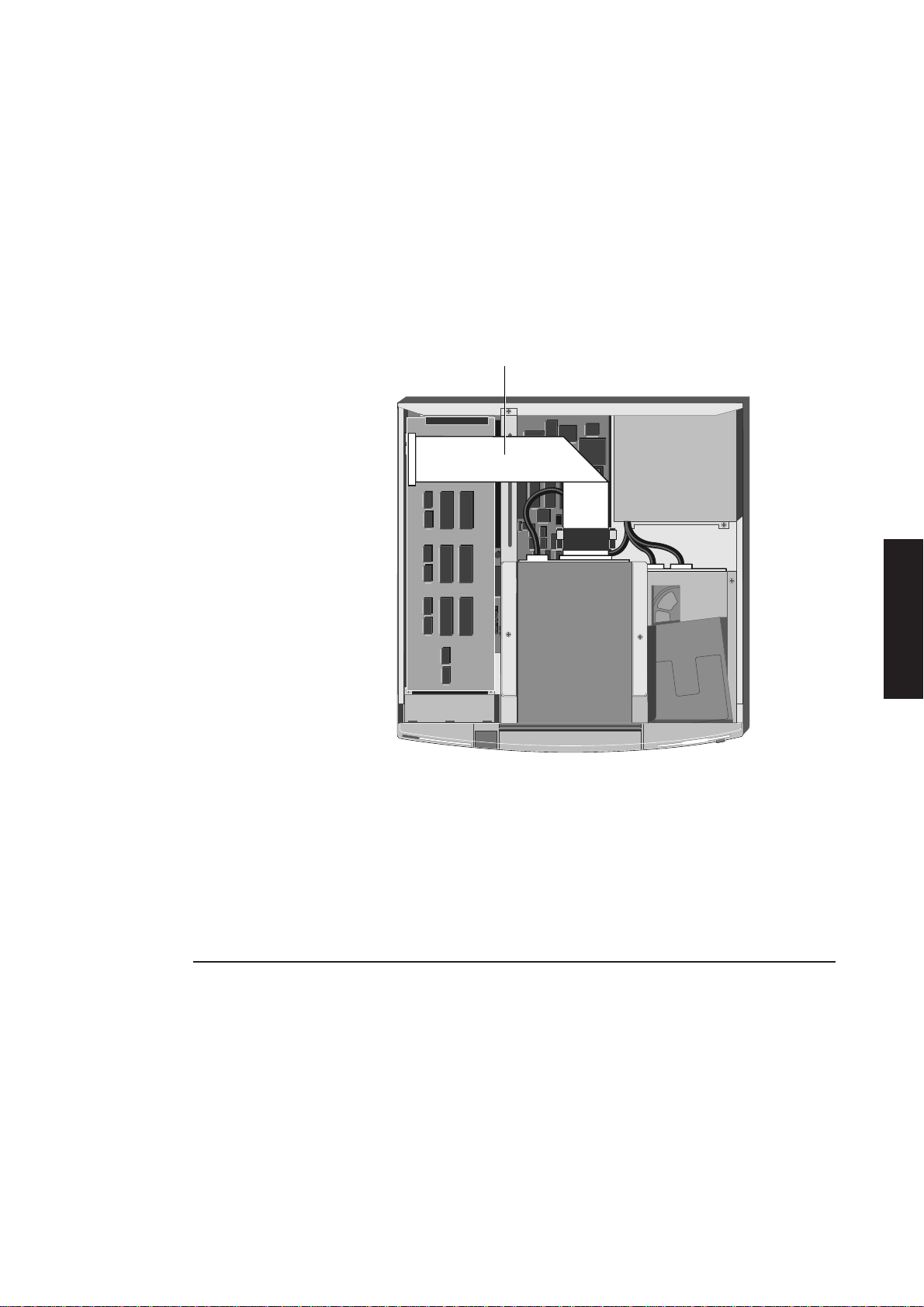

Installation The XEN provides three slots for the installation of ISA compatible expansion cards.

Installation of an expansion card in the XEN is a simple process requiring the removal

of only the system unit cover and a blanking plate. The following instructions and

illustrations describe how to install a card.

1. Remove the system unit cover.

2. With the system unit cover removed, the space for expansion cards will be visible.

It is on the left side of the system unit behind the activity indicators and the volume

control. Use the illustration below to help you identify this area.

PROCESSOR

UPGRADE SOCKET

BLANKING

PLATES

EXPANSION

CARD

CONNECTORS

POWER

SUPPLY

Chapter 5 Chapter 3

2/18 XEN HARDWARE TECHNICAL REFERENCE

CARD

GUIDES

BRACE

SIMM

SOCKETS

5.25"

DRIVE BAY

3.5"

DRIVE BAY

System unit

At the rear of the area are three metal blanking plates, one for each expansion card

slot. These plates cover slots in the rear of the system unit which will be used by

expansion cards.

At the front of the area are three guides. These ensure that the front edge of any

full length card is secured.

3. The blanking plates are each secured by a screw. Decide which of the available slots

you wish to install the card in, then remove the appropriate blanking plate.

In general it is easiest to start with the lowest slot and work towards the top, but

there a couple of exceptions. If you are installing a card which uses the video feature

connector on the system board then it is best to install the card in the lowest slot.

If you are installing a drive controller card that you want to connect to a drive in

the 5.25" drive tray then it is easiest to install it in the top slot.

Warning

The video feature connector on the Revision D XEN system board uses a non-standard

pinout. In order to use this connector you need to make up a special cable.

Contents

Chapter 1

Chapter 2

Information on identifying the revision of the system board, and a pin out of the

video feature connector are given in Appendix B.

To remove the blanking plate, first unscrew the securing screw, then slide the plate

out of its slot. Keep the screw, you will use it later to secure the card.

4. Before you install the card ensure that the card is correctly configured for your

system. Refer to appendix D for configuration information.

5. Position the expansion card alongside the slot in which you wish to install it. Align

the rear of the card with the slot in the rear of the system unit, and, if the card is

full length, the front of the card with the card guide.

Note

If the card uses the video feature connector on the system board, you must plug the video

feature cable into the system board socket before you install the card.

Chapter 2

Chapter 3

Chapter 3

Chapter 5

6. Slide the card into the slot ensuring that the card edge connector engages correctly

with the backplane.

XEN HARDWARE TECHNICAL REFERENCE 2/19

System unit

ContentsChapter 1

7. Carefully push the card fully home. Do not apply excessive pressure.

8. Secure the card by replacing the screw that you removed in step 4.

9. Connect any signal cables to the card.

Note

If you have installed a video display adapter that is CGA, EGA or VGA compatible you must

disable the system board video adapter by removing a jumper. If you do not remove this

jumper it is unlikely that either the video card or system board video adapter will operate

correctly.

The jumper is identified in the illustration on page 2/6. If you have a revision D

system board there is no video disable jumper. Refer to Appendix B for further

information.

10.Replace the system unit cover.

Chapter 2

Chapter 2

Chapter 3

Memory

Chapter 5 Chapter 3

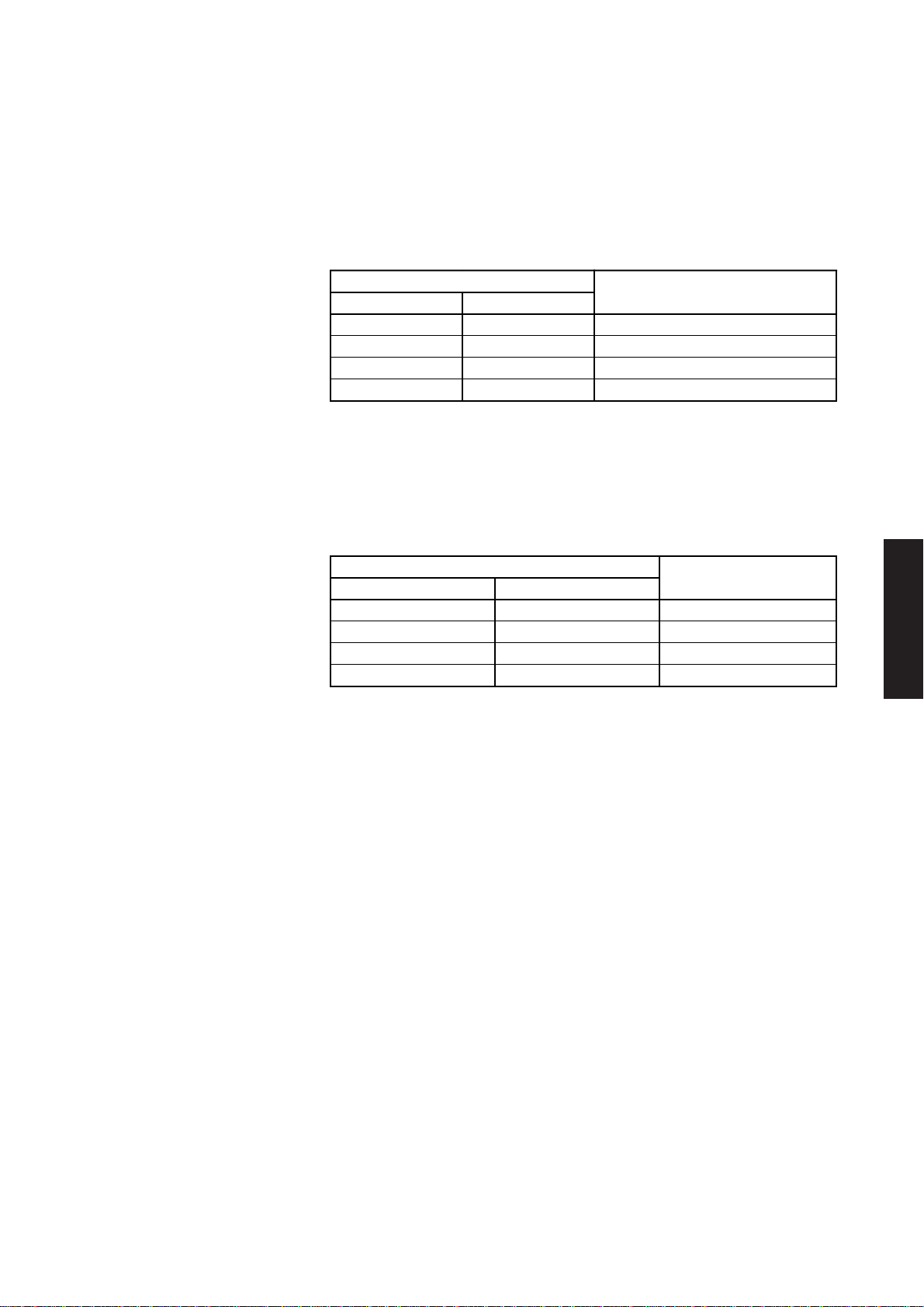

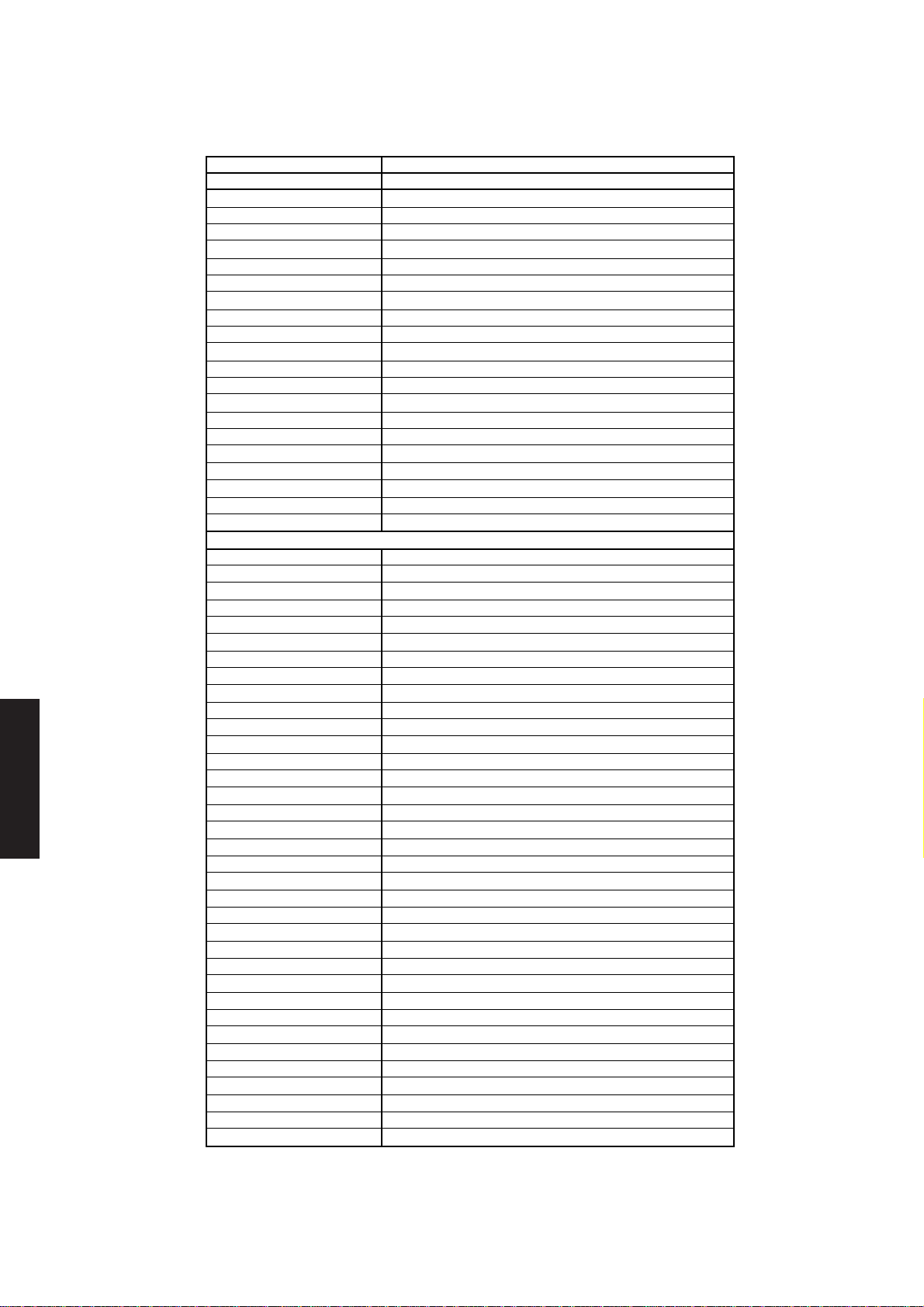

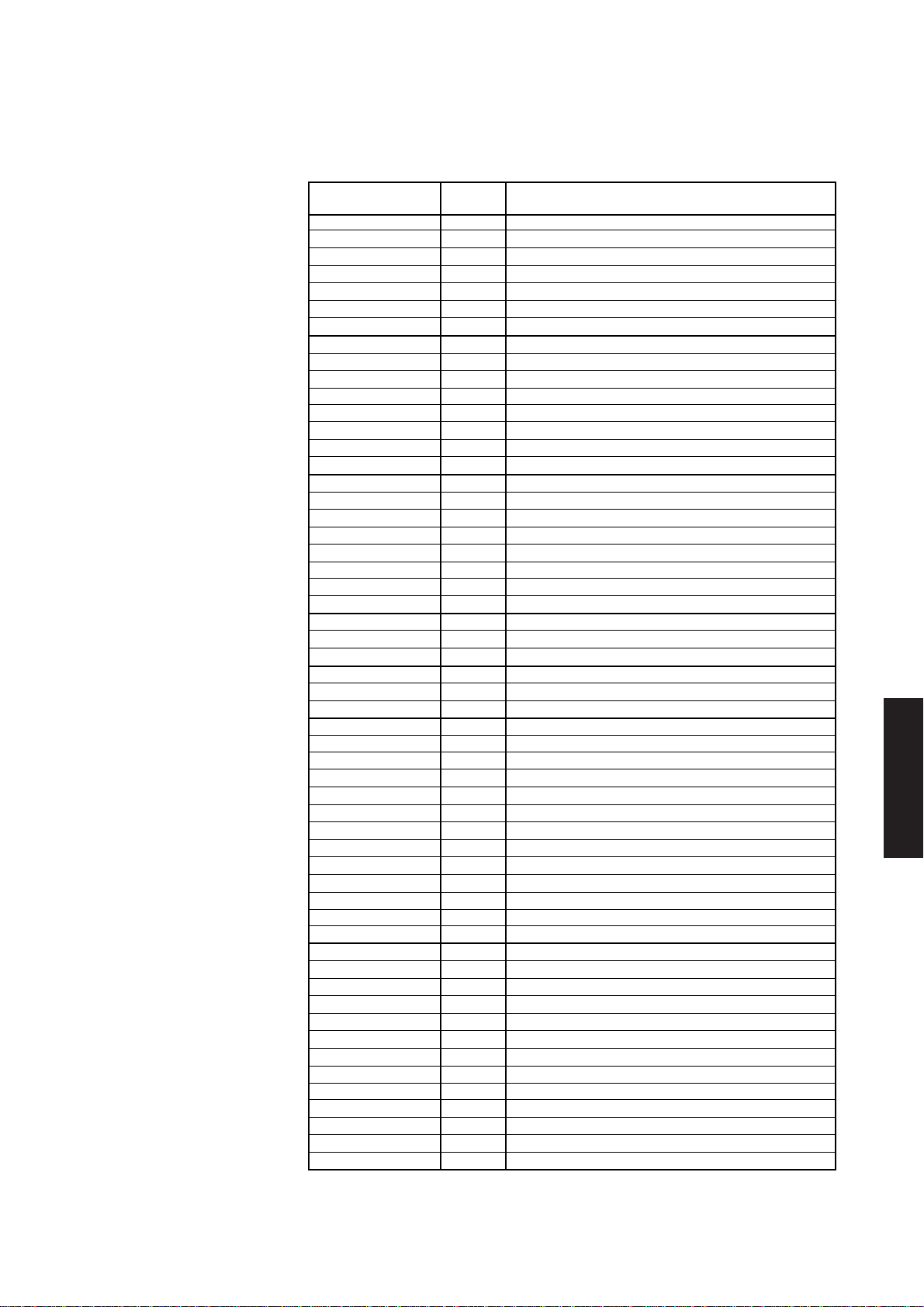

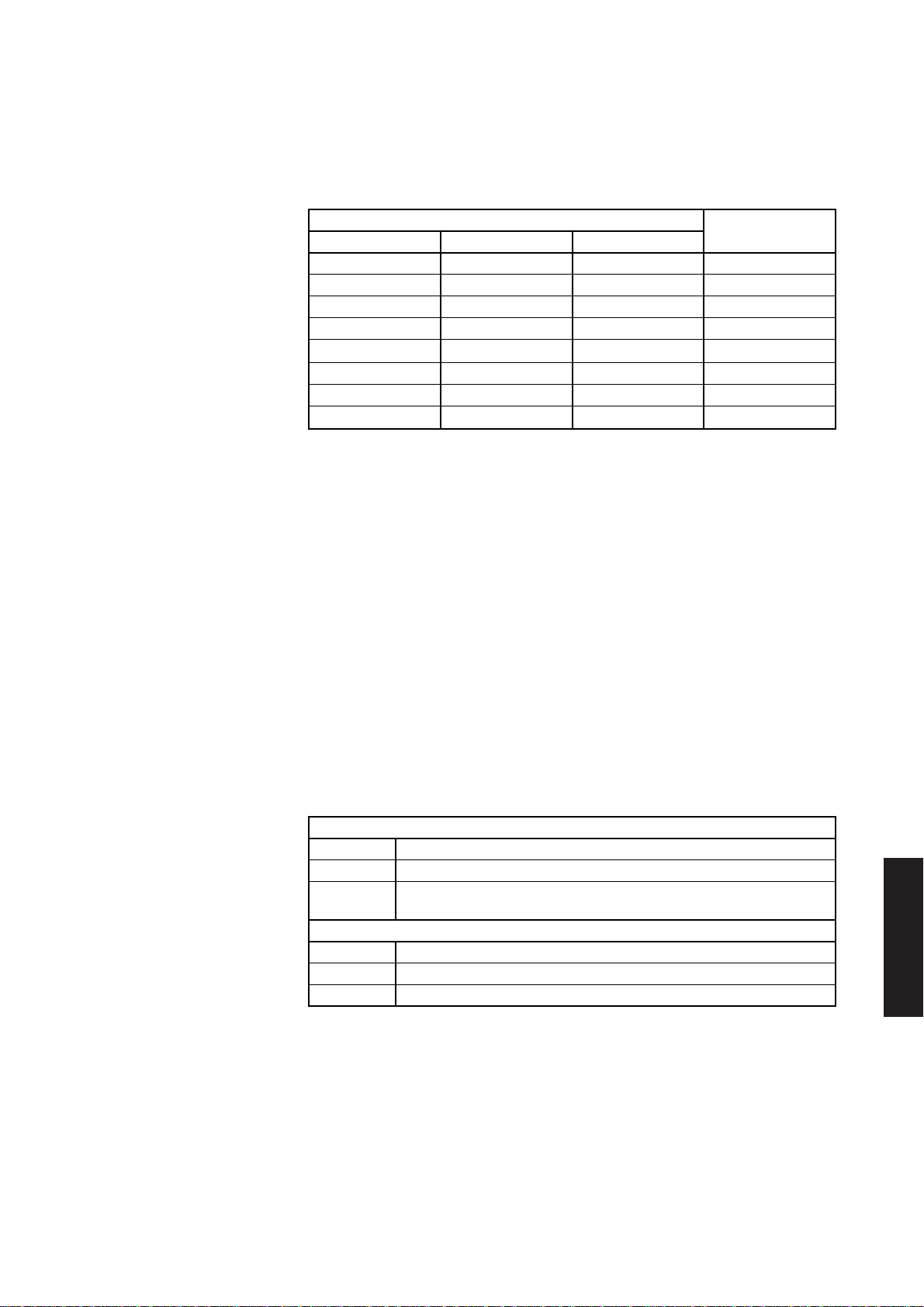

Configurations The XEN system board is fitted with 4 Mbytes of on-board memory, and sockets for

two SIMMs (Single In-line Memory Modules). Each socket can be empty, or fitted with

a SIMM of 4Mbyte (1Mx36), 8Mbyte (2Mx36), 16Mbyte (4Mx36) or 32Mbyte capacity.

The table below identifies the possible memory capacities using the various SIMM

combinations.

MM1

capacity

- - - 4 4

4 - 4 4 8

8 - 8 4 12

16 - 16 4 20

32 - 32 4 36

4 4 8 4 12

4 8 12 4 16

4 16 20 4 24

8 8 16 4 20

8 16 24 4 28

16 16 32 4 36

32 4 36 4 40

32 8 40 4 44

32 16 48 4 52

32 32 64 4 64

MM2

capacity

Upgrade

capacity

System

board

memory

Available

memory

Note

When a 32Mbyte SIMM is installed in MM2 the system board memory is disabled.

It should be noted that, for all combinations the SIMM in MM1 can be swapped with

that in MM2. In every case the computer will operate correctly when it is powered up,

and in most cases there will be no difference in the operation of the computer.

2/20 XEN HARDWARE TECHNICAL REFERENCE

System unit

There are only two exceptions to this. In the two situations given below, although the

computer will operate if the SIMMs are swapped it is preferable if the SIMMS are

installed as described.

• If you are upgrading to 24 Mbytes of system memory, i.e. you have one 4 and one

16 Mbyte SIMM, the 4 Mbyte SIMM should always be installed in MM1.

• If you are installing a 32Mbyte SIMM it should always go in MM1 unless there is

a 32Mbyte SIMM in the socket already.

If in either of the cases above you install a 4 or 32 Mbyte in MM2 when you power the

system up you will be prompted to swap the SIMMs.

Contents

Chapter 1

Installation In order to install a memory upgrade you must remove the system unit cover and the

5.25" drive tray.

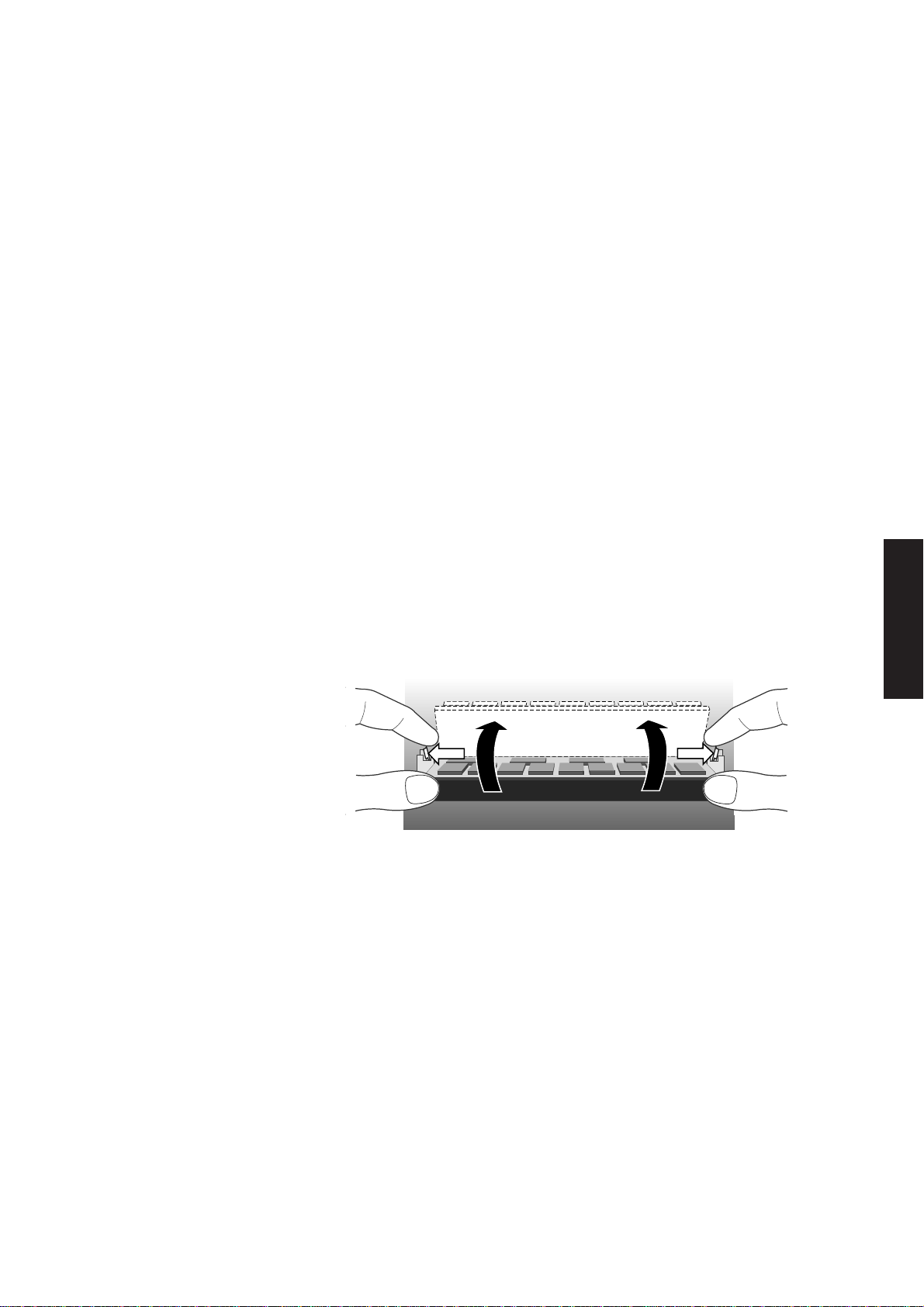

Removing a SIMM

If you wish to install an upgrade in a SIMM socket which is already occupied you must

first remove the existing SIMM.

1.Lever the metal clips on each side of the socket gently away from the SIMM using

your forefingers.

2.Place your thumbs on the top edge of the SIMM and move it gently towards the

vertical.

Chapter 2

Chapter 2

Chapter 3

Chapter 3

3.When the SIMM has rotated through 20°, taking care to avoid touching any of the

components on the SIMM, grip the top corners of the SIMM between thumb and

first finger and carefully pull the SIMM out of the socket.

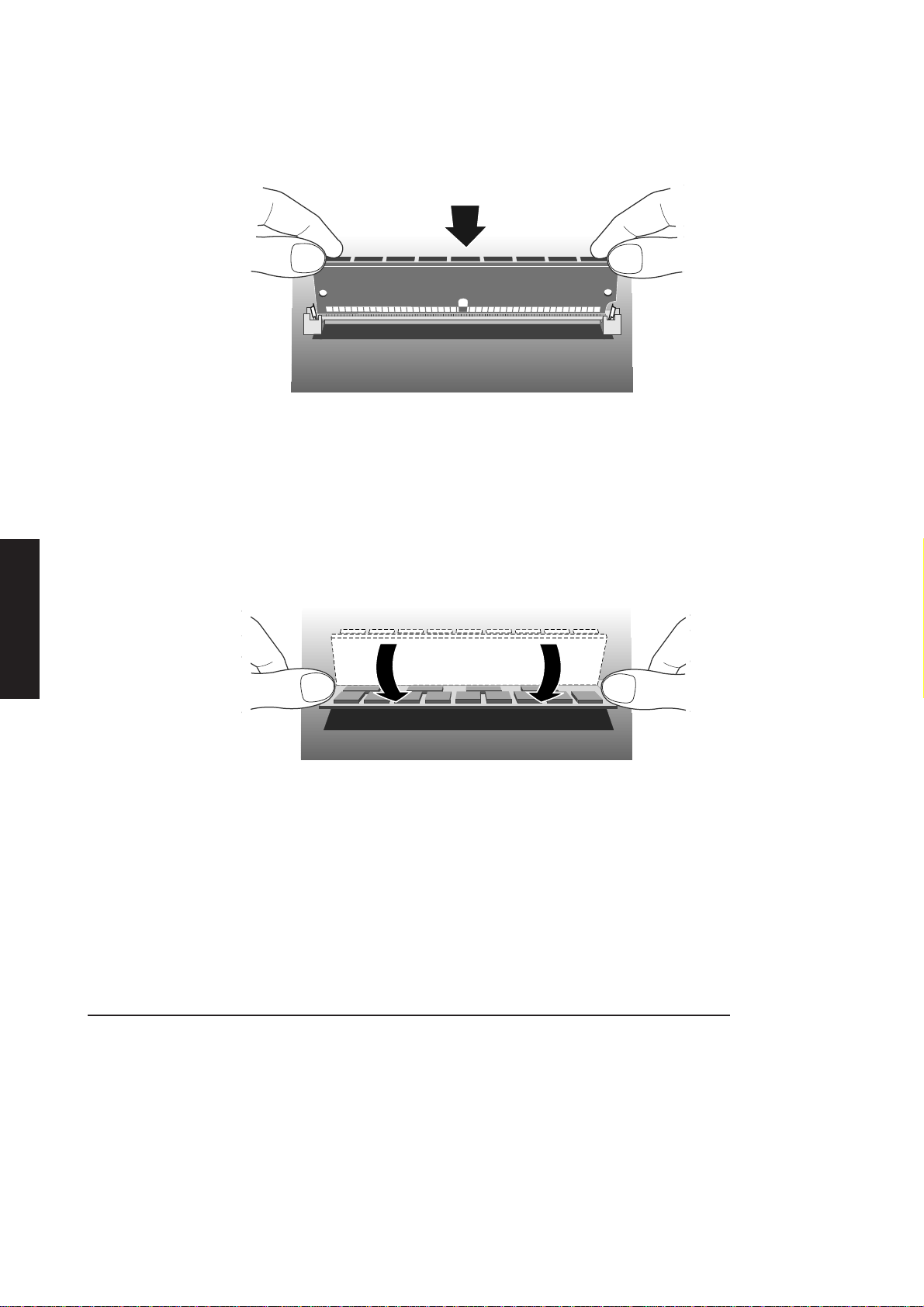

Inserting a SIMM

From the table of possible SIMM combinations decide which SIMM capacity will be

installed in the socket. Then install the SIMM.

To fit a SIMM:

1.The SIMM will only install in one orientation. There is a cutout at one end of the

SIMM next to the connector strip.

Hold the SIMM with the cutout on the right and metal connector strip nearest the

system board.

XEN HARDWARE TECHNICAL REFERENCE 2/21

Chapter 5

System unit

ContentsChapter 1

Chapter 2

2. Position the SIMM above the socket with the SIMM tilted slightly towards the front

of the system unit.

3. Lower the SIMM into the socket, and ensure that the SIMM is properly located in

the connector.

4. Pushing gently on the top corners rotate the SIMM towards the horizontal until it

clips into place. Do not use excessive force.

Chapter 2

Chapter 3

Chapter 5 Chapter 3

Processor upgrades

If the SIMM will not rotate easily remove it and start again.

5. If the SIMM is properly located the SIMM should remain in position held by the

securing clips, and with a small plastic lug through the holes on either side of the

SIMM.

If you want to install a second SIMM repeat the process above. Once you have

completed installation you can replace the 5.25" drive tray and reassemble the system.

The next time you power the system up the SETUP utility will be invoked automatically.

The XEN system board is fitted with a processor socket that supports any Intel486SX,

Intel487SX, Intel486DX, Intel486DX2 or OverDrive processor with a maximum

external clock speed of 33MHz.

Any other Intel processor using the same pinout as one of these processors could also

be installed, subject to the same 33MHz maximum external clock speed restriction.

2/22 XEN HARDWARE TECHNICAL REFERENCE

System unit

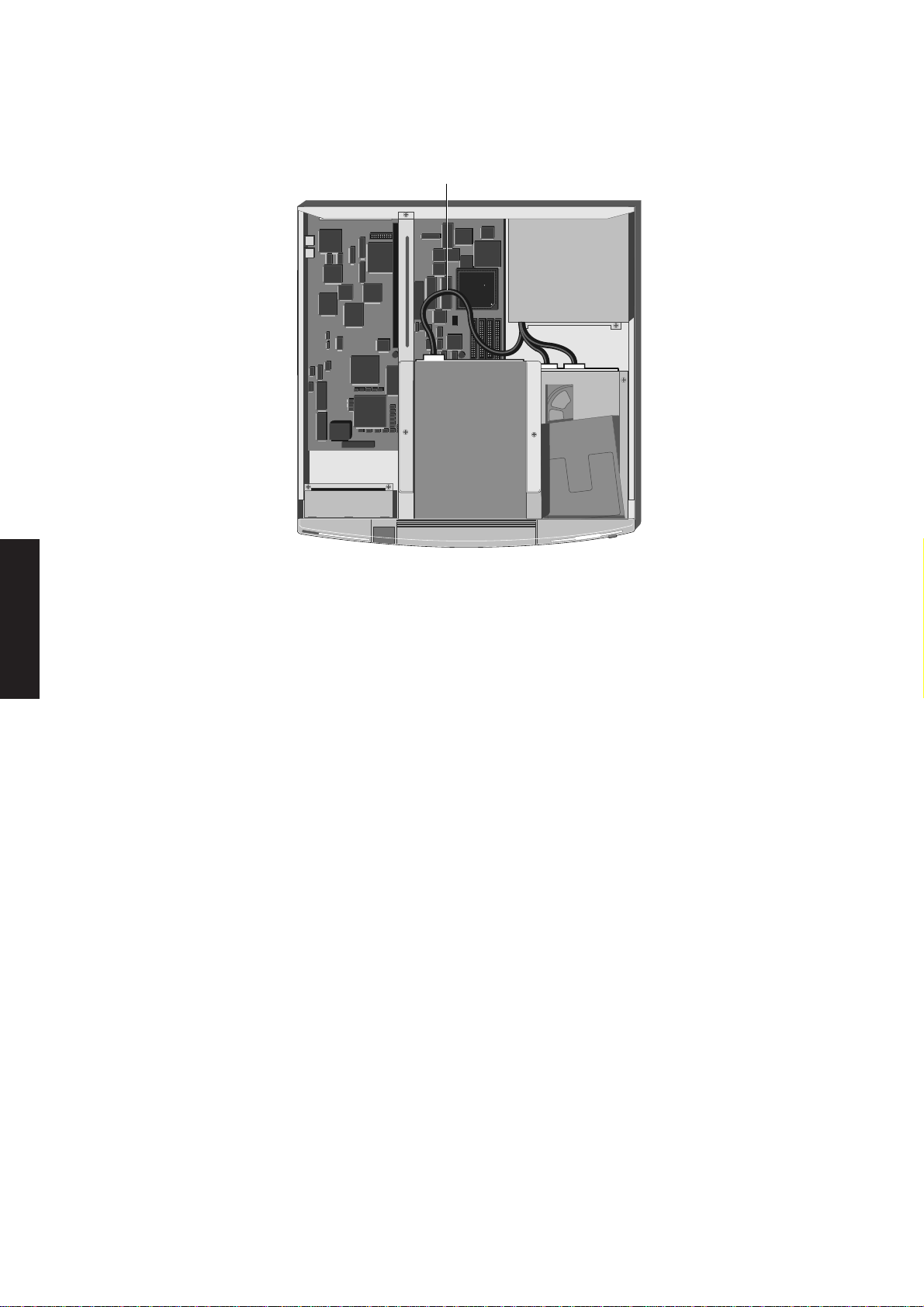

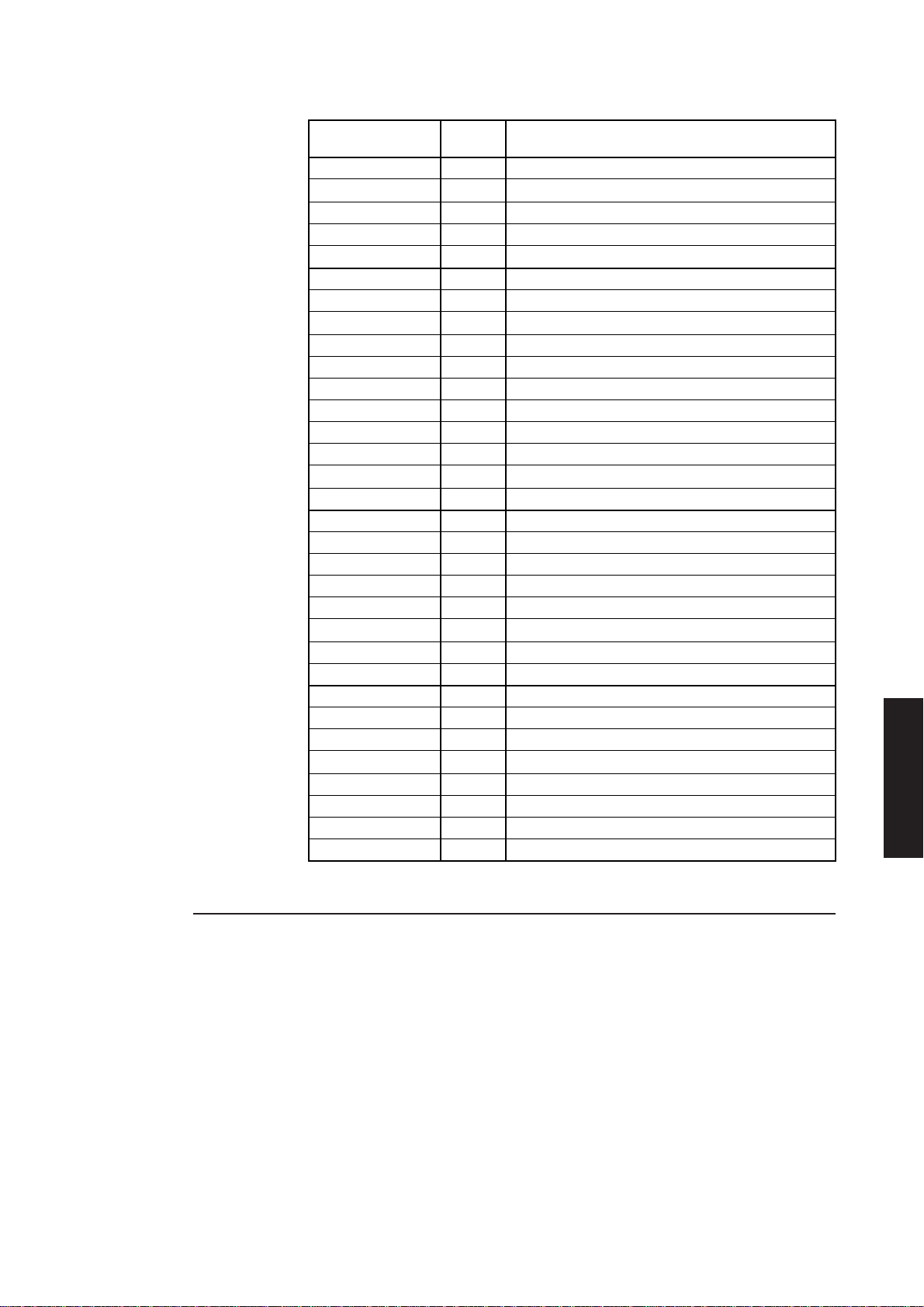

The table below lists the possible upgrades for each processor type and speed.

Current Processor Speed Upgrade Processor Speed

Intel486SX 25 Intel487SX 25

Intel487SX 33

OverDrive 25

OverDrive 33

Intel486SX 33 Intel487SX 33

OverDrive 25

OverDrive 33

Intel486DX 33 OverDrive 25

OverDrive 33

Note

This table lists the processors supported by the system board. There is no guarantee that any

particular upgrade processor will be available at any given time.

Depending on the processor type fitted in your system unit the processor socket may

already be occupied. Before installing the upgrade processor you must first check

whether the processor socket is occupied, and if it is, remove the existing processor.

Instructions on locating the socket and removing a processor are given below.

Contents

Chapter 1

Chapter 2

Chapter 2

Chapter 3

1. Remove the system unit cover.

2. Identify the processor upgrade socket.

UNOCCUPIED SOCKET

OCCUPIED SOCKET

int l

e

D

OVER

V

R

I

E

If the socket is occupied you will have to remove the processor before you can

install the upgrade processor.

Chapter 3

Chapter 5

XEN HARDWARE TECHNICAL REFERENCE 2/23

System unit

ContentsChapter 1

Chapter 2

3. Your upgrade processor is supplied with an extraction tool which resembles a

miniature garden rake.

4. Carefully insert the prongs of the extractor between the bottom of the processor

and its socket. You may need to twist the extractor gently from side to side to work

the prongs into place.

Chapter 2

Chapter 3

Chapter 5 Chapter 3

Be careful to ensure that the prongs do not go between the system board and the

socket.

5. Ease the processor up slightly by pushing inwards on the extractor’s handle.

Warning

Do not push hard on the handle. The processor must be removed gradually and evenly by

working the tool under each edge in turn. Attempting to lift one edge of the processor too

far will damage the processor, or the socket, or both.

6. Remove the extractor and repeat the process on each edge of the processor,

gradually easing the processor out of its socket. If necessary work your way round

the processor two or three times.

7. Once the processor is free of its socket lift it out of the system unit and place it on

the anti-static foam provided with the upgrade processor.

2/24 XEN HARDWARE TECHNICAL REFERENCE

System unit

Installation Having identified the upgrade socket, and ensured that it does not have a processor in

it you are ready to install your new upgrade processor.

1. The upgrade processor and socket are keyed to ensure that the processor can only

be installed in one orientation.

The inside of one corner of the socket has a key hole, the outside of the same corner

is missing three holes. The processor has a positioning guide in the form of a small

dot of paint. Use the following illustration to help identify these features.

int l

e

D

OVER

V

R

I

E

POSITIONING

GUIDE

KEYED

CORNER

Contents

Chapter 1

Chapter 2

2. Carefully position the upgrade processor above the socket with the positioning

guide on the processor over the keyed corner of the socket.

If the upgrade processor does not occupy all four rows of holes it should be

positioned centrally as shown below.

PROCESSOR

IN CENTRE

int l

e

D

UNOCCUPIED

HOLES ON

EACH SIDE

OVER

V

R

I

E

Chapter 2

Chapter 3

Chapter 3

Chapter 5

Warning

If the processor is misaligned it will not go into the socket, and any attempt to force it will

damage the processor, or the socket, or both.

XEN HARDWARE TECHNICAL REFERENCE 2/25

System unit

3. Gently insert the upgrade processor making sure that it is correctly aligned with the

socket and that you do not bend or otherwise damage the pins.

ContentsChapter 1

Chapter 2

4. Once you are certain that all the pins on the processor are in the holes in the socket

apply firm even pressure to the top of the processor to seat the pins in the socket.

5. With the upgrade processor installed you must now ensure that the upgrade

socket, and system board clock speed are correctly configured for your new

processor.

Configuring the system board below describes how to ensure that when you reassemble your system the new processor will work.

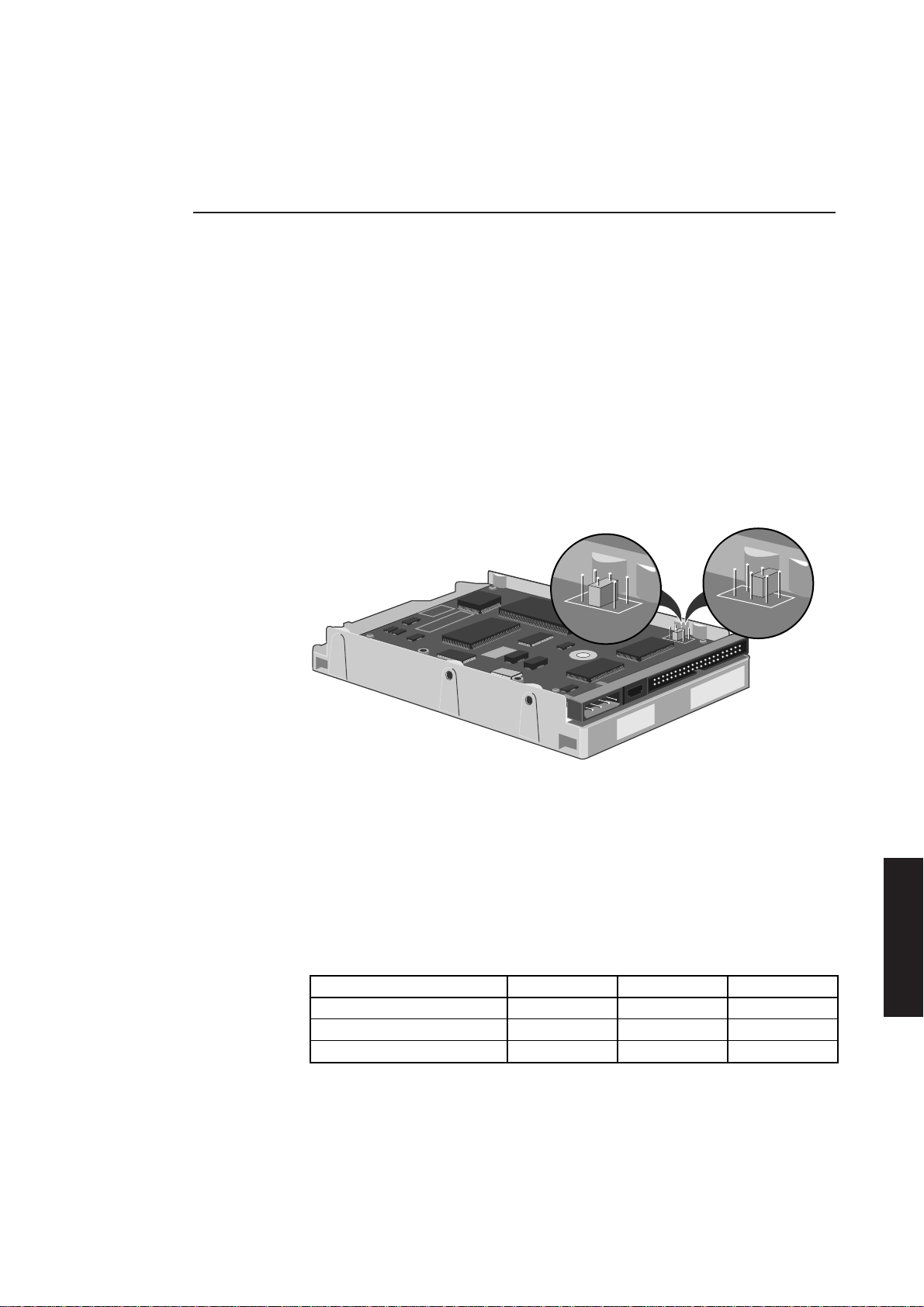

Configuring the The XEN system board supports a range of processor speeds and the upgrade socket

system board supports a range of processor types. The system board clock speed and the upgrade

socket are configured using four switches in a set of six by the socket.

It is vital that both the system clock speed, and the upgrade socket configuration are

set correctly. Follow the instructions below to check the settings and adjust them as

necessary.

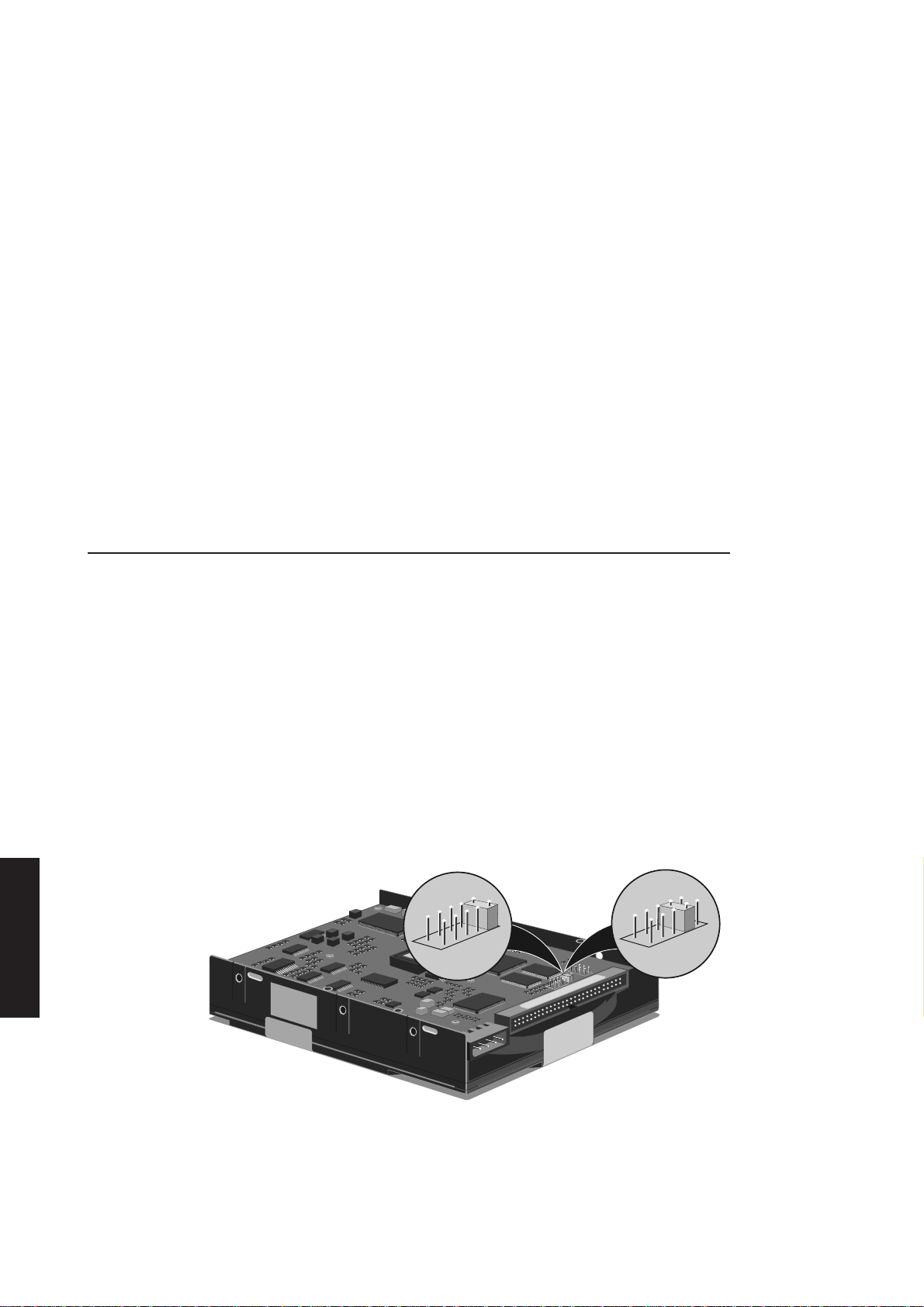

1. Use the following illustration to identify the switches.

Chapter 2

Chapter 3

Chapter 5 Chapter 3

6

5

4

3

int l

e

D

OVER

V

R

I

1 2

E

ON

SWITCH PACK

The switches numbered 2 and 3 are used to select the system clock speed. Switches

4 and 5 are used to configure the upgrade socket.

Warning

Under no circumstances should switches 1 and 6 of the switch pack be moved. It is essential

that both switch 1 and switch 6 are in the on position.

2/26 XEN HARDWARE TECHNICAL REFERENCE

System unit

2. From the table below, and the label on your upgrade processor or its packaging,

decide which processor type you have installed.

Since the Intel487SX and OverDrive processors require the same configuration

you will normally set switches 4 and 5 to the Off/Off position. The other selections

are for processors normally installed during manufacture.

Contents

Chapter 1

Switch

4 5

off off Intel487SX/OverDrive

off on Intel486DX/Intel486DX2

on off Intel486SX

on on not used

3. Having decided which selection you require check the positions of switches 4 and

5, and if necessary move them to the appropriate position.

4. From the table below, and the label on your upgrade processor, or its packaging

decide which system clock speed you need to select.

Switch Clock speed

2 3

on on 16

on off 20

off on 25

off off 33

You will almost certainly want to set the clock speed to either 25 or 33MHz.

Processor

(MHz)

Chapter 2

Chapter 2

Chapter 3

Chapter 3

Note

Systems equipped with the on-board Ethernet interface have a minimum clock speed of

25MHz.

If you have installed an Intel487SX you must set the system clock speed to match

the speed of the coprocessor.

If you have installed an OverDrive processor you should set the system clock speed

to match the external interface speed of the processor. OverDrive processors use

Intel’s clock doubling technology and the processor runs at twice the speed of its

interface to the system board.

The labelling on the OverDrive processor or its packaging should make it clear what

its external interface speed is.

5. Having decided which selection you require check the positions of switches 2 and

3, and if necessary move them to the appropriate position.

6. Once you are satisfied that you have installed the upgrade and configured the

system correctly, reassemble the system.

Chapter 5

XEN HARDWARE TECHNICAL REFERENCE 2/27

System unit

5.25" drives

ContentsChapter 1

Chapter 2

The 5.25" drive tray in the XEN system unit can contain any half height 5.25" device.

Apricot supplies a range of tape and CD-ROM drives, and a 5.25" floppy drive, for this

tray.

The following instructions describe the installation of a drive in the tray. The Generic instructions apply to all drives, and describe the physical installation of a drive.

Instructions specific to each drive type are given after the generic instructions.

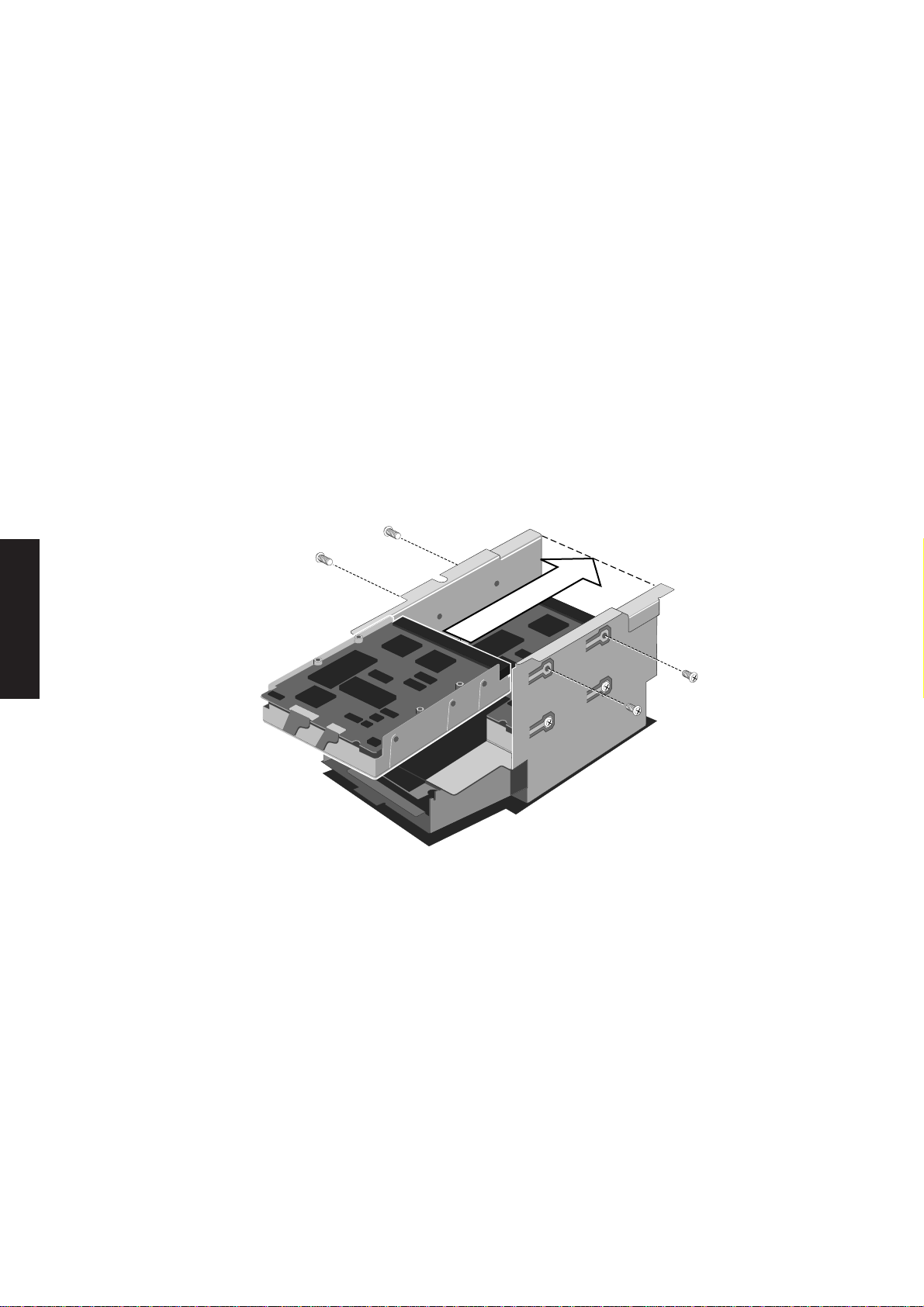

Generic 1. Remove the system unit cover.

5.25" BAY

Chapter 2

Chapter 3

Chapter 5 Chapter 3

SECURING SCREWS

2. Remove the drive tray as described in the dismantling instructions earlier in this

section.

3. The front of the tray may be fitted with a blanking plate. If it is, turn the tray over

and remove the two screws that secure the blanking plate. The blanking plate is no

longer required, but you may wish to store it somewhere safe in case you wish to

remove the drive later.

SECURING SCREWS

BLANKING PLATE

If the drive tray is not fitted with a blanking plate, the 5.25" drive aperture is

obscured by a blanking plate attached to the top of the front of the chassis, behind

the drive bay door. Break this blanking plate out by bending it backwards and

returning it to the vertical position several times.

4. Remove the drive from its packaging. With the drive there should be four screws

and a signal cable. Some drives may be supplied with additional items.

2/28 XEN HARDWARE TECHNICAL REFERENCE

System unit

5. If necessary configure the drive. Drives supplied by Apricot will be correctly

configured for installation in a XEN.

For information on how Apricot-supplied drives are configured see the drive

specific information following these installation instructions.

6. Identify the top and bottom of the drive.

7. Rest the drive, top down, on a suitable anti-static surface.

8. With the drive tray upside-down place it over the drive. The front of the drive must

be at the end where the blanking plate was fitted.

Contents

Chapter 1

9. Line up the holes in the underside of the drive with those in the base of the drive

tray.

SECURING

SCREW

HOLES

COMPACT

Chapter 2

Chapter 2

Chapter 3

Chapter 3

10.Insert the four drive securing screws, and tighten them until they are finger tight.

11.Gently tighten the four screws.

12.Replace the drive tray.

XEN HARDWARE TECHNICAL REFERENCE 2/29

Chapter 5

System unit

ContentsChapter 1

Chapter 2

13.Connect the drive tray power cable to the power connector on the drive.

5.25" DRIVE

POWER CABLE

int l

e

D

OVER

V

R

I

E

Chapter 2

Chapter 3

Chapter 5 Chapter 3

14.The drive has now been installed and connected to a power cable. You must now

connect it to a signal cable. Instructions on connecting each of the types of drive

to a signal cable is given under the appropriate heading overleaf.

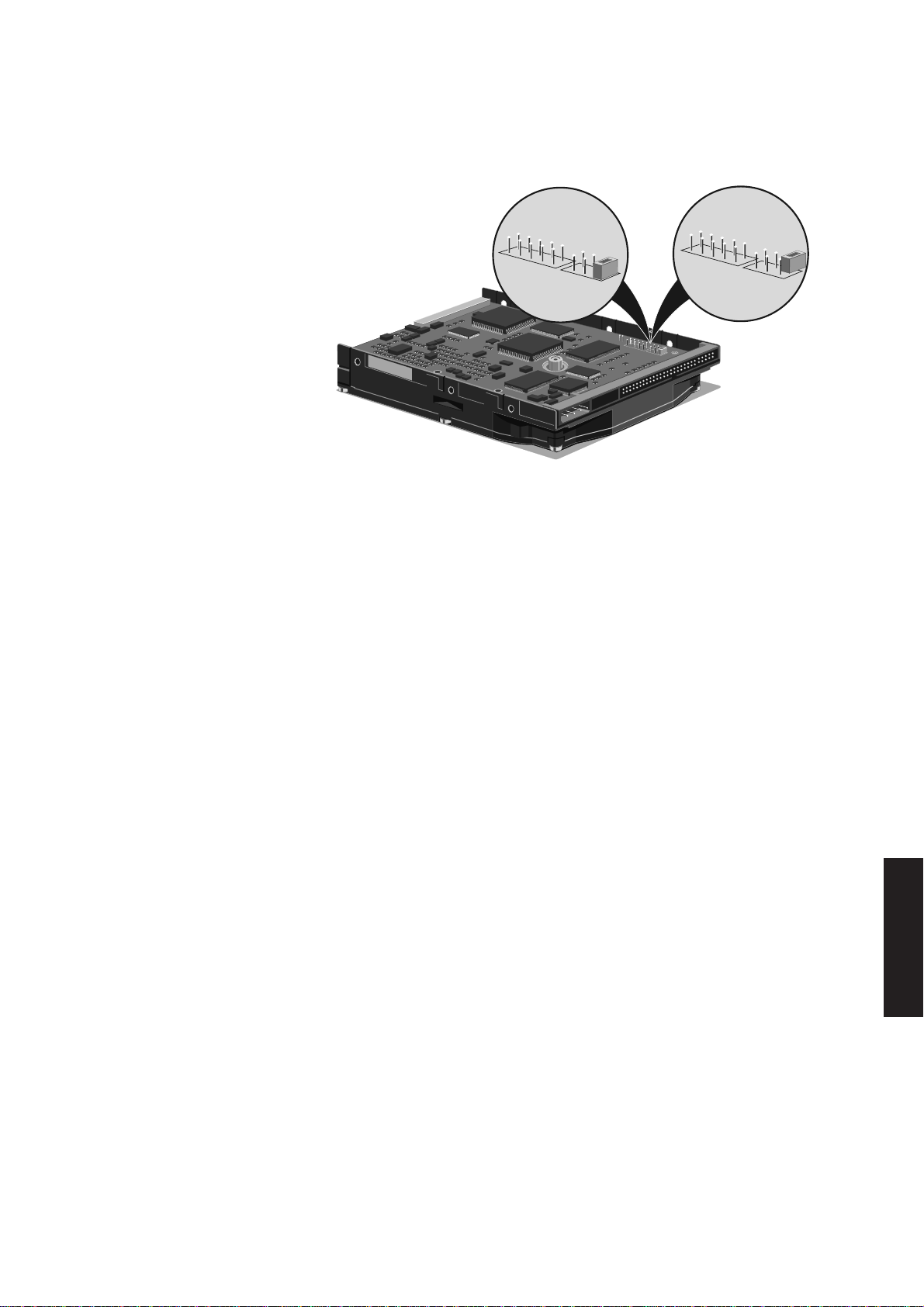

5.25" floppy Cabling

or Irwin FTD

The 5.25" floppy and Irwin FTD drives supplied by Apricot come complete with a

suitable signal cable. The signal cable must be connected between the signal connector

on the rear of the drive, and the socket marked PL38 on the system board.

Use the label on the inside of the system unit cover to identify PL38.

Configuration

The only configuration on these drives is via the drive select jumpers at the rear of the

drive. The jumpers should be set to drive select 1 (DS1).

SLCD CD-ROM Cabling

The Apricot SLCD CD-ROM drive is supplied with two signal cables. The wide data

cable must be connected between the rear of the SLCD CD-ROM drive and PL36 on

the system board. The narrow audio cable must be connected between the drive and

PL4 on the system board.

Use the label on the inside of the system unit cover to identify PL36 and PL4.

Notes

1. If there is an expansion card installed in the bottom slot you will have to remove it in order

to access PL4.

2. On system boards which have only the standard PC audio facility there is no audio connector

(PL4) on the system board.

2/30 XEN HARDWARE TECHNICAL REFERENCE

System unit

Configuration

There are no configuration options on the SLCD CD-ROM drives. DOS drivers for the

SLCD CD-ROM drive are described in help files on a diskette supplied with the drive.

Contents

SCSI drives Cabling

Apricot upgrade kits are supplied with a suitable signal cable. The cable should be

connected between the SCSI card and the rear of the drive.

The following illustration shows the routing of the cable.

SCSI CABLE

int l

486

i

Chapter 1

Chapter 2

e

TM

DX

Chapter 2

Chapter 3

Configuration

Each SCSI drive is assigned an identity on the SCSI bus, these are known as SCSI IDs.

All Apricot SCSI tape drives for XEN are supplied configured with SCSI ID 2. The SCSI

CD-ROM drive is supplied configured with ID 5.

All Apricot SCSI drives are supplied with termination resistors installed.

3.5" hard disk drive

The XEN supports one 1.6" high or two 1" high, 3.5" hard disk drives.

Preparation To install a hard disk drive you must first remove the 3.5" drive bay:

1. Remove the system unit cover.

2. Remove the 5.25" drive tray

3. Remove the 3.5" drive bay.

Chapter 3

Chapter 5

XEN HARDWARE TECHNICAL REFERENCE 2/31

System unit

Drive The XEN 3.5" drive bay supports two 1" high hard disk drives. In order for the drive

configuration or drives to operate they must be correctly configured.

ContentsChapter 1

Chapter 2

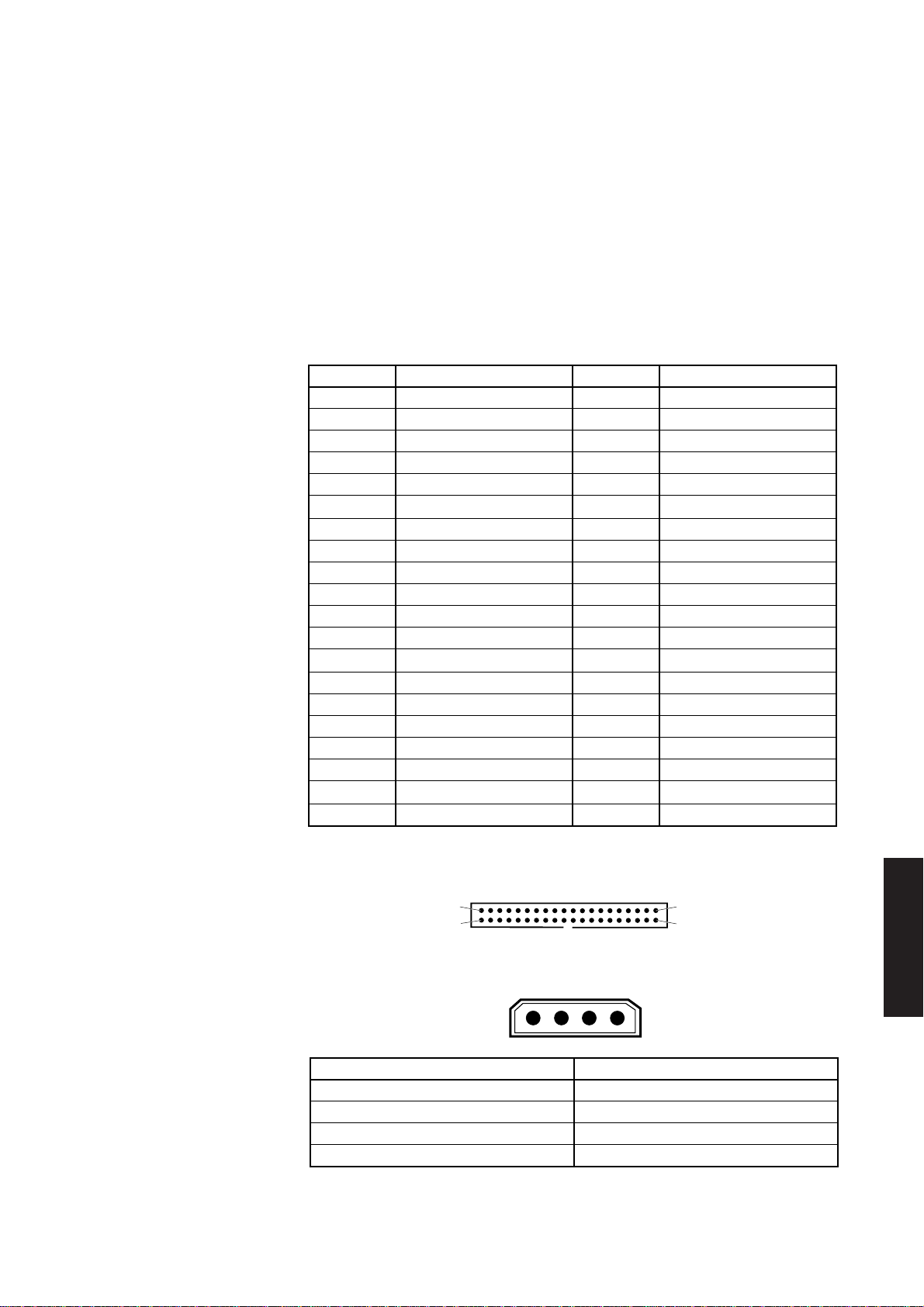

The IDE interface supports a maximum of two drives. These drives are known as

Master and Slave. A single drive, or the boot device in a dual drive system, must be

configured as Master. The second, non-bootable, drive in a dual drive system must be

configured as Slave.

IDE drives are normally configured using jumpers on the drive. Configuration details

may vary from drive to drive. Apricot drives are supplied with documentation

describing how to configure the drive.

If you are uncertain about configuring the drive check with your supplier.

Installing the 1. Having configured the drive, turn the drive bay upside-down and rest it on a flat

drive surface with the front of the floppy drive towards you.

2. Slide the hard disk drive you are installing into the bay from the front, with the drive

circuit board up, and its connectors away from you.

Chapter 2

Chapter 3

Chapter 5 Chapter 3

Warning

If there is a drive in the bay already, be careful to ensure that the new drive does not touch

it.

3. Line up the screw holes on the drive with those in the bay, insert the securing screws

and tighten them until they are finger tight.

Note

If you are installing a hard disk drive in a system that previously had only a floppy drive

there will be two sets of holes available in the bay. Install the hard drive in the position closer

to the floppy drive.

4. Carefully tighten the screws.

5. Turn the bay over.

You can now reassemble the system.

2/32 XEN HARDWARE TECHNICAL REFERENCE

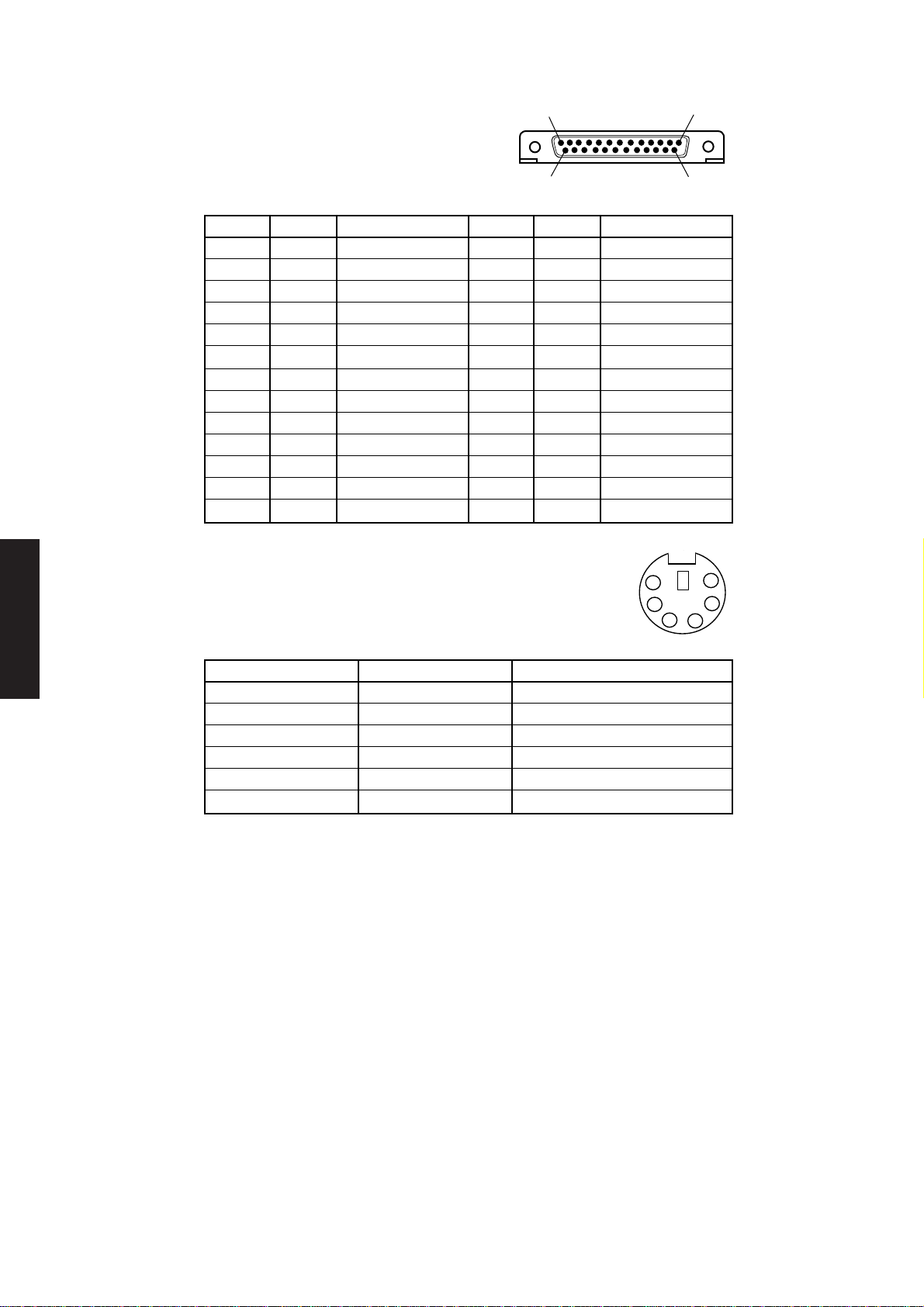

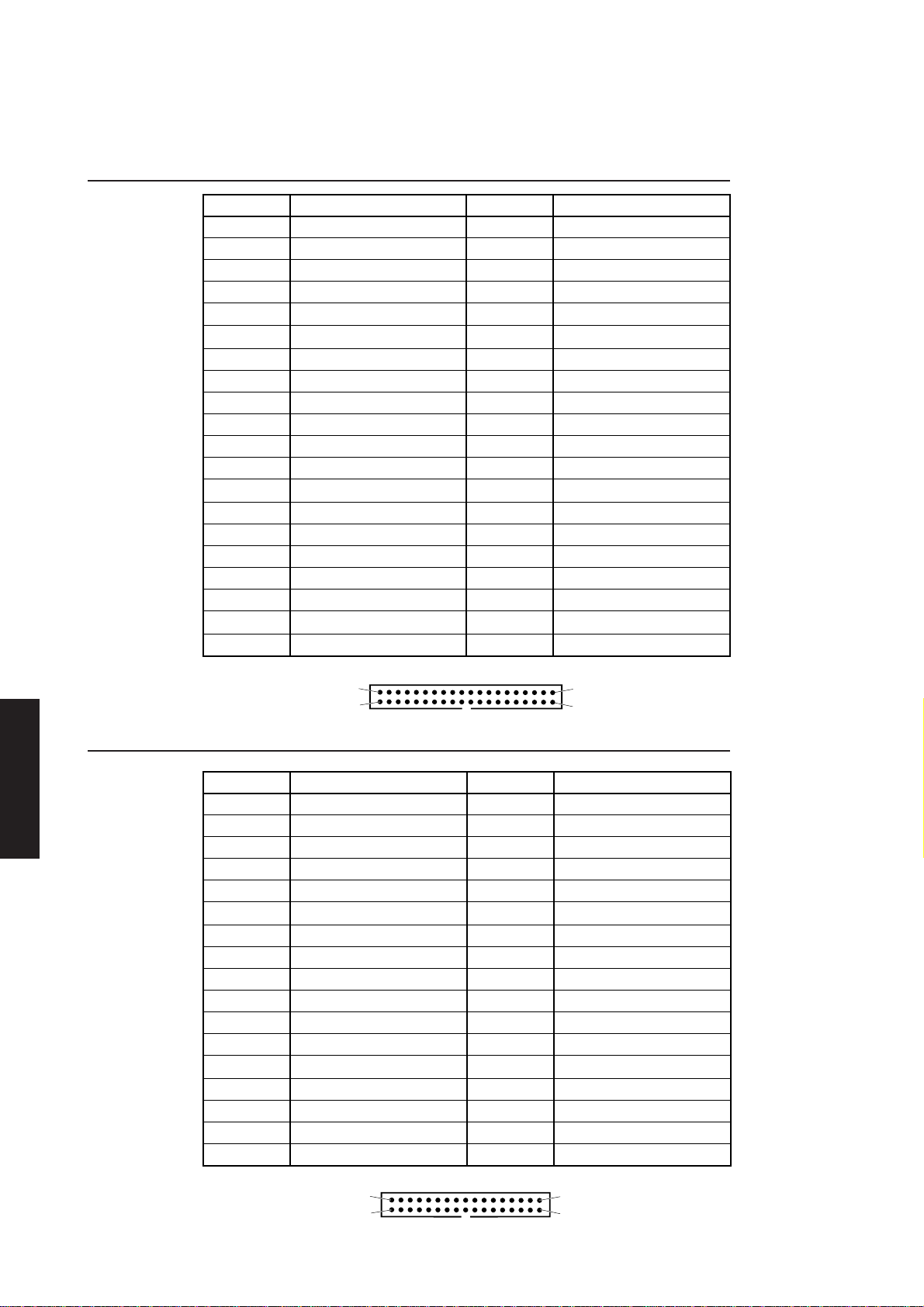

2.5 SYSTEM UNIT CONNECTORS

The following illustrations and tables show the layout, pin numbering and pinout of each

of the connectors on the rear panel of the system unit.

System unit

Contents

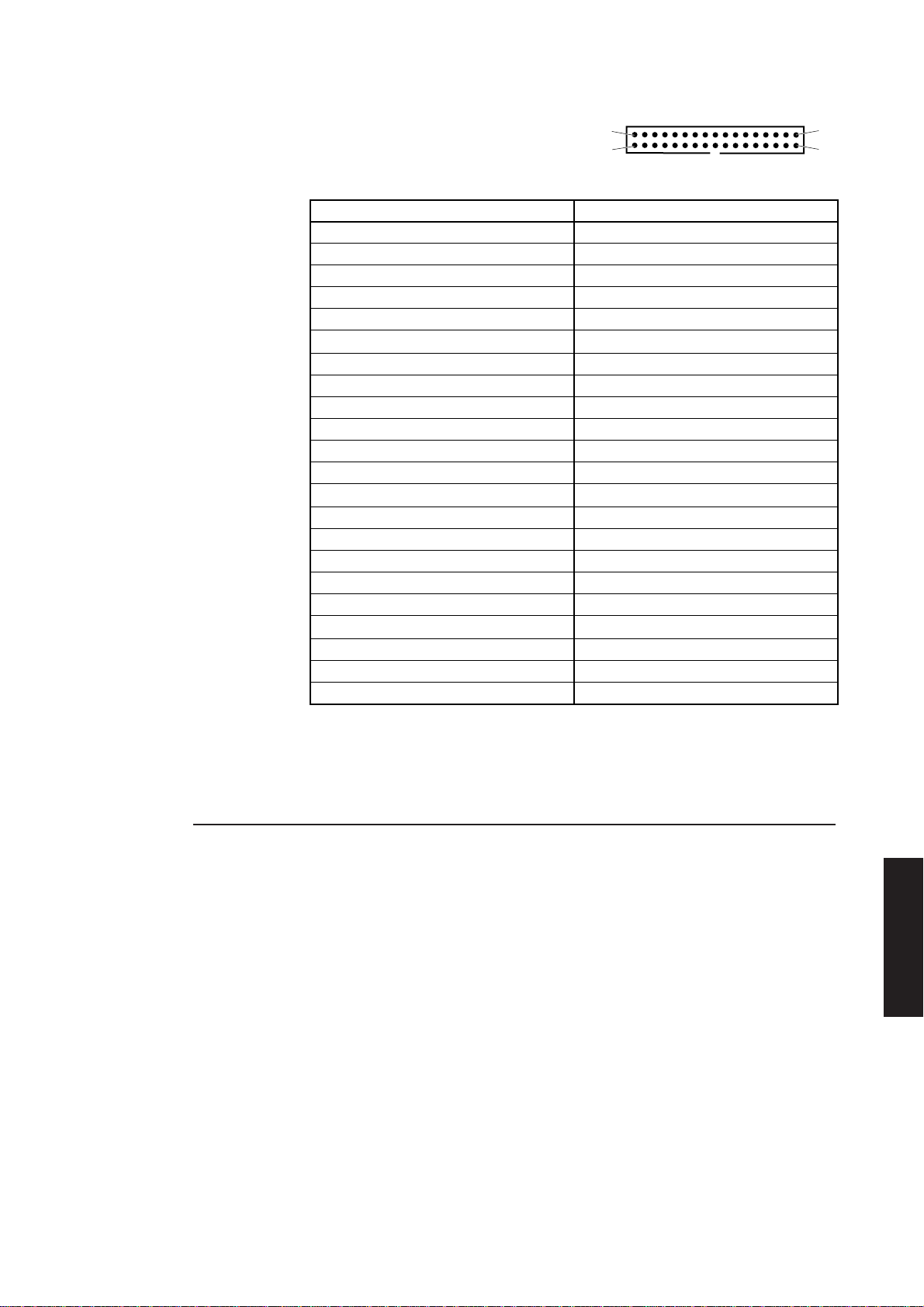

VGA The VGA display connector is a 15-pin D-shell.

Pin I/O Output

1 O Red

2 O Green

3 O Blue

4 NA Reserved

5 NA Digital Gnd

6 NA Red rtn

7 NA Green rtn

8 NA Blue rtn

9 NA Plug

10 NA Digital Gnd

11 NA Reserved

12 NA Reserved

13 O Hsync

14 O Vsync

15 NA Reserved

10

5

1

6

1115

Chapter 1

Chapter 2

Chapter 2

Chapter 3

Serial port The serial port uses a male 25-pin D-shell connector.

Pin I/O Signal name

2 O Transmit data (COM1)

3 I Receive data (COM1)

4 O Request to send (COM1)

5 I Clear to send (COM1)

6 I Data set ready (COM1)

7 NA Signal ground

8 I Data carrier detect (COM1)

12 I Data carrier detect (COM2)

13 I Clear to send (COM2)

14 O Transmit data (COM2)

16 I Receive data (COM2)

19 O Request to send (COM2)

20 O Data terminal ready (COM1)

22 I Ring indicate (COM1)

1

14

13

25

Chapter 3

Chapter 5

All other pins are not connected.

XEN HARDWARE TECHNICAL REFERENCE 2/33

System unit

Parallel port The parallel port uses a female 25-pin D-shell

connector.

13 1

ContentsChapter 1

Chapter 2

Keyboard/mouse The keyboard and mouse connectors are both miniature 6-pin

Pin I/O Signal name Pin I/O Signal name

1 I/O Strobe 14 O Autofeed XT2 I/O Data bit 0 15 I Error-

3 I/O Data bit 1 16 O Init4 I/O Data bit 2 17 O Slct In5 I/O Data bit 3 18 NA Ground

6 I/O Data bit 4 19 NA Ground

7 I/O Data bit 5 20 NA Ground

8 I/O Data bit 6 21 NA Ground

9 I/O Data bit 7 22 NA Ground

10 I Ack- 23 NA Ground

11 I Busy 24 NA Ground

12 I PE 25 NA Ground

13 I SLCT

connectors DIN connectors.

25

14

6

5

4

3

2 1

Chapter 2

Chapter 3

Chapter 5 Chapter 3

Pin I/O Signal name

1 I/O Data

2 NA Reserved

3 NA Ground

4 NA +5Vdc

5 I/O Clock

6 NA Reserved

2/34 XEN HARDWARE TECHNICAL REFERENCE

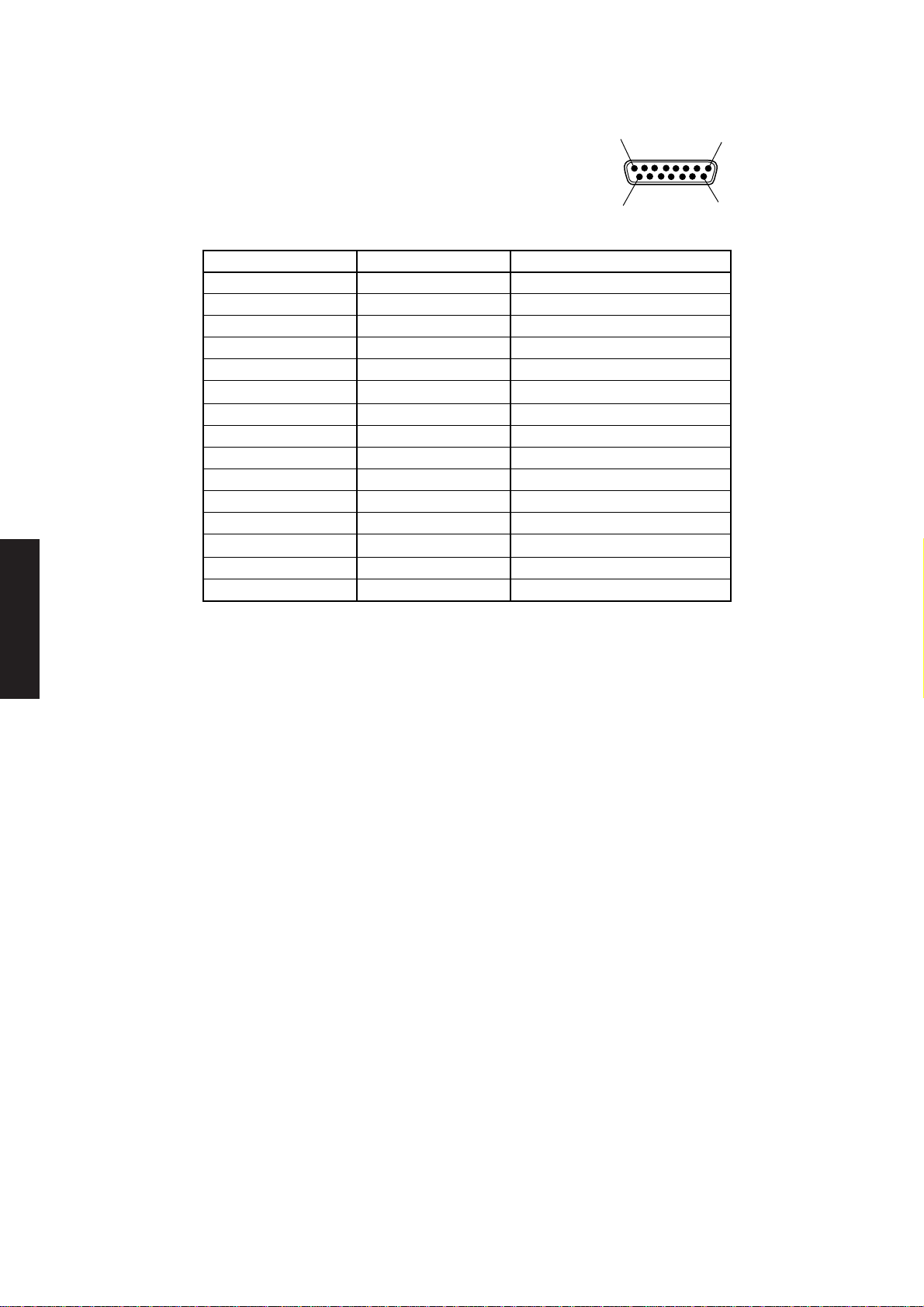

Ethernet Thick

The thick Ethernet connector is a 15-pin female D-shell which

uses a slide to hold the male and female connectors together.

System unit

8

Contents

1

Pin I/O Signal

1 NA Collision presence shield

2 I Collision presence (+ve)

3 O Transmit (+ve)

4 NA Receive shield

5 I Receive (+ve)

6 NA Power return

7 NA Reserved (+ve)

8 NA Reserved shield

9 I Collision presence (-ve)

10 O Transmit (-ve)

11 NA Transmit shield

12 I Receive (-ve)

13 NA Power

14 NA Power shield

15 NA Reserved (-ve)

Thin

The thin Ethernet connector is a BNC socket.

15

9

Chapter 1

Chapter 2

Chapter 2

Chapter 3

Core Signal

Shield Return

Twisted pair (TPE)

The unshielded twisted pair Ethernet port is an

RJ45 connector.

Pin Function

1 Transmit data +

2 Transmit data -

3 Receive data +

4 Not used

5 Not used

6 Receive data 7 Not used

8 Not used

1 2 3

Chapter 3

4

5

6

7

8

Chapter 5

XEN HARDWARE TECHNICAL REFERENCE 2/35

System unit

ContentsChapter 1

Chapter 2

Audio Joystick/MIDI port

The Joystick/MIDI port connector is a 15-pin female

D-shell compatible with the port found on Sound Blaster cards.

Pin I/O Function

1 NA +5V dc

2 I GP4 Joystick/A right button

3 I GP0 Joystick/A x-coordinate

4 NA Ground

5 NA Ground

6 I GP1 Joystick/A y-coordinate

7 I GP5 Joystick/A left button

8 NA +5V dc

9 NA +5V dc

10 I GP6 Joystick/B right button

11 I GP2 Joystick/B x-coordinate

12 O MIDI Out

13 I GP3 Joystick/B y-coordinate

14 I GP7 Joystick/B left button

15 I MIDI In

8

15

1

9

Chapter 2

Chapter 3

Chapter 5 Chapter 3

Audio input

The audio input connector is a standard 3.5mm socket. Input sensitivity is software

controllable to suit a range of devices from a microphone to hi-fi equipment line outputs

and personal stereo headphone outputs.

Audio output

The audio output connector is a standard 3.5mm stereo headphone socket.

2/36 XEN HARDWARE TECHNICAL REFERENCE

SYSTEM BOARD

Chapter 3

Contents

System board

3 SYSTEM BOARD

3.1 Introduction ............................3/2

General....................................... 3/2

System Identification Number

(SIN) ........................................ 3/2

Major components ............... 3/2

Description ................................ 3/4

Processor upgrades..............3/5

System reset .......................... 3/5

3.2 Processor system .................3/5

3.3 VL82C486 ................................3/6

Memory controller...............3/6

System control port B......... 3/6

Interrupt structure................... 3/6

List of hardware interrupts 3/7

Non-Maskable Interrupts....3/8

Direct Memory Access ........... 3/8

Address generation.............. 3/8

System timers............................ 3/9

Operation............................... 3/9

3.4 System memory ...................3/9

General....................................... 3/9

Read only memory (ROM).....3/9

Random access memory

(RAM) ....................................... 3/10

3.5 Video controller ...................3/10

General.....................................3/10

Video controllers................3/12

Video disable jumper .........3/12

3.6 Floppy disk controller ......3/12

3.7 Hard disk and SLC

interfaces ...............................3/13

General.....................................3/13

Interface signal descriptions.3/13

Host reset ............................3/13

Host data 0-15 .................... 3/13

Host I/O channel ready.....3/13

Host IOW............................ 3/13

Host IOR.............................. 3/13

Host IRQ14 .........................3/13

Host IOCS16.......................3/13

Host ADDR 0-2..................3/13

Chip select 0, 1 ...................3/13

3.8 Peripherals controller ......3/14

Serial ports...............................3/14

Programmable baud-rate

generator..............................3/14

Parallel port ............................. 3/15

3.9 82C113A .................................3/15

Real time clock (RTC) RAM 3/15

Contents of RTC RAM .....3/15

Keyboard port ........................3/19

Keyboard password

security .................................3/20

3.10 LOC Technology ................3/20

3.11 Ethernet port .......................3/20

General.....................................3/20

82596 LAN coprocessor ..3/21

82503 dual serial

transceiver ...........................3/21

7997....................................... 3/21

3.12 Professional audio ..............3/22

General.....................................3/22

YMZ263 multimedia

controller ............................. 3/23

YMF262 FM synthesizer....3/23

LMC835 mixer ....................3/23

CD-ROM audio ..................3/23

Microphone/line input .......3/23

PC beep ................................ 3/23

LMC1982 volume/tone

control .................................. 3/23

Front panel volume control. 3/

23

Power amplifier...................3/23

3.13 System board

connectors ............................3/24

Hard disk drive connector ...3/24

SLC interface connector.......3/24

Floppy drive connectors.......3/25

Audio data................................3/25

System board power

connector.................................3/26

Front panel connector .......... 3/26

VESA connector ..................... 3/26

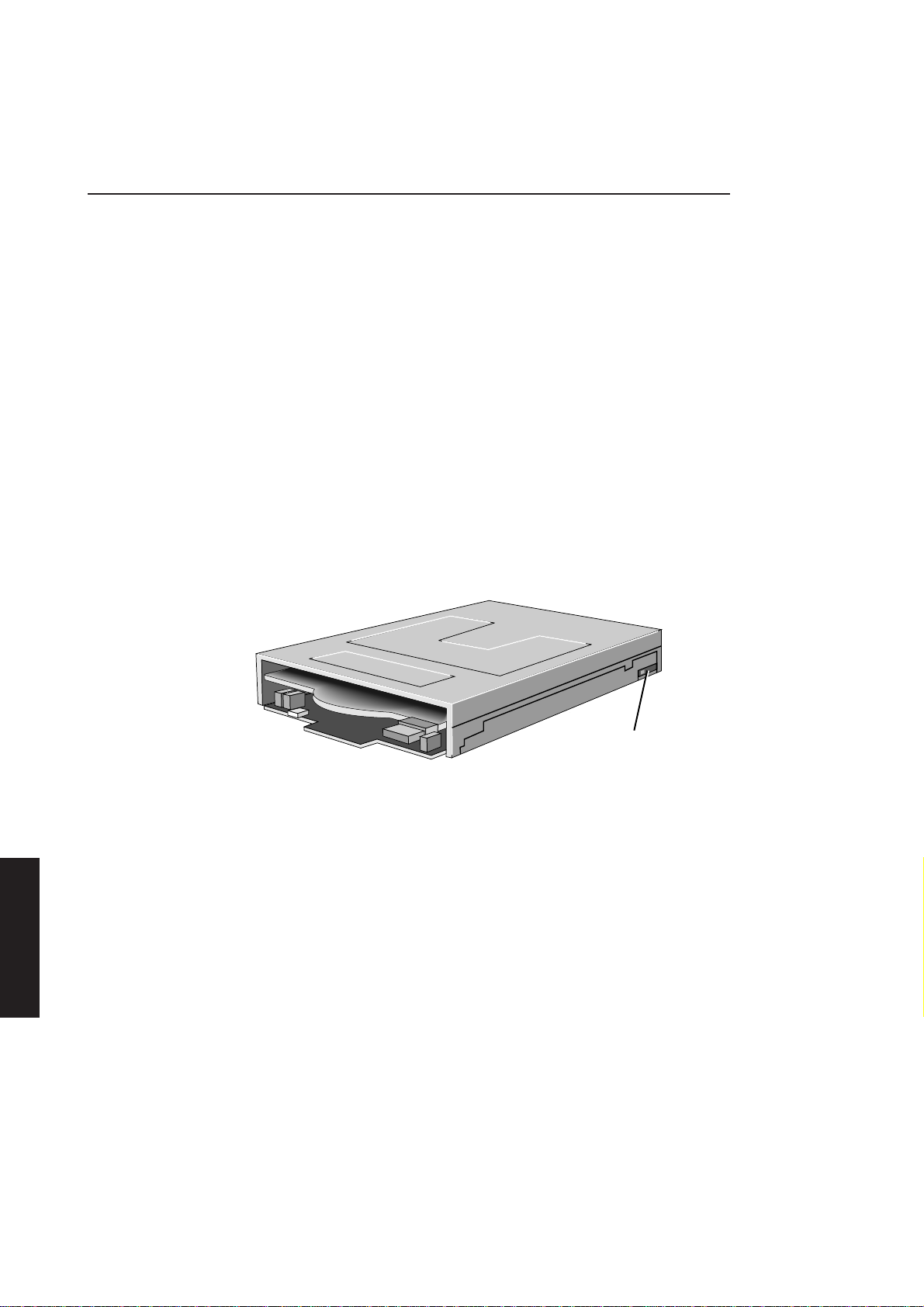

Battery jumper........................3/27

Chapter 2

Chapter 3

Chapter 3

Chapter 3

Chapter 1

Contents

Chapter 5

XEN HARDWARE TECHNICAL REFERENCE 3/1

System board

3.1 INTRODUCTION

General

Chapter 2

This section describes the XEN system board and the operation of its processing

system and interface circuits.

The XEN range uses a highly integrated, IBM AT compatible system board. In addition