A P Products GmbH

The A P Products

Test-Clip Special

LINECARD

IC Test Clips

A P Products Test Clips the industry standard for faster, easier DIP IC testing, quality

control inspection and field service. The Test Clips provide easy attachment, „handsfree“ testing and positive clamping. Reliable contacts and rugged construction allow a

save way for testing.

Over 150 models to fit every size DIP up to 64 pins

Nailhead and connector compatible „headless“ available

Female Header

The wide standard assortment of female headers include single, double and triple

row female headers with up to 36 pins per row which can easily be cut down to

any desired length.

A P Products

A variety of gold and tin platings available

Mate with industry standard connectors or headers with contacts spaced on 2,54mm

Male Header

A P Products offers a wide range of either custom made or standard male headers.

The wide assortment of standard male headers include single, double and triple

row, straight and right angle, gold and solder plating and in various pinlength up

to 36 pins per row.

2,36mm / 5,97mm / 8,07mm interface area

Mate with industry standard connectors or headers with contacts spaced on 2,54mm

Molded-On Cable

Molded-On cable assemblies are suited for board to board interconnects. As a

result of the „Molded-On“ technology cable and contacts are one piece and

therefore inseparable. There are no individual components to become apart.

Different cable and connector styles available

Custom configurations welcome

100% factory tested

A P Products GmbH

Postfach 1158

D-71089 Weil im Schönbuch

Deutschland

Tel.: +49-7157-5348-0

Fax: +49-7157-5348-39

Web: www.ap-products.de

E-mail: info@ap-products.de

A P Products Ltd.

80 Cromwell Road

Saffron Walden, CB11 4BE

Great Britain

Tel.: +44-1799-526602

Fax: +44-1799-521408

Web: www.ap-products.co.uk

E-mail: info@ap-products.co.uk

A P Products S.r.l.

Viale Abruzzi, 87

I-20131 Milano

Italia

Tel.: +39-02-29404697

Fax: +39-02-29523280

Web: www.ap-products.com

E-mail: info-i@ap-products.com

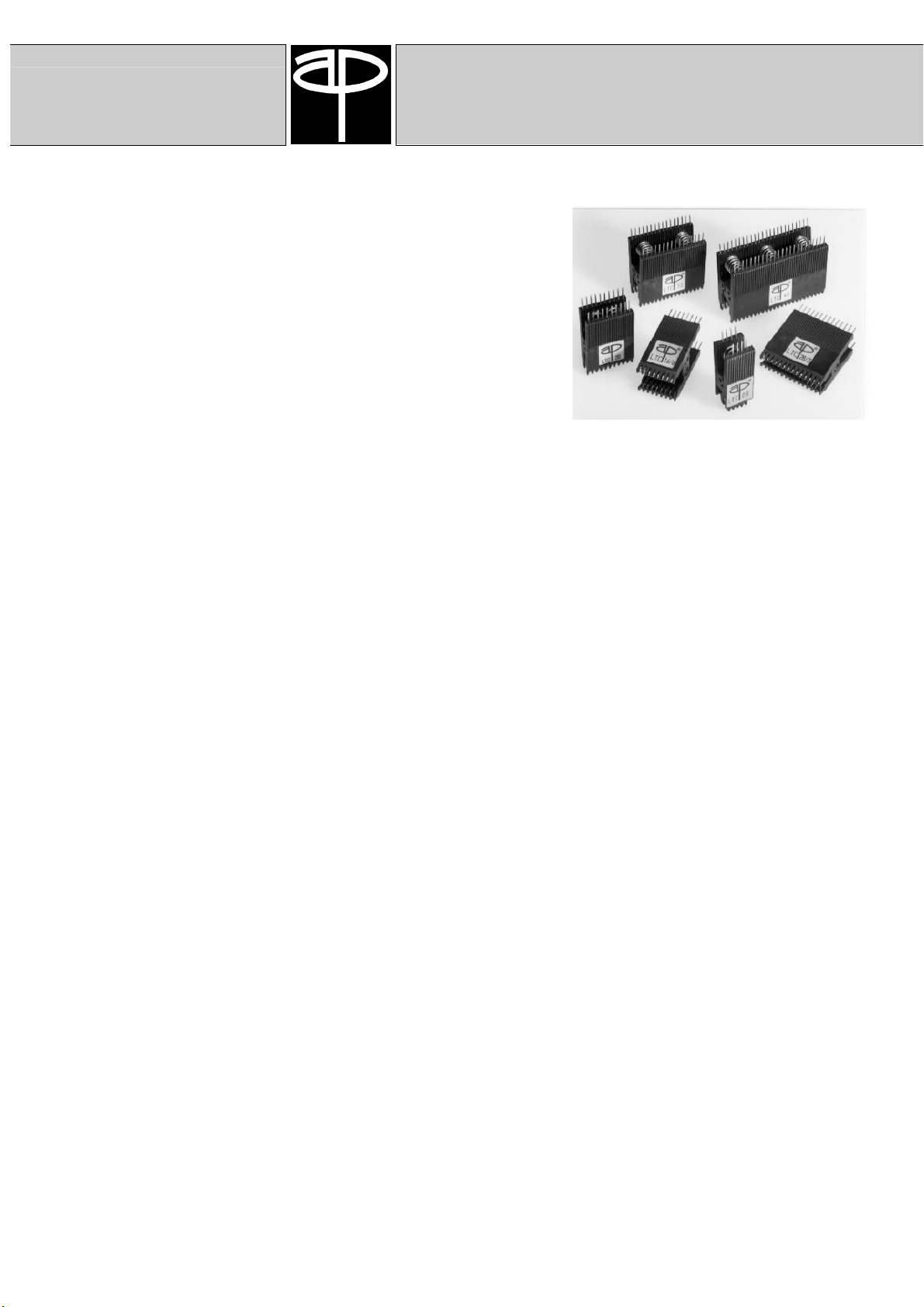

AP1100

A P Products GmbH

TEST

-

CLIP

The IC Test-Clip for fast, safe access to DIP Leads

Since 1967 in the market, our Test-Clip has remained the industry

standard for faster easier DIP IC Testing, quality control inspection,

and field service. A P Products Test-Clips have become an

indispensable tool to the electronic industry.

We're introducing today the industry largest selection of Test-Clips.

With 144 models to fit every size DIP up to 64-pins and both nailed

and connector-compatible "headless" leads available in every size,

A P Products has just the right Test-Clip to meet your DIP testing

requirements.

• Easy attachment

Narrow nose shape for working on high density PC-boards. Fits onto IC's with only 2,5 mm between leads and

adjacent components.

• Positive clamping

The heavy duty industrial grade metal springs provide a firm positive grip to the DIP under test. The weight of the

probes and test leads can't disturb connections, eliminating intermittents and false readings.

• Reliable contacts

Proven contact wiping action for optimum reliability. New are "Paint Cut" contacts for ICs with antistatic protection

coating, as often used in military applications. These contacts will cut through the protective coating. Stripping the

coat prior to testing is no longer necessary. The test marks can easily be touched up after testing.

• Save way to test

The contact comb fits between DIP leads to eliminate any possibility of shorting out chips.

• Rugged construction

Body material is tough, engineering grade glass filled PBT. The contacts are made from hardened Nickel Silver.

Hinge design with steel pivot pin for smooth, long lasting use.

Specifications:

Plastic: PBT, glass filled (30%), UL 94 VO

Contacts: CuNi18Zn20, unplated or gold plated

Temp. Range: -55 °C to +165 °C

Rel. Humidity: <80%

Max. Current: 2 A

Max. Voltage: 250 V

Test Voltage: Contact - Contact = 1000 V

Contact - Ground = 1500 V

3

A P Products™ Test Clip Product Matrix

DIL / DIP Testclips

Shrink DIP

Testclips

Standard Model Connector Compatible Connector Compatible

(with Nail Heads) (with Headless Heads) (with Nail Heads) (with Headless Heads) (with Headless Heads)

Lead

Count /

Plating

8

Alloy 900695 900690-08 900741-08 900737-08

Gold 900743-08 900739-08 900741-08-AU 900737-08-AU

14

Alloy 900698 900690-14 900741-14 900737-14

Gold 900743-14 900739-14 900741-14-AU 900737-14-AU

16 900790-16 900789-16

Alloy 900700 900702 900690-16 900689-16 900741-16 900740-16 900741- 900736-16

Gold 900743-16 900742-16 900739-16 900738-16 900741-16-AU 900740-16-AU 900741- 900736-08-AU

18

Alloy 900703 900690-18 900741-18 900737-18

Gold 900743-18 900739-18 900741-18-AU 900737-18-AU

20

Alloy 900704 900690-20 900741-20 900737-20

Gold 900743-20 900739-20 900741-20-AU 900737-20-AU

22 900789-22 900790-22

Alloy 900706 900705 900689-22 900690-22 900740-22 900741-22 900736-22 900737-22

Gold 900742-22 900743-22 900738-22 900739-22 900740-22-AU 900741-22-AU 900736-22-AU 900737-22-AU

24 900789-24 900790-24

Alloy 900715 900714 900689-24 900690-24 900740-24 900741-24 900736-24 900737-24

Gold 900742-24 900743-24 900738-24 900739-24 900740-24-AU 900741-24-AU 900736-24-AU 900737-24-AU

28

Alloy 900717 900718 900689-28 900690-28 900740-28 900741-28 900736-28 900737-28

Gold 900742-28 900743-28 900738-28 900739-28 900740-28-AU 900741-28-AU 900736-28-AU 900737-28-AU

32

Alloy 900719 900690-32 900741-32 900737-32

Gold 900743-32 900739-32 900741-32-AU 900737-32-AU

36

Alloy 900720 900690-36 900741-36 900737-36

Gold 900743-36 900739-36 900741-36-AU 900737-36-AU

40

Alloy 900722 900690-40 900741-40 900737-40

Gold 900743-40 900739-40 900741-40-AU 900737-40-AU

42 Alloy 900747-42

Gold

Alloy

44

Gold

48 Alloy 900724 900690-48 900741-48 900737-48 900790-48

Gold 900743-48 900739-48 900741-48-AU 900737-48-AU

Alloy

52

Gold

64 Alloy 900726* 900690-64* 900741-64* 900737-64* 900790-64* 900747-64 900748-64

Gold 900743-64* 900739-64* 900741-64-AU* 900737-64-AU*

Alloy

68

Gold

Alloy

84

Gold

DIP DIP DIP DIP DIP DIP DIP DIP DIP DIP Shrink-DIP Shrink-DIP Shrink-DIP SOIC SOIC SOJ LCC PLCC

.300" wide

(7,62 mm)

Duck Bill Contacts Knife Edge Contacts Paint Cut Contacts

.600" wide

(15,24 mm)

.300" wide

(7,62 mm)

.600" wide

(15,24 mm)

Standard Model Connector Compatible

Part Numbers

.300" wide

(7,62 mm)

.600" wide

(15,24 mm)

Part Numbers Part NumbersPart Numbers Part Numbers

.300" wide

(7,62 mm)

.600" wide

(15,24 mm)

.300" wide

(7,62mm)

900790-08

900790-14

900790-18

900790-20

900789-28 900790-28

.600" wide

(15,24 mm)

900790-32

900790-36

900790-40

900746-28 900747-28

.400" wide

(10,16 mm)

Connector Compatible

(with Headless Heads)

Part Numbers

.600" wide

(15,24 mm)

900747-52

.750" wide

(19,05 mm)

Surface Mount Test Clips

Square ContactsSquare Contacts

Connector Compatible

(with Headless Heads)

Part Numbers

.150" wide

(3,81 mm)

923650-08

923655-08

923650-14

923655-14

923650-16

923655-16

923650-18

923655-18

923650-20

923655-20

923650-24

923655-24

923650-28

923655-28

.300" wide

(7,62 mm)

923660-08

923665-08

923660-14

923665-14

923660-16

923665-16

923660-18

923665-18

923660-20

923665-20

923660-24

923665-24

923660-28

923665-28

.300" wide

(7,62 mm)

923660-20

923665-20

923660-24

923665-24

923660-28

923665-28

923680-20

923685-20

923680-28

923685-28

923680-44

923685-44

923680-52 923670-52

923680-68

923685-68

923680-84

923685-84

923670-20

923675-20

923670-28

923675-28

923670-44

923675-44

923670-68

923675-68

923670-84

923675-84

* 64 position DIL Test Clip and IC are .900" (22,86 mm) wide

A P Products GmbH

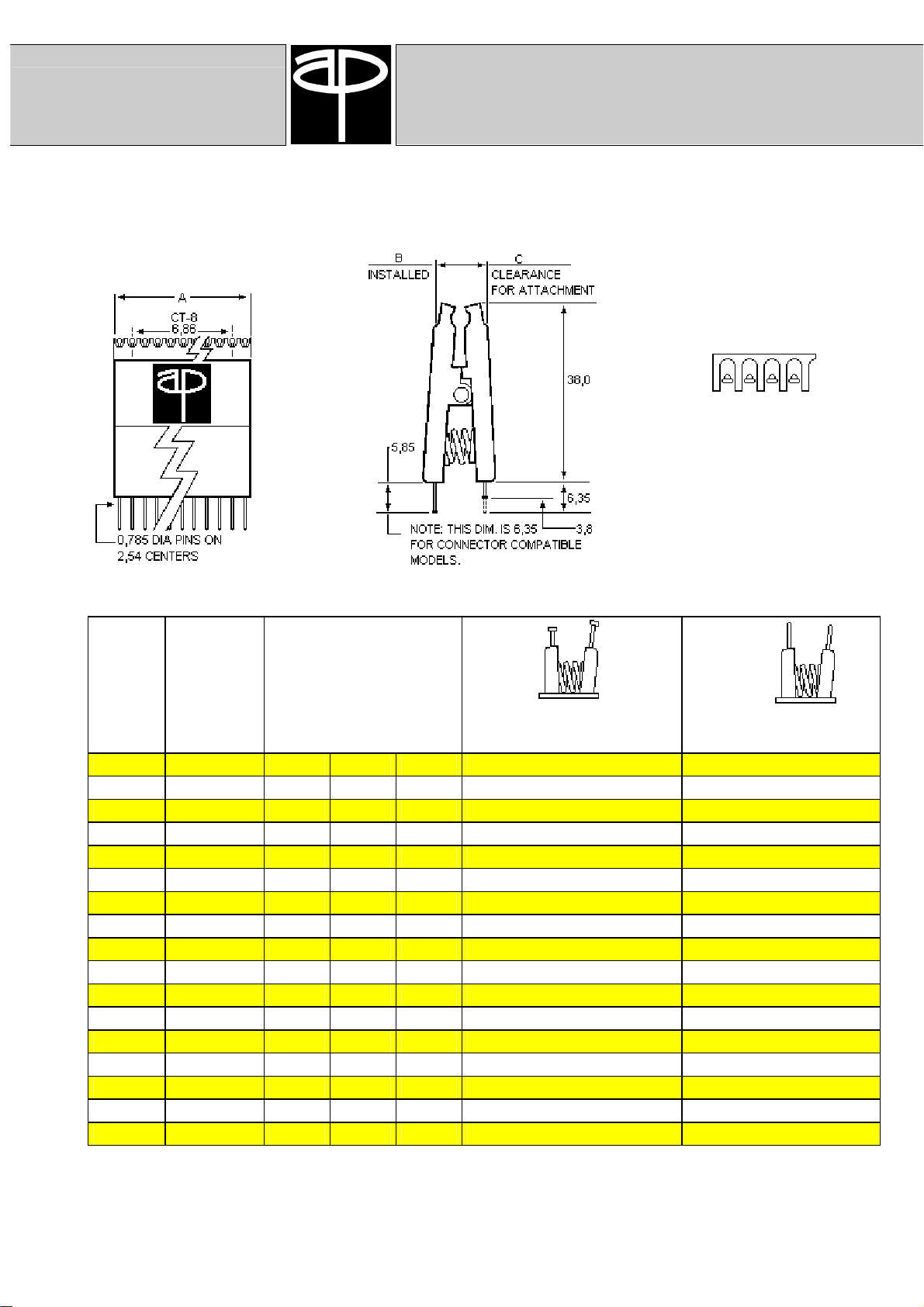

DIP TEST

-

CLIP

Standard

The Standard Test-Clip

Flat contacts for maximum interface surface area.

Top view showing flat contacts

Dimensions

Number

of pins

08 7,62 / 0,3 16,06 12,20 12,95 900695 900743-08 900690-08 900739-08

14 7,62 / 0,3 18,60 12,20 12,95 900698 900743-14 900690-14 900739-14

16 7,62 / 0,3 21,13 12,20 12,95 900700 900743-16 900690-16 900739-16

16 15,24 / 0,6 21,13 19,30 20,57 900702 900742-16 900689-16 900738-16

18 7,62 / 0,3 23,67 12,20 12,95 900703 900743-18 900690-18 900739-18

20 7,62 / 0,3 26,21 12,20 12,95 900704 900743-20 900690-20 900739-20

22 7,62 / 0,3 28,75 12,20 12,95 900706 900742-22 900689-22 900738-22

22 15,24 / 0,6 28,75 19,30 20,57 900705 900743-22 900690-22 900739-22

24 7,62 / 0,3 31,29 12,20 12,95 900715 900742-24 900689-24 900738-24

24 15,24 / 0,6 31,29 19,30 20,57 900714 900743-24 900690-24 900739-24

28 7,62 / 0,3 36,37 12,20 12,95 900717 900742-28 900689-28 900738-28

28 15,24 / 0,6 36,37 19,30 20,57 900718 900743-28 900690-28 900739-29

32 15,24 / 0,6 41,45 19,30 20,57 900719 900743-32 900690-32 900739-32

36 15,24 / 0,6 46,53 19,30 20,57 900720 900743-36 900690-36 900739-36

40 15,24 / 0,6 51,61 19,30 20,57 900722 900743-40 900690-40 900739-40

48 15,24 / 0,6 61,77 19,30 20,57 900724 900743-48 900690-48 900739-48

64 22,86 / 0,9 82,10 26,67 27,43 900726 900743-64 900690-64 900739-64

row to row

mm / inch

Dimensions

A

(mm)

B

C

Nickel-Silver Gold

Part number

Part number

Nickel-Silver Gold

5

Knife-Edge

TEST

-

CLIP

The Knife-Edge Test-Clip

Specially formed contacts to cut through dirt build-up on IC pins.

A P Products GmbH

Top view showing knife-edge

Dimensions

Number

of pins

08 7,62 / 0,3 16,06 12,20 12,95 900741-08 900737-08 900737-08-AU

14 7,62 / 0,3 18,60 12,20 12,95 900741-14 900737-14 900737-14-AU

16 7,62 / 0,3 21,13 12,20 12,95 900741-16 900737-16 900737-16-AU

16 15,24 / 0,6 21,13 19,30 20,57 900740-16 900736-16 900736-16-AU

18 7,62 / 0,3 23,67 12,20 12,95 900741-18 900737-18 900737-18-AU

20 7,62 / 0,3 26,21 12,20 12,95 900741-20 900737-20 900737-20-AU

22 7,62 / 0,3 28,75 12,20 12,95 900740-22 900736-22 900736-22-AU

22 15,24 / 0,6 28,75 19,30 20,57 900741-22 900737-22 900737-22-AU

24 7,62 / 0,3 31,29 12,20 12,95 900740-24 900736-24 900736-24-AU

24 15,24 / 0,6 31,29 19,30 20,57 900741-24 900737-24 900737-24-AU

28 7,62 / 0,3 36,37 12,20 12,95 900740-28 900736-28 900736-28-AU

28 15,24 / 0,6 36,37 19,30 20,57 900741-28 900737-28 900737-28-AU

32 15,24 / 0,6 41,45 19,30 20,57 900741-32 900737-32 900737-32-AU

36 15,24 / 0,6 46,53 19,30 20,57 900741-36 900737-36 900737-36-AU

40 15,24 / 0,6 51,61 19,30 20,57 900741-40 900737-40 900737-40-AU

48 15,24 / 0,6 61,77 19,30 20,57 900741-48 900737-48 900737-48-AU

64 22,86 / 0,9 82,10 26,67 27,43 900741-64 900737-64 900737-64-AU

row to row

mm / inch

Dimensions

A

(mm)

B

C

Part number

Nickel-Silver

Part number

Nickel-Silver Gold

contacts

6

A P Products GmbH

TEST

-

CLIP

PAINT CUT

The Paint-Cut Test-Clip

Specially formed and hardened contacts designed to cut through antistatic paint on PC-Boards.

Top-view showing

contacts

Side-view showing contacts

Paint Cut contacts are for ICs with antistatic protection coating, as often used in military applications. These

contacts will cut through the protective coating. Stripping the coat prior to testing is no longer necessary. The test

marks can easily be touched up after testing

Number

of pins

24 7,62 / 0,3 31,29 12,20 12,95 900789-24

28 7,62 / 0,3 36,37 12,20 12,95 900789-28

08 7,62 / 0,3 16,06 12,20 12,95 900790-08

14 7,62 / 0,3 18,60 12,20 12,95 900790-14

16 7,62 / 0,3 21,13 12,20 12,95 900790-16

18 7,62 / 0,3 23,67 12,20 12,95 900790-18

20 7,62 / 0,3 26,21 12,20 12,95 900790-20I

24 15,24 / 0,6 31,29 19,30 20,57 900790-24

28 15,24 / 0,6 36,37 19,30 20,57 900790-28

40 15,24 / 0,6 51,61 19,30 20,57 900790-40

48 15,24 / 0,6 61,77 19,30 20,57 900790-48

64 22,86 / 0,9 82,10 26,67 27,43 900790-64

Dimensions

row to row

A

Dimensions (mm)

B

C

Part number

7

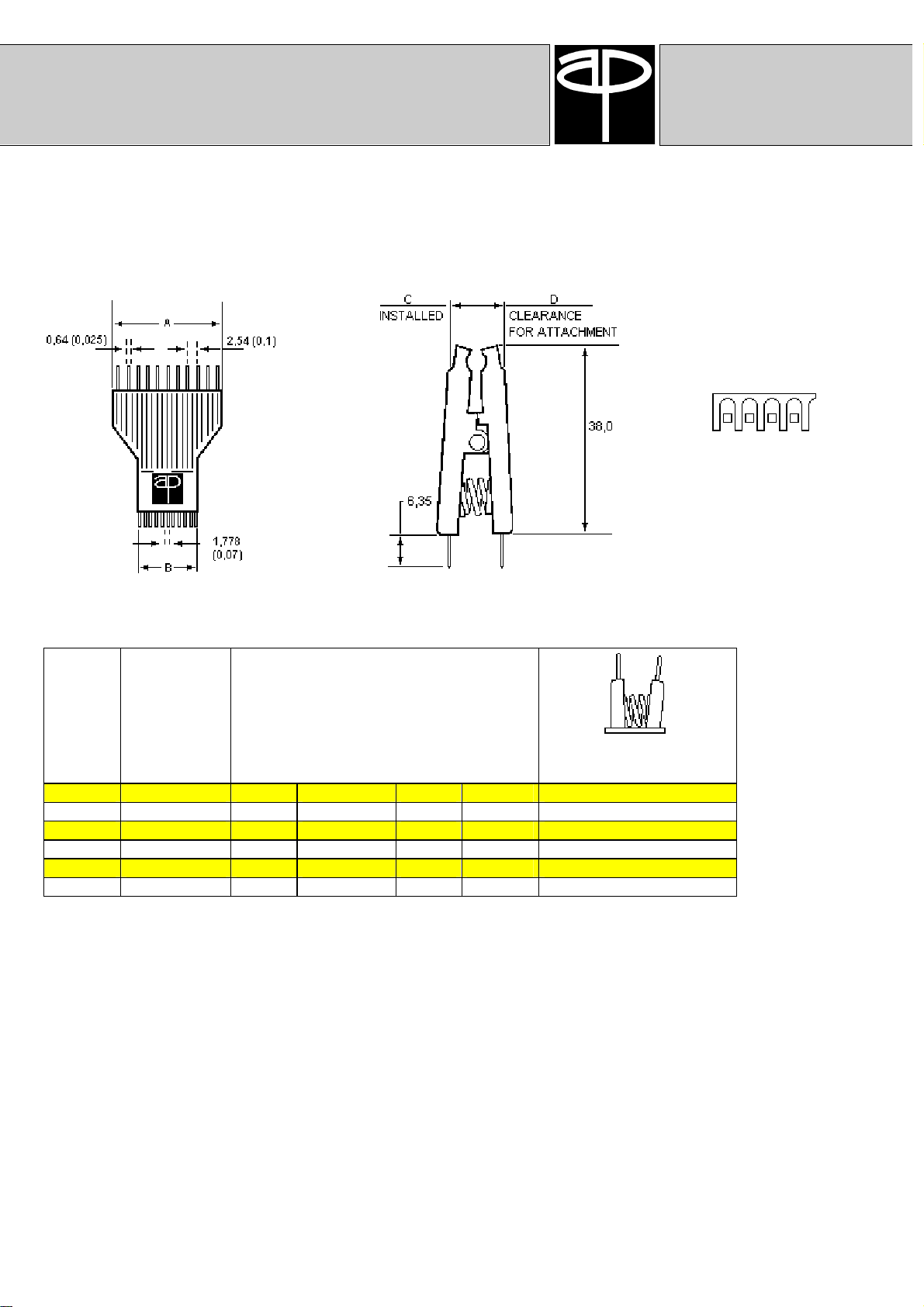

Shrink-DIP

TEST

-

CLIP

A P Products GmbH

The Shrink-DIP Test-Clip

1,778 mm on the interface side and 2,54 mm on the connector side make the Test-Clip compatible to

standard connectors.

Dimensions

Number

of pins

28 10,16 / 0,4" 36,67 25,27 16,25 17,00 900746-28

28 15,24 / 0,6" 36,67 25,27 19,30 20,57 900747-28

42 15,24 / 0,6" 54,15 37,72 19,30 20,57 900747-42

52 15,24 / 0,6" 66,85 46,61 19,30 20,57 900747-52

64 15,24 / 0,6" 82,10 57,28 19,30 20,57 900747-64

64 19,05 / 0,75" 82,10 57,28 24,13 25,40 900748-64

row to row

mm / inch

A

Dimensions

(mm)

B

C D

Part number

Nickel-Silver

View showing contacts

in IC mating area

8

A P Products GmbH

TEST

-

CLIP

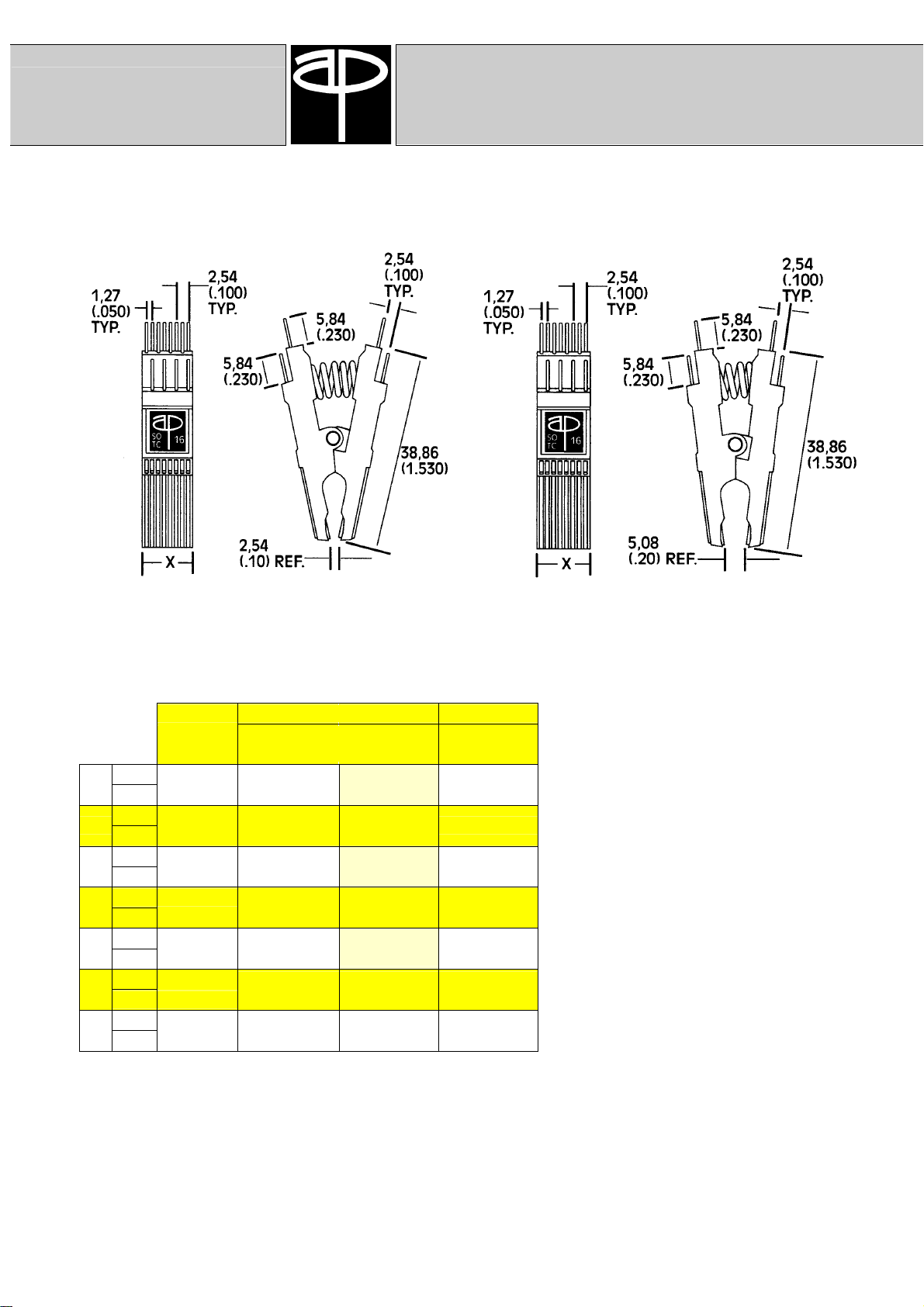

Small Outline

The Small-Outline Test-Clip

For .150" and .300" small outline ICs. The connector end is staggered to accommodate standard pitch connectors.

Alloy 5,59 mm

8

Gold (0,220")

Alloy 9,40 mm

14

Gold (0,370")

Alloy 10,67 mm

16

Gold (0,420")

Alloy 11,97 mm

18

Gold (0,470")

Alloy 13,21 mm

20

Gold (0,520"

Alloy 15,75 mm

24

Gold (0,620")

Alloy 18,29 mm

28

Gold (0,720")

"Narrow" Version

(0,150" wide IC's)

SOIC SOIC SOJ

"X"

Dimension

.150" wide

(3,81 mm)

923650-08

923655-08

923650-14

923655-14

923650-16

923655-16

923650-18

923655-18

923650-20

923655-20

923650-24

923655-24

923650-28

923655-28

.300" wide

(7,62 mm)

923660-08

923665-08

923660-14

923665-14

923660-16

923665-16

923660-18

923665-18

923660-20

923665-20

923660-24

923665-24

923660-28

923665-28

.300" wide

(7,62 mm)

923660-20

923665-20

923660-24

923665-24

923660-28

923665-28

"Wide" Version

(0,300" wide IC's)

The SOTC is specially designed for "Small

Outline IC's" (IC's with a small circumference).

Although the distance between pins at the end

of the IC is only 1,27 mm (0,050''), a distance

of 2,54 mm between pins is reached at the tap

end.

This pitch enables an easy attachment of the

test point and ensures that unnecessary short

circuits are avoided.

The standard 0,64 mm square pins enable an

easy attaching of the respective connectors or

"wire wrapping".

Like all of our Test-Clips, the SOTC has an

extra strong pressure spring, which ensures a

safe contact. Furthermore, it has an insulator

in order to avoid any short circuits. With this

small Test-Clip even SOIC's having a distance

of only 0,64 mm can be tested.

9

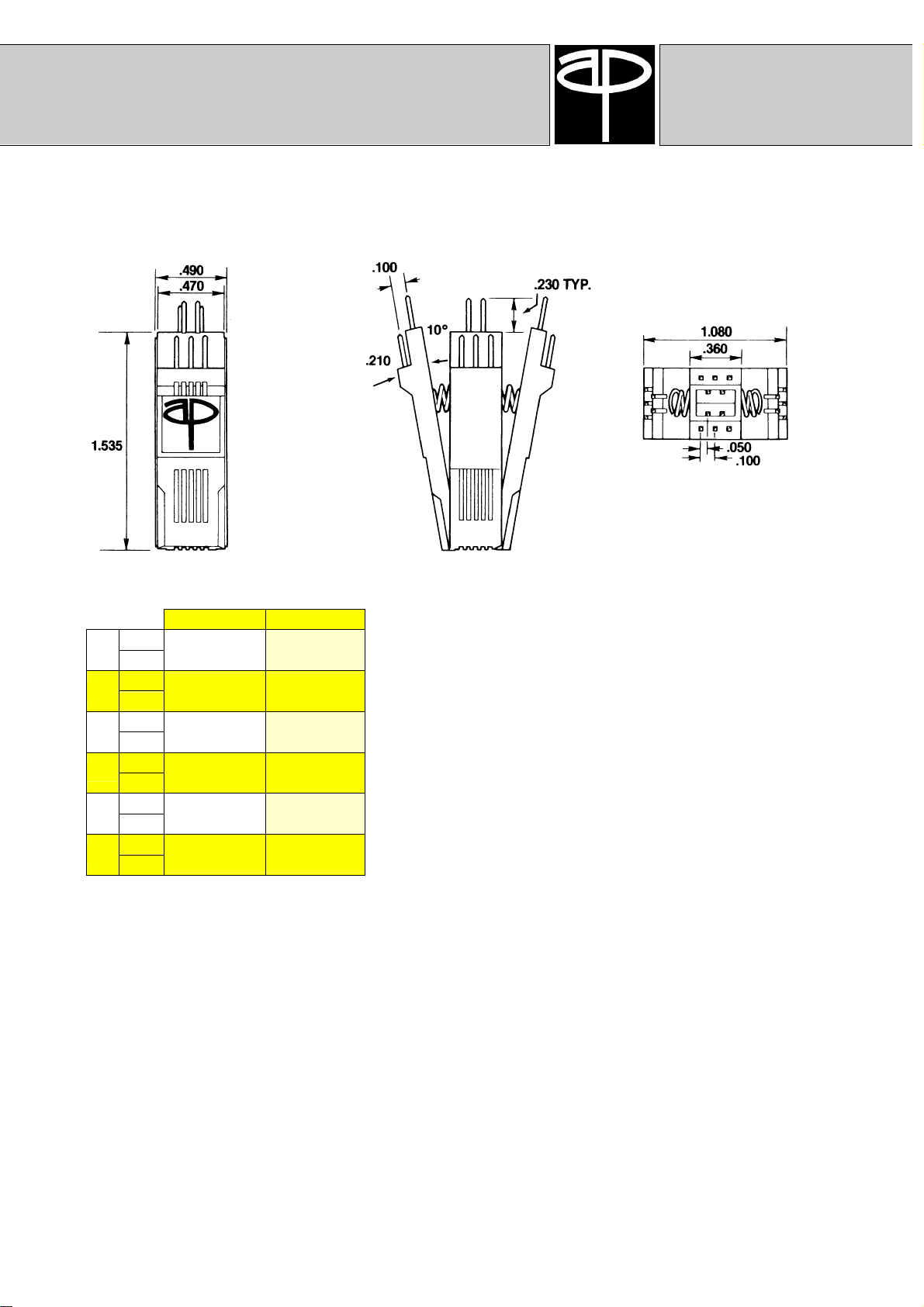

Surface Mount

TEST

-

CLIP

The PLCC Test-Clip

All four sides open simultaneously for easy attachment on PLCC or LCC chips.

Alloy

20

Gold

Alloy

28

Gold

Alloy

44

Gold

Alloy

52

Gold

Alloy

68

Gold

Alloy

84

Gold

LCC PLCC

923680-20

923685-20

923680-28

923685-28

923680-44

923685-44

923680-52

923685-52

923680-68

923685-68

923680-84

923685-84

923670-20

923675-20

923670-28

923675-28

923670-44

923675-44

923670-52

923675-52

923670-68

923675-68

923670-84

923675-84

This Test-Clip is for testing Plastic Leaded Chip Carrier (PLCC) style

integrated circuits. The unique action wedge design with all four

sides opening simultaneously provides a faster and easier

attachment to the PLCC.

The helical compression spring and insulating contact combs insure

integrity in contact when testing. Our narrow body design allows

components to be tested with as little as 2,54 mm (0,1") lead-to-lead

spacing, side stackable at 0,200" lead-to-lead spacing.

Probe access points are immediately visible for fast and safe

individual lead testing, while staggered contact rows on 0,100"

centers allow for easy probe attachment and help prevent accidental

shorting of adjacent probes, Industry standard 0,635 mm square

contact pins permit easy attachment of female socket connectors or

wire wrapping.

A P Products GmbH

10

A P Products GmbH

Assessories

Logical Connection

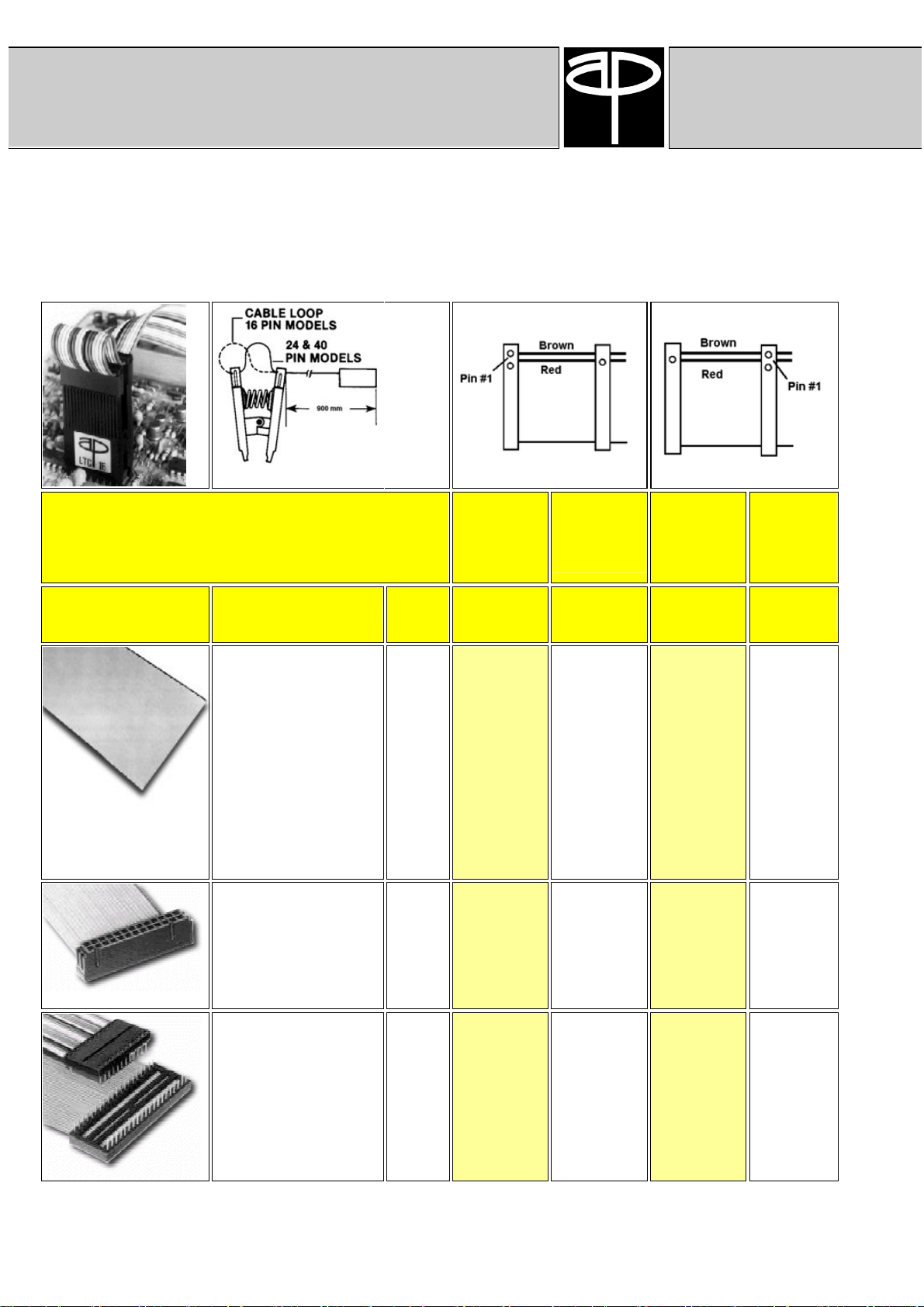

The Logical Connection

Remote test equipment can be easily connected to a PCB when the performance proven

A P Products IC Test-Clip is combined with our complete, tested, ready-to-use cable

assembly.

We call this combination "The Logical Connection". It is the ideal connection from a

logic analyzer to an IC.

On one end, a pair of single-row socket connectors attach to the pins of a connectorcompatible model Test-Clip. On the other end the cable is left open for an easy attachment

of customer specific connectors. Logical Connections with preinstalled connectors are also

available

Logical Connection for Dual Inline

Packages (Through-Hole ICs)

Narrow nose shape

fits high density PC boards; fits onto ICs with only 0,1'' between leads or adjacent

components.

Probe holes

in the back of all connectors allow easy access to individual lines.

Positive clamping

The heavy duty industrial grade metal springs provide a firm positive grip to the DIP

under test. The weight of the probes and test leads can't disturb connections,

eliminating intermittents and false readings.

Cable loop

between connectors allows free actuation of the Test-Clip for clearance over all

package styles.

Molded-on connectors

provide optimum electrical integrity and strain relief. (not available on all configurations)

Custom configurations

can be ordered by contacting factory.

Logical Connection for Shrink DIP

Packages (Through-Hole ICs)

Logical Connection for Small Outline

Packages (Surface Mount ICs)

Logical Connection for PLCC Packages

(Surface Mount ICs)

11

only (No Test

Logical Connection

Assessories

Logical Connection for Dual Inline Packages

A P Products GmbH

(Through-Hole ICs)

Remote End Termination

Connector Description

none 08

Socket Connector

- mates with two rows of

0,635mm (0,025")

square or diameter pins

on 2,54 mm (0,100")

centers.

DIP Connector

- mates with standard

DIP sockets

No. of

Contact

s

14

16

18

20

22

24

28

32

36

40

48

64

14

16

20

26**

40

50**

64

08

14

16

20

24

28

40

Logical

Connection

(Test Clip

and Cable

Assembly)

Part

Number*

923930-08

923930-14

923930-16

923930-18

923930-20

923930-22

923930-24

923930-28

923930-32

923930-36

923880-40

923880-48

923880-64

923931-14

923931-16

923931-20

923931-24

923881-40

923881-48

923881-64

923934-08

923934-14

923934-16

923934-20

923934-24

923934-28

923934-40

Cable

Assembly

Clip)

Part

Number*

922490-08

922490-14

922490-16

922490-18

922490-20

922490-22

922490-24

922490-28

922490-32

922490-36

922590-40

922590-48

922590-64

922491-14

922491-16

922491-20

922491-24

922591-40

922591-48

922591-64

922494-08

922494-14

922494-16

922494-20

922494-24

922494-28

922494-40

Logical

Connection

(Test Clip

and Cable

Assembly)

Part

Number*

923880-08

923880-14

923880-16

923880-18

923880-20

923880-22

923880-24

923880-28

923880-32

923880-36

923930-40

923930-48

923930-64

923881-14

923881-16

923881-20

923881-24

923931-40

923931-48

923931-64

923884-08

923884-14

923884-16

923884-20

923884-24

923884-28

923884-40

Cable

Assembly

only (No

Test

Clip)

Part

Number*

922590-08

922590-14

922590-16

922590-18

922590-20

922590-22

922590-24

922590-28

922590-32

922590-36

922490-40

922490-48

922490-64

922591-14

922591-16

922591-20

922591-24

922491-40

922491-48

922491-64

922594-08

922594-14

922594-16

922594-20

922594-24

922594-28

922594-40

* Part number suffix denotes number of pins in Test Clip.

** On 26 position connectors, position #25 and #26 are unused. On 50 position connectors, position #49 and #50 are unused.

12

A P Products GmbH

Assessories

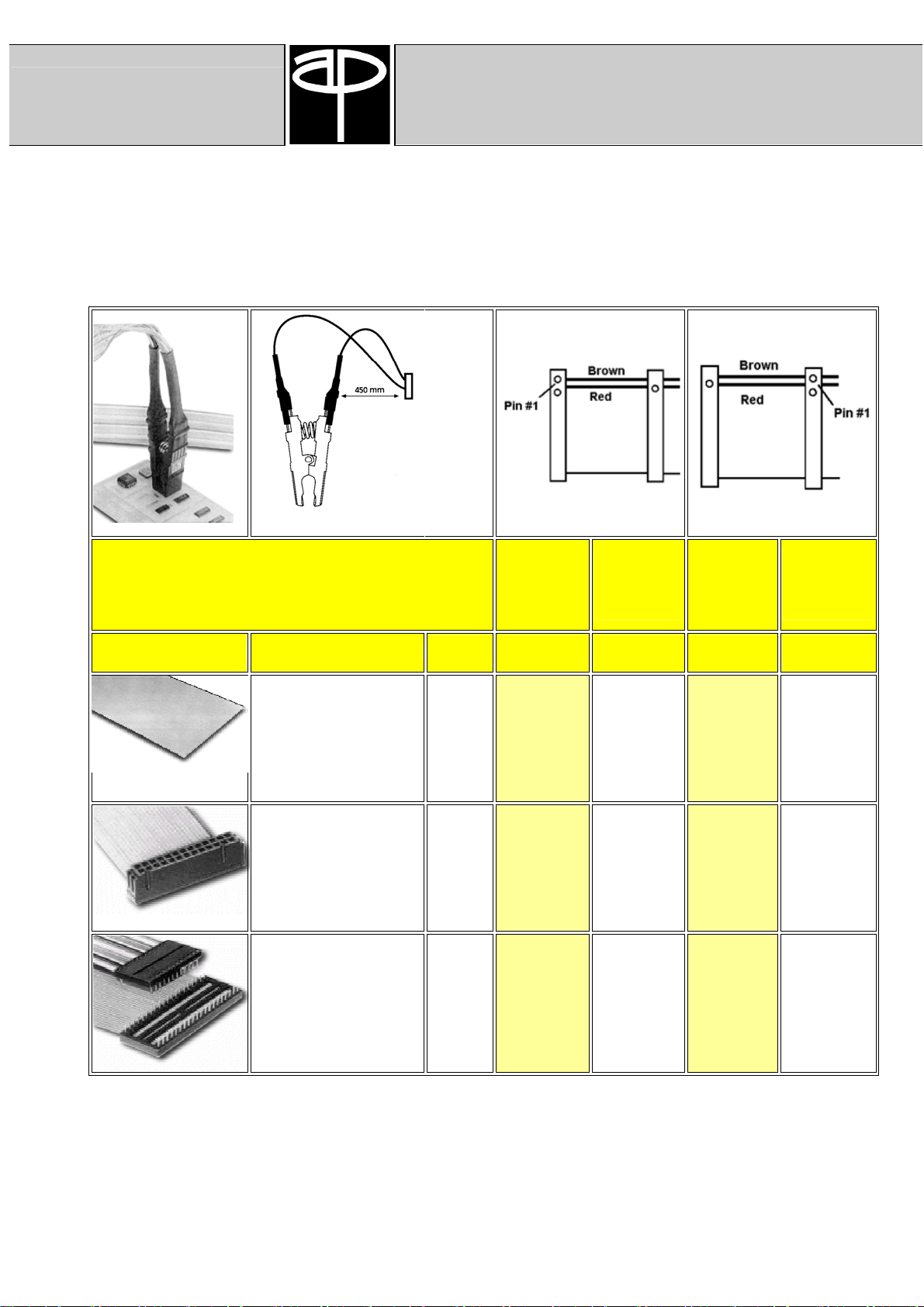

Logical Connection

Logical Connection for Small Outline Packages

(Surface Mount ICs)

Remote End Termination

Connector Description

none 08

Socket Connector

- mates with two rows of

0,635mm (0,025")

square or diameter pins

on 2,54 mm (0,100")

centers.

DIP Connector

- mates with standard

DIP sockets

No. of

Contacts

14

16

18

20

24

28

10**

14

16

20**

20

26**

34**

08

14

16

18

20

24

28

Logical

Connection

(Test Clip

and Cable

Assembly)

Part

Number*

924930-08

924930-14

924930-16

924930-18

924930-20

924930-24

924930-28

924931-08

924931-14

924931-16

924931-18

924931-20

924931-24

924931-28

924934-08

924934-14

924934-16

924934-18

924934-20

924934-24

924934-28

Cable

Assembly

only (No

Test Clip)

Part

Number*

924490-08

924490-14

924490-16

924490-18

924490-20

924490-24

924490-28

924491-08

924491-14

924491-16

924491-18

924491-20

924491-24

924491-28

924494-08

924494-14

924494-16

924494-18

924494-20

924494-24

924494-28

Logical

Connection

(Test Clip

and Cable

Assembly)

Part

Number*

924880-08

924880-14

924880-16

924880-18

924880-20

924880-24

924880-28

924881-08

924881-14

924881-16

924881-18

924881-20

924881-24

924881-28

924884-08

924884-14

924884-16

924884-18

924884-20

924884-24

924884-28

Cable

Assembly onl

y (No

Test Clip)

Part

Number*

924590-08

924590-14

924590-16

924590-18

924590-20

924590-24

924590-28

924591-08

924591-14

924591-16

924591-18

924591-20

924591-24

924591-28

924594-08

924594-14

924594-16

924594-18

924594-20

924594-24

924594-28

* Part number suffix denotes number of pins in Test Clip.

** On 10 position connectors, position #09 and #10 are unused.

On 20 position connectors, position #19 and #20 are unused.

On 26 position connectors, position #25 and #26 are unused.

On 34 position connectors, position #29 to #34 are unused.

13

Logical Connection

Assessories

Logical Connection for PLCC Packages

A P Products GmbH

(Surface Mount ICs)

Remote End Termination

Connector Description

none 20

Socket Connector

- mates with two rows of

0,635mm (0,025") square or

diameter pins on 2,54 mm

(0,100") centers.

No. of

Contacts

28

44

52**

68**

84**

20

34***

50***

26**

34**

50**/****

Logical

Connection

(Test Clip and

Cable Assembly)

Part Number* Part Number*

925880-20

925880-28

925880-44

925880-52

925880-68

925880-84

925881-20

925881-28

925881-44

925881-52

925881-68

925881-84

Cable Assembly only

(No Test Clip)

925590-20

925590-28

925590-44

925590-52

925590-68

925590-84

925591-20

925591-28

925591-44

925591-52

925591-68

925591-84

* Part number suffix denotes number of pins in Test Clip.

** 2 Cables with individual ends

*** On 34 position connectors, position #29 to #34 are unused.

On 50 position connectors, position #44 to #50 are unused.

**** On 50 position connectors, position #44 to #50 are unused.

14

JAHRE

TEST CLIP

®

A P Products

GmbH

®

Bäumlesweg 21

D-71093 Weil im Schönbuch

Germany

Telefon: +49 (71 57) 53 48-0

Telefax: +49 (71 57) 53 48-39

Internet: www.ap-products.com

E-Mail: info@ap-products.com

Loading...

Loading...