A P Products GREAT JUMPERS User Manual

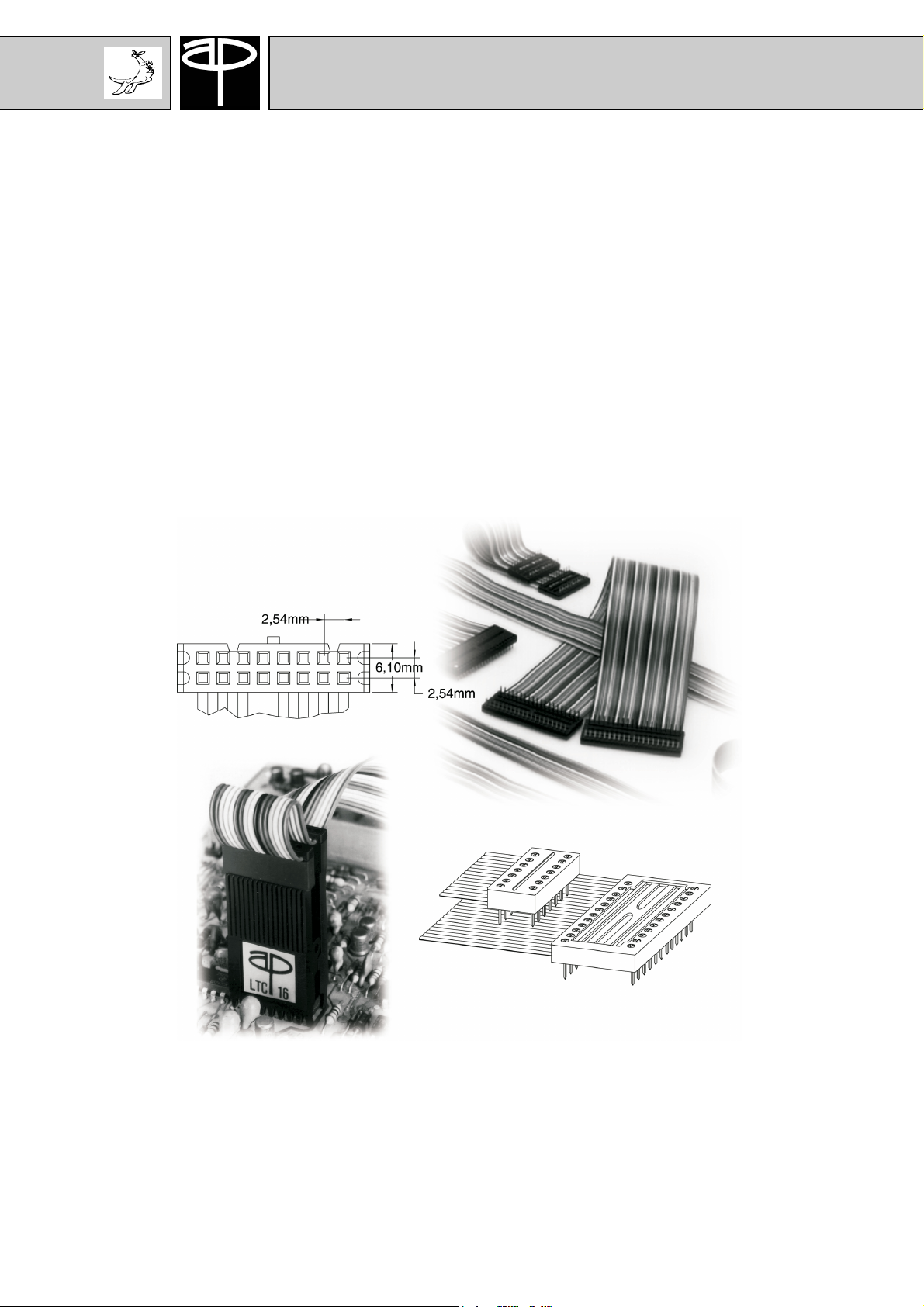

Great Jumper

CABLE ASSEMBLIES A P PRODUCTS GREAT JUMPERS

A P Products

A P Products

About A P Products ...

Since A P Products has first joined the market in 1967 with the IC-Testclip it has developed into preferred manufacturer

of proprietary, high performance Electronic Interconnect Products. Those provide cost-effective solutions to the electronic

and mechanical challenges posed by ever-increasing signal frequencies and decreasing package sizes.

A P Products has earned a reputation for its responsiveness and creativity in solving unusual interconnect problems

concerning e.g. packaging specifications.

Initially known as A P Incorporated, and steadily growing for nearly 20 years, Associated Enterprises took products to

market through ist subsidiary companies known as A P Products Inc., APTronics, Chabin, Symbex, 4C and A P

Products GmbH. The task of A P Products GmbH as an international sales organisation was to handle the assembly and

sales functions, while research and development was centralized and provided by Associated Enterprises. Component

level manufacturing was performed by a Division of Associated Enterprises, known as Omnitec.

In 1986 A P Products GmbH became a seperate company, but the relationship to Associated Enterprises is still close.

Cooperation on projects and resource-sharing is most common; nevertheless manufacturing now is also part of A P

Products GmbH functions.

A P Products GmbH policy is to sell mostly indirect through local distibutors. Additional offices in Saffron Walden, Great

Britain and in Milano, Italy help to organize the market.

An over 650 m² stock and a team of about 20 co-workers - dedicated to excellence, flexibility and responsiveness ensure a short delivery time and products made to customer specification. A P Products GmbH is always trying to

provide the customers with on-time delivery of competitive standard products as well as innovative, high-quality and costeffective solutions to unique interconnection problems.

Also made by A P Products:

IC Test Clips

A P Products Test Clips the industry

standard for faster, easier DIP IC

testing, quality control inspection and

field service. The Test Clips provide easy

attachment, „hands-free“ testing and

positive clamping. Reliable contacts and

rugged construction allow a save way

for testing.

• Over 150 models to fit every size DIP

up to 64 pins.

• Nailhead and connector compatible

„headless“ available.

Male Header

A P Products offers a wide range of

either custom made or standard male

headers. The wide assortment of

standard male headers include single, double and triple row, straight and

right angle, gold and solder plating

and in various pinlength up to 36 pins

per row.

• 2,36mm / 5,97mm / 8,07mm

interface area

• Mate with industry standard

connectors or headers with

contacts spaced on 2,54mm

Female Header

The wide standard assortment of

female headers include single, double

and triple row female headers with up

to 36 pins per row which can easily be

cut down to any desired length.

• A variety of gold and tin platings

available

• Mate with industry standard

connectors or headers with contacts

spaced on 2,54mm

A P Products GmbH

Postfach 1158

D-71089 Weil im Schönbuch

Deutschland

Tel.: +49-7157-5348-0

Fax: +49-7157-5348-39

Web: www.ap-products.de

E-mail: info@ap-products.de

A P Products Ltd.

80 Cromwell Road

Saffron Walden, CB11 4BE

Great Britain

Tel.: +44-1799-526602

Fax: +44-1799-521408

Web: www.ap-products.co.uk

E-mail: info@ap-products.co.uk

A P Products S.r.l.

Viale Abruzzi, 87

I-20131 Milano

Italia

Tel.: +39-02-29404697

Fax: +39-02-29523280

Web: www.ap-products.com

E-mail: info-i@ap-products.com

AP1100

Great Jumper

A P Products

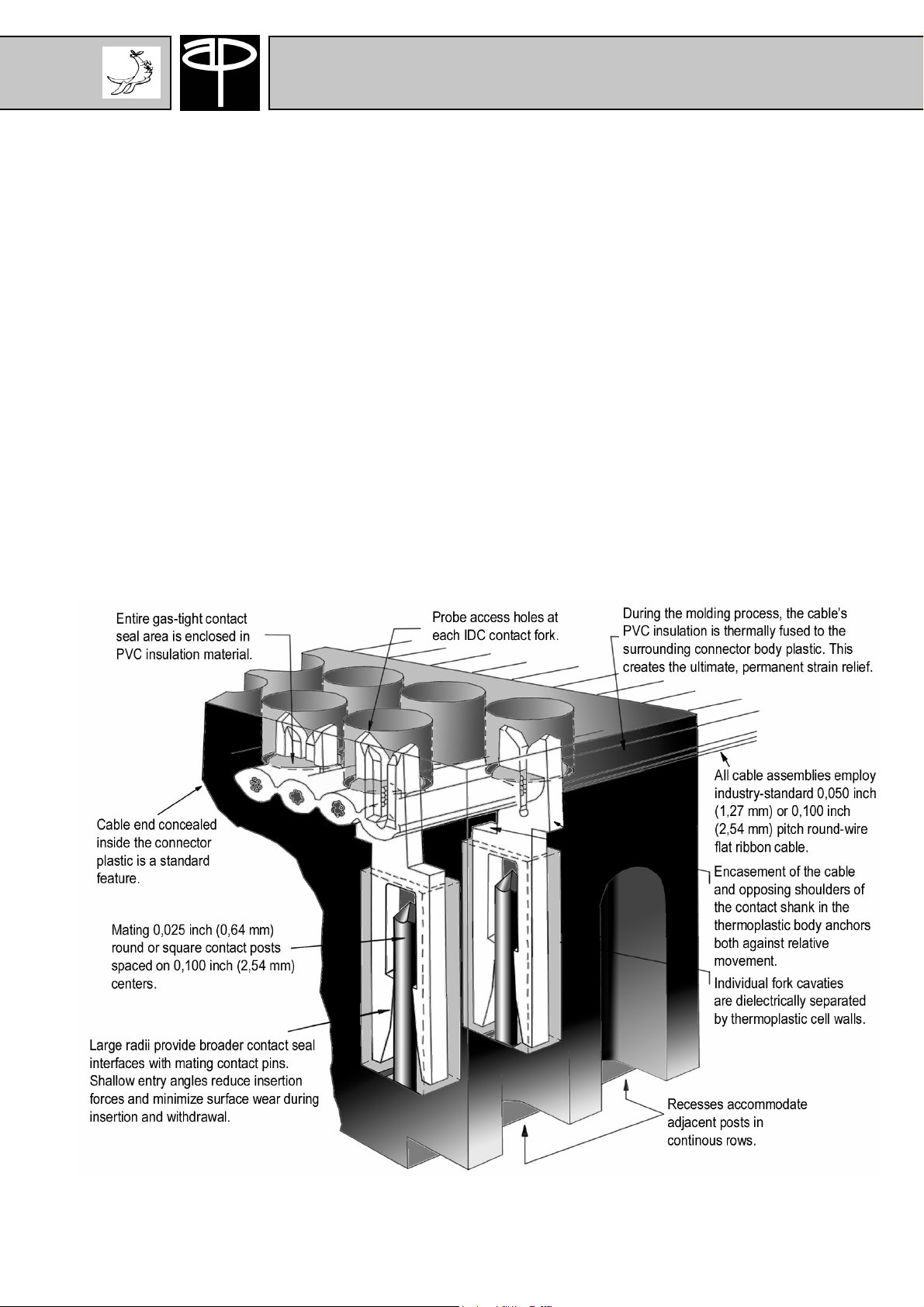

Technical Information: Molded-On Concept

Molded-On is the term we at A P

Products use to describe the

integration of cable and contact

into one-piece, inseparable cable

assemblies by means of injection

molding. The process, itself, is

unique in the industry, and so are

the resulting functional and

economic advantages in

interconnection systems.

The most obvious advantage of

"molded-on" cable assemblies is

that they are one piece and

therefore inseparable. There are

no individual components to come

apart, lose, stock, assemble, test

or scrap. They are factory tested

and ready to install when shipped.

Integral Molding

Flat ribbon cable conductors are

IDC mass terminated to

preformed contacts and the entire

terminated cable end is enclosed

in a mold configured as a

connector. Hot, molten polyester

thermoplastic is then injected into

the connector mold under intense

pressure. The pressurized molten

plastic penetrates and fills all mold

cavity space while simultaneously

engulfing the shouldered portion

of the contacts, the cable cut off

end, and the insulated lead-in

portion of the cable itself. The PVC

insulation is thermally fused to the

polyester plastic of the connector

body.

The finished part, now an integral,

single-end assembly, cools and is

ejected from the mold. For doubleended assemblies, the opposite

cable end also is IDC mass

terminated to contacts and

molded into a connector body.

One-piece daisy chain assemblies

are produced by using throughcable molds that permit any

connector body style to be molded

around IDC mass terminated

contacts anywhere on the cable.

Special configuration, one-piece

assemblies incorporating any

number of connectors, with the

same or different body styles and

A P Products

sizes, are easily produced to

customer specifications with our

unique „molded-on“ process.

Structural and Electrical

A polyester thermoplastic was

selected for the connector body

material because of inherent

mechanical strength, dielectric

strength, flame retardants and

moldability properties.

The advantages for one-piece

cable assemblies (listed in the

picture) are numerous and

distinctive. These benefits derive

exclusively from the „molded-on“

concept, and are unachievable

with other manufacturers’ cable

assemblies consisting of many

separate plastic and metal parts

that rely on mechanical means of

attachment to the cable.

Unlike multi-piece mechanical

assemblies, A P Products’ onepiece cable assemblies have no

air space between adjacent IDC

contacts. The contacts and cable

are embedded in a solid block of

plastic, providing significantly

improved insulation resistance

and higher breakdown voltage.

Because the body plastic encases

the shouldered portion of the

contact shank as well as the cable,

it functions as a unifying medium

that anchors both against relative

motion. This important advantage

is markedly absent in assembled

connectors where the contacts are

only loosely retained by

mechanical means.

Another unique advantage of

„molded-on“ cable assemblies is

that they need no added-on strain

relief as do mechanically joined

assemblies. Thermal fusing of the

cable to the connector plastic

creates the ultimate strain relief

that is unachievable by simply

clamping. The „molded-on“ strain

relief also permits a low profile

since bulky wrap-around covers

are unnecessary.

The constant overriding

consideration in the design of

each style of A P Products'

"molded-on" connector is that the

engineering design adheres to

accepted industry-standard

interconnection techniques for

plug/unplug and solder-in

applications. The resulting

engineered one-piece assemblies

interface with all industry-standard

interconnections with ease and

precision and may be used as

direct replacements for

mechanically joined connector/

cable assemblies.

The physical configuration of each

connector style is dimensioned to

mate precisely at every critical

OEM interconnection system

interface; electrical contacts; PC

board contact and mounting hole

patterns; polarity keys, slots and

tabs; lock/eject latches and where

necessary, external envelope

clearance dimensions. However,

in noncritical areas, such as those

portions of the connector bodies

that do not interface with OEM

system devices, space-saving low

profiles and generally more

compact housing are

characteristic of A P Products'

connector designs.

These features are made possible

primarily because the molding

process permits elimination of

unreliable mechanical covers and

separate bulky strain reliefs.

All connectors are recognized

under the Component Program of

U.L., Inc. (File number and yellow

card available.)

A P Products GmbH

Postfach 1158

D-71089 Weil im Schönbuch

Deutschland

Tel.: +49-7157-62424

Fax: +49-7157-63340

Web: www.ap-products.de

E-mail: info@ap-products.de

A P Products Ltd.

80 Cromwell Road

Saffron Walden, CB11 4BE

Great Britain

Tel.: +44-1799-526602

Fax: +44-1799-521408

Web: www.ap-products.co.uk

E-mail: info@ap-products.co.uk

A P Products S.r.l.

Viale Abruzzi, 87

I-20131 Milano

Italia

Tel.: +39-02-29404697

Fax: +39-02-29523280

Web: www.ap-products.com

E-mail: info-i@ap-products.com

AP1100

Great Jumper

A P Products

Technical Information: Cable Materials

Flat ribbon cables employed in

cable assemblies are of industrystandard geometry - AWG 26 or

AWG 28 conductor size, 0,050

inch (1,27 mm) center-to-center

conductor spacing, and PVC

insulation material. This geometry

is specifically designed to meet

the stringent, high-speed, digital

signal transmission requirements

of the computer and peripheral

equipment industries.

The close-tolerance spacing of the

parallel-conductor geometry

produces the consistently uniform

and predictable controlled

impedance and capacitance

characteristics shown in the table

below. The use of PVC insulation

uniformly convoluted as measured

in a ground-signal-ground

configuration.

Cable assemblies also are

compatible with industry-standard

IDC-mass-termination techniques

and maintain excellent impedance

continuity at the cable/contact

juncture. Their symmetrical

convolutions permit reliable

termination from either side to

accomodate both „stripe-up“ and

„stripe-down“ cable configurations.

Solid conductors in the 0,050-inchflat-ribbon cable geometry also are

available on special order. Send

specifications for samples and

quotation.

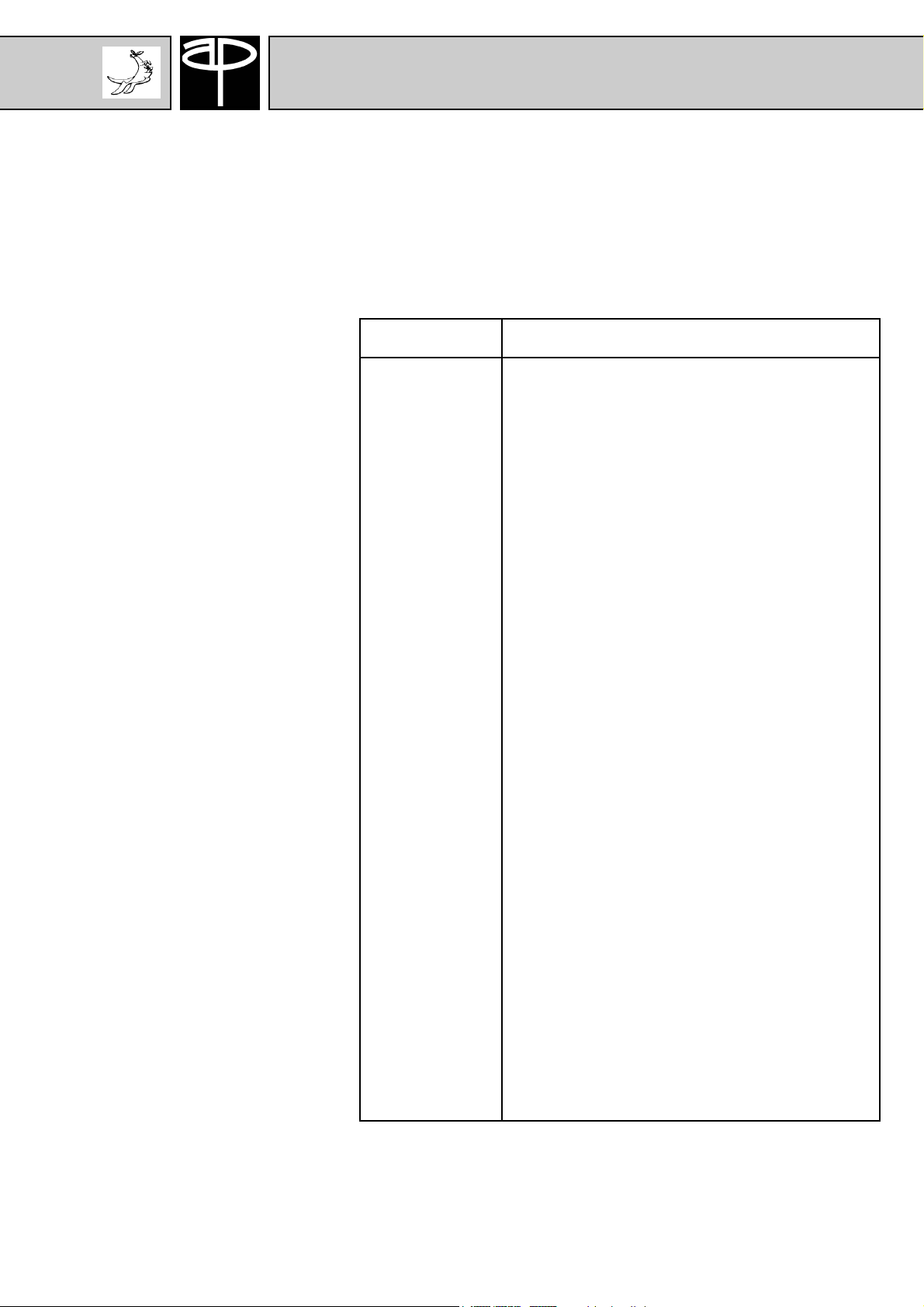

Cable Style No.:

39304 39306 39322

Physical

Insulation

Material:

Color:

First Conductor:

Conductor

Size:

Stranding:

Material:

Resistance:

(Ohms/1000ft.)

Gray Gray Multi

Red Red Brown

28 AWG 28 AWG26 AWG

7 x 36 7 x 367 x 34

Copper Copper Copper

65 41 65

Electrical

Voltage Rating:

Insulation

Resistance:

(Ohms/1000ft.)

Impedance

Unbalanced:

Capacitance

Unbalanced:

Inductance

Unbalanced:

Propagation Delay

Unbalanced:

108,00 Ohms 89,00 Ohms

12,80 pF/ft. 16,20 pF/ft. 14,10 pF/ft.

0,15 µH/ft. 0,13 µH/ft. 0,15 µH/ft.

1,40 ns/ft. 1,44 ns/ft. 1,47 ns/ft.

>1x10

10

PVCPVC PVC

300V300V 300V

10

>1x10

>1x10

105,00 Ohms

9

„Tear-down“ separation between

conductors is readily

accomplished for circuit routing of

separate conductors.

Cables also have excellent flexing

characteristics and are easily

folded to any required

configurations.

Environmental

Temperature

Rating:

Flammability

Rating:

-4°C to 105°C

UL: VW-1

AWM

-4°C to 105°C -4°C to 105°C

UL: VW-1

AWM

UL: VW-1

AWM

A P Products

Technical Information: Contact Materials

All contacts in cable assemblies

(Great Jumper) or headers are

tempered nickel-silver alloys. This

metal was selected for its

excellent overall combination of

characteristics which provide

reliable electrical performance with

or without gold plating or cladding.

High Strength

The high content of alloying

elements in nickel silvers provide

superior strength, hardness, and

ductility at lower cost than other

high-strength metals. The

hardening and the large volume of

solute nickel and zinc atoms in the

basic crystalline structure of

copper. This process eliminates

the need for costly heat treating

and provides a high workhardening rate.

Surface Finish Materials

Surface (Minimum Thickness 1,27 µm)

No.

Base metal (no additional surface)

00

Tinned 2,54 µm (Tin/Lead, non RoHS)

01

Gold 0,25 µm

02

03

Gold 0,51 µm (available on request)

04

Gold 0,76 µm (available on request)

05

Tinned 2,54 µm (RoHS compliant)

99 Other contact finishes can be produced.

Send specifications for quotation.

Fatigue Strength

Nickel silver posseses a

maximum fatigue strength in

excess of 25.000 psi for

100.000.000 cycles. This

characteristic permits consistent

Cladding and Plating

Nickel silver readily accepts any

thickness of gold plating and inlay

cladding. Both are offered as

options on Great Jumpers

contacts (see table as above).

retention of normal forces over a

long service life.

Spring Properties

The properties of stiffness and

resilience, which combine to

create a contact’s spring

characteristics, are inherent in

nickel-silver alloys. The modulus

of elasticity (18.000.000 psi)

provides excellent stiffness while

being sufficiently low when

combined with the high yield

strength (92.000 to 120.000 psi) to

produce superior resilience resulting in high normal force

capabilities for producing gas-tight

contact seals.

A P Products GmbH

Postfach 1158

D-71089 Weil im Schönbuch

Deutschland

Tel.: +49-7157-5348-0

Fax: +49-7157-5348-39

Web: www.ap-products.de

E-mail: info@ap-products.de

Corrosion Resistance

Another invaluable characteristic

of nickel silver is its superior

resistance to oxidation, fretting,

thermal shock, tarnish and

corrosive attack by moistures

containing dissolved salts.

Solderability

Nickel silver needs only

conventional cleaning or fluxing to

remove any thin surface film before

soldering or brazing by traditional

production methods, including

wave soldering.

A P Products Ltd.

80 Cromwell Road

Saffron Walden, CB11 4BE

Great Britain

Tel.: +44-1799-526602

Fax: +44-1799-521408

Web: www.ap-products.co.uk

E-mail: info@ap-products.co.uk

A P Products S.r.l.

Viale Abruzzi, 87

I-20131 Milano

Italia

Tel.: +39-02-29404697

Fax: +39-02-29523280

Web: www.ap-products.com

E-mail: info-i@ap-products.com

AP1100

Loading...

Loading...