Page 1

Unicode™ 2 Series Customized Control Stations

CONTROLSCONTROLS: NEC/CEC, ATEX/IECEX INCREASED SAFETY CONTROL STATIONS

© November 2016

Increased Safety

Polyamide, Fiberglass Reinforced Polyester, 316L Stainless Steel, Aluminum

NEC:

Class I, Division 2, Groups A, B, C, D

Class II, Groups E, F, G

Class III

Ex de IIC/DIP A21

IP66, Type 4X

CEC:

Class I, Division 2, Groups A, B, C, D

Class II, Groups F, G

Class III; Type 4X

Class I, Zone 1, AEx de IIC/ AEx tD 21

IP66

Applications

• Local control stations and motor control stations for use

in hazardous areas covering the broadest possible range

of applications.

• Control of equipment at:

— Power plants

— Chemical and petrochemical plants

— Petroleum reneries

— Reverse osmosis plants

— Pulp and paper processing plants

— Various industrial applications

• Push buttons and selector switches are used in conjunction

with contactors or magnetic starters for remote control of

motors in hazardous locations. They provide circuit control

and/or selection.

• Pilot lights provide visual assurance that an electrical function

is being performed at a remote or hazardous location.

• For use in washdown areas.

Features

• Employs Ex de method of protection which eliminates the need

for external seals.

• Operators include push buttons, illuminated push buttons,

selector switches, control and load break switches and LED

pilot lights.

• Pilot light employs high intensity single LED with lifetime of

100,000 hours that can be used at:

— 12 Vac to 254 Vac 50/60 Hz

— 12 Vdc to 60 Vdc

• Up to 3 contact blocks per actuator can be used.

• Contact block technical data:

— IEC rated operating voltage (Ue): 500 Vac – 110 Vdc

— IEC switching capacity:

– AC 12: 16 Amps/400 Vac

– AC 14: 10 Amps/400 Vac

– AC 15: 6 Amps/500 Vac

– DC 13: 2 Amps/24 Vdc and 1 Amp/110 Vdc

— NEMA switching capacity: A600: 10 Amp/600 Vac

• Selector switch technical data:

— IEC rated operating voltage: 690 Vac

— IEC rated operating current: maximum 16 Amps

— IEC switching capacity:

– AC1: 16 Amps/690 Vac

– AC15: 16 Amps/415 Vac

– AC3: 8 Amps/500 Vac

– AC3: 4 Amps/690 Vac

– AC3: 16 Amps/690 Vac

– DC1: 10 Amps/24 Vdc

– DC1: 6 Amps/60 Vdc

– DC1: 6 Amp/110 Vdc (2 contacts wired in series)

– DC1: 6 Amp/220 Vdc (3 contacts in series)

— NEMA switching capacity: A600: 10 Amps/600 Vac

• Enclosures are rated for IP66 with rmly secured gasket.

• Operators and contact blocks are spaced for easy wiring.

• Wide selection of termination methods available.

• Choice of DIN rail mounted high performance contact

block suitable for low intensity (less than 5 mA).

• TS35 rail mounted components held securely in place

during operation and easily removed for service.

• Brass Inserts are provided for TS35 DIN rails or mounting

plate to be installed inside the enclosure.

ATEX/IECEx:

Zone 1 and 2 – 21 and 22

II 2 GD

Ex de IIC/Ex demb IIC/ Ex tD A21

IP66 – IK10

Polyester Polyamide

Stainless Steel Aluminum

• Captive, corrosion resistant stainless steel cover screws.

Standard Materials

• Polyamide

— Body, cover, cable gland and blanking plug: polyamide, black

nish

• Fiberglass Reinforced Polyester (FRP)

— Body and cover: berglass reinforced polyester, black nish

• Stainless Steel

— Body, cover and cover screws: 316L stainless steel, natural

nish

• Aluminum

— Body and cover: aluminum with gray epoxy powder coating.

• Cable gland and blanking plug: polyamide

• Cover screws for 316L stainless steel or aluminum body:

304 stainless steel

• Cover screws for berglass reinforced polyester body:

316 stainless steel

• Optional nameplates: stainless steel

Accessories

• Key for changing actuator blocks.

• Guard for mushroom head actuator.

• Padlockable guard.

• M5 and M6 earth stud.

• Combination drain and breather available in brass, polyamide

and stainless steel.

Overall hazardous location and ingress protection rating depends on the rating of the optional certified components used.

183

Page 2

Unicode™ 2 Series Customized Control Stations

CONTROLS CONTROLS: NEC/CEC, ATEX/IECEX INCREASED SAFETY CONTROL STATIONS

© November 2016

Increased Safety

Polyamide, Fiberglass Reinforced Polyester, 316L Stainless Steel, Aluminum

NEC:

Class I, Division 2, Groups A, B, C, D

Class II, Groups E, F, G

Class III

Ex de IIC/DIP A21

IP66, Type 4X

Options

• Nameplates: Lamacoid with different color combinations.

• Padlocking facility at left, center, right or any position on

selector switches.

• Padlocking facility for momentary and maintained push buttons.

NEC/CEC Certifications and Compliances

• Fiberglass Reinforced Polyester (FRP)

— Certication Type CSPe

— Temperature Class: T5 or T6

— Ambient Temperature: -55°C to +60°C (-67°F to +140°F)

— CAN/CSA Standards: C22.2 No. 0-M91, No. 25-M66, No.

213-M1987. No. 94-M91, No. 60079-0:07, No.

60529-2005, E60079-7-2003

— UL Standards: 60079-0, 60079-7, 50

— Other Standards: ANSI/IEC 60529-2004, ANSI/ISA 12.12.01-

2011

— cCSAus Certicate: 2356952

• Stainless Steel

— Certication Type JBe

— Temperature Class: T6 (at +40°C) or T5 (at +55°C)

— Surface Temperature: T80 °C (at +40°C) to T95 °C

(at +55°C) (T176 °F to T203 °F)

— Ambient Temperature: -40 °C to +55 °C (-40 °F to +131°F)

— CAN/CSA Standard: C22.2 No. O-M91, No. 25-M66, No.

213-Ml987, No. 60079-0:07, No. 60529-2005,

E60079-7-2003

— UL Standard: 60079-0, 60079-7

— Other Standards: ANSl/IEC60529-2004,

ANSI/ISA 12.12.01-2011

— cCSAus Certicate: 2356734

ATEX/IECEx Certification and Compliances

• Polyamide

— Certification Type PCe

— Gas: Zone 1 and 2

– Conforming to ATEX 94/9/CE: II 2 G

– Type of Protection: Ex de IIC/Ex demb IIC

– Temperature Class: T6

— Dust: Zone 21 and 22

– Conforming to ATEX 94/9/CE: II2 D

– Type of Protection: Ex tD A21

— Surface Temperature: T75 °C (T167 °F)

— Ambient Temperature: -20 °C to +55 °C (-4 °F to +131 °F)

— CE Declaration of Conformity: 50221

— ATEX Certicate: LCIE 00 ATEX 6047

— Index of Protection according EN/IEC 60529: IP66

— Impact Resistance (shock): IK09

• Fiberglass Reinforced Polyester (FRP)

— Certication Type CSPe

— Gas: Zone 1 and 2

– Conforming to ATEX 94/9/CE: II 2 G

– Type of Protection: Ex de IIC/Ex demb IIC

– Temperature Class: T6

— Dust: Zone 21 and 22

– Conforming to ATEX 94/9/CE: II2 D

– Type of Protection: Ex tD A21

— Surface Temperature: T75 °C (T167 °F)

— Ambient Temperature: -55 °C to +60 °C (-67°F to +140°F)

(empty enclosure, temperature to be determine according

actuator)

— CE Declaration of Conformity: 52084

Overall hazardous location and ingress protection rating depends on the rating of the optional certified components used.

INMETRO certification available on special request only. Contact your local sales representative for more information.

CEC:

Class I, Division 2, Groups A, B, C, D

Class II, Groups F, G

Class III; Type 4X

Class I, Zone 1, AEx de IIC/ AEx tD 21

IP66

— ATEX Certicate: LCIE 00 ATEX 3032X

— IECEx Certicate: IECEx LCI 09.0016X

• Stainless Steel

— Certication Type JBe

— Gas: Zone 1 and 2

— Dust: Zone 21 and 22

— Surface Temperature: T80 °C to T95 °C (T176 °F to T203 °F)

— Ambient Temperature: -50 °C to +70 °C (-58 °F to +158 °F)

— CE Declaration of Conformity: 50232

— ATEX Certicate: LCIE 02 ATEX 6118X

— IECEx Certicate: LCI 11.0008X

— Index of Protection according EN/IEC 60529: IP66

— Impact Resistance (shock): IK10

• Aluminum

— Certification Type PCe

— Gas: Zone 1 and 2

— Dust: Zone 21 and 22

— Surface Temperature: T75 °C (T167 °F)

— Ambient Temperature: -55 °C to +60 °C (-67 °F to +140 °F)

— CE Declaration of Conformity: 50221

— ATEX Certificate: LCIE 02 ATEX 6047

— Index of Protection according EN/IEC 60529: IP66

— Impact Resistance (shock): IK10

EURASEC Certification

• Certification Type PCe (Polyamide)

— EURASEC RU C-FR ГБ05.B.00911

• Certification Type CSPe (Fiberglass Reinforced Polyester)

— EURASEC RU C-FR ГБ05.B.00911

• Certification Type JBe (Stainless Steel)

— EURASEC RU C-FR ГБ05.B.00911

• Certification Type PCe (Aluminum)

— EURASEC RU C-FR ГБ05.B.00911

Other Certification

• Certification Type PCe (Polyamide)

— INMETRO Certicate: BVC 11.0640-X

• Certification Type CSPe (Fiberglass Reinforced Polyester)

— INMETRO Certicate: BVC 11.0637-X

• Certification Type JBe (Stainless Steel)

— INMETRO Certificate: BVC 11.0418-X

ATEX/IECEx:

Zone 1 and 2 – 21 and 22

Ex de IIC/Ex demb IIC/ Ex tD A21

IP66 – IK10

– Conforming to ATEX 94/9/CE:

– Type of Protection: Ex de IIC/Ex demb IIC

– Temperature Class: T5 to T6

– Conforming to ATEX 94/9/CE: II2 D

– Type of Protection: Ex tD A21

(empty enclosure, temperature to be determine according

actuator)

– Conforming to ATEX 94/9/CE: II 2 G

– Type of Protection: Ex de IIC/Ex demb IIC

– Temperature Class: T6

– Conforming to ATEX 94/9/CE: II2 D

– Type of Protection: Ex tD A21

(empty enclosure, temperature to be determine according

actuator)

II 2 GD

II 2 G

184

Page 3

Unicode™ 2 Series Customized Control Stations

CONTROLSCONTROLS: NEC/CEC, ATEX/IECEX INCREASED SAFETY CONTROL STATIONS

© November 2016

Increased Safety

Polyamide, Fiberglass Reinforced Polyester, 316L Stainless Steel, Aluminum

NEC:

Class I, Division 2, Groups A, B, C, D

Class II, Groups E, F, G

Class III

Ex de IIC/DIP A21

IP66, Type 4X

CEC:

Class I, Division 2, Groups A, B, C, D

Class II, Groups F, G

Class III; Type 4X

Class I, Zone 1, AEx de IIC/ AEx tD 21

IP66

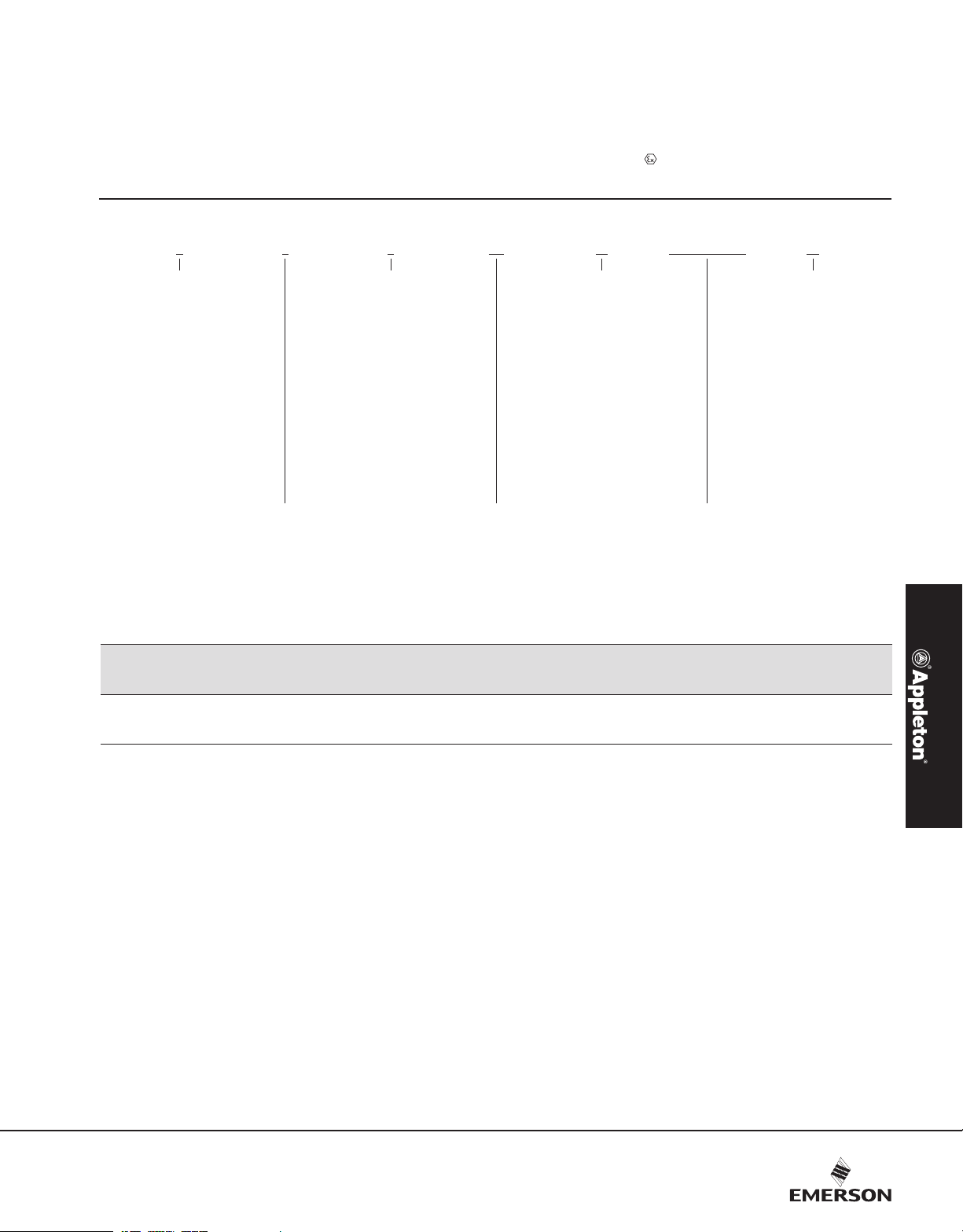

Catalog Numbering Guide - Unicode 2 Enclosures

U 2 3 W2 11 A1SA00G1SA00 T6

U - ATEX/IECEx Certified

Series:

Unicode 2 Series

Enclosures

Size:

1 - Size 1

2 - Size 2

3 - Size 3

Material Type and Mounting:

2 - Polyester rail mounted

4 - Polyamide rail mounted

6 - Stainless steel rail mounted

8 - Aluminum rail mounted

Cover Layout:

Size 1, 2 and 3 available

See following page

Entry Configuration:

Bottom, Top and Feed Thru

available

See below

ATEX/IECEx:

Zone 1 and 2 – 21 and 22

II 2 GD

Ex de IIC/Ex demb IIC/ Ex tD A21

IP66 – IK10

Options:

T6 - M6 earth stud

T8 - M8 earth stud

T1 - M10 earth stud

P5 - M5 earth stud

for polyamide or

polyester, M25 entry

required

P6 - M6 earth stud

for polyamide or

polyester, M20 entry

required

EP - Brass earth continuity

plate (2 x M20 for

polyamide box)

Devices:

Actuator, Pilot Light, Contact Blocks

1 to 6 devices per unit

and Accessories

See following pages

Entry Configuration

NPT Metric

1/2” 2 x 1/2” 3/4” 2 x 3/4” 1” M20 2 x M20 M25 2 x M25

Bottom Z1 Z2 Z3 Z4 Z5 W1 W2 W3 W4

Top Y1 Y2 Y3 Y4 Y5 V1 V2 V3 V4

Feed Thru X1 X2 X3 X4 X5 U1 U2 U3 U4

Overall hazardous location and ingress protection rating depends on the rating of the optional certified components used.

Polyamide versions: Only 2 x M20 available at bottom.

Not recognized for use in any NEC/CEC governed hazardous areas.

185

Page 4

Unicode™ 2 Series Customized Control Stations

CONTROLS CONTROLS: NEC/CEC, ATEX/IECEX INCREASED SAFETY CONTROL STATIONS

© November 2016

Increased Safety

Polyamide, Fiberglass Reinforced Polyester, 316L Stainless Steel, Aluminum

NEC:

Class I, Division 2, Groups A, B, C, D

Class II, Groups E, F, G

Class III

Ex de IIC/DIP A21

IP66, Type 4X

CEC:

Class I, Division 2, Groups A, B, C, D

Class II, Groups F, G

Class III; Type 4X

Class I, Zone 1, AEx de IIC/ AEx tD 21

IP66

ATEX/IECEx:

Zone 1 and 2 – 21 and 22

II 2 GD

Ex de IIC/Ex demb IIC/ Ex tD A21

IP66 – IK10

Drilled Cover Layout

Size 1

1 2 3

10

11

01 02 27

Size 2

1 1

21

4

32 1

32

65

4

32

65

V V

4

10

11

34 03 04 05 06 07 08 09 26 28 29

Size 3

20

21

1

4

1

4

7

1

5 6

2 3

4

10

11

12

13

2 3

5 6

2 3

4

7

1

5 6

7

2 3

5 6

7

25 10 11 12 13 14 15 16 17 18 19

10

11

12

1

5 6

8 9

2 3

5 6

8 9

V

4

V

5 6

V

4

7

20 21 22 23 24 30 31 32 33

Device Examples with Options

Push button with 1 NO contact and green

(unmarked) insert

Push button with 1 NC contact, padlocking device

and red (unmarked) insert

Push button with 2 NO contacts and START green

insert

Push button with 2 NO contacts, padlocking

device and START green insert

Push button with 2 NO contacts, padlocking

device, START green insert and DOWN small

legend plate

Red push-pull emergency stop mushroom head

with 2 NC contacts and padlocking device

Red push-pull emergency stop mushroom head

with 1 NO + 1 NC contacts and protective guard

Red push-pull emergency stop mushroom head

with 1 NO + 1 NC contacts and padlocking device

Green illuminated push button with 1 NO contact LG5

Green illuminated push button with 2 NO contacts,

padlocking device and START green insert

Description

V

5 6

7

A5G

A92R

A103

A1203

A1203SA10

D23

D31

D33

LG1203

2 3

5 6

14 15

16 17

14 15

16 17

18 19

V

5 6

Description

Green pilot light PG

Red pilot light with STOP large legend plate PRLA08

2-position rotary actuator with 2 NO contacts and

padlocking device

2-position rotary actuator with 2 NO contacts and

HAND—AUTO small legend plate

3-position I—O—II rotary actuator (I + II

maintained) with 2 NO contacts

H12

H1SH05

J1

3-position I—O—II rotary actuator (I + II

maintained) with 2 NO contacts and

J1LJ06

FORWARD—OFF—REVERSE large legend plate

2-position 2-pole switch US32

2-position 2-pole switch with 0—I large legend

plate

US32 LH01

2-position 4-pole switch US35

2-position 4-pole switch with 0—I large legend

plate

2 position 2-pole selector switch with

STOP—START large legend plate

3 position 2-pole selector switch with

OFF—0—ON large legend plate

US35LH01

US30LH04

US31LJ02

Overall hazardous location and ingress protection rating depends on the rating of the optional certified components used.

Stainless steel version only.

186

Page 5

Unicode™ 2 Series Customized Control Station Functions

CONTROLSCONTROLS: NEC/CEC, ATEX/IECEX INCREASED SAFETY CONTROL STATIONS

© November 2016

Increased Safety

Polyamide, Fiberglass Reinforced Polyester, 316L Stainless Steel, Aluminum

NEC:

Class I, Division 2, Groups A, B, C, D

Class II, Groups E, F, G

Class III

Ex de IIC/DIP A21

IP66, Type 4X

CEC:

Class I, Division 2, Groups A, B, C, D

Class II, Groups F, G

Class III; Type 4X

Class I, Zone 1, AEx de IIC/ AEx tD 21

IP66

Devices

Push Buttons, Momentary Contacts (3 maximum)

With 2 NO momentary contacts A1

With 2 NC momentary contacts A2

With 1 NO + 1 NC momentary contacts A3

With 2 NO + 1 NC momentary contacts A4

With 1 NO momentary contact A5

With 1 NO + 2 NC momentary contacts A6

With 3 NO momentary contacts A7

With 3 NC momentary contacts A8

With 1 NC momentary contact A9

Guard and Padlocking Devices

Guard for mushroom head push button 1

Padlocking device for push button and rotary actuator 2

Padlocking device for mushroom head push button 3

Inserts for Push Buttons and Illuminated Push Buttons

Green (unmarked) G

Red (unmarked) R

Yellow (unmarked) Y

White (unmarked) W

Blue (unmarked) B

Black (unmarked) N

ON (green) 01

OFF (red) 02

START (green) 03

STOP (red) 04

MARCHE (green) 05

ARRET (red) 06

I (green) 07

O (red) 08

Legend Plates

Legend Plates for Push Buttons and Pilot Lights

(Located Above Device)

Text Small Large

Blank SA00 LA00

ON SA01 LA01

OFF SA02 LA02

FORWARD SA03 LA03

REVERSE SA04 LA04

JOG SA05 LA05

RUN SA06 LA06

START SA07 LA07

STOP SA08 LA08

UP SA09 LA09

DOWN SA10 LA10

FAST SA11 LA11

SLOW SA12 LA12

RAISE SA13 LA13

LOWER SA14 LA14

OPEN SA15 LA15

CLOSE SA16 LA16

LOW SA17 LA17

HIGH SA18 LA18

TEST SA19 LA19

RESET SA20 LA20

ATEX/IECEx:

Zone 1 and 2 – 21 and 22

II 2 GD

Ex de IIC/Ex demb IIC/ Ex tD A21

IP66 – IK10

Legend Plates (Continued)

Legend Plates for Push Buttons and Pilot Lights

(Located Above Device)

EMERGENCY STOP SA21 LA21

MARCHE SA22 LA22

ARRET SA23 LA23

ARRET D’URGENCE SA24 LA24

HAUT SA25 LA25

BAS SA26 LA26

Devices

Illuminated Push Buttons, Momentary Contacts (2 maximum)

Green with 2 NO momentary contacts LG1

Green with 2 NC momentary contacts LG2

Green with 1 NO + 1 NC momentary contacts LG3

Green with 1 NO momentary contacts LG5

Green with 1 NC momentary contacts LG9

Red with 2 NO momentary contacts LR1

Red with 2 NC momentary contacts LR2

Red with 1 NO + 1 NC momentary contacts LR3

Red with 1 NO momentary contacts LR5

Red with 1 NC momentary contacts LR9

For other colors replace 2nd letter to B for Blue, W for White and Y for

Yellow. Example: Blue — LB1

Device Options

Push buttons complete with key removable in both positions

(2 contacts maximum)

With 2 NO contacts E1

With 2 NC contacts E2

With 1 NO + 1 NC contacts E3

With 1 NO contact E5

With 1 NC contact E9

Push buttons complete with key removable in ON position

(2 contacts maximum)

With 2 NO contacts F1

With 2 NC contacts F2

With 1 NO + 1 NC contacts F3

With 1 NO contact F5

With 1 NC contact F9

Push buttons complete with key removable in OFF position

(2 contacts maximum)

With 2 NO contacts G1

With 2 NC contacts G2

With 1 NO + 1 NC contacts G3

With 1 NO contact G5

With 1 NC contact G9

Overall hazardous location and ingress protection rating depends on the rating of the optional certified components used.

187

Page 6

Unicode™ 2 Series Customized Control Station Functions

CONTROLS CONTROLS: NEC/CEC, ATEX/IECEX INCREASED SAFETY CONTROL STATIONS

© November 2016

Increased Safety

Polyamide, Fiberglass Reinforced Polyester, 316L Stainless Steel, Aluminum

NEC:

Class I, Division 2, Groups A, B, C, D

Class II, Groups E, F, G

Class III

Ex de IIC/DIP A21

IP66, Type 4X

Black Mushroom Head Push Buttons, Momentary Contacts

(3 maximum)

With 2 NO momentary contacts B1

With 2 NC momentary contacts B2

With 1 NO + 1 NC momentary contacts B3

With 2 NO + 1 NC momentary contacts B4

With 1 NO momentary contact B5

With 1 NO + 2 NC momentary contacts B6

With 3 NO momentary contacts B7

With 3 NC momentary contacts B8

With 1 NC momentary contact B9

Red Mushroom Head Push Buttons, Momentary Contacts

(3 maximum)

With 2 NO momentary contacts R1

With 2 NC momentary contacts R2

With 1 NO + 1 NC momentary contacts R3

With 2 NO + 1 NC momentary contacts R4

With 1 NO momentary contact R5

With 1 NO + 2 NC momentary contacts R6

With 3 NO momentary contacts R7

With 3 NC momentary contacts R8

With 1 NC momentary contact R9

Red Mushroom Head Emergency Stop Buttons, Maintained

(3 contacts maximum)

Push-pull version with 2 NO maintained contacts D1

Push-pull version with 2 NC maintained contacts D2

Push-pull version with 1 NO + 1 NC maintained

contacts

Push-pull version with 2 NO + 1 NC maintained

contacts

Push-pull version with 1 NO maintained contact D5

Push-pull version with 1 NO + 2 NC maintained

contacts

Push-pull version with 3 NO maintained contacts D7

Push-pull version with 3 NC maintained contacts D8

Push-pull version with 1 NC maintained contact D9

Red Mushroom Head Emergency Stop Buttons, Maintained

Contacts (2 maximum)

Key to release with 2 NO maintained contacts C1

Key to release with 2 NC maintained contacts C2

Key to release with 1 NO + 1 NC maintained contacts C3

Key to release with 1 NO maintained contact C5

Key to release with 1 NC maintained contact C9

LED Pilot Lights

Blue color PB

Green color PG

Red color PR

White color PW

Yellow color PY

Overall hazardous location and ingress protection rating depends on the rating of the optional certified components used.

Device Options

Devices

CEC:

Class I, Division 2, Groups A, B, C, D

Class II, Groups F, G

Class III; Type 4X

Class I, Zone 1, AEx de IIC/ AEx tD 21

IP66

2 Positions O-I Rotary Actuator (O and I Maintained)

With 2 NO maintained contacts H1

With 2 NC maintained contacts H2

With 1 NO + 1 NC maintained contacts H3

With 2 NO + 1 NC maintained contacts H4

With 1 NO maintained contact H5

With 1 NO + 2 NC maintained contacts H6

With 3 NO maintained contacts H7

With 3 NC maintained contacts H8

With 1 NC maintained contact H9

Legend Plates for 2-Position Selector Switches

(Located Above Device)

O—I SH01 LH01

ON—OFF SH02 LH02

START—STOP SH03 LH03

STOP—START SH04 LH04

HAND—AUTO SH05 LH05

MANU—AUTO SH06 LH06

FORWARD—REVERSE SH07 LH07

REMOTE—LOCAL SH08 LH08

MARCHE—ARRET SH09 LH09

3 Positions I-O-II Rotary Actuator (I and II maintained)

With 2 NO maintained contacts J1

With 2 NC maintained contacts J2

With 1 NO + 1 NC maintained contacts J3

With 2 NO + 1 NC maintained contacts J4

With 1 NO + 2 NC maintained contacts J6

D3

D4

D6

With 3 NO maintained contacts J7

With 3 NC maintained contacts J8

3 Positions I-O-II Rotary Actuator (I and II spring-return to O)

With 2 NO contacts K1

With 2 NC contacts K2

With 1 NO + 1 NC contacts K3

With 2 NO + 1 NC contacts K4

With 1 NO + 2 NC contacts K6

With 3 NO contacts K7

With 3 NC contacts K8

3 Positions I-O-II Rotary Actuator (I Maintained and II SpringReturn to O)

With 2 NO contacts M1

With 2 NC contacts M2

With 1 NO + 1 NC contacts M3

With 2 NO + 1 NC contacts M4

With 1 NO + 2 NC contacts M6

With 3 NO contacts M7

With 3 NC contacts M8

3 Positions I-O-II Rotary Actuator (I Spring-Return to O + II

Maintained)

With 2 NO contacts N1

With 2 NC contacts N2

With 1 NO + 1 NC contacts N3

With 2 NO + 1 NC contacts N4

With 1 NO + 2 NC contacts N6

With 3 NO contacts N7

With 3 NC contacts N8

ATEX/IECEx:

Zone 1 and 2 – 21 and 22

Ex de IIC/Ex demb IIC/ Ex tD A21

IP66 – IK10

Tex t Small Large

II 2 GD

Devices

188

Page 7

Unicode™ 2 Series Customized Control Station Functions

CONTROLSCONTROLS: NEC/CEC, ATEX/IECEX INCREASED SAFETY CONTROL STATIONS

© November 2016

Increased Safety

Polyamide, Fiberglass Reinforced Polyester, 316L Stainless Steel, Aluminum

NEC:

Class I, Division 2, Groups A, B, C, D

Class II, Groups E, F, G

Class III

Ex de IIC/DIP A21

IP66, Type 4X

CEC:

Class I, Division 2, Groups A, B, C, D

Class II, Groups F, G

Class III; Type 4X

Class I, Zone 1, AEx de IIC/ AEx tD 21

IP66

Devices

16A Selector Switches

Other contact arrangements are available, contact your local sales

representative.

2 position 2-pole

Selector switch

3 position 2-pole

Selector switch

2 position 2-pole

switch

3 position 2-pole

Selector switch with

spring return from

135° to 90°

3 position 2-pole

Selector switch with

spring return from 45°

to 90°

2 position 4-pole

switch

US30

US31

US32

US33

US34

US35

ATEX/IECEx:

Zone 1 and 2 – 21 and 22

II 2 GD

Ex de IIC/Ex demb IIC/ Ex tD A21

IP66 – IK10

Devices

Ammeters 48 x 48 mm

1A C.T.and 3 F.L.C. with 0-1-3 scale VA13

1A C.T. and 5 F.L.C. with 0-1-5 scale VA15

1A C.T. and 6 F.L.C. with 0-1-6 scale VA16

5A C.T. and 3 F.L.C. with 0-1-3 scale VA53

5A C.T. and 5 F.L.C. with 0-1-5 scale VA55

5A C.T. and 6 F.L.C. with 0-1-6 scale VA56

Box Options

Earth Stud

M6 earth stud T6

M8 earth stud T8

M10 earth stud T1

M5 earth stud for polyamide or polyester,

M20 entry required

M6 earth stud for polyamide or polyester,

M25 entry required

Earth Continuity Plate

Brass EP

Plug

Cover blanking plug BP

P5

P6

3 position 4-pole

Selector switch

2 position 4-pole

Selector switch

3 position 3-pole

Selector switch with

spring return from 45°

to 90°

3 position 3-pole

Selector switch with

spring return from

135° to 90°

Legend Plates for 3-Position Selector Switches

(Located Above Device)

Tex t Small Large

I—O—II SJ01 LJ01

OFF—O—ON SJ02 LJ02

START—NORMAL—STOP SJ03 LJ03

HAND—OFF—AUTO SJ04 LJ04

MANUAL—O—AUTO SJ05 LJ05

FORWARD—OFF—REVERSE SJ06 LJ06

LOCAL—REMOTE—AUTO SJ07 LJ07

LOCAL—O—REMOTE SJ08 LJ08

MARCHE—NORMAL—ARRET SJ09 LJ09

US36

US37

US38

US39

Overall hazardous location and ingress protection rating depends on the rating of the optional certified components used.

Additional configurations available. See Unicode 2 Series 16 Amp Switches in the Component and Accessories section. Choose the contact arrangement,

then add the last four digits of the switch part number in the custom configured control station catalog number.

Ammeters are not NEC/CEC Certified.

189

Loading...

Loading...