Page 1

Panelboard Protection

on a Global Scale

Appleton™ Panelboards Brochure

Selection guide.

Page 2

No matter what environment, location or

power requirement, our panelboards have

your facility covered.

From a petrochemical plant in Saudi Arabia to a grain processing facility in America’s heartland,

Appleton™ panelboards by Emerson are there, providing protection and control of electrical

apparatus and circuits in hazardous, damp, wet or corrosive environments according to NEC,

CEC, ATEX and IEC standards. Emerson’s complete range of designs, materials and options - from

factory sealed to non-factory sealed and increased safety to ameproof - help ensure you have

the exibility to make the perfect panelboard choice.

We know what you need from a panelboard: protection, durability, ease of installation and low

maintenance costs. We build all of it in, so we can keep earning your trust year after year.

1

Page 3

Our products provide protection and control of electrical apparatus

and circuits in hazardous, damp, wet or corrosive environments

according to NEC, CEC, ATEX and IEC standards.

NEC/CEC ATEX/IECEx

Lighting Panelboards Lighting and Power Panelboards

Class I, Division 2; Class I, Zone 1, AEx de IIB+H

PlexPower™ RQ p5

Class I, Division 1 and Division 2

ALPN and ALPF p6

XP p7

EWP and D2P p8

Power Panelboards

Class I, Division 2; Class I, Zone 1

PlexPower RF p9

2

Zone 1 – 2; Zone 21 – 22, Ex db eb IIB+H

PlexPower IEC p12

DPD p13

2

Class I, Division 1 and Division 2

APPN and APPF p10

XP p11

2

Page 4

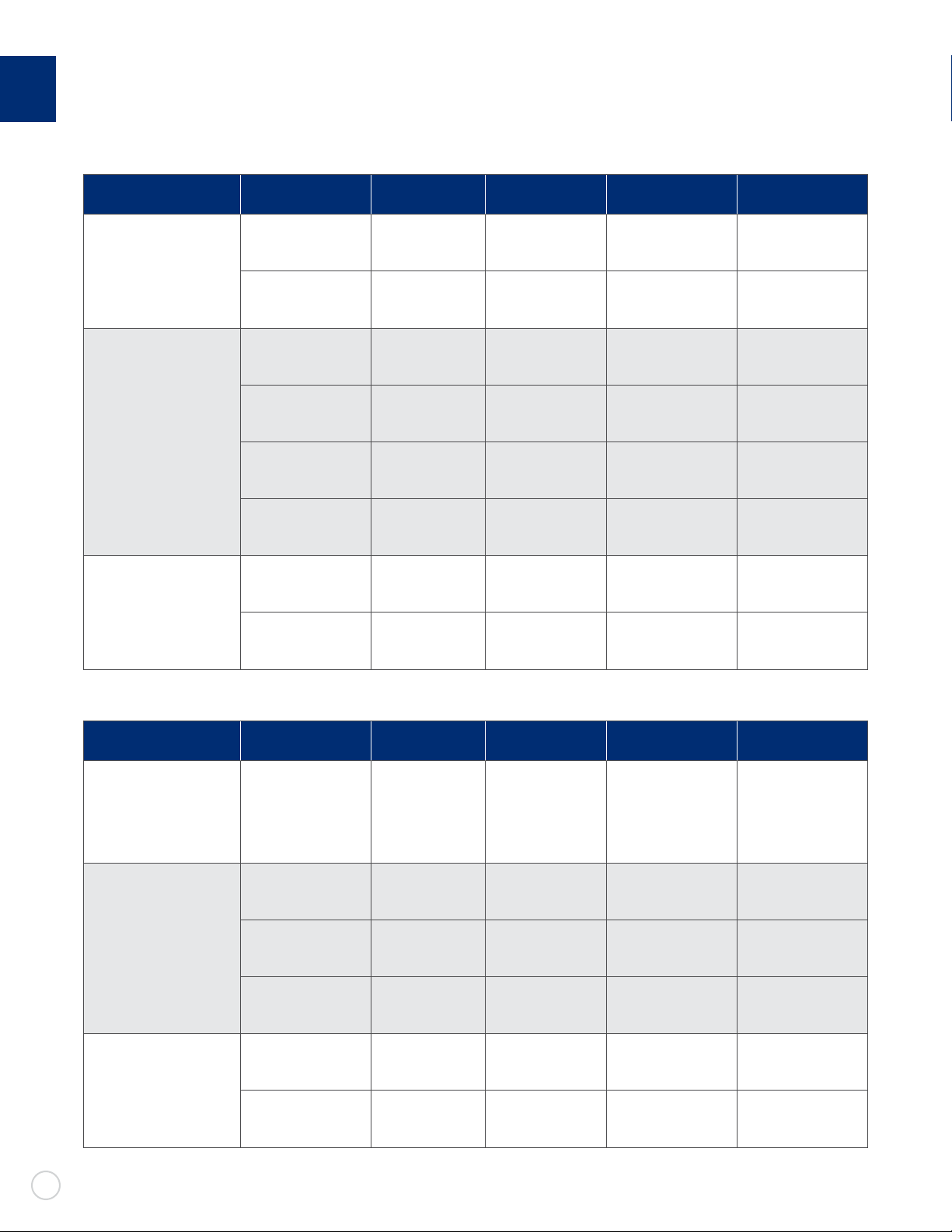

Panelboard Selection Guide

Lighting Panelboards

Rating/Certification

Enclosure

Typ e

Enclosure

Rating Voltage

Number

of Circuits

Maximum

Amperage Rating

NEC/CEC:

Class I, Division 2,

Groups B, C, D

Class I, Zone I

AEx de IIB+H

NEC/CEC:

Class I, Division 1 and 2,

Groups B, C, D

ATEX/IECEx:

Zone 1-2

Zone 21-22

Ex db eb IIB+H

2

2

Stainless Steel Type 4X

Cast Aluminum Type 4X 120/240, 240 12-36 100 1, 2, 3 100 Yes UL Yes D2P

Cast Aluminum Type 4X

Cast Aluminum Type 4X

Cast Aluminum Type 4X

Cast Aluminum Type 4X 120/240, 240 12-36 100 1, 2, 3 100 Yes UL Yes EWP

Fiberglass

Reinforced Polyester

or Stainless Steel

Marine Grade

Aluminum Alloy

IP66

IP66 415/ 500/ 690 3-24 160

120/240, 240,

120/208

120/240, 240,

120/208, 24Vdc

120/240, 240,

120/208, 24Vdc

120/240, 120/208,

277/480, 480,

347/600, 600

220-240/ 380-415,

440

3-54 150

12-42 225

12-42 225 1, 2, 3 100 Yes UL Yes ALPF

1-48 225 1, 3 100 Yes cCSAus Yes XP

1-72 200

Power Panelboards

Rating/Certification

NEC/CEC:

Class I, Division 2,

Groups B, C, D

Class I, Zone I

AEx de IIB+H

NEC/CEC:

Class I, Division 1 and 2,

Groups B, C, D

ATEX/IECEx:

Zone 1-2

Zone 21-22

Ex db eb IIB+H

2

2

Enclosure

Typ e

Stainless Steel Type 4X

Cast Aluminum Type 4X

Cast Aluminum Type 4X

Cast Aluminum Type 4X

Fiberglass

Reinforced Polyester

or Stainless Steel

Marine Grade

Aluminum Alloy

Enclosure

Rating Voltage

IP66

IP66 415/ 500/ 690 3-24 160

277/480, 480,

347/600, 600

277/480, 480, 600,

24Vdc, 25/250Vdc

277/480, 480, 600,

24Vdc, 25/250Vdc

120/240, 120/208,

277/480, 480,

347/600, 600

220-240/380-415,

440

Number

of Circuits

3-42 150

12-42 225

12-42 225 2, 3 100 No UL Yes APPF

1-48 225 1, 3 200 No cCSAus Yes XP

1-72 200

Maximum

Amperage Rating

For PlexPower RQ, main lugs only.

3

Page 5

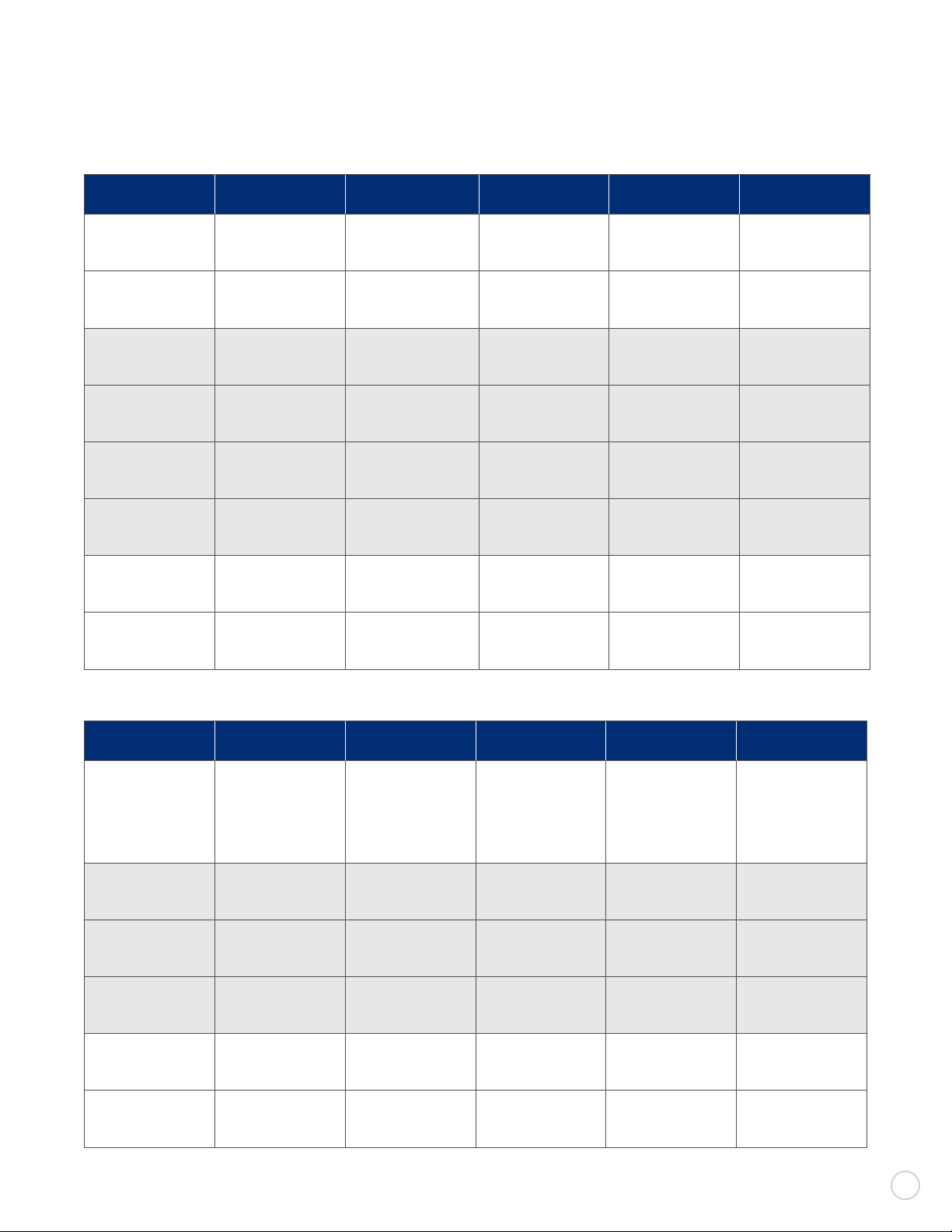

Panelboard Selection Guide (continued)

Maximum Branch

Number of Poles

1, 2, 3 60 Yes cCSAus Yes PlexPower RQ

1, 2, 3 100 Yes UL No ALPN

1, 2, 3, 4 63 Yes LCIE No PlexPower IEC

Amperage Rating GFI / EPD

Certification

Agency Factory Sealed Product Series

1, 2, 3, 4 63 Yes LCIE No DPD

Maximum Branch

Number of Poles

1, 2, 3 150 No cCSAus Yes PlexPower RF

2, 3 100 No UL No APPN

1, 2, 3, 4 63 No LCIE No PlexPower IEC

Amperage Rating GFI / EPD

Certification

Agency Factory Sealed Product Series

1, 2, 3, 4 63 Yes LCIE No DPD

4

Page 6

NEC/CEC Lighting Panelboards

Class I, Division 2, Groups B, C, D; Class I, Zone 1, AEx de IIB+H

PlexPower RQ Series

The Appleton PlexPower panelboard delivers component-level protection

that increases hazardous location safety and exibility while greatly reducing

and simplifying maintenance. It transfers the amepath from the panelboard

enclosure to individual circuit breaker housings. Its modular design offers the

convenience of eld-replaceable breakers. The PlexPower panelboard is most

commonly used for lighting, heat tracing and other electrical equipment.

Features

• No external conduit or cable seals required making installation and

commissioning faster, easier, and less costly.

• Limitless exibility through horizontal and vertical coupling options.

• Features a ground-breaking design that uses individual breaker housings to

minimize the downtime and costs associated with servicing circuit breakers

in hazardous locations.

Main Breaker

Module

Branch Breaker

Module

• PlexPower breakers accommodate off-the-shelf breakers, making

replacements readily available.

• The lighter weight panelboard enclosure can be quickly opened in the eld

for easier servicing.

• Supplied with standard hard drawn, tin plated, copper bus bar for superior

corrosion resistance.

• Standard models offer 3 circuit to 54 circuit panelboard congurations.

• Supplied standard with dead front.

• Standard conguration includes internal actuators and a solid door; factory

installed options include window door or external actuators.

• Branch circuit breakers available in 1-, 2- and 3-pole. Current ratings on

branch breakers:

— 1-pole: 120 Volts, 60 Amps maximum.

— 2- and 3-pole: 240 Volts, 40 Amps maximum.

• Main circuit breakers up to 150 Amps, 3-pole.

• 120/240 Volt breaker module terminal wire range #14-1/0.

• Branch and main breakers can be padlocked in either the “On” or “Off”

position.

2

5

Page 7

NEC/CEC Lighting Panelboards

Class I, Division 1 and 2, Groups B, C, D

ALPN Series and ALPF Series

The Appleton ALPN Series and ALPF Series panelboards are designed for short

circuit and overload protection and control of lighting circuits. They are available

in both low or high Amp versions. Both offer explosionproof, dust-ignitionproof

and watertight (NEMA 4X) protection to meet both NEC and CEC Class I,

Division 1 standards. The ALPN Series non-factory sealed panelboards provides

a central location for a controlled switching system of large quantities of branch

circuits for lighting systems. The ALPF Series panelboards feature a spacious

compartment for easy wiring and installation. They are factory sealed and

ALPN

ALPF

provide an extra measure of safety.

Features

• Breaker operators included as standard.

• Breakers are housed in the panel section and are prewired to maximum

circuit capacity, then wired to numbered terminals in the wiring

compartment.

• ALPF terminal compartment is interconnected to panel section with sealing

hubs and unions which are poured with sealing compound.

• O-ring gasket insures watertight integrity.

• Permits selection of 1-, 2- or 3-pole breakers.

• Precision machined ame path between body and cover.

• Bolt on stainless steel slotted mounting feet.

• Breaker operators can be padlocked in the “On” or “Off” position.

• Chassis assembles with main at top (bottom optional).

• Provisions for 12, 18, 24, 30, 36 and 42 circuit 1-pole chassis.

• 100 Amp or 225 Amp main lug.

• Up to 100 Amp backfed main breaker available with main lug chassis.

• Up to 225 Amp main breaker available with main breaker chassis.

• Factory installed ground and neutral bar are standard.

6

Page 8

NEC/CEC Lighting Panelboards

Class I, Division 1 and 2, Groups B, C, D

XP Series

The Appleton XP Series of pre-wired circuit breaker panelboards protects and

controls lighting. The XP is both explosionproof and watertight for indoor

or outdoor use. The panelboard and top junction box are factory sealed,

eliminating the need for labor intensive eld wiring and sealing ttings. Exclusive

rotary slide circuit breaker operators align with breakers in the “On” or “Off”

position when cover is being closed.

Features

• Wiring from branch circuit breakers in the panelboard to the terminal blocks

in the terminal enclosure are factory sealed, eliminating the need of labor

intensive eld wiring and use of sealing ttings.

• Conduit entries in top or bottom positioned terminal enclosure can be either

eld installed or factory installed to customer requirements.

• Four sizes of panelboards available.

• Removable hinged cover gives unobstructed access to interior. Left hand

hinges are standard. Right hand hinges are available.

• Detailed marking is plainly visible for easy circuit identication.

• Installation is easy with keyhole mounting lugs to simplify mounting.

7

Page 9

NEC/CEC Lighting Panelboards

EWP: Class I, Division 1 and 2, Groups B, C, D

D2P: Class I, Division 2, Groups B, C, D; Class I, Zone I

EWP Series and D2P Series

The compact Appleton EWP Series panelboards offers superior protection

against explosions. They are designed for use in Class I and Class II, Division 1

manufacturing and processing environments where ignitable vapors, gases

or combustible dusts are present. The Appleton D2P Series is designed for

use in Class I, Division 2 areas where ignitable vapors or gases may be present,

or in Class II, Division 1 areas where combustible dusts are present. These

panelboards come factory sealed, eliminating the need for external branch seal

ttings (except for Division 1, Groups B and C). The EWP and D2P are ideal for

damp, wet or corrosive conditions and are most commonly used for lighting

applications.

Features

EWP

D2P

• 3" Main conduit openings for both top and bottom feed of junction

compartment.

• Permits selection of 1-, 2- or 3-pole breakers. 10,000 Amp Vac interrupting

capacity is standard. (22,000 AIC also available; contact your local

representative.)

• Spring loaded, corrosion resistant aluminum breaker actuators feature a

self-locating design for actuating 1-, 2-, or 3-pole breakers in any sequence.

• Rotary actuating handles may be individually padlocked.

• Handles lock in either “On” or “Off” position without interfering with the

tripping of breakers.

• Double door design — one for junction compartment and one for breaker

compartment. Both doors are fully gasketed to provide raintight t for both

compartments.

• Two O-ring gaskets on each breaker handle shaft prevent the entrance

of water.

• Hinge design allows the doors to be lifted off.

• Breakers are prewired to terminal block, minimizing installation time.

• Insulated neutral lug provided as standard.

• Provision for drains/breathers in both compartments.

• Voltage ratings: 120 Vac for 1-pole and up to 240 Vac for 2- or 3-pole.

• Type THHN minimum size #10 AWG copper wire — +90 °C (+194 °F) — used

in panelboards.

• Main lug feeder wires are crimped and installed in single conductor.

• Stainless steel captive, spring-out Quad-Lead® bolts for ease of access.

8

Page 10

NEC/CEC Power Panelboards

Class I, Division 2, Groups B, C, D; Class I, Zone 1, AEx de IIB+H

PlexPower RF Series

The Appleton PlexPower panelboard delivers component-level protection

that increases hazardous location safety and exibility while greatly reducing

and simplifying maintenance. It transfers the amepath from the panelboard

enclosure to individual circuit breaker housings. Its modular design offers the

convenience of eld-replaceable breakers. The PlexPower panelboard is most

commonly used for power panels and other electrical equipment.

Features

• No external conduit or cable seals required making installation faster, easier,

and less costly.

• Limitless exibility through horizontal and vertical coupling options.

• Features a ground-breaking design that uses individual breaker housings to

minimize the downtime and costs associated with servicing circuit breakers

in hazardous locations.

Module

• PlexPower breakers accommodate off-the-shelf breakers, making

replacements readily available.

• The lighter weight panelboard enclosure can be quickly opened in the eld

for easier servicing.

• Supplied with standard hard drawn, tin plated, copper bus bar for superior

corrosion resistance.

• Standard models offer 3 circuit to 42 circuit panelboard congurations.

• Supplied standard with dead front.

• Standard conguration includes internal actuators and a solid door; factory

installed options include window door or external actuators.

• Branch circuit breakers available in 1-, 2- and 3-pole. Current ratings on

branch breakers:

— 1-pole: 277, 347 Volts, 60 Amps maximum.

— 2- and 3-pole: 480, 600 Volts, 150 Amps maximum.

• Main circuit breakers up to 150 Amps, 3-pole.

• 277/480, 480, 347/600, 600 Volt breaker module terminal wire range

#14-4/0.

• Branch and main breakers can be padlocked in either the “On” or “Off”

position.

2

9

Page 11

NEC/CEC Power Panelboards

Class I, Division 1 and 2, Groups B, C, D

APPN Series and APPF Series

The Appleton ALPF Series factory sealed and APPN Series non-factory sealed

power distribution panelboards are designed to provide protection and control

of electrical equipment in hazardous locations. Available in both low or high

Amp versions, they are used to centrally control switching systems for multiple

branch circuits that are used for heat trace, small motors and other electrical

equipment. Both offer explosionproof, dust-ignitionproof and watertight (NEMA

4X) protection to meet both NEC and CEC Class I, Division 1 standards. The ALPF

Series breakers are housed in a separate panel section and wired to terminals in a

separate wiring compartment.

APPN

APPF

Features

• Breaker operators included as standard.

• Breakers are housed in the panel section and are prewired to maximum

circuit capacity, then wired to numbered terminals in the wiring

compartment.

• Terminal compartment is interconnected to panel section with sealing hubs,

and unions which are poured with sealing compound.

• O-ring gasket insures watertight integrity.

• Permits selection of 1-, 2- or 3-pole breakers.

• Precision machined ame path between body and cover.

• Bolt on stainless steel slotted mounting feet.

• Breaker operators can be padlocked in the “On” or “Off” position.

• Chassis assembles with main at top (bottom optional).

• Provisions for 12, 18, 24, 30, 36 and 42 circuit 1-pole chassis.

• 100 Amp or 225 Amp main lug.

• Up to 100 Amp backfed main breaker available with main lug chassis.

• Up to 225 Amp main breaker available with main breaker chassis.

• Factory installed ground and neutral bar are standard.

10

Page 12

NEC/CEC Power Panelboards

Class I, Division 1 and 2, Groups B, C, D

XP Series

The Appleton XP Series pre-wired circuit breaker panelboard protects and

controls heat trace circuits. The XP Series is explosionproof and watertight

making it the ideal choice for indoor or outdoor use. The panelboard and top

junction box are factory sealed, eliminating the need for labor intensive eld

wiring and sealing ttings. Exclusive rotary slide circuit breaker operators align

with breakers in the “On” or “Off” position when cover is being closed.

Features

• Wiring from branch circuit breakers in the panelboard to the terminal blocks

in the terminal enclosure are factory sealed, eliminating the need of labor

intensive eld wiring and use of sealing ttings.

• Conduit entries in top or bottom positioned terminal enclosure can be either

eld installed or factory installed to customer requirements.

• Four sizes of panelboards available.

• Removable hinged cover gives unobstructed access to interior. Left hand

hinges are standard. Right hand hinges are available.

• Detailed marking is plainly visible for easy circuit identication.

• Installation is easy with keyhole mounting lugs to simplify mounting.

11

Page 13

ATEX/IECEx Lighting and Power Panelboards

Zone 1-2; Zone 21-22, Ex db eb IIB+H

PlexPower IEC Series

Simplify ameproof protection for lighting, heat trace and power circuit

distribution in Zone 1 and 2–21 and 22 environments. The Appleton PlexPower

IEC panelboard minimizes downtime with a true MCCB main breaker and

standard, off-the-shelf main and branch breakers that can be stocked and

quickly replaced in the eld. There is no longer a need to replace a main fuse or

to order and wait for delivery of expensive epoxy encapsulated branch breakers.

These panelboards deliver unprecedented design exibility. PlexPower features

a modular enclosure, bus bar system, optional removable gland plate and the

capacity to handle main breakers up to 200 Amps and branch breakers up to 63

PlexPower™ IEC with fiberglass

reinforced polyester enclosure

PlexPower™ IEC with stainless

steel enclosure on switchrack

Main Breaker

Module

Branch Breaker

Module

Amps.

Features

• 1 circuit to 72 circuit panelboard congurations are standard, with or

without main breaker.

• Branch circuit breakers available in 1-, 2- 3- and 4-pole. Current ratings on

branch breakers:

— 1-pole: 120, 240 Volts, 63 Amps maximum.

— 2-, 3- and 4-pole: 240 and 415 Volts, 63 Amps maximum.

• Main circuit breaker:

— 40 to 200 Amps, 2- , 3- or 4-pole.

• No external conduit or cable seals required thus making installations faster,

easier, and less costly.

• Limitless exibility through horizontal and vertical coupling options.

• Features a ground-breaking design that uses individual breaker housings to

minimize the downtime and costs associated with servicing circuit breakers

in hazardous locations.

• The lighter weight panelboard enclosure can be quickly opened in the eld

for easier servicing.

• Breaker modules supplied with captive bolts.

• 240/415 Volt breaker module 8-pole terminal wire range 2.5 mm2 through

10 mm2 (standard), 16 mm2 with special lug.

• 600 Volt main breaker module 4-pole terminal wire range 16 mm2 through

150 mm2.

• Fiberglass reinforced polyester enclosure or stainless steel enclosure

available.

2

12

Page 14

ATEX/IECEx Lighting and Power Panelboards

Zone 1-2; Zone 21-22, Ex db eb IIB+H

DPD Series

Appleton™ ameproof DPD Series distribution panelboards are used to provide

protection and control of electrical equipment in hazardous areas where

ignitable vapors, gases or highly combustible dusts are present. These compact

units provide a centrally controlled switching system. They feature non-sealed

breakers housed in a gray marine grade aluminum alloy enclosure.

Features

• Lighting panelboards are available in 6, 12, 18 and 24 circuits.

• Heat tracing panelboards are available in 6, 12, 18 and 20 circuits.

• 3- or 4-Pole isolator switch or main breaker.

— Branch circuit breaker available with B, C or D tripping curve.

— GFI branch circuit breaker available with B, C or D tripping curves except

for 1+N poles.

• 1, 2, 3, 4 and 1+N poles branch circuit breakers.

• Isolator and breaker handles included as standard, can be padlocked in

“Off” position.

• Copper bus bar as standard.

• Fully prewired on outgoing terminal block.

• M8 earth-crossing terminal.

• Hinged door.

• 4 xing lugs.

2

13

Page 15

With over 70 years in the industry, Appleton™ is one

of the rst and most respected names in custom

switchracks for hazardous and adverse locations.

Designed and engineered to meet the most

challenging demands year after year.

Emerson’s switchracks offer an innovative, unique solution for the complete protection

and control of electrical circuit equipment in one integrated package. Choose the necessary

Appleton™ electrical products that t the rating, electrical switching and controlling

requirements. Every switchrack is engineered, fabricated and assembled in-house by

qualied technicians. Our switchracks are built to comply with NEC/CEC or ATEX/IEC Standards.

ATEX/IEC versions comply with Directive 2014/34/EU and Directive 1999/92/EC for CENELEC and

IEC governed locations.

Our switchracks are designed for safety and performance and built to customer specications.

We have developed our capabilities with attention to our customer’s key concerns of custom

design, quality components, turnkey fabrication and guaranteed satisfaction.

14

Page 16

The world’s leading manufacturing and

process facilities turn to Emerson as the

trusted source of electrical products.

Appleton is the cornerstone brand of Emerson’s Electrical

Components and Lighting business; trusted worldwide to make

electrical installations safer, more productive and more reliable.

United States

(Headquarters)

Appleton Grp LLC

9377 W. Higgins Road

Rosemont, IL 60018

United States

T +1 800 621 1506

Australia Sales Office

Baysw ater, Vict oria

T +61 3 9721 0348

Korea Sal es Office

Seoul

T +82 2 3483 1555

Emerson.com

LinkedIn.com/company/emerson

The Emer son logo is a tr ademark an d service ma rk of Emerso n Electr ic Co. Appleto n is a registe red tradema rk of Applet on Grp LLC.

All othe r marks are th e propert y of their re spectiv e owners. © 2018 Emer son Elec tric Co. All ri ghts reser ved.

Europe

ATX ™ SA S

Espace I ndustriel N ord

35, rue André Durouchez,

CS 980 17

80084 A miens Cedex 2, France

T +33 3 2254 1390

China Sa les Offic e

Shanghai

T +86 21 3338 7000

Jebel Ali- Dubai Off ice

Emers on, Building A

Appleton Group

Jebel Ali Free Zon e- South

T +971 4 811 81 00

Canada

EGS Elec trical Gro up Canada Ltd.

99 Unio n Street

Elmira ON , N3B 3L7

Canada

T +1 888 765 2226

Middle East Sales Office

Dammam, Saudi Arabia

T +966 13 510 3702

Asia Pacific

EGS Priv ate Ltd.

Block 40 08, Ang Mo Kio Ave 10,

#04 -16 TechPlace 1,

Singapore 569625

T +65 6556 1100

Chile Sa les Offic e

Las Condes

T +56 2928 4819

Latin America

EGS Comercializadora Mexico S

de RL de C V

Calle 10 N°145 Piso 3

Col. San P edro de los Pino s

Del. Álvaro Obregon

Ciudad de México. 01180

T +52 55 5809 5049

India Sales Office

Chennai

T +91 44 3919 7300

Loading...

Loading...