Page 1

N2LED Series Emergency Luminaires

LED/AREA: NEC/CEC EMERGENCY

© March 2018

Non-Metallic Emergency Egress Lighting Systems with Remote or Direct Mounted Lamps.

NEC/CEC:

Class I, Division 2, Groups A, B, C, D

Class I, Zone 2, Group IIC

NEMA Type 4X

IP66

Marine Outside Type (Salt Water)

Applications

• Enclosed and gasketed, non-metallic emergency lighting

system suitable for use in areas where ammable gases or

vapors may become present due to abnormal, unusual or

accidental conditions dened by NEC as Class I, Division 2,

Groups A, B, C and D and Class I, Zone 2, Group IIC.

• Typical applications include manufacturing plants, reneries,

petrochemical and chemical plants, waste and sewerage

treatment facilities, food processing facilities, and other

industrial manufacturing or process facilities subject to wet or

corrosive conditions.

• Non-hazardous areas where dirt, dust or corrosion would

reduce life of ordinary emergency lighting systems.

Features

• Enclosures are raintight and suited for operation in highly

corrosive and wet locations.

• The electronics consist of a solid-state charger, transfer circuit

and low voltage battery disconnect circuit.

• The integrated, illuminated push to test button is mounted on

the system housing using a neoprene O-ring gasket to seal out

moisture and liquids.

• Capacity is sufcient for the connection of 6 output watts

(maximum).

• System supports 4 light heads (at 1.5 Watts each) in any main/

remote combination utilizing up to 6 Watts of output power.

— This allows for a main unit without any light heads to drive up

to 4 remote units or any other combination of 4 lights.

• Provides 100% lumen output for 90 minutes of operation with

four light heads or 180 minutes of operation with two light

heads.

• The solid-state charger maintains battery at full charge

• Upon power failure or utility voltage (AC) below 50 V, the DC

emergency lighting load is connected to the battery.

• During emergency operation, the battery is automatically

protected from deep discharge damage by a low-voltage

battery disconnect (LVD) circuit.

• Upon restoration of normal power, the charger brings the battery

to full capacity within acceptable UL time standards (typically

within 24 hours).

• Integrated, illuminated push to test button:

— Indicates presence of AC line voltage and system error codes

— Activates push to test function

• A universal input circuit allows operation from 120 to 277 Vac,

50/60 Hz lines.

• Maintenance-free NiCd battery is suited for harsh temperature

environments of 0 ºC to +55 ºC (+32 to +131 ºF).

• Remote lamp head assemblies (one or two) are available for

mounting of lamp heads away from main power supply system.

• An automatic test feature provides periodic self-test of the

system functions every 30 days.

• Status indicator light allows easy monitoring of system status

and failure modes.

Standard Materials

• Lighting system:

— Body: berglass reinforced polyester

— Cover gasket: continuous silicone

— Push to test switch: berglass reinforced polyester (FRP),

neoprene gaskets

— Hub: nickel plated brass

— Cover screws: stainless steel

— Lampheads: aluminum

• Remote unit:

— Body: berglass reinforced polyester (FRP); specially

formulated with low resistivity, will not hold static charge

— Cover screws: stainless steel

— Gasket: neoprene gasket

NEC/CEC Certifications and Compliances

• UL Standards:

— 1598A (Supplemental Requirements for Luminaires for

Installation on Marine Vessels)

— 924 (Emergency Lighting and Power Equipment)

— 844 (Electric Luminaires Hazardous Locations)

• CSA Standards:

— C22.2 No. 141-M1985 unit equipment for emergency lighting

— C22.2 No. 137-M1981 non-incendive electrical equipment for

use in Class I, Division 2 hazardous locations

• Life Safety Code NFPA101® – Section 5-9 (Emergency Lighting)

• Marine wet locations suitability, Type 4X

• cCSAus Certied: 2715744

135

Page 2

N2LED Series Emergency Luminaires

LED/AREA: NEC/CEC EMERGENCY

© March 2018

Enclosed and Gasketed

Non-Metallic Emergency Egress Lighting Systems with Remote or Direct Mounted Lamps.

NEC/CEC:

Class I, Division 2, Groups A, B, C, D

Class I, Zone 2, Group IIC

NEMA Type 4X

IP66

Marine Outside Type (Salt Water)

Order using catalog numbering guide below or select catalog number from tables on following pages.

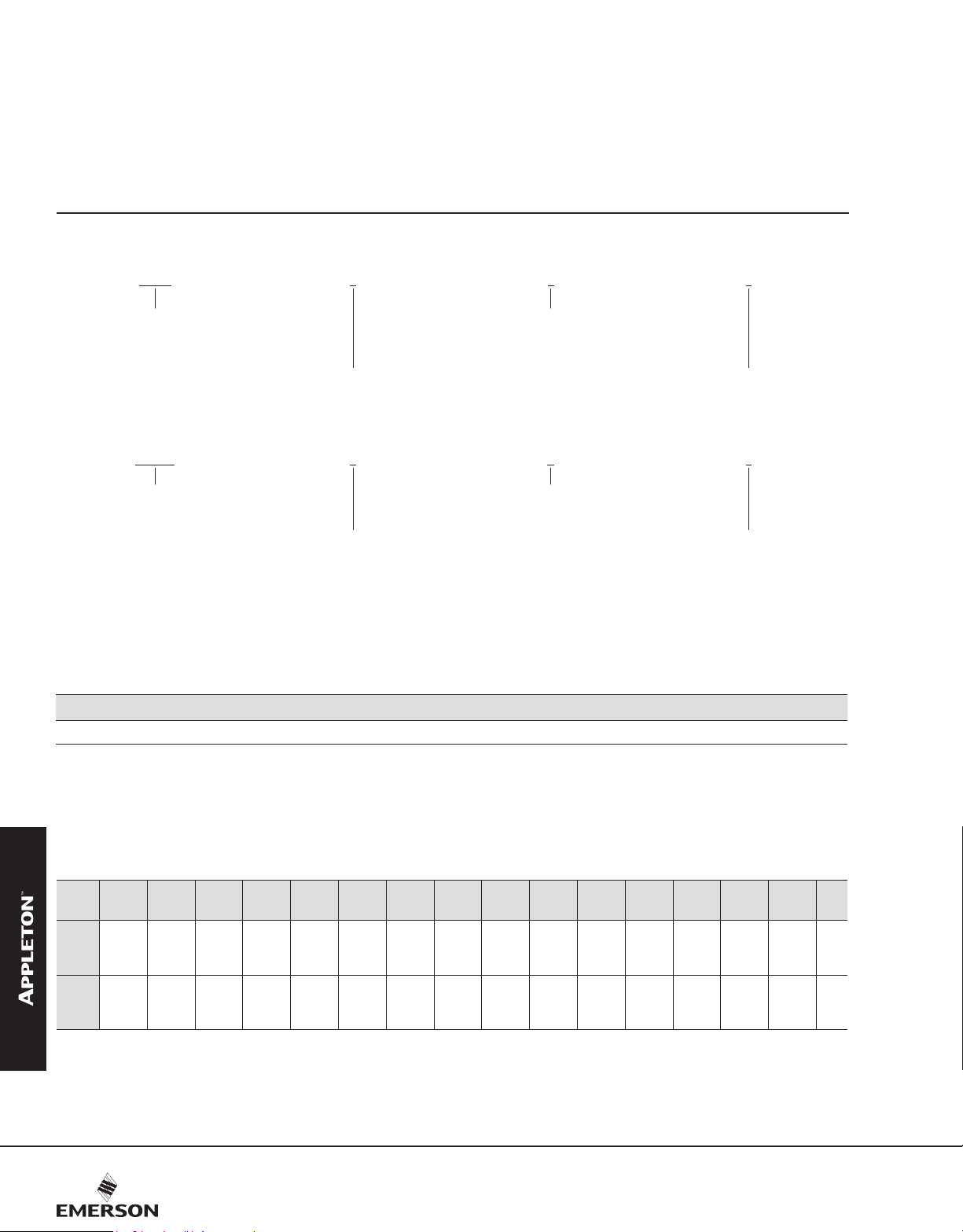

Catalog Numbering Guide For N2LED Master Units

N2LED 0 T 1

N2LED - Emergency Lighting

Series:

System

Number of Direct Mounted Lamps:

0 - None

2 - Two

Catalog Numbering Guide For N2LED Remote Units

N2LEDR 1 R 1

Series:

N2LEDR - Remote Emergency

Lighting System

Number of Direct Mounted Lamps:

1 - One

2 - Two

Thermal Performance — Operating Temperatures

Wire Supply Ambient Temperature “T” Number

60 °C (140 °F) 0 ºC to +55 ºC (+32 ºF to +131 ºF). T6

Entry Location:

T - Top Entry

Entry Size:

1 - 3/4" NPT

Hub Position/Entry Location:

R - Right

Entry Size:

1 - 3/4" NPT

“T” Numbers Represent the Maximum Lamp Temperature for Class I, Division 2 Locations

“T”

Number T1 350 325 T2 T2A T2B T2C T2D T3 T3A T3B T3C T4 T4A T5 T6

Temp

Range

(ºC)

Temp.

Range

(˚ºF)

351-

664-

450

842

326-

350

619-

662

301-

325

574-

617

281-

300

538-

572

261-

280

502-

536

231-

260

448-

500

216-

230

421-

446

201-

215

394-

419

181-

200

358-

392

166-

180

331-

356

161-

165

322-

329

136-

160

277-

320

121-

135

250-

275

101-

120

214-

248

86-

100

187-

212

136

85

185

Page 3

N2LED Series Emergency Luminaires

LED/AREA: NEC/CEC EMERGENCY

© March 2018

Enclosed and Gasketed

Non-Metallic Emergency Egress Lighting Systems with Remote or Direct Mounted Lamps.

NEC/CEC:

Class I, Division 2, Groups A, B, C, D

Class I, Zone 2, Group IIC

NEMA Type 4X

IP66

Marine Outside Type (Salt Water)

Lamp Comparison Chart

Number

of LED Lamps Input Power Lumens CRI Lamp Life (Hours) Color Temp CCT

1 1.256 Watts 131.0 70 50,000+ 5000K

2 2.513 Watts 257.8 70 50,000+ 5000K

Photometric and Electrical Measurements at Ambient Temperature (25°C +/- 1°C) – Distribution Method

Number

of LED Lamps

1 Up 2.9 437.0 1.256 1.000 131.0 104.3

2 Up 2.9 874.0 2.513 1.000 257.8 102.6

Note: Drive remote unit lamphead(s) only from the N2LED master unit

Base

Orientation

Input

Voltage

Vdc

Input

Current

(mA)

Input

Power

(Watts)

Input

Power

Factor

Absolute

Luminous Flux

(Lumens)

Lumen Efficacy

(Lumens Per

Watt)

Wire Sizing For Remote Installations

For copper wire, maximum distance (feet) between power supply and remote unit to limit voltage drop to 5%.

Wire Gage Maximum Wire Length m (ft)

18 AWG 23.8 (78)

16 AWG 38.1 (125)

14 AWG 60.4 (198)

12 AWG 96.0 (315)

10 AWG 152.4 (500)

System Status

Status Indication Status Description Status Definition

No light AC power removed from circuit

*

*_*_

**_**_

***_***_

****_****_

Continuous red steady light Battery fully charged

Red light blinks once every second Battery charging

Red light blinks twice repeatedly Battery failure

Red light blinks three times repeatedly LED lamp head failure

Red light blinks four times repeatedly Emergency circuit charger board failure

137

Page 4

N2LED Series Emergency Luminaires

LED/AREA: NEC/CEC EMERGENCY

© March 2018

Enclosed and Gasketed

Non-Metallic Emergency Egress Lighting Systems with Remote or Direct Mounted Lamps.

NEC/CEC:

Class I, Division 2, Groups A, B, C, D

Class I, Zone 2, Group IIC

NEMA Type 4X

IP66

Marine Outside Type (Salt Water)

Main System

Number

of LED Lamps

Emergency Lighting System With Two Direct Mount Lamps

2 3 3/4” 120-277 50/60 Hz 3.27 (7.2) N2LED2T1

Emergency Lighting System Without Direct Mount Lamps

— — 3/4” 120-277 50/60 Hz 3.04 (6.7) N2LED0T1

Total Watts

of LED Lamps

Hub

Size

Input

Voltage Frequency

Weight

kg (lb) Catalog Number

Remote System

Remote Mount With One Lamp

Remote Mount With Two Lamps

Replacement Parts

Number

of LED Lamps

1 1.5 3/4” Dead End Hub on Right 1.45 (3.2) N2LEDR1R1

2 3 3/4” Dead End Hub on Right 1.59 (3.5) N2LEDR2R1

Total Watts

of LED Lamps

Nickel Plated Brass M25 Male, 3/4" NPT Female Hub 737DM3T25

Hub

Size

Description Catalog Number

Emergency Lamp Kit N2LEDLH

Emergency Battery Pack Kit N2LEDBP

Emergency Circuit Charger Board Kit N2LEDCB

Hub

Position

Weight

kg (lb) Catalog Number

138

Page 5

N2LED Series Emergency Luminaires

LED/AREA: NEC/CEC EMERGENCY

© March 2018

125° 125°

125°

125°

125°

125°

125°

125°

110° 110°

110° 110°

23.0

Enclosed and Gasketed

Non-Metallic Emergency Egress Lighting Systems with Remote or Direct Mounted Lamps.

NEC/CEC:

Class I, Division 2, Groups A, B, C, D

Class I, Zone 2, Group IIC

NEMA Type 4X

IP66

Marine Outside Type (Salt Water)

Dimensions in Millimeters (Inches)

Emergency Lighting System With Two Direct Mount Lamps

(0.90)

249.0

(9.80)

223.0

(8.80)

200.0

(7.90)

125° 125°

125°

216.0 (8.50)

125°

105.0

(4.10)

43.0

(1.70)

95.0

(3.70)

95.0 (3.70)

146.0 (5.75)

189.0 (7.44)

Adjustment Angle — Top View Side View

110° 110°

125°

125°

125°

125°

Emergency Lighting System Without Direct Mount Lamps

105.0 (4.10)

200.0

(7.90)

216.0 (8.50)

12.0 (0.50)

95.0 (3.70)

43.0

(1.70)

146.0 (5.75)

189.0 (7.44)

95.0

(3.70)

139

Page 6

N2LED Series Emergency Luminaires

LED/AREA: NEC/CEC EMERGENCY

© March 2018

91.0 (3.60)

110°110°

180°

180°

91.8 (3.62)

170°170°

Enclosed and Gasketed

Non-Metallic Emergency Egress Lighting Systems with Remote or Direct Mounted Lamps.

NEC/CEC:

Class I, Division 2, Groups A, B, C, D

Class I, Zone 2, Group IIC

NEMA Type 4X

IP66

Marine Outside Type (Salt Water)

Dimensions in Millimeters (Inches)

Remote Mount With One Lamp

219.0 (8.60)

170.0 (6.70)

170.0 (6.70)

91.0 (3.60)

85.0 (3.30)

23.0 (0.90)

91.0 (3.0)

131.0 (5.16)

153.0 (6.02)

Adjustment Angle — Top View Side View

180°

180°

40.0 (1.60)

110°110°

91.0 (3.60)

140

Page 7

N2LED Series Emergency Luminaires

1

0

0

1

1

0

0

1

LED/AREA: NEC/CEC EMERGENCY

© March 2018

Enclosed and Gasketed

Non-Metallic Emergency Egress Lighting Systems with Remote or Direct Mounted Lamps.

NEC/CEC:

Class I, Division 2, Groups A, B, C, D

Class I, Zone 2, Group IIC

NEMA Type 4X

IP66

Marine Outside Type (Salt Water)

Photometric Data — DATA SHOWN IS ABSOLUTE

MODEL: N2LED, Wall Mount LED Emergency Luminaire, Single Lamp

Candela Distribution

0.0 22.5 45.0 67.5 90.0 Zone Lumens % Fixture

0 663 663 663 663 663 0-30 117.9 90.0

5 603 569 547 540 527 0-40 125.5 95.8

10 377 350 370 394 391 0-60 130.2 99.4

15 188 172 202 249 255 60-90 0.8 0.6

20 86 80 97 123 119 0-90 131.0 100.0

25 36 34 42 41 46 90-180 0.0 0.0

30 15 14 16 30 36 0-180 131.0 100.0

35 6 6 9 20 25

40 3 3 6 11 14

45 2 2 4 5 3

50 2 2 3 2 2

55 2 2 2 2 2

60 1 1 1 1 1

65 0 0 1 1 1

70 0 0 0 0 0

75 0 0 0 0 0

80 0 0 0 0 0

85 0 0 0 0 0

90 0 0 0 0 0

Zonal Lumen Summary

Distance in units of mounting height (10 ft)

5 fc 0.5 fc

2.5 fc 0.2 fc

1 fc 0.1 fc

MODEL: N2LED, Wall Mount LED Emergency Luminaire, Two Lamp

Candela Distribution

0.0 22.5 45.0 67.5 90.0 Zone Lumens % Fixture

0 1241 1241 1241 1241 1241 0-30 230.9 89.6

5 1196 1110 1049 1011 989 0-40 246.7 95.7

10 844 764 761 763 737 0-60 255.9 99.3

15 469 426 461 506 486 60-90 1.8 0.7

20 225 206 239 264 234 0-90 257.8 100.0

25 93 87 107 91 97 90-180 0.0 0.0

30 40 37 40 66 74 0-180 257.8 100.0

35 17 16 23 44 51

40 7 7 14 26 28

45 4 5 8 11 6

50 4 4 6 5 4

55 4 4 5 4 3

60 2 2 3 3 2

65 1 1 2 2 1

70 0 1 1 1 1

75 0 0 0 1 0

80 0 0 0 0 0

85 0 0 0 0 0

90 0 0 0 0 0

Zonal Lumen Summary

Distance in units of mounting height (10 ft)

10 fc 0.5 fc

5 fc 0.2 fc

2.5 fc 0.1 fc

1 fc

141

Loading...

Loading...