Page 1

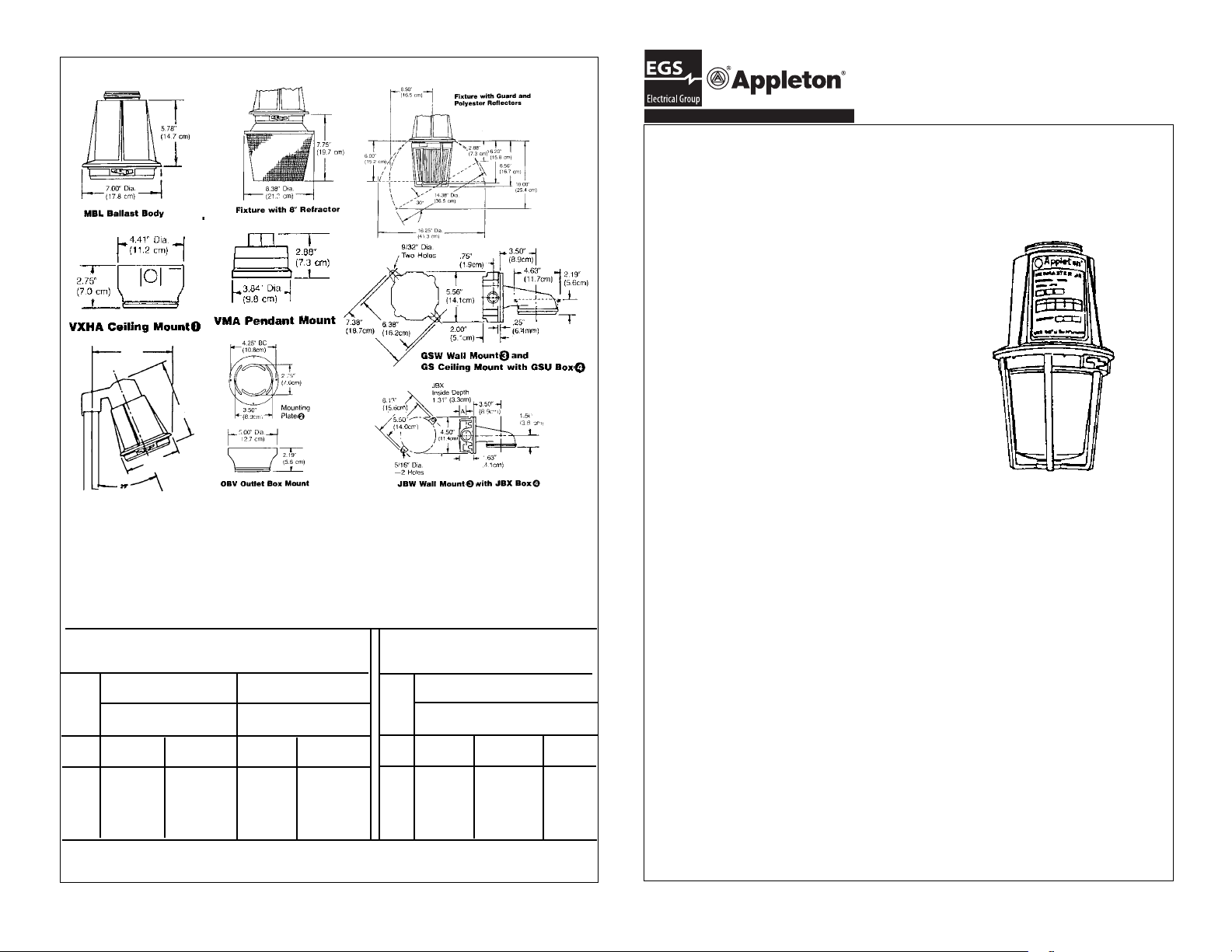

Mercmaster Jr.™ Dimensions: 35, 50, 70, 100 and 150 Watt,

INSTRUCTION SHEET

654031-001

Mercmaster Jr.™Enclosed and

Gasketed HPS Lighting Fixtures.

High Pressure Sodium. Suitable for Use in Wet Locations.

Unilets®for use with Threaded Metal Conduit.

120V Integral Ballast. Medium Base Socket for Medium Base Lamps.

Applications

•

Inexpensive HID integrally ballasted

fixture for use in hazardous locations –

inexpensive to buy and inexpensive to

operate (uses one-fifth as much electrical

energy as incandescent and three quarters

as much as fluorescent).

•

Enclosed and gasketed HID lighting

fixtures for use in tunnels, walkways,

bridges, storage facilities, processing plants,

parking lots, foundries, manufacturing plants,

power plants and other locations where

moisture, dirt, dust or corrosive atmospheres are encountered.

Features

•

“Wireless” design. Threading of fixture

unit onto mounting hood makes electrical

connection. Only wiring required is attaching

two wires to connection block in mounting

hood.

•

Safe, easy servicing without disconnecting

any wiring. “Wireless” fixture unit easily

threads off mounting hood for convenient

servicing.

•

Quick, easy conversion from Appleton V-51

incandescent installation to Mercmaster Jr.

HID. Just remove V-51 fixture unit and

thread Mercmaster Jr. fixture unit onto

existing V-51 mounting hood.

Standard Materials

•

Mounting Hoods: copper-free aluminum

(4/10 of 1% max. copper content) or

malleable iron.

•

Ballast bodies: copper-free aluminum

(4/10 of 1% max. copper content).

•

Reflectors: fiberglass-reinforced polyester or porcelain.

•

Globe: 35W-100W, threaded prismatic

glass and threaded polycarbonate: 150W

threaded heat-resistant prismatic glass.

•

Refractor: heat-resistant prismatic glass.

Standard Finishes

•

Ballast bodies, aluminum guard and VMA,

VXHA-A, OBVW1-A, OBV1-A. JBW1-A,

JB1-A, GSW2, and MS mounting hoods:

epoxy power coat finish. Two coat baked finish, electrostatically applied for complete,

uniform surface protection.

•

VA, VXHA, OBVW1, OBV1, GS-2, JBW1,

AND JB1 malleable iron mounting hoods:

triple coat – (1) zinc electroplate; (2) dichromate; and (3) aluminum polymer enamel.

•

Steel guard: zinc electroplate

Options

•

Fuses for fixtures. Factory installed.

Compliances

•

UL Standard 1572, 844 and 1598A.

•

Suitable for use in wet locations.

•

NEMA 4X.

Class I Div. 2 Groups A, B, C, and D

Temperature identification numbers of Mercmaster Jr.

Fixtures

With Globe or with With 8"

Globe & Reflector Refractor

UL/NEC Temp. UL/NEC Temp.

Ident. No. Ident No.

Lamp Nameplate Temperature Nameplate Temperature

Watt Marking Range Marking Range

035 T3C 136-160

0

C T3C 136-1600C

050 T2D 201-2150C T2D 201-2150C

070 T2B 231-260

0

C T2B 231-2600C

100 T2A 261-2800C T2A 261-2800C

150 T2 281-3000CT2 281-3000C

Class II Div.1 & 2 Groups E, F and G

Temperature Identification Numbers

With Globe, with Globe & Reflector

or With 8" Refractor

UL/NEC Temp.

Ident. No.

Lamp Nameplate Temperature

Watts Marking Range Groups

035 T4A 101-120

0

C E, F, G

050 T3C 136-1600C E, F, G

070 T3A 166-1800C E, F

100 – –

150 – – –

1Mounting holes 9/32" diameter on 5-1/8'' centers

2Mounting Plate is a separate piece furnished with Outlet Box Mount fixture. The 2.75" dimension is for

mounting on 3-1/4" octagonal boxes and the 3.50" dimension is for 4" octagonal boxes.

3Wall Mount fixtures provide the following wall clearances: with GSU box—2" from wall with globe and

1-5/16" from wall with refractor; with JBX box—1-5/8" from wall with globe and 15/16" from wall with refractor. Reflectors cannot be used with Wall Mount fixtures.

4Order GSU or JBX Box separately.

5Standard dome or 30" angle reflectors can be used with Stanchion Mount.

7.00"

17.8 cm

10.00"

25.4 cm

9.61"

25.3 cm

Page 2

MERMASTER JR.

FIXTURE FOR HAZARDOUS LOCATIONS

AND MARINE OUTSIDE (SALTWATER) APPLICATIONS

INSTALLATION AND MAINTENANCE INSTRUCTIONS

(Read carefully before beginning installation)

1. Verify that the supply line is a 120 Volt, 60 Hertz system.

2. Verify that the fixture operating temperature marked on nameplate complies with temperature

restrictions of hazardous area.

3. Use supply wire rated for temperature noted on nameplate.

INSTALLATION OF MOUNTING ACCESSORIES

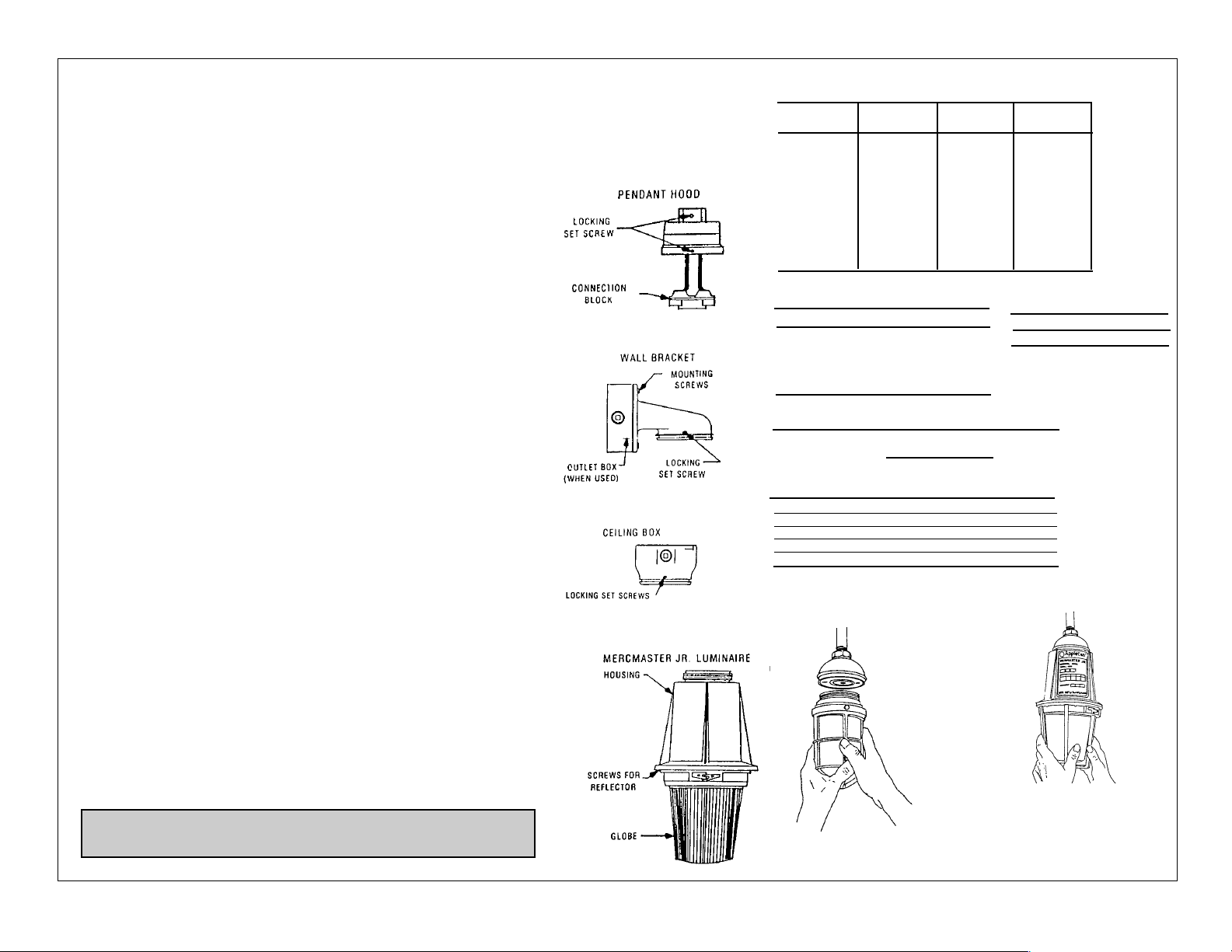

1. Pendant Hood

Remove connection block from hood by loosening two mounting screws. Connect the threaded hood onto conduit and tighten locking set screw. Connect the ground wire to green screw

provided in hood. Connect supply wires to connection block. Replace connection block in

mounting hood and tighten securely.

2. Wall Bracket

Install wall bracket onto support surface or outlet box with the required bolts through the external mounting holes. Remove connection block and connect supply wires. Replace connection

block onto mounting hood and tighten securely.

3. Ceiling Box

Install ceiling box on support surface with two bolts through two external mounting holes.

Remove connection block and connect electrically as described under wall bracket.

INSTALLATION OF FIXTURE

1. Fixture is completely wired, needing no additional field wiring.

2. Installation of Lamp, Globe and Refractor:

Check lamp type and wattage against fixture nameplate, then install lamp, making sure lamp

is fully seated into the socket. Rethread the globe or refractor tightly to housing.

3. Installing Fixture on Mounting Accessory:

Thread assembled fixture into mounting accessory, electrical contacts will automatically

engage. Insure that fixture is tightly threaded, then tighten locking set screw in bottom of

mounting accessory.

4. Installation of Reflector and Guard:

To install reflector, mount onto three mounting screws located at the flange area of the housing, using the mounting clips attached to the reflector. Turn reflector clockwise until it is

locked into place and tighten mounting screws. To install guard, push upward and twist clockwise until it snaps into place.

5. Cleaning Fixture

To maintain good lighting efficiency, globe and reflector should be cleaned periodically. Use a

mild detergent and rinse with clean water.

6. Relamping:

To relamp after disconnecting power, remove globe (or refractor) and old lamp. Install new

lamp as described in item #2 “Installation of Lamps. Globe and Refractor”.

CAUTION:

Disconnect fixture from supply circuit before opening to service. Keep tightly closed

when in operation.

▲

REPLACEMENT PARTS

CATALOG NO. WATTS AND BALLAST SOCKET

LAMP TYPE PART NO.

MBL35-120 35W HPS 661174-201 662016-001

MUL35-120 35W HPS 661174-201 662016-001

MBL50-120 50W HPS 661174-203 662016-001

MUL50-120 50W HPS 661174-203 662016-001

MBL70-120 70W HPS 661174-205 662016-001

MUL70-120 70W HPS 661174-205 662016-001

MBL100-120 100W HPS 661174-207 662016-001

MUL100-120 100W HPS 661174-207 662016-001

MBL150-120 150W HPS 661174-209 662016-001

MUL150-120 150W HPS 661174-209 662016-001

CONNECT BLOCK ASSEMBLY

(COMMON TO ALL CATALOG NUMBERS)

DESCRIPTION PART NUMBER

Connection Block 607471-001

#6-32 x 1/4 Tap Screw P05647-000

#6-32 x 1/4 Screw P01533-000

White Wire Assembly 660005-005

Black Wire Assembly 660004-005

Ambient Suitability of

Mercmaster Jr. Fixtures

35W 50W 70W 100W

40

0

C400C250C250C

All fixtures suitable for operation

at -40

0

F.

Electrical Specifications (Reactor Ballast)

Line Current

In Amperes

Line

Lamp Voltage Starting Operating Input

Watts 60Hz HPF HPF Watts

35 120 0.40 0.40 43

50 120 0.68 0.54 60

70 120 0.90 0.75 83

100 120 1.20 1.00 117

150 120 2.20 1.50 171

Conversion from Appleton V-51 incandescent installation to HID Mercmaster Jr.

is easy and fast.

Step No. 2: Thread

Mercmaster Jr. HID fixture

unit onto existing V-51

mounting hood – and

conversion is completed.

Step No. 1:After power

is shut off, remove present incandescent V-51

fixture unit from existing

V-51 mounting hood.

Loading...

Loading...