Page 1

PRODUCT SELECTOR - CONNECTORS FOR LIQUIDTIGHT FLEXIBLE METAL CONDUIT (LFMC)

O-Z/Gedney™ Product Family Material Finish Trade Size Configurations Selection Key

4Q and 4Q-T

Series

4Q-FM Series Malleable Iron Zinc Electroplate 3/8" to 5"

4Q-WM Series

4Q-LT

Ground-Tite™

Series

4Q-FML

Ground-Tite™

Series

4Q-TG Series

Malleable Iron Zinc Electroplate 3/8" to 6" Straight, 45°, 90°

Malleable Iron

and Stainless

Steel

Malleable Iron Zinc Electroplate 3/8" to 6"

Malleable Iron Zinc Electroplate 3/8" to 5"

Malleable Iron

Zinc Electroplate 3/8" to 4" Straight

Hot Dip / Mechanically

Galvanized

3/8" to 6"

Straight Female

Hub for connection

to RMC/IMC

Straight (3/8” to

6”),

45° (3/8” to 5”),

90° (3/8” to 5”)

Female Straight

Hub for connection

to RMC/IMC

Straight (3/8" to 6"),

45° (3/8" to 5"),

90° (3/8” to 5”)

Standard Liquidtight connector.

Use with LFMC in heavy

commercial and industrial

applications

Female hub threads directly

to conduit threads. Transition

from RMC/IMC to LFMC in heavy

commercial and industrial

applications

Strain Relief with stainless

steel wire-mesh grip. Prevents

conduit pull-out and alleviates

flexing stress

To externally ground LFMC

in commercial and industrial

applications; maximum 6 foot

length of LFMC

To externally ground LFMC

in commercial and industrial

applications; maximum 6 foot

length of LFMC

Hot Dip / Mechanically

Galvanized connectors for

atmospheres containing severe

corrosives

Appleton™ and O-Z/Gedney™ Material Finish Trade Size Configurations Selection Key

High grade stainless steel

4QSS-T Series316 Grade

Stainless Steel

4QS and

4QS-T Series

LMM and

LML Series

NMM and NML

Series

O-Z/Gedney™ 4Q = plain throat; O-Z/Gedney™ 4Q-T = insulated throat

Steel and

Malleable Iron

Zinc Diecast Natural 3/8" to 4" Straight, 90°

Nylon Natural 3/8" to 1" Straight, 90°

Natural 3/8" to 2" Straight, 45°, 90°

Zinc Electroplate 3/8" to 4" Straight, 45°, 90°

LFMC connectors are ideal in

areas that are subject to severe

corrosive influences

Standard Liquidtight connector.

Use with LFMC in commercial

and light industrial applications

Cost-competitive liquidtight

connectors. Use with LFMC in

residential and light commercial

applications

For use with Type B Liquidtight

Flexible Nonmetallic Conduit

(LFNC) in residential and light

commercial installations

Page 2

PRODUCT SELECTOR - CONNECTORS FOR LIQUIDTIGHT FLEXIBLE METAL CONDUIT (LFMC)

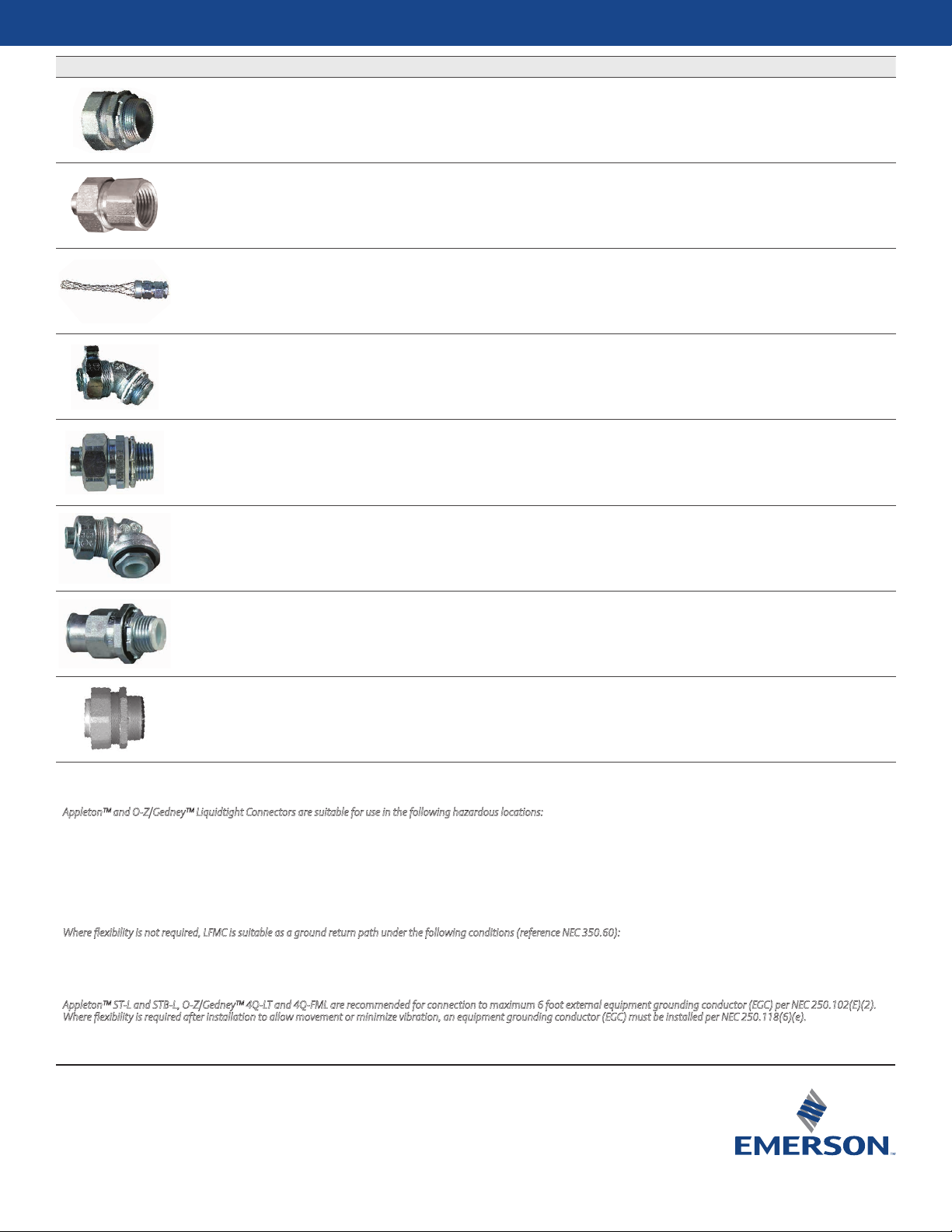

Appleton™ Material Finish Trade Size Configurations Selection Key

ST and STB

Series

STF Series

STB-SR,

STB-FSR and

STN-SR Series

ST-L and

STB-L Series

Steel and

Malleable Iron

Steel and

Malleable Iron

Steel, Malleable

Iron and

Stainless Steel

Steel and

Malleable Iron

ST-AL SeriesAluminum

(copperfree)

STN Series

Steel and

Malleable Iron

Steel: Zinc Electroplate

Malleable: Triple Coat

Steel: Zinc Electroplate

Malleable: Triple Coat

Steel: Zinc Electroplate

Malleable: Triple Coat

Steel: Zinc Electroplate

Malleable: Triple Coat

3/8" to 4" Straight, 45°, 90°

3/8" to 4" Straight

3/8" to 3" Straight, 45°, 90°

3/8" to 4" Straight, 45°, 90°

Natural 3/8" to 4"

Steel: Zinc Electroplate

Malleable: Triple Coat

3/8" to 4"

Straight (3/8" to 4"),

90° (3/8" to 2")

Straight (3/8" to 4"),

90° (3/8" to 1")

Standard Liquidtight connector.

Use with LFMC in heavy

commercial and industrial

applications

Female hub threads directly

to conduit threads. Transition

from RMC/IMC to LFMC in heavy

commercial and industrial

applications

Strain Relief with stainless

steel wire-mesh grip. Prevents

conduit pull-out and alleviates

flexing stress

To externally ground LFMC

in commercial and industrial

applications; maximum 6 foot

length of LFMC

Use with LFMC in corrosive

industrial applications where

aluminum material is prefered

for corrosion resistance

Space-saving hub with insulated

throat fits almost flush inside

sheet metal enclosure,

maximizing interior wiring space

STNM and

STNM-SR

Series

PG-STB and

ISO-STB Series

Appleton™ ST = plain throat; Appleton™ STB = insulated throat

Appleton™ and O-Z/Gedney™ Liquidtight Connectors are suitable for use in the following hazardous locations:

• Class I Division 2 per NEC 501.10(B)(2)

• Class I Zone 2 per NEC 505.15(C)(2)

• Class II Division 1 per NEC 502.10(A)(2)

• Class II Division 2 per NEC 502.10(B)(2)

• Class III Division 1 per NEC 503.10(A)(3)

• Class III Division 2 per NEC 503.10(B)

• Intrinsically Safe Systems per NEC 504.20

• Bonding locknuts are recommended when installed in slipholes

• LFMC shall include a wire-type Equipment Bonding Jumper per NEC 501.30(B), 502.30(B)and 503.30(B)

Where flexibility is not required, LFMC is suitable as a ground return path under the following conditions (reference NEC 350.60):

• Per NEC 250.118(6)(a), the conduit is terminated in listed fittings (i.e. Appleton™ ST and O-Z/Gedney™ 4Q and LM Series)

• Per NEC 250.118(6)(b), trade sizes 3/8” and 1/2” contain conductors protected by max 20 amp overcurrent protection

• Per NEC 250.118(6)(c), trade sizes 3/4” to 1-1/4” contain conductors protected by max 60 amp overcurrent protection

• Per NEC 250.118(6)(d), the ground fault current path does not exceed 6 feet

• Larger sizes and/or higher overcurrent protection will require an equipment grounding conductor (EGC)

Appleton™ ST-L and STB-L, O-Z/Gedney™ 4Q-LT and 4Q-FML are recommended for connection to maximum 6 foot external equipment grounding conductor (EGC) per NEC 250.102(E)(2).

Where flexibility is required after installation to allow movement or minimize vibration, an equipment grounding conductor (EGC) must be installed per NEC 250.118(6)(e).

Steel and

Malleable Iron

Steel and

Malleable Iron

Zinc Electroplate 3/8" to 2" Straight, 90°

Steel: Zinc Electroplate

Malleable: Triple Coat

PG: 3/8" to 2"

ISO: 3/8" to 1"

Straight, 45°, 90°

For use with Type A Liquidtight

Flexible Nonmetallic Conduit

(LFNC). Insulated throat is

standard

PG and ISO metric threads on

male hub body with ferrule and

cap to accept standard trade

size LFMC

Loading...

Loading...