EGS Electrical Group • 7770 N. Frontage Road • Skokie, Illinois 60077

Rev. C 12/20/99 Page 1

650167-002

INSTRUCTION SHEET

BEAM-MASTER INSTALLATION / INSTRUCTION SHEET

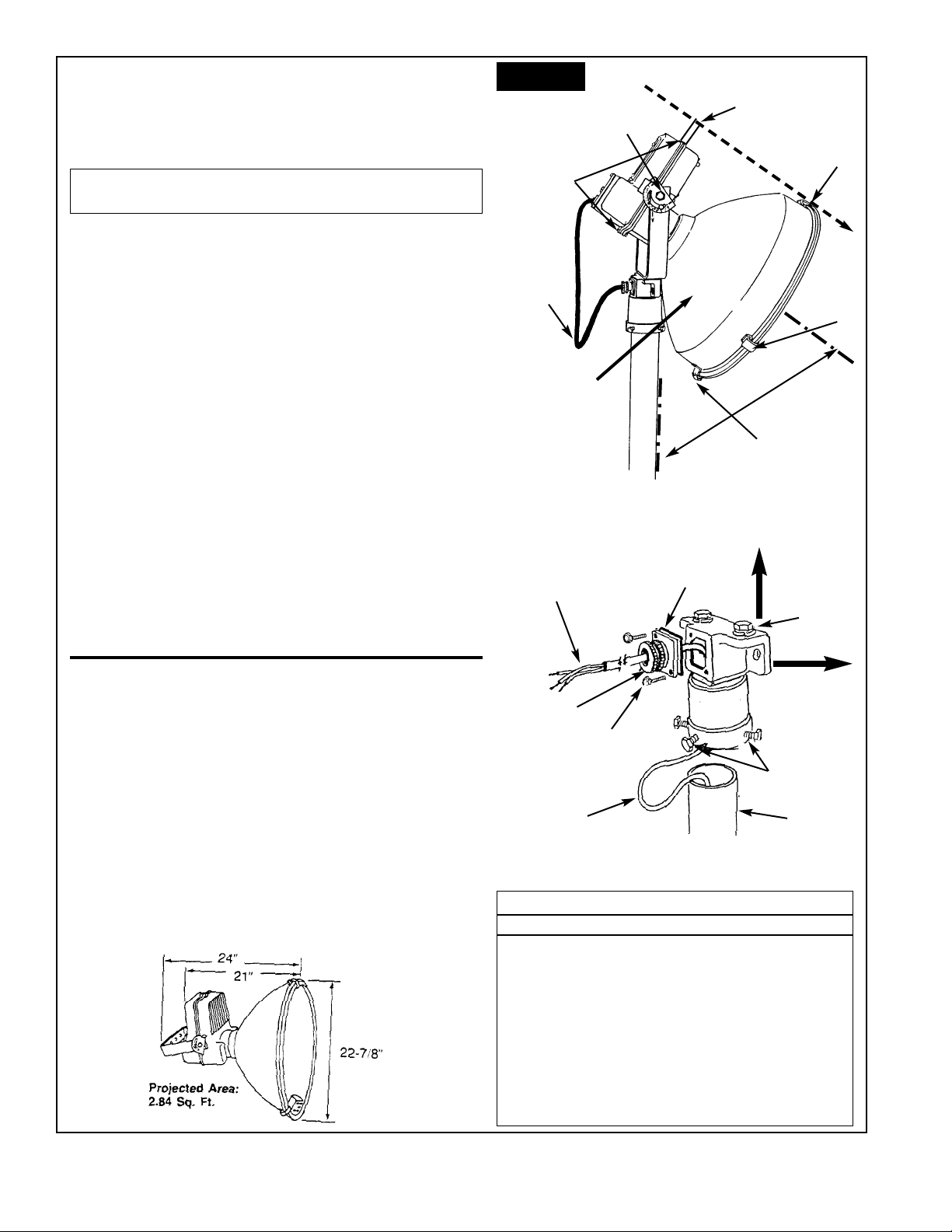

IMPORTANT: To obtain full range of vertical aiming angles

(From NADIR to 90°), trunnion must be horizontal.

1. Cross Arm Bracket catalog number

G-AM-8-CA

• Use two 1/2" x 1-1/4" hex head bolts, and

lockwashers provided to attach trunnion to

bracket (see Figure 1).

• Next, attach Cross Arm Bracket to cross arm.

Hardware is not provided.

2. Pole Top Slipfitter catalog number

G-AM-8-SF

• Use two 1/2" x 1-1/4" hex head bolts provided,

attach trunnion to pipe slip fitter.

• Position slip fitter over top of pipe and secure

with four 3/8" set bolts.

3. Pipe Wall Bracket catalog number

G-AM-8-WB

• Attach fixture trunnion to cross arm bracket

G-AM-8-CA, use one 3/4" x 1-1/4" hex head

bolt and one 3/8" x 1" bolt to attach cross arm

bracket to top of pipe/wall bracket.

(See Figure 1).

WARNING:

Make certain power is off before starting installation

or any maintenance.

CAUTION: This fixture is designed for permanent installation

in ordinary (Non-Hazardous) or wet locations in accordance

with the National Electrical Code and all applicable local codes.

• Do not use in areas of limited ventilation or in high ambient

enclosures.

• The lamp and fixture operate at high temperatures, contact

with combustible material can cause fire and personal contact

can cause severe burns.

G-AM-8-CA

G-AM-8-WB

G-AM-8-SF

WIRING:

• Use 14/3, 90C, 600 volt cable for connection to supply.

• Sufficient cable must be allowed between fixture and junction

box to permit rotation of the fixture through its entire range of

rotation.

1. Loosen four screws "A" and remove wiring cover "B".

2. Loosen bushing clamp Plate "C" and feed supply cable thru

the bushing. Tighten bushing clamp plate.

3. Connect power leads to ballast primary leads in accordance

with N.E.C. and local codes.

4. CAUTION: Cap all unused power leads on multi-tap

ballasts.

5. Connect ground leads to green lead, provided in fixture. Do

Not use pole as ground.

6. Replace wire cover, NOTE: Make sure gasket is in proper

place.

7. In high humidity areas; use a punch to knock-out weep hole

in lower ballast half of housing.

VERTICAL: Using Protractor

•For vertical aiming using protractor supplied with fixture.

• First determine the vertical aiming angle from NADIR.

(From the lighting layout).

• Then depending on trunnion position follow these steps:

(Step 1 Horizontal - Step 2 Vertical)

1. For horizontally mounted trunnion.

NOTE: For greatest accuracy, trunnion must be level.

A. Loosen aiming bolt "G" and trunnion/fixture bolt "D"

rotate protractor "E" counter-clockwise until tab hits housing.

B. Determine aiming angle from layout and add 90° to that

angle (Example: Aiming angle from layout - 50° add 90° so

that result is 140°). ( Continued on page 2 )

AIMING: By Sighting

• For Horizontal aiming,

loosen bolt top or bolts holding pipe fitter, wall fitter or

cross arm bracket and rotate

floodlight to desired direction.

• For Vertical aiming, by

sight, Loosen top screw "J"

and mount aiming bar "H" in

vertical position and tighten

screw.

• Loosen aiming bolt "G" and

trunnion Bolts "D" sight

through notch in aiming latch

"F" at top of reflector with

target.

• Tighten trunnion bolts "D"

and then position tab on

Protractor index "E" against housing and tighten aiming bolt "G".

AIMING

BAR H

AIMING

SCREW J

AIMING

LATCH F

AIMING ANGLE

G-AM-8-WB

WALL

BRACKET

G-AM-8-CA

CROSS ARM

BRACKET

CROSS

ARM BOLT

TRUNNION

V - MARK

TA B

PROTRACTOR

JUNCTION

BOX

COVER - B

BUSHING

CLAMP

PLATE - C

COVER

SCREWS - A

AIMING

BOLT G

TRUNNION

BOLT D

FIGURE 1

EGS Electrical Group • 7770 N. Frontage Road • Skokie, Illinois 60077

Page 2

650167-002 Rev. C 12/20/99

C. While holding protractor tab against housing, rotate fixture

until desired angle. (Eg 140°) is at the "V" alignment mark on

trunnion bracket.

2.For Vertical mounted trunnion.

FOLLOW SAME PROCEDURE AS ABOVE EXCEPT:

• Do not add 90° to desired aiming angle.

SERVICE AND LAMPING

1. Loosen aiming bolt "D" and rotate fixture until glass lens cover

is in the straight up position.

• Tighten bolts "D" to lock fixture in this maintenance position.

2. Release three spring latches "E" and open glass lens cover

assembly for relamping and cleaning.

• To maintain lighting performance, the glass cover and inside

reflector should be cleaned periodically.

• To clean, wipe reflector and glass lens cover with a soft clean

damp cloth. If this is not sufficient, use a mild liquid cleaner.

• Do Not Use strong alkaline or acid cleaners, they may damage

reflector finish.

3. Install lamp in socket.

• Check nameplate for correct lamp type and wattage.

• Close cover assembly and secure the three latches "E" .

BALLAST SERVICE

1. Loosen aiming bolt "D" and rotate fixture until glass lens cover

is in the downward position.

2. Loosen two screws "J" and open ballast housing.

• Capacitor and ballast are only resting in stationary half of fixture.

3. Perform required service and close housing.

CAUTION

• Ensure that gasket around perimeter of housing is intact before

tightening screws.

• Ensure that wires will not be pinched when closing cover.

AIMING

BAR H

BALLAST

HOUSING

SCREWS

(2) J

DRIP

LOOP

HINGE

60° MIN.

AIMING

BOLT D

AIMING

LATCH F

SPRING

LATCH E

REFLECTOR

TOUCHES

POLE AT 60°

PULL 10" AND ENOUGH

CABLE FOR DRIP LOOP

IN FIXTURE WIRING

APPLICATION

VERTICAL

MOUNTING

HORIZONTAL

MOUNTING

PRESSURE

PLATE WITH

GASKET

CORD GRIP

1

3

4

#14-3, 90C, 600 V

CABLE FOR

CONNECTION TO

SUPPLY

POLE

SLIPFITTER INSTRUCTIONS

NOTE: Flexible cord or cable shall be type SOWA or SOOWA and

have a temperature rating as indicated on the product nameplate.

Cord should have a diameter between 0.5" and 0.625". Cords

outside of this range may prevent the proper functioning of the

clamp and result in water entry.

1. Loosen two screws on pressure plate for cable entrance.

2. Feed pole and bracket cable through cable entrance (#14 AWG

cable).

• Leave at least 10" of slack to make connections inside fixtures.

• Tighten pressure plate.

3. Mount slipfitter onto pole and tighten (4) mounting bolts.

4. Remove mounting bolt and place through center hole of yoke on

fixture.

• Mount fixture to slipfitter and secure mounting bolt tightly.

FIGURE 2

REPLACEMENT PARTS LIST

ITEM PART NUMBER

Glass Lens Cover Assembly 59566943001

Bushing Cord Entrance 59080816001

Clamp-Cord Bushing 59080820001

Socket 59759485005

Tr unnion 59607566001

Plate Wiring Access 59766024004

Lamp Stabilizer Spring 59766038001

Wire Insulator 59080540009

Gasket Reflector 59765973001

Plate Index 59765898002

Aiming Bar 59601297001

Reflector Housing Heavy Duty 59766292002

WARNING: Aiming angles of less than 60° are not possible with

a vertically mounted trunnion. See Figure 2.

Loading...

Loading...