Appleton Instruction Sheet: Appleton™ A-51 LED Series Lighting Fixture for Groups A, B, C, D, 650592-000 Manuals & Guides

650592-000

INSTRUCTION SHEET

Installation and Maintenance Instructions for the

Appleton™ AA-51 LED Series Lighting Fixture

FOR PROPER AND SAFE INSTALLATION OF THIS PRODUCT PLEASE READ THE FOLLOWING INSTRUCTIONS

AND KEEP THIS MANUAL FOR FUTURE REFERENCE.

AA-51 LED Series lighting fixtures

for Hazardous Location

Class I, Div. 1, Groups A, B, C, D

Suitable for Group A, when used with Pendant Mount Only

Class II, Div. 1, Groups F and G

Class III

WARNING GENERAL

1. DO NOT MODIFY UNIT IN ANY WAY. Modication

may affect safety and reliability.

2. Improper use or failure to follow these instructions

could result in serious injury or property damage.

3. Operator should be instructed in the safe and

proper usage and maintenance of this product.

WARNING ELECTRICAL

1. Disconnect electrical power before installation,

adjustment and maintenance.

2. DO NOT overload; the amperage and voltage indicated

on the nameplate must not be exceeded.

3. Check continuity before connecting electrical power.

4. All installations must comply with applicable local

and/or National Electrical Code®.

5. Before installing check xture unit nameplate and

carton labels to be sure you have correct xture and

mounting hood. Circuit must be deactivated before

installing xture.

CAUTION GENERAL

1. All AA-51 LED Series Fixtures are to be mounted

vertically with globe facing down.

The xture unit MUST BE installed with one of the

following mounting hoods for safe operation. Failure to

use fixture unit with one of the following mounting hoods

voids warranty as well as the UL Listing and creates the

risk of re or explosion.

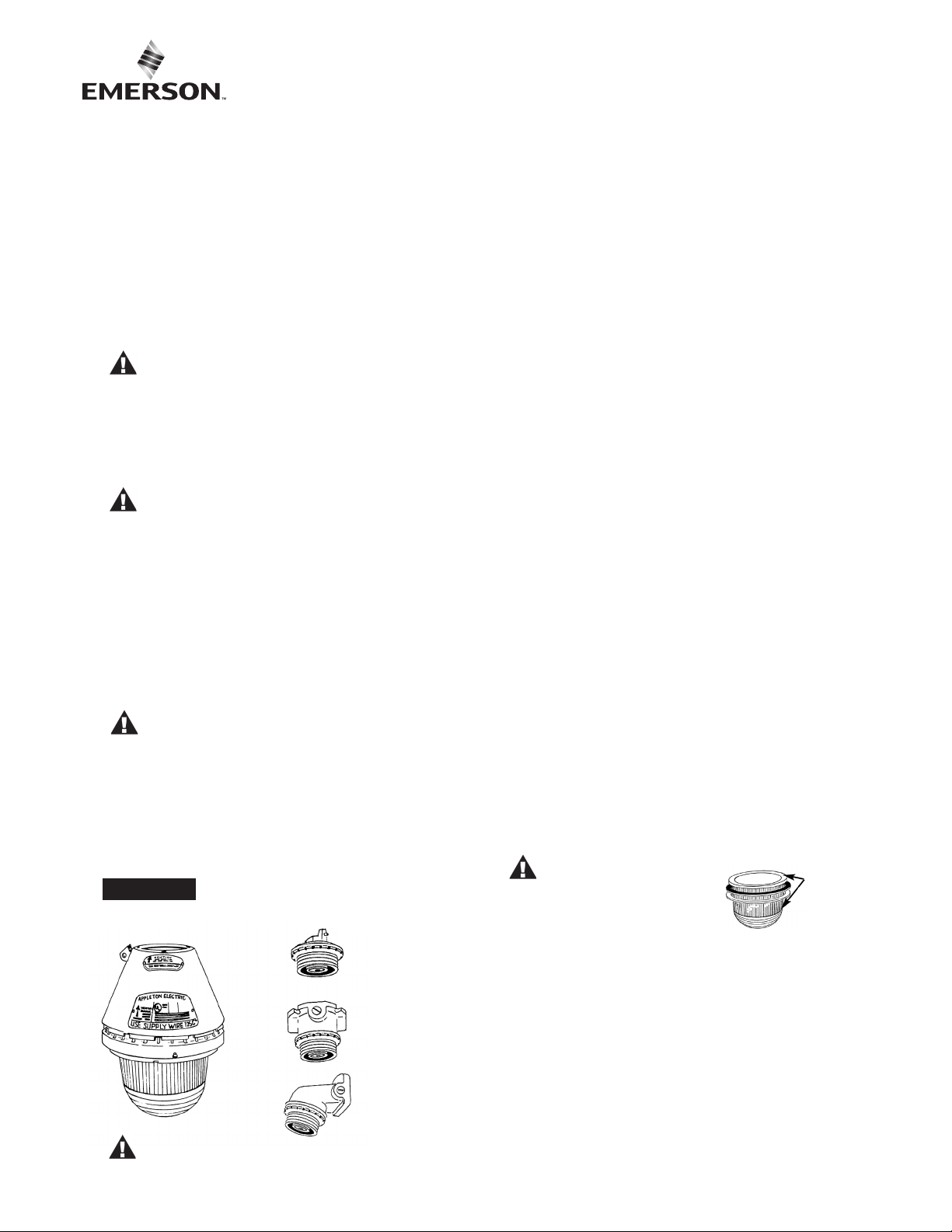

FIGURE 1

The AA-51 fixture MUST BE installed with:

AAP-50, AAP-75,

AEP-50, AEP-75

Pendant Hood - ONLY

*Group A with this hood.

(One hub, rigid or flexible mounting)

AAC-50, AAC-75,

AEC-50, AEC-75

Ceiling Hood

(Four hubs, three close-up plugs)

AASB-50, AASB-75,

AESB-50, AESB-75

Short Wall Bracket Hood

(Two hubs, one close-up plug)

FIXTURE INSTALLATION INSTRUCTIONS

Use the installation drawing as a guide. Install mounting

hood rst as all wiring connections are made in the

mounting hood. The fixture unit requires no internal

wiring connections.

1. Remove the connection block (VPT-7) from the

mounting hood by loosening (but not removing) the two

Phillips head screws. Turn connection block

counter-clockwise to remove.

2. When using ceiling (AAC- ) or short bracket (AASB-),

mounting hoods, threaded adapter (59064050000) can

be removed by lifting gasket (59064034000) to access

set screw.

• Loosen set screw and turn adapter

counter-clockwise for easier access to junction box.

3. Install mounting hood to conduit system (and/or

wall or ceiling). If using pendant, secure the hood to

the conduit system with the set screw.

4. Pull supply wires from the conduit into the junction box.

• Use supply wire rated 110°C minimum.

5. Secure threaded adapter (where applicable) to junction

box and tighten all set screws. Make connection of

supply wires to the VPT-7 connection block by

attaching “HOT” voltage lead to the black wire and

common “neutral” lead to the white wire on the

connection block.

6. Secure VPT-7 connection block to threaded adapter or

mounting hood by slipping over Phillips head screws;

turning clockwise and tightening screws.

7. Inspect threads of mounting hoods and of the xture

unit to be sure they are clean and free of damage.

Inspect globe for any chips, scratches or cracks.

CAUTION GENERAL

Chipped, scratched or cracked

globes will fail. Replace any

such defective lamp housing.

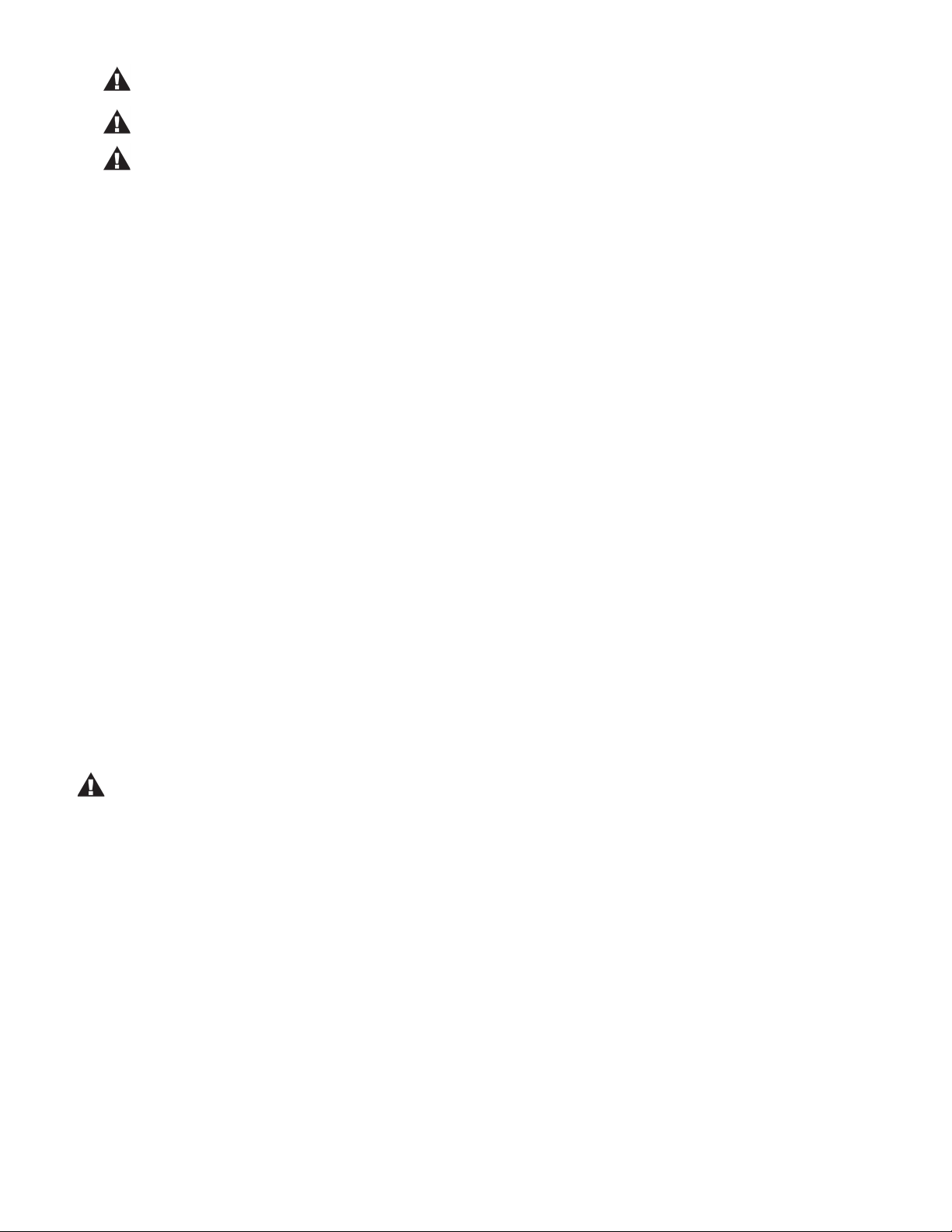

8. Thread the xture unit into mating threads of mounting

hood until tight against gasket of mounting hood.

Locking spring of xture unit should engage with

notches on mounting hood.

9. Install guard and/or reector if desired. Check tightness

of set screws and all threaded joints. Activate supply

circuit to test xture.

MUST BE

FREE OF

CHIPS OR

CRACKS

IMPORTANT: Remove all unused conduit plugs

and reinstall with pipe sealant.

650592-000 Rev. B 07/17/18 • Page 1 of 8Appleton • 1.800.621.1506 • www.appletonelec.com

NOTE: All installations must comply with applicable local and/or National Electrical Code.

CAUTION:

CAUTION: All AA-51 LED series fixtures are to be mounted vertically with globe facing down.

Disconnect supply circuit before opening or relamping fixture.

MAINTENANCE DATA

• To maintain maximum light output from this xture, it should be cleaned periodically as follows:

1. Alkaline or acidic cleaners will attack the protective coating of epoxy on the xture and should not be used.

The aluminum exterior of this fixture should be cleaned only with a mild soap or cleaner, and should

be rinsed with water immediately.

This will allow the epoxy to protect the xture from corrosive elements in the atmosphere and result in longer

xture life.

2. The glass globe should be cleaned using a soft cloth and a non-abrasive cleaner. The globe should be

regularly inspected for scratches or chips. If the globe is scratched or chipped, it must be replaced.

3. The porcelain enamel reector may be cleaned with any non-abrasive detergent or glass cleaner.

• These periodic cleaning procedures are important to prevent the accumulation of dust and dirt which

will impair the light output of the xture.

• When removing and repairing xture, lubricate threads only with Appleton TLC-3 conductive, high

temperature lubricant. This should only be necessary if threads are no longer coated with the blue or

black color of the TLC-3 dry lm Teon® lubricant.

OPERATIONAL DATA

• The xture must be operated in an environment that does not exceed 55°C.

• The xture may be operated on AC power only up to 277 VAC and 300 VDC.

• Use supply wire rated 110°C minimum.

WARNING

• To reduce the risk of fire or explosion, do not install where the operating temperature exceeds

ignition temperature of hazardous atmospheres.

• Refer to the nameplate on the fixture for maximum operating temperature and for proper

fixture classification.

Teon® is a registered trademark of E. I. du Pont de Nemours and Company.

650592-000 Rev. B 07/17/18 • Page 2 of 8Appleton • 1.800.621.1506 • www.appletonelec.com

SHORT BRACKET INSTALLATION

1. Remove threaded adapter from junction box for

easier access to conduit system.

2. Remove VPT-7 Connection Block from threaded

adapter.Pull supply wire (110°C minimum) into

junction box.

3. Replace threaded adapter and secure set screw.

4. Connect supply wires to appropriate “black” wire

and “white” wire on VPT-7 block per installation

instructions.

5. Push VPT-7 connector block into place and tighten

screws. Install xture unit.

• Remove unused conduit plug and reinstall

with pipe sealant.

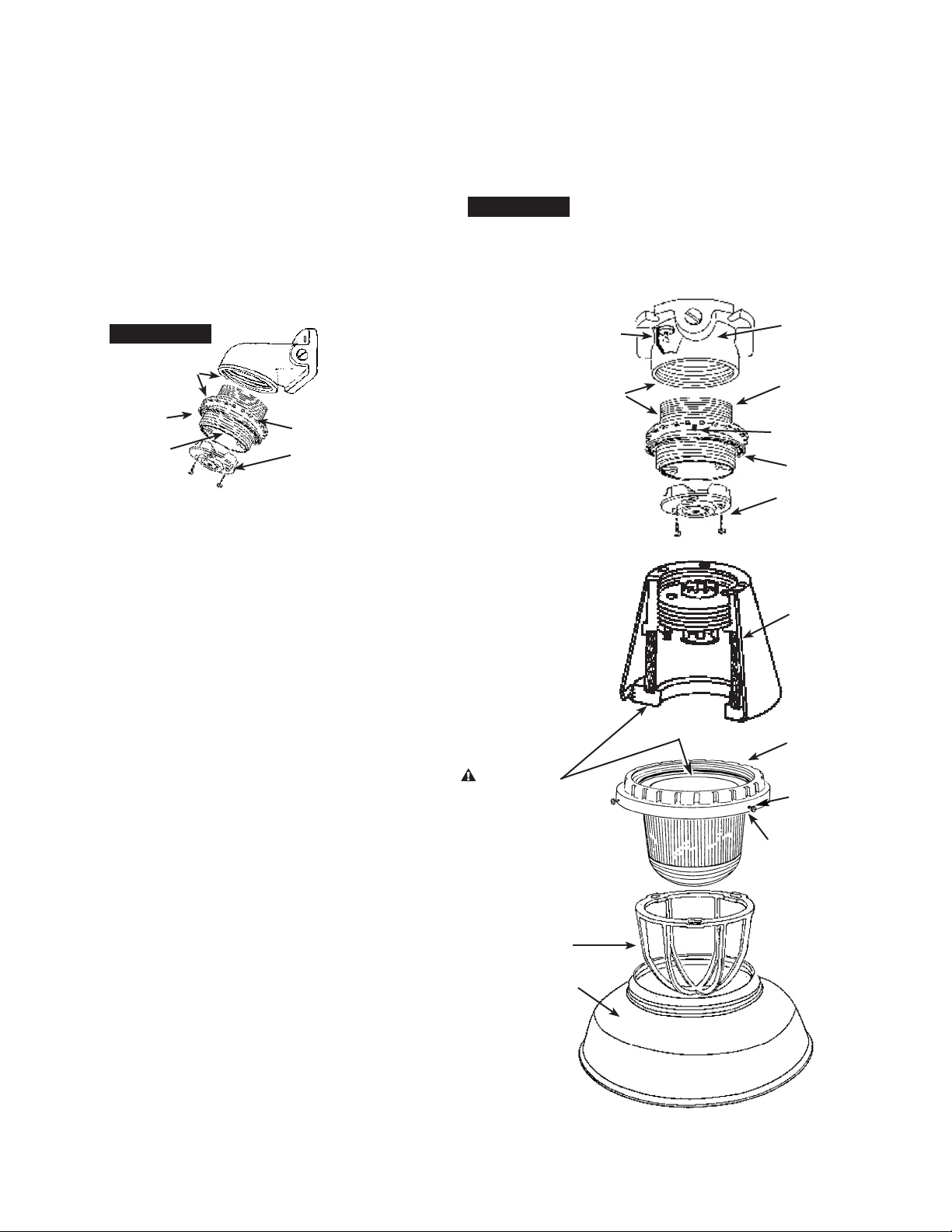

FIGURE 3

AA-51 LED FIXTURE SHOWN WITH

CEILING MOUNTING HOOD

FIGURE 2

TLC-3 LUBRICANT

SHOULD BE APPLIED

TO ALL THREADS

SET SCREW

GROUNDING

SCREW

AASB-50/75

15° SHORT

BRACKET

59064050000

THREADED ADAPTER

VPT-7 CONNECTOR BLOCK

SCREW #8 -32 x 1/2" PH. HD.

GREEN GROUNDING SCREW

TLC-3 LUBRICANT

BOTTOM LOCKING

SPRING WITH SCREW

#8-32 x 1/4" RD. HD.

JUNCTION BOX

Four hubs and

three close-up plugs

59064050000

THREADED ADAPTER

SLOTTED SET SCREW

1/4" - 20 x 3/8"

590640849

FIBER GASKET

VPT-7

CONNECTOR BLOCK

SCREWS (2)

#8 -32 x 1/2" PH. HD.

FIXTURE BODY

TLC-3 LUBRICANT

IMPORTANT NOTE

ALL GRIME AND GRIT MUST BE

REMOVED FROM GROUND

SURFACES OF FIXTURE BODY AND

GLOBE CONTACT POINTS.

ALSO APPLY TLC-3 LUBRICANT

TO GLOBE RING THREADS.

AAGUA-15

ALUMINUM GUARD

AARW-15ST

STANDARD PORCELAIN REFLECTOR

REFLECTOR MOUNTING

SCREWS (3)

# 8-32 x 3/8" RD. HD.

GLOBE AND RING ASSEMBLY

AAGUA-15

650592-000 Rev. B 07/17/18 • Page 3 of 8Appleton • 1.800.621.1506 • www.appletonelec.com

Loading...

Loading...