Page 1

Industrial Control Transformers

© January 2017

Design Choices

SolaHD offers a broad range of industrial control solutions

for the most demanding industrial applications. Our products

exceed NEMA ratings for inrush and regulation to ensure

control systems are powered correctly. Electromagnetic

control components demand inrush currents up to 10

times the transformer’s nominal rating. While this inrush is

occurring, the output side of the transformer must not fall

below 85% of nominal as specied by NEMA ST-1, Part 4.

Using a transformer that does not meet these ratings may

cause erroneous shutdowns of downstream processes.

To meet your complete control needs, SolaHD's four series

of control transformers, all of which exceed the NEMA

standards. The Selection Chart can be used to identify the

appropriate transformer for your application.

The SBE series is available from 50 - 5000 VA, 55°C rise

and features copper windings and encapsulation (through

1000 VA) for longer life and protection from the environment.

This low temperature performance can mean smaller cabinet

size or longer life for any electronic components that may

be nearby.

The SMT series are 115°C rise, aluminum wound and for

applications where good voltage regulation and higher

power capacities (1000-5000 VA) are required.

A. Sealed VA - Total steady state sealed VA is the

volt-amperes that the transformer must deliver to

the load circuit for an extended period of time.

B. Inrush VA - Total inrush VA is the volt-amperes that the

transformer must deliver upon initial energization of the

control circuit. Energization of electromagnetic devices

takes 30-50 milliseconds. During this inrush period the

electromagnetic control devices draw many times normal

current – 3-10 times normal is typical.

The International series meets IEC requirements and IP20

(touch proof covers ordered separately for E models) for

European applications.

The HSZ series rounds out SolaHD’s line with an enclosed

series of control transformers from 1 - 10 kVA that feature

either a UL Listed Type 3R, 4, 4X or 12 enclosure.

This unique design, featuring copper windings and

encapsulated construction, can help system designers

meet harsher environmental standards or design for a safer

installation outside of a control cabinet. The HSZ series is for

applications where cost or heat issues make mounting the

transformer outside the control panel necessary.

SolaHD is pleased to offer custom transformers 1 kVA

and larger. If you can't nd what you are looking for here, we

are happy to provide a quote on a custom transformer if

available. Contact your local sales representative for more

information.

Sizing an Industrial Control Transformer

For proper transformer selection, three characteristics of

the load circuit must be determined in addition to the

minimum voltage required to operate the circuit. These

are total steady state (sealed) VA, total inrush VA, and inrush

load power factor.

C. Inrush Load Power Factor is difcult to determine without

detailed vector analysis of all the load components.

Generally such an analysis is not feasible, therefore, a

safe assumption is 40% power factor (PF). Until recently

20% PF was commonly used for transformer calculations,

however, tests conducted on major brands of control

devices indicate that 40% PF is a safer default

assumption.

Selection Steps

1. Determine the supply and load voltages. The supply

voltage is the available voltage to the control transformer.

The load voltage is the operating voltage of the devices

that will be connected to the transformer output.

2. Calculate the total sealed VA by adding the VA

requirements of all components that will be energized

together (timers, contactors, relays, solenoids, pilot

lamps, etc.). Sealed VA data is available from the control

device manufacturer.

3. Add the inrush VA of all components that will be

energized together. Be sure to include the sealed VA

of components that do not have an inrush, (lamps,

timers, etc.) as they present a load to the transformer

during maximum inrush.

184

Page 2

Industrial Control Transformers

© January 2017

4. Calculate selection inrush VA in one of the following

two ways:

A. Selection inrush VA =

(VA sealed)2 + (VA inrush)

√

2

Alternative Method

B. VA sealed + VA inrush = Selection inrush

Method B will result in a slightly oversized transformer.

5. If your line voltage varies 10% or more, contact Technical

Services for assistance.

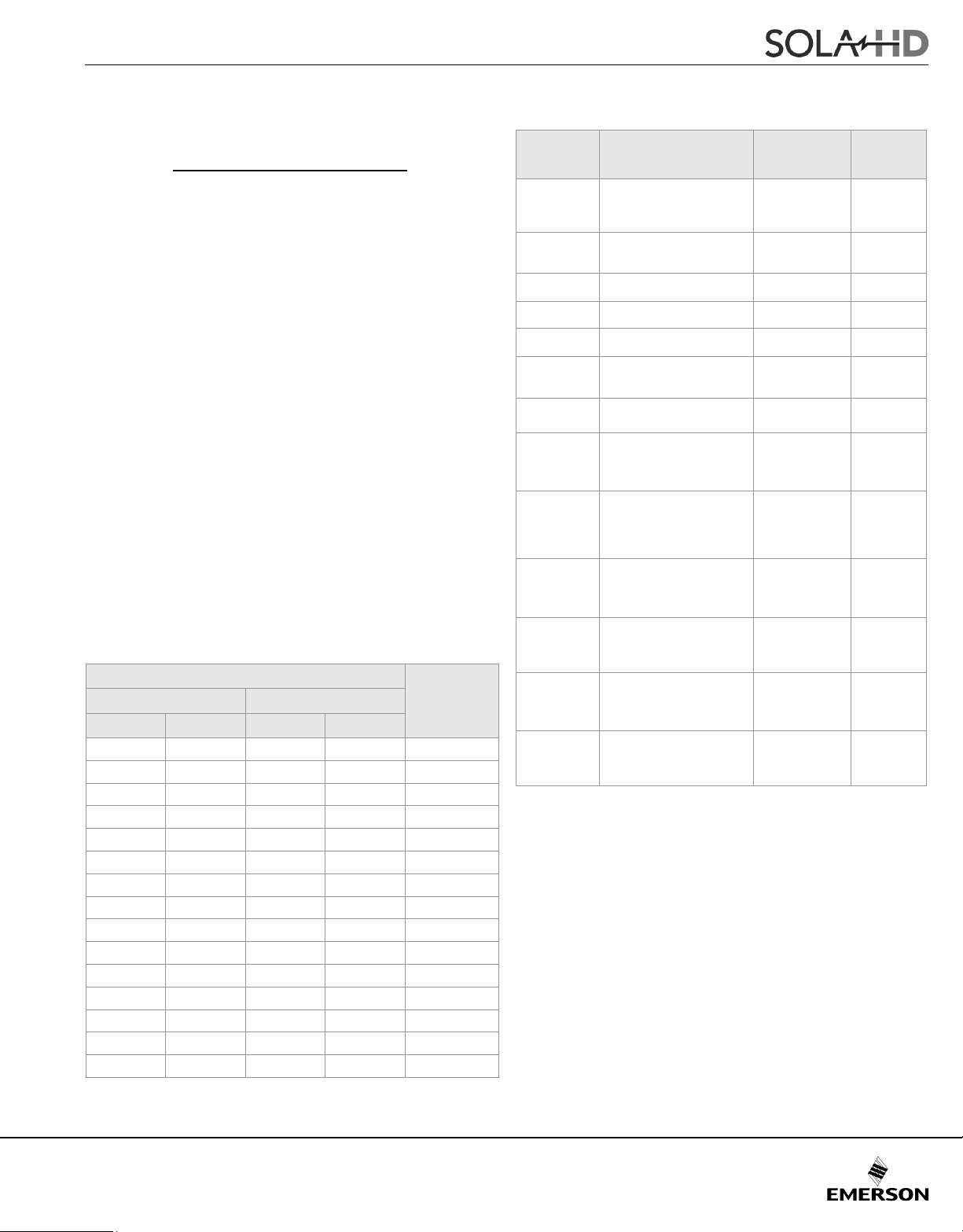

6. Utilizing the regulation data chart below, select the

transformer VA needed for your application from the

“Transformer VA Rating” column. Check to be sure that

the nameplate VA rating exceeds the sealed VA of the

control circuit calculated in Step 1. If it does not, select a

larger transformer VA that exceeds the circuit sealed VA.

By following the above procedure, the secondary voltage

delivered by the transformer will be 90% of the nameplate

secondary voltage under maximum inrush conditions at

rated input voltage.

Now refer to the selection tables on the following pages

for the style you have chosen. Select your transformer

according to your required voltage and VA capacity.

Regulation Data – Inrush VA at 20% and 40% Power Factor

20% PF

1

Transformer

2

40% PF

VA Rating

2

Selection Inrush VA

Type SBE Type SMT

2

20% PF

294 207 N/A N/A 50

515 363 N/A N/A 75

696 490 N/A N/A 100

1362 959 N/A N/A 150

2131 1501 N/A N/A 200

2883 2031 N/A N/A 250

3608 2541 N/A N/A 300

4777 3364 N/A N/A 350

7601 5353 N/A N/A 500

12939 9112 N/A N/A 750

18703 13171 8277 5829 1000

23814 16066 17182 12100 1500

34586 24356 22834 16080 2000

45633 32770 34506 24300 3000

158000 111000 71284 50200 5000

1

Assuming the transformer is to deliver a minimum of 90% secondary

voltage during inrush conditions.

2

See C. Inrush Load Power Factor on page previous page.

40% PF

2

Chart A: Voltage Code Chart

Voltage Code Primary Voltage

240 x 480

None

A

D

E

JL

JN

R

TC

TE

TF

TH

MH

MC

Note: "—" indicated tap not used.

* 60 Hz only at 277, 575 or 600 V.

230 x 460

220 x 440

240/480/600

230/460/575

240 x 480 24 60

120 x 240 24 60

208/240/277 120/24 60

208/240/480/600

200/230/460/575

480 240 50/60

208/240/—

200/230/400

—/220/380

208/240/—

—/277/480

200/230/400

—/220/380

208/240/—/480/*600

200/230/400/460/*575

220/*277/380

240/—/480

230/400/460

220/380/440

208/240/—/480/600

200/230/400/460/575

—/220/380/440/550

208/240/—/480/600

200/230/400/460/575

—/220/380/440/550

Secondary

Voltage

120

115

110

120/99

115/95

120/24

115/23

120/ — /24

115/24/23

110/23/ —

24

24

24

23

120

115

110

120/240

115/230

110/220

120/240

115/230

110/220

120/ — /24

115/24/23

110/23/ —

Hertz

60

50/60

50/60

50/60

60

60

50/60

50/60

60

60

50/60

50/60

60

50/60

50/60

60

50/60

50/60

60

50/60

50/60

60

50/60

50/60

185

Page 3

Industrial Control Transformers

© January 2017

VA

INTERNATIONAL SBE SERIES ENCAPSULATED INTERNATIONAL SFP SERIES ENCAPSULATED

TC TE TF TH TH MH MC

Temp 55°C 80°C

50 E050TC E050TE E050TF E050TH

100 E100TC E100TE E100TF E100TH

150 E150TC E150TE E150TF E150TH

250 E250TC E250TE E250TF E250TH

500 E500TC E500TE E500TF E500TH

750 E750TF E750TH CE750MC

1000 CE1000TH CE1000MH CE1000MC

1500 CE1500TH CE1500MH CE1500MC

2000 CE2000TH CE2000MH

Choosing the Correct Series

The SBE series of industrial control transformers provide

voltage regulation which exceeds NEMA standards. They

have a 55°C rise and have copper windings and are 50/60

The International series have multiple voltage taps for easy

application. These units also meet IEC 61558-1, 61558-2-2

and are CE marked for easy export to European countries.

Hz rated. The SBE series can handle signicant inrush with a

minimal drop in output voltage.

The HSZ series is for applications where cost or heat

issues make mounting the transformer outside the control

The SMT series are 115°C rise, aluminum wound and are for

applications where good voltage regulation and higher power

capacities are required.

panel necessary. This series has 80°C rise and has

copper winding for industrial applications. These units are

enclosed with UL Listed/NEMA Type 3R enclosures. Also

available in UL Listed/NEMA Type 4, 4X and 12.

Selection Chart

VA

-- D E JL JN -- -- -- A R

Temp 55°C 115°C 80°C

50

75

100

150

200

250

300

350

500

750

1000

1500

2000

3000

5000

75000

100000

* Change HZxxxx to HZ12xxxx for Type 12 or 4 applications or HZ4Xxxxx for Type 4X applications.

E050 E050D E050E E050JL E050JN

E075 E075E

E100 E100D E100E E100JL E100JN

E150 E150E E150JN

E200 E200E

E250 E250D E250E E250JL E250JN

E300 E300E

E350 E350E

E500 E500D E500E E500JL E500JN

E750 E750E

E1000 T1000 HZ1000 HZ1000A HZ1000R

SBE ENCAPSULATED

SBE OPEN

(SZO)

Y1500 T1500 HZ1500 HZ1500A HZ1500R

Y2000 T2000 HZ2000 HZ2000A HZ2000R

Y3000 T3000 HZ3000 HZ3000A HZ3000R

Y5000 T5000 HZ5000 HZ5000A HZ5000R

SMT OPEN HSZ * TYPE 3R

HZ75000 HZ75000A HZ75000R

HZ10000 HZ10000A HZ10000R

Selection Chart - International Series

186

Loading...

Loading...