Page 1

501581-001 INSTRUCTION SHEET

Installation Instructions for Appleton™ Contender® EDS-EDSC Series

1- and 2-Gang Control Assemblies for Use In Class I, Group C and D,

Class II, Group E, F, and G, and CLASS III, Division 1 and 2 Hazardous Locations

WARNING: Electrical power must be turned OFF before and during installation and maintenance. Failure to follow safety

instructions may cause ignition of hazardous atmospheres resulting in serious personal injury and/or property damage.

CAUTION: Care must be taken to prevent the ground surface of the bodies and covers from becoming scratched, dented, or

otherwise damaged as this could affect the explosion-proof features of these assemblies.

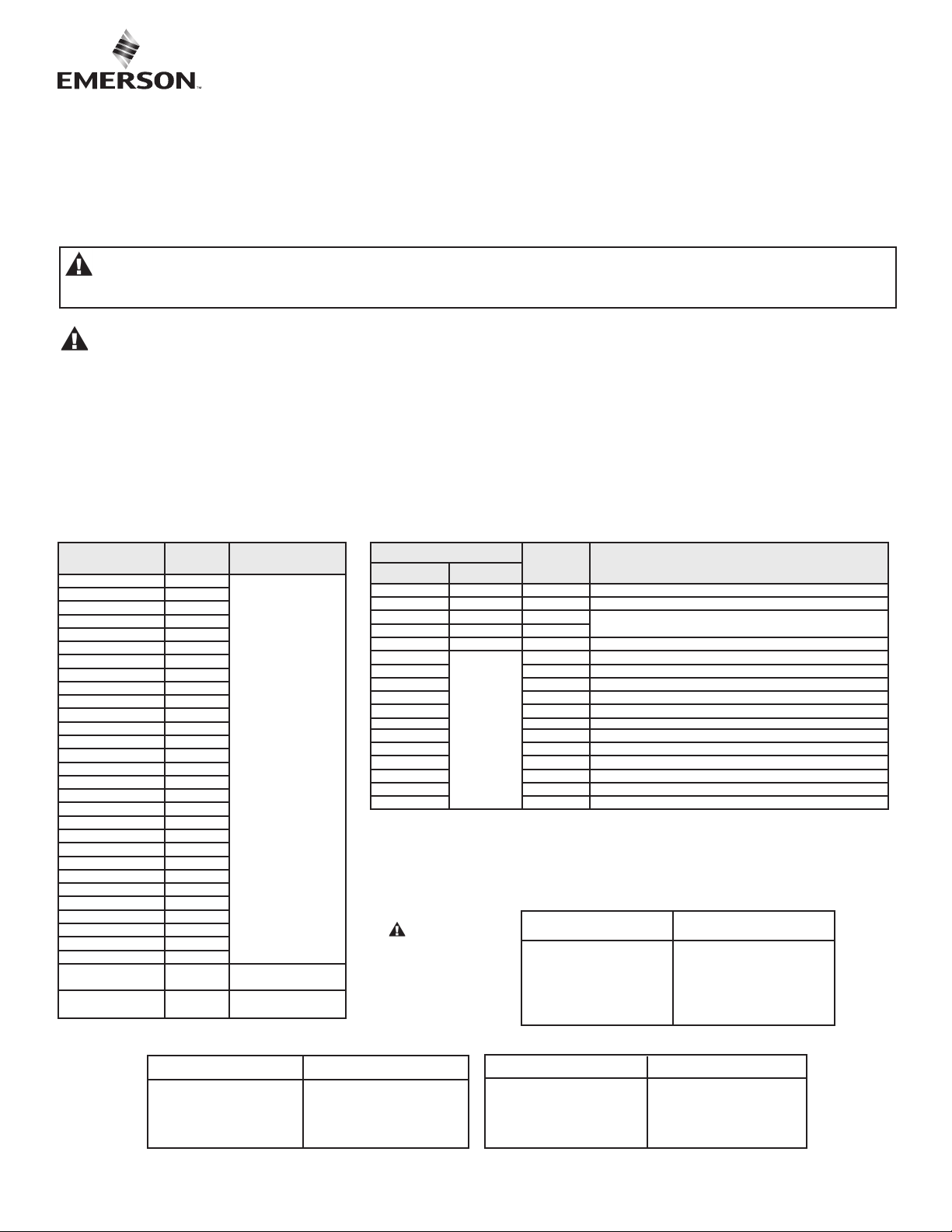

Appleton control assembly covers and devices are UL Listed for use with Appleton listed control assembly bodies, and are

UL Classied for use with UL Listed Crouse-Hinds bodies shown below.

ASSEMBLY: Check ground surfaces of all components for foreign material prior to assembly. Surfaces must be clean and

undamaged. Install the desired cover and device assembly on the body. Secure the cover assembly to the body by tightening the

screw provided with the cover.

The following cover with device and combination of cover and device are UL Listed control assemblies when assembled to Appleton

bodies and are UL Classied for use with the Crouse-Hinds bodies listed below. These combinations are suitable for use in Class I,

Group C and D; Class II, Group E, F, and G; and Class III hazardous locations.

COVER WITH

DEVICE*

EDKL-U3 YES

EDKL-J3 YES

EDKL-J1U2 YES

EDKL-J2U1 YES

EDK-DPB NO

EDKB-12 YES

EDKB-35 YES

EDKB-102 YES

EDKB-345 YES

EDKB-DU1 YES

EDKB-DU2 YES

EDKB-J1** YES

EDKB-J1DU1 YES

EDKB-J1U1 YES

EDKB-J1U2 YES

EDKB-J2 YES

EDKB-345-S636 YES

EDKB-U1

EDKB-U2

EDSK-B

EDKB-102-S634 YES

EDKB-102-S635 YES

EDKB-345-S634 YES

EDKB-345-S635 YES

EDKB-UM1

EDKB-DPB YES

EDKB-DPBM YES

EDKB-RU1 YES

EDKB-RU2 YES

EDKB-PC120 YES

EDKB-PC277

FACTORY

SEALED?

YES

YES

YES

YES

ELECTRICAL RATING

PUSHBUTTON

SWITCH

600 VAC MAX. HEAVY

PILOT DUTY

PILOT LIGHT 125 VAC

MAX. 60 Hz

1

25VAC-60HZ

1000VA LOAD

277VAC-60HZ

1000VA LOAD

COMBINATION OF

COVER* DEVICE

EDSK-MS EFS-2MS-Q NO 2P 30A-250VAC. 20A-600VAC, 2HP-230VAC. 3HP-575VAC

EDSK-MS EFS-3MS-Q NO 3P 30A-250VAC, 20A-600VAC, 3HP-125VAC, 15HP-600VAC

EDSK-RU1 EDS-RU1-Q NO

EDSK-RU2 EDS-MRU2-Q NO

EDS-F23W-Q YES 3W 20A-120VAC, 20A-277VAC, 1HP-120VAC, 2HP-240VAC

EDS-F24W-Q

EDS-F33W-Q YES 3W 30A-120VAC, 30A-277VAC, 2HP-120VAC, 2HP-240VAC

EDS-F21-Q YES 1P 20A-120VAC, 20A-277VAC, 1HP-120VAC, 2HP-240VAC

EDS-F22-Q YES 2P 20A-120VAC, 20A-277VAC , 1HP-120VAC, 2HP-240VAC

EDS-F31-Q YES 1P 30A-120VAC, 30A-277VAC, 2HP 120,VAC, 2HP-240VAC

EDS-F32-Q YES 2P 30A-120VAC, 30A-277VAC, 2HP-120VAC, 2HP-240VAC

EDSK-1MSAB YES 1P 1HP-115/230VAC

EDSK-1MSW*** YES 1P 1HP-115/230VAC, 1/4HP-32VDC, 1/4HP-250DC

EDSK-2MSAB*** YES 2P 1HP-115/230VAC, 3/4HP-32VDC, 3/4HP-250VDC

EDSK-2MSW*** YES 2P 1HP115/230VAC, 1/4HP-32VDC, 1HP-125VDC, 1/4HP-250VDC

EDSK-MC2*** YES 2P 30A-250VAC, 20A-600VAC, 2HP-230VAC, 3HP-575VAC

EDSK-MC3 YES 3P 30A-250VAC, 20A-600VAC, 3HP-125VAC, 15HP-600VAC

* With or without sufx -A

** With or without sufx -S801, -S802, -S803, -S804

*** Heater table supplied with these devices must be afxed in or near the enclosure for future reference

Blank cover for use singly with 2-gang body only

Device rating must match rating stamped on cover

With or without sufx -L

WARNING: To prevent

ignition of Group C and D

atmospheres, seals must be

installed within ve (5) feet on

each conduit opening.

COVER WITH

DEVICE

FACTORY

SEALED?

600 VAC MAX

HEAVY PILOT DUTY

YES 4W 20A-120VAC, 20A-277VAC, 1HP-120VAC, 2HP-240VAC

APPLETON APPLETON

2-GANG TANDEM THREE DEVICE

EDS177 EDSC177 EDS147 EDSC147

EDS277 EDSC277 EDS247 EDSC247

EDS377 EDSC377 EDS347 EDSC347

EDS177-SA EDSC177-SA EDS147-SA EDSC147-SA

EDS277-SA EDSC277-SA EDS247-SA EDSC247-SA

EDS377-SA EDSC377-SA EDS347-SA EDSC347-SA

ELECTRICAL RATING

APPLETON APPLETON

1-GANG BODY 2-GANG BODY

EDS171 EDSC171 EDS172 EDSC172

EDS271 EDSC271 EDS272 EDSC272

EDS371 EDSC371 EDS372 EDSC372

EDS171-SA EDSC171-SA EDS172-SA EDSC172-SA

EDS271-SA EDSC271-SA EDS272-SA EDSC272-SA

EDS371-SA EDSC371-SA EDS372-SA EDSC372-SA

CROUSE-HINDS CROUSE-HINDS

1-GANG BODY 2-GANG BODY

EDS171 EDSC171 EDS172 EDSC172

EDS271 EDSC271 EDS272 EDSC272

EDS371 EDSC371 EDS372 EDSC372

EDS171-SA EDSC171-SA EDS172-SA EDSC172-SA

EDS272-SA EDSC271-SA EDS272-SA EDSC272-SA

EDS371-SA EDSC371-SA EDS372-SA EDSC372-SA

501581-001 Rev. P 03/27/17 • Page 1 of 4

Page 2

8. Check pushbutton switch and pilot light electrically and mechanically

for proper operation.

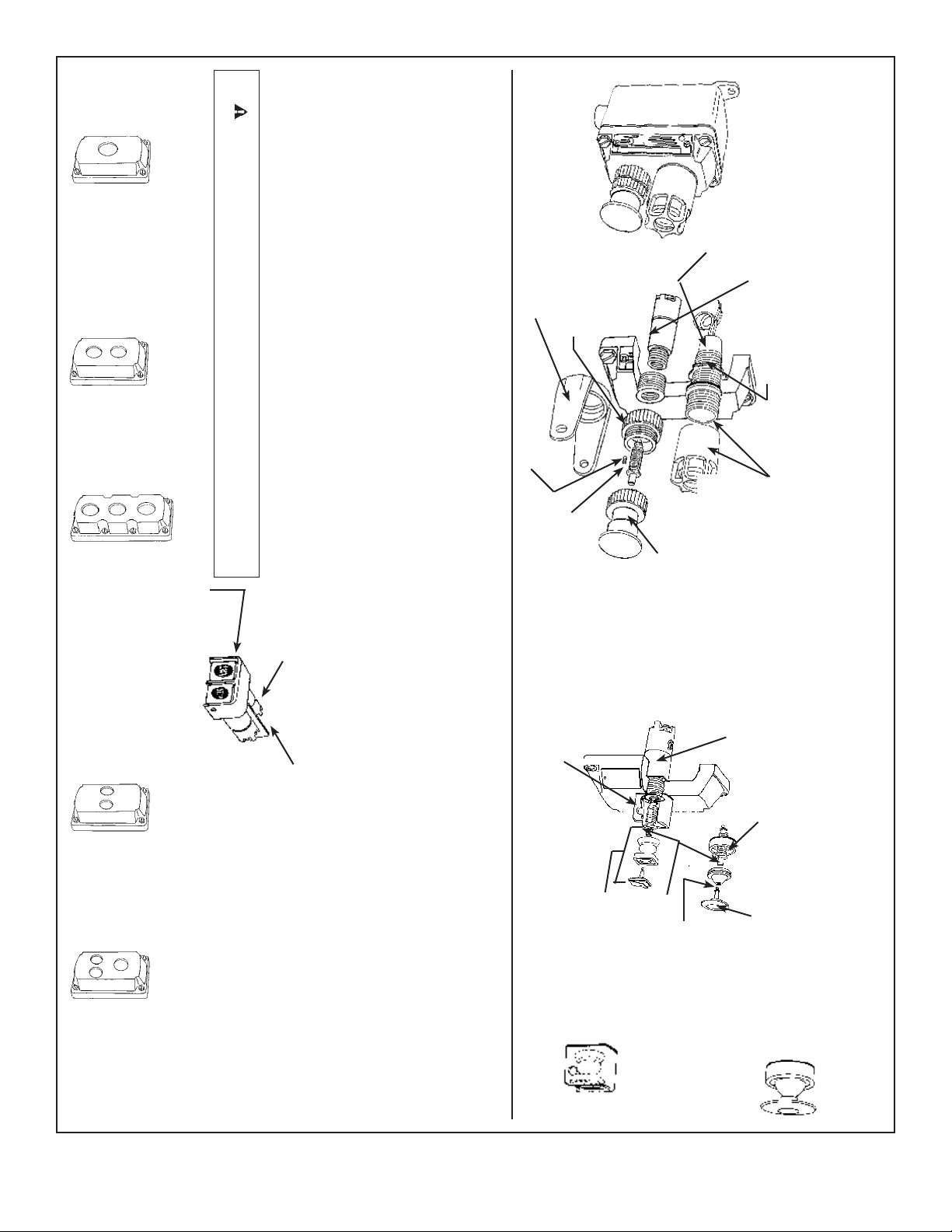

COLLAR MUST BE INSTALLED IN THE INTENDED MANNER AS SHOWN.

CAUTION: WHEN CHECKING PUSHBUTTON ELECTRICALLY GUARD OR

One Pushbutton

Switch Cover or one Pilot Light

EDSK-1 J

EDSK-1 J-A

6. Tighten shaft bushing with 1/2" nut driver to “lock” pushbutton in place, thread set

7. Thread Button and cover assembly onto collar until fully seated.

screw onto collar along side of hex at of shaft bushing.

5. Insert shaft into bushing. Put shaft bushing assembly thru hole in collar and thread

1/2" nut driver to remove shaft bushing and shaft from push assembly. (Set these parts

aside for later reassembly in step 5.)

face of cover.

bushing into pushbutton opening. Hold pushbutton from inside of cover to prevent it

from turning. If a Lockout Guard is used, put shaft bushing assembly thru collar

and lockout.

MAINTAINED CONTACT PUSHBUTTON SWITCH AND PILOT LIGHT

1. Pilot light must be installed in 3/4" 14 NPSM opening.

2. Pushbutton switch must be installed in 1/2" 14 NPSM opening.

3. Unscrew button and cover assembly from collar. Remove set screw from collar. Use a

4. Thread Push Button from inside of cover until front of pushbutton is ush with

Installation of Pushbutton Switch and Pilot Light in Contender® EDSK Series Covers

3/4" 14

NPSM

Tapped

Hole

EDSK-2J-A

3/4" 14

NPSM

Tapped

Holes

Three Pushbutton or

Three Pilot Lights or

Combination Pushbutton &

Pilot Light

EDSKL-3PB

EDSKL-3PBA

Two Pushbutton

Switch Cover or

Two Pilot Light Cover

EDSK-2J

GUARD & GASKET

TWO BUTTONS

DOUBLE PUSHBUTTON WITH TWO BUTTON GUARD

6. Press Weather Boot and Button assembly in shaft hole until fully seated.

SWITCH ASSEMBLY

7. Check pushbutton switch and pilot light electrically and mechanically for proper operation.

TWO PUSHBUTTON

OPTIONAL LOCK GUARD

COLLAR AND GASKET

ASSEMBLY

SET SCREW

SHAFT BUSHING

ASSEMBLY

ASSEMBLY

SINGLE PUSHBUTTON SWITCH WITH ONE BUTTON GUARD

2. Remove set screw from guard, use a 1/2" nut driver to remove shaft bushing and shaft from

3. Thread pushbutton from inside of cover until front of pushbutton is ush with face of cover

4. Insert shaft into bushing. Put shaft bushing assembly thru hole in guard and thread bushing

5. Tighten shaft bushing with a 1/2" nut driver to “lock” pushbutton switch in place. Thread set

into pushbutton opening. Hold pushputton from inside of cover to prevent it from turning.

screw onto collar along side of hex at on shaft bushing.

1. Single pushbutton with one button guard must be installed in 3/4" 14 NPSM opening.

pushbutton assembly (set a side for later assembly).

PUSHBUTTON

SET SCREW

SWITCH

SPLS-AM-B (AMBER)

SPLS-GR-B (GREEN)

SPLS-CL-B (CLEAR)

SPLS-OP-B (OPAL)

SPLS-BL-B (BLUE)

BUTTON AND COVER

PILOT LIGHT

LOCKNUT

PILOT LIGHT ASSEMBLY

SPLS-RE-B (RED)

Explosion-Proof and Dust-Ignition-Proof

1/2" 14 NPSM

Tapped Holes

EDS K-2SP-A

Tapped Hole

1/2" 14 NPSM

Tapped Holes

Two Pushbutton

Switch Cover

EDSK-2SP

Switch Cover or Pilot Light

& Two P. B. Switch Cover

EDSK-1JSS

EDSK-1JSS-A

3/4" 14 NPSM

two button guard must be installed into two

1/2" 14 NPSM openings (approximately

1-1/6" apart).

2. Proceed as in steps (2) through (6) above.

Be sure insulator is in place.

Three Pushbutton

INSULATOR

1. Double Pushbutton assembly, with

GUARD AND GASKET

ASSEMBLY NPB-LG1

BUTTON ASSEMBLY

NBN-WB

GUARD AND GASKET

ASSEMBLY NPB-LG1

WEATHER BOOT AND

SHAFT BUSHING

RUBBER BOOT

ASSEMBLY

PUSHBUTTON

SWITCH

COLLAR AND GASKET

ASSEMBLY

PUSHBUTTON

MUSHROOM

ASSEMBLY

BUTTON ASSEMBLY

NMRB-GR (GREEN)

NMRB-BL (BLACK)

NMRB-RE (RED)

MUSHROOM PUSH

501581-001 Rev. P 03/27/17 • Page 2 of 4

Page 3

7. Check Selector Switches electrically and mechanically for proper operation.

handle pointing to “OFF” marking on nameplate, press operator housing down rmly

on operator collar and fasten in place with four (4) housing screws.

assembly through collar into Selector Switch and tighten bushing securely.

the two 1/2" threaded holes in cover. Thread in Selector Switch from inside of cover.

(See Note)

3. Use 1/2" nut driver to remove shaft bushing.

4. Place operator collar and gasket assembly on face of cover and line up openings with

5. Insert shaft through shaft bushing. While holding Selector Switch, thread shaft/bushing

6. Insert operator handle and teon gasket in operator housing. With arrow in operator

SELECTOR SWITCH

1. Selector Switch must be installed in 1/2" 14 NPSM opening(s).

2. Remove four housing screws, operator housing and handle assembly.

SELECTOR

SWITCH

INSULATOR

GASKET ASSEMBLY

OPERATOR COLLAR AND

Installation of Selector Switch in Contender® EDSK Series Covers

SELECTOR SWITCH COVERS

EDSK-2SP

EDSK-2SP-A

Two 1/2" tapped holes

BLANK

HAND

BLANK

AUTO

FWD

REV

START - STOP

ON

UP

DOWN

OFF

START

RUN

STOP

JOG

BUSHING

HOUSING

SCREWS (4)

AUTO

AUTO

OFF

HAND

REM

OFF

SHAFT

SHAFT

TWO POSITION NAMEPLATE THREE POSITION NAMEPLATE

SHAFT BUSHING

OPERATOR HANDLE

ASSEMBLY

TEFLON GASKET

OPERATOR

HOUSING

NOTE: Threaded aluminum shell of Selector Switch Assembly MUST TOUCH the

under side of operator collar gasket for proper operation of mechanism.

CLAMPING

SCREW

ASSEMBLY

SWITCH

CLOSE-UP

B.

PLUG

If two Selector Switches are to be installed, make sure insulator is in place.

Explosion-Proof and Dust-Ignition-Proof

SELECTOR

A. If one Selector Switch is to be installed, close up remaining 1/2" opening from

inside of cover with close-up plug provided. Tighten securely with screwdriver.

Tighten clamping screw to insure water tightness.

SLNP-FR

SLNP-HA

SLNP-B

SELECTOR SWITCH COVERS

PILOT LIGHT AND

EDSK-1JSS

EDSK-1JSS-A

ESKB-3JPB

One 3/4" tapped hole on top

Two 1/2" tapped holes on bottom

HAND

FWD

RUN

1

OFF

OFF

OFF

OFF

AUTO

JOG

REV

2

SLNP102

SLNP-FOR

SLNP-HOA

SLNP-ROJ

SLNP-SS

SLNP-OO

SLNP-UD

HAND - OFF -AUTO

STOP

JOG

Ð

RUN

OFF

Ð

START

RUN

Ð

SLNP-JOR

SLNP-SRS

SLNP-B3

SLNP-AO

SLNP-AH

SLNP-OR

SLNP-RJ

LOCAL

HAND

AUTO

REV

OFF

OFF

OFF

OFF

HAND

FWD

REM

REM

SLNP-LOR

SLNP-HOR

SLNP-ROF

SLNP-AOH

5

SHAFT BUSHING

ASSEMBLY

6

HOUSING

SCREWS (4)

B

OPERATOR COLLAR AND GASKET

ASSEMBLY HOUSING

OPERATOR

HOUSING

501581-001 Rev. P 03/27/17 • Page 3 of 4

Page 4

PILOT LIGHTS

Nominal Volts

50/60 Hertz

Pilot Light Transformer

Source

Nominal 120V

Primary

Voltage

Source

Nominal 220, 440, 550V

SELECTOR SWITCHES

Left Center

Style Position Position Position

2 Position None

2 Circuit

2 Position None

4 Circuit

Voltages above 125 volts

Nominal Volts Primary

50/60 Hertz Voltage

Transformer Range

220-110 220-240

440-110 440-480

550-110 550-600

Right

PUSHBUTTON STATIONS

Momentary Maintained

1 Circuit 2 Cir

Universal Universal Universal

Always disconnect primary power source before

opening the enclosure for inspection or service.

cuit 1 Circuit

EDS snap switch (toggle)

sealing well with wiring

diagram.

Pilot lights and sealing wells

are furnished with pigtail

leads for eld connection by

use of wire nuts.

WARNING

3 Position

2 Circuit

3 Position

4 Circuit

Pushbutton Stations and Selector Switches Screw Terminals

NC= Normally Closed

NO

NC

NO= Normally Open

Factory Sealed Pushbutton

Switch is supplied with optional

NC

NO

Crimp-Type Terminal

Strip the insulation on each conductor wire back 3/8".

Use a slotted head screwdriver to loosen the eld wiring

terminal screws the required 3 or 4 turns.

Insert the bare wire conductor(s) on either side of the terminal

screw(s), under the terminal wire screw(s), and securely tighten

the screw(s). NOTE: Do Not exceed 15 in– lbs of torque.

C

D

B

Single Gang

3.72

5.88

1.31

5.31

.34 DIA.

2 Places

Two Gang

2.63

5.31

1. Frequent inspection should be made. A schedule

for maintenance checks should be detrmined by the

environment and frquency of use. It is recommended

that inspection should occur at least once a year.

2. Perform visual, electrical and mechanical checks on

all components on a regular base.

3. Visually check for undue heating evidenced by

discoloration of wires or other components, damaged

or worn parts or leakage evidenced by water or

corrosion in the interior.

4. Electrical check to make sure that all connections are

clean and tight, and that contacts in the components

make or break as required.

5. Mechanically check that all parts are properly

assembled, and that operating mechanisms

move freely.

5.88

Three Device

1.31

7.47

3.72

8.13

2-G Tandem

1.31

10.53

3.72

11.16

A

Hub Single Gang Two Gang Three Device 2-G Tandem

(in.) Dim. A Dim. B Dim. C Dim. D Dim. A Dim. B Dim. C Dim. D Dim. A Dim. B Dim. C Dim. D Dim. A Dim. B Dim. C Dim. D

1/2 .75 6.81 3.06 2.69 .88 6.81 3.06 2.69 1.00 9.19 3.06 2.69 .88 12.09 3.31 2.88

3/4 .88 6.81 3.06 2.69 .88 6.81 3.06 2.69 1.00 9.19 3.06 2.69 .88 12.09 3.31 2.88

1 1.00 7.03 3.06 2.69 1.00 7.03 3.06 2.69 1.00 9.19 3.06 2.69 1.00 12.31 3.31 2.88

Except as expressly provided by Appleton Grp, LLC (Appleton), Appleton products are intended for ultimate purchase by industrial users and for operation by persons trained and experienced in the use and maintenance of this equipment

and not for consumers or consumer use. Appleton warranties DO NOT extend to, and no reseller is authorized to extend Appleton’s warranties to any consumer.

While every precaution has been taken to ensure accuracy and completeness in this manual, Appleton Grp, LLC. assumes no responsibility, and disclaims all liability for damages resulting from use of this information or for any errors or

omissions. Specications are subject to change without notice. The Appleton and Emerson logos are registered in the U.S. Patent and Trademark Ofce. All other product or service names are the property of their registered owners.

©2017 Appleton Grp, LLC. All rights reserved.

1.31

7.41

1.31

1.31

Loading...

Loading...