Page 1

650398-001

Installation Instructions for Code-Master™ Strob e Lights for Fire

Alarm Hearing Impaired Use In Hazardous Locations

Description

The Code-Master™ light is an inrush current

limited strobe light that is UL Listed as a signaling appliance for the hearing impaired and

is intended for indoor use in UL Listed compatible fire alarm systems and other applications requiring electrical supervision of signaling circuit fi eld wiring. The strobe fl ashes a 360degree beam of light approximately 65 times per

minute. The strobe is UL Listed for use in Class

I, Division 1, Group C and D; Class I, Division 2,

Group A, B, C and D; Class II, Division 1, Group

E, F, and G; Class II, Division 2, Group F and G;

and Class III Division 1 and 2 hazardous locations with Operating Temperature Codes per

the following chart.

Temperature Codes

Ambient Class I, Div. 2 Class I, Div. 1 Class II, Div. 1

Temp. Groups A, B, C & D Groups C & D Class III, Div. 1 & 2

40ºC 260ºC (T2B) 85ºC (T6) 120ºC (T4A)

55ºC 260ºC (T2B) 85ºC (T6) 120ºC ( T4A)

65ºC 280ºC (T2A) 85ºC (T6) 135ºC (T4)

These devices are also UL 1971 Listed for

visual signaling use for the hearing impaired

with a 75 cd light output per Table 3.

Installation

!

To reduce the risk of ignition of hazardous

atmospheres and shock, do not apply power

to the unit until installation has been completed and unit is tightly assembled and secured.

Install this unit in accordance with the applicable

requirements in the latest edition of the National

Electr

ical Code.

NOTE: This unit must be mounted vertically

with the globe assembly vertically facing down

in Hearing Impaired Applications.

WARNING

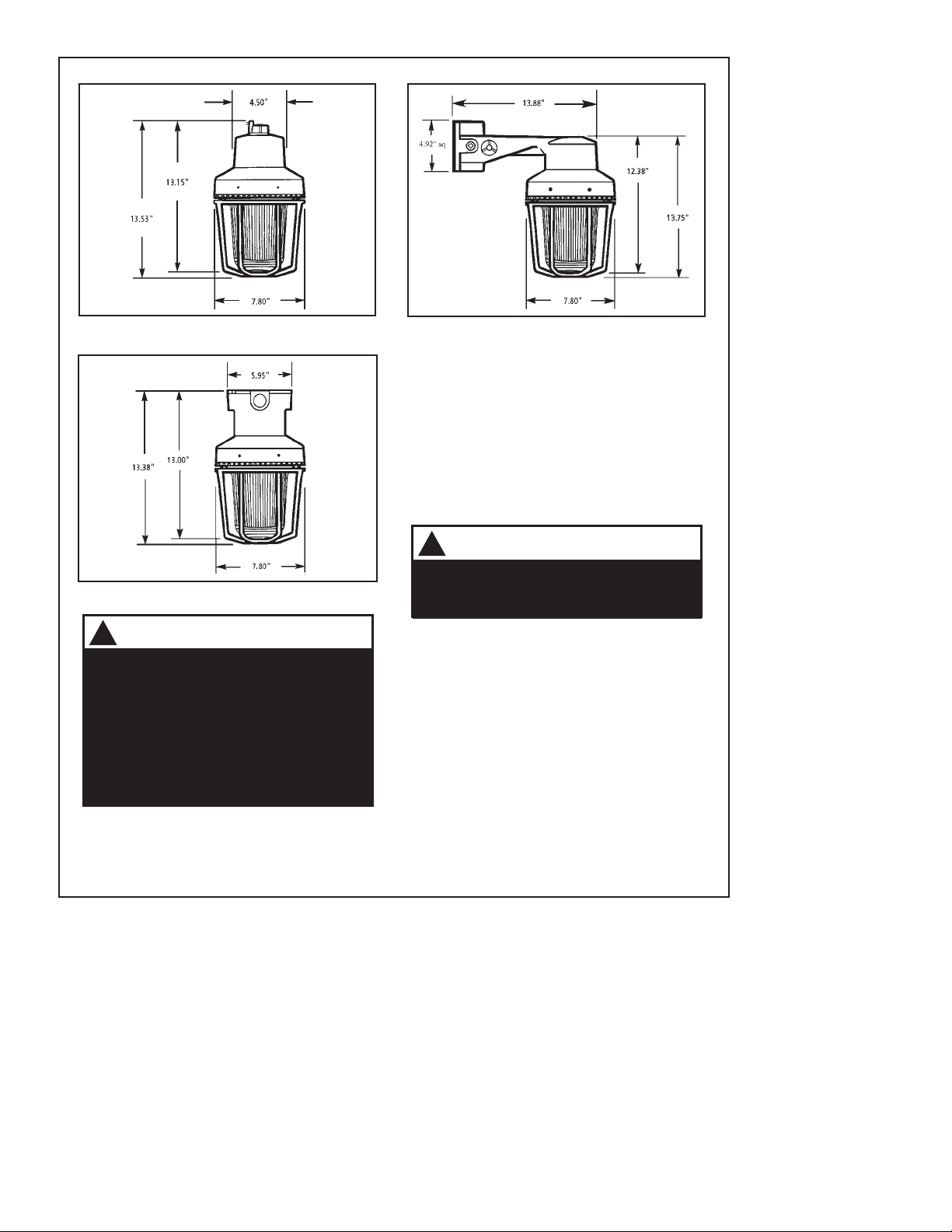

1. Mount using the f

a. Pendant Mounting (Figures 1 and 4): Install

explosion-proof hanger box (not supplied).

Secure 3/4” (19 mm) NPT threaded conduit

(not supplied) to the box. Install the mounting

assembly, catalog number CAP75, on the

conduit. Proceed to step 2.

b. Ceiling Mounting (Figures 2 and 4): Mount

the ceiling box, catalog number CAC75, using

appropriate hardware (not supplied) suitable

for the mounting surface. Proceed to step 2.

c. Bracket Mounting (Figures 3 and 4): Install

the mounting bracket, catalog number CALB75.

using appropriate hardware (not supplied) for the

mounting surface. Pull the fi eld wiring through

the mounting bracket. Proceed to step 2.

2. Extend the required power source wiring

down through the mounting assembly. See Table

4 for required supply wire temperature ratings.

3. Refer to Figure 4. Loosen the (2) screws

holding the circuit block in place. Rotate and

remove the circuit block.

4. A ground screw is provided in the wiring

compartment for attachment of field earth

ground wire.

5. Connect the two red positive (+) and two black

negative (-) wire leads to the supervised circuit

in accordance with Figure 4.

6. Install the fi xture on the mounting assembly.

!

To reduce the risk of ignition of hazardous

atmospheres and shock, keep assembly

tightly closed when circuits are energized.

7. Apply power to the unit and ensure proper

function.

ollowing applicable method.

WARNING

Rev. B 650398-001 03/29/05 Page 1

Page 2

Figure 1. Detail of Pendant mounting.

Figure 3. Detail of Bracket Mounting.

Maintenance

1. Loosen the (3) guard screws and remove the

guard.

2. Loosen the globe and ring assembly set

screw. Insert a suitable tool into the notches

in the globe and ring assembly and loosen the

assembly by prying in a counterclockwise direction. Remove the ring and globe assembly.

Figure 2. Detail of Ceiling Mounting.

!

To reduce the risk of ignition of hazardous

atmospheres and shock, keep assembly

tightly closed when circuits are energized.

To reduce the risk of ignition of hazardous

atmospheres and shock, disconnect from the

supply and circuit and allow fi ve (5) minutes

for stored energy to dissipate before disassembling the unit.

For strobe tube replacement, disconnect from

the supply circuit and allow fi ve minutes for

stored energy to dissipate before starting work

or disassembly.

Page 2 Rev. B 650398-001 03/29/05

WARNING

!

When replacing the strobe tube, do not handle

the tube. Hold the strobe tube only by its base

to prevent damage to the tube.

3. Refer to Table 2 for the correct replacement

catalog number and replace the necessary

part.

4. To replace, simply screw the unit on until it

seats fi rmly onto its gasket. Tighten the unit

another 1/8 to 1/4 turn. Tighten the setscrew.

5. Reinstall the guard, where applicable, and

secure using the three supplied screws.

6. After the unit is assembled, apply power and

make sure the unit functions properly.

WARNING

Page 3

Table 1. Code-Master™ Strobe Light Specifi cations

Cat. No. Method Voltage after Init. surge) after init. surge) (Initial) Size Rated Output

Mounting (Continuous RMS, (outgoing Surge* conduit Flash Rated Light

CSST2030PDCCL Pendant 20V DC 1.08A 3A 10A for 0.7 ms 3/4Ó 360º beam 75cd

and CAP75 Figure 1 24V DC 0.95A 2.8A 12A for 0.7 ms NPT of light at per

CSST2030PDCCL Ceiling 30V DC 0.83A 2.6A 15A for 0.7 ms -65 fpm Table 3

and CAC75 Figure 2

CSST2030PDCCL Bracket

and CALB75 Figure 3

Operating Current* Park Current*

*Use the operating current to establish the wire gauge and standby power requirements. Consult the control unit

manufacturer to determine surge and peak current effects and maximum number of strobes on the system.

Table 2.

Code-Master™ Strobe Light

Replacement Parts

Mounting Replacement

Cat. No. Method Strobe

CSST2030PDCCL Pendant Cat. No.

and CAP75 Figure 1 S865

CSST2030PDCCL Ceiling

and CAC75 Figure 2

CSST2030PDCCL Bracket

and CALB5 Figure 3

Table 4

Supply Wire Temperature Markings

Ambient Supply Wire

Temperature Temperature Marking

40ºC 75ºC

55ºC 85ºC

65ºC 110ºC

Table 3.

Light output dispersion when mounted

with the assembly vertically facing down.

Percent

Degrees* of 75 cd Rating

0, Pointing Down 100

5 - 25 90

30 - 45 75

50 55

55 45

60 40

65 35

70 35

75 30

80 30

85 25

90 25

*Tolerance of ±degree is permitted.

Rev. B 650398-001 03/29/05 Page 3

Page 4

Figure 4. Wiring Diagram

NOTE: DC POLARITY OF CIRCUIT SHOWN IN SUPERVISORY STATE (SIGNAL IN ACTIVE). CIRCUIT POLARITY TO REVERSE TO ACTIVATE

SIGNAL. ELECTRICAL SUPERVISION REQUIRES WIRE TO BE BROKEN AT EACH DEVISE.

DEVICE FOR CONSTANT INPUT VOLTAGE. DO NOT CONNECT TO ÒCODEDÓ OR PULSATING VOLTAGE.

FROM

POWER SOURCE

OR PREVIOUS

SIGNALING

DEVICE

CODE-MASTER

STROBE

CODE-MASTER

STROBE

KEY

LIGHT SYMBOL

WIRE NUT SYMBOL

END OF LINE

RESISTOR, WHEN

REQUIRED WITH

SUPERVISED

SYSTEM

NOTE: For non-fi re alarm stand-alone use tie the two red leads together and tie the two black leads together

Figure 5. Operating Current vs. Operating Input Voltage Range.

CURRENT VS. VOLTAGE

20

15

12

10

10

5

0

20Vdc

3.0

1.6

INPUT VOLTAGE

2.8

1.4

Figure 6. Disassembly of the Code-Masterª Strobe.

MOUNTING

HOOD

STROBE

TUBE

GLOBE & RING

ASSEMBLY

GUARD

(OPTIONAL)

15

Serge

Peak

Operating

2.6

1.1

30Vdc24Vdc

Page 4 Rev. B 650398-001 03/29/05

Loading...

Loading...