Page 1

Code•Master™ PLT Factory Sealed Luminaires

FLUORESCENT/AREA: NEC/CEC EXPLOSIONPROOF

© May 2019

Explosionproof, Dust-Ignitionproof

Integrally Ballasted. 26 W, 32 W, 42 W, 52 W, 64 W, 84 W Compact Fluorescent. For use with Threaded Metal Conduit.

NEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 4X

Suitable for use in wet locations

CEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

CSA 4X

Applications

• For use in hazardous locations such as plants where plastics,

paints, thinners and petrochemicals are manufactured, and in

other areas where ignitable vapors, dust, moisture and corrosive

elements may be present.

• For use in areas where an instant-on white light is desired.

• Suitable for use in wet locations.

• Standard xtures designed for 26 W, 32 W, 42 W, 52 W (two 26

W), 64 W (two 32 W), and 84 W (two 42 W) PLT lamps.

• Cold weather starting to a minimum temperature of -18 °C

(0 °F) for the Code•Master Jr. PLT and -30 °C (-22 °F) for the

Code•Master 2 PLT.

Features

• Fixtures operate safely in high ambient temperatures.

• Arrangement of heat-producing components results in efcient

heat dissipation for cooler xture operation.

• Patented “wireless” design. Threading of xture unit onto

mounting hood makes electrical connection. The only

wiring required is attaching two wires to connection block

in mounting hood.

• Connection block is easily wired: (a) loosen two screws; (b)

make wire connections; and (c) reposition connection block.

• Safe, easy servicing without disconnecting any wiring.

“Wireless” xture unit threads off mounting hood for convenient

servicing or for immediate replacement with a “stand-by” unit.

• Acme double-lead threads speed installation and xture removal

from mounting hood – only half as many turns are required

as for single-lead threads. The threads do not stick, or gall,

eliminating problems often encountered with single-lead threads

during xture unit removal.

• All threaded joints are ame-tight.

• Factory sealed. External seals not required for Groups C and D.

• Fixtures for use in Group B locations are furnished complete

with UL required sealing tting for Code•Master Jr. PLT only.

• Heat- and impact-resistant globes have smooth

dust-resistant exterior.

• Superior corrosion resistance, with epoxy powder coat nish.

• Fluorescent light source reduces energy cost.

• Strategic location of lamp socket, in combination with interior

prism design of the glass globe, provides optimum light

distribution and control.

• Choice of mountings – pendant, ceiling, bracket and stanchion.

• Optional guards protect globes from damage. Secured to xture

with three stainless steel screws.

• Fiberglass reinforced polyester reectors, in standard dome

or 30° angle styles, are ideal in installations where luminaire is

subject to exceptionally severe corrosive atmospheres. The

high bay aluminum reector is intended for installations where

mounting height work planes range from 6 to 9 m (20 to 30 ft).

• Fluorescent lamp life of 10,000 hours reduces relamping cost

compared to incandescent, and provides superior T numbers.

Standard Materials

• Ballast bodies and guards: copperfree (4/10 of 1% max.)

aluminum

• Pendant mounting hoods: diecast copperfree (4/10 of 1% max.)

aluminum

• Ceiling, bracket and stanchion mounting hoods: sand cast

copperfree (4/10 of 1% max.) aluminum

• Reectors: berglass reinforced polyester (white) or aluminum

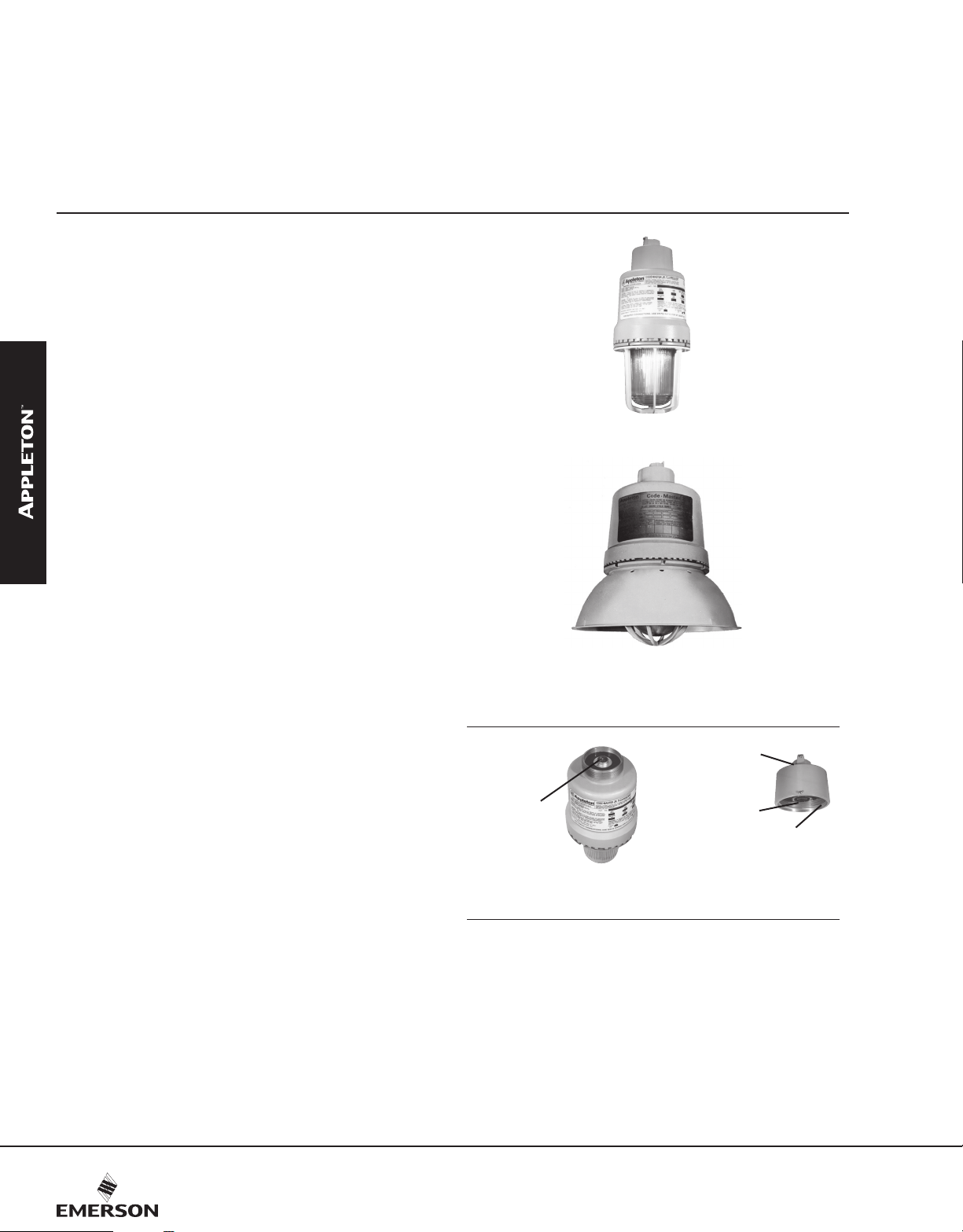

26-42W

Code•Master Jr. PLT

52-84W

Code•Master 2 PLT

Illustrated Features

Mounting Hood

Collector Ring

and Pin

As Fixture unit is threaded into mounting

hood an automatic electrical connection is made.

Connection Block

Double Lead

Acme Threads

Standard Finishes

• Ballast bodies, guards and mounting hoods: epoxy powder

coat nish, electrostatically applied for complete, uniform

corrosion protection

NEC/CEC Certifications and Compliances

• UL Standard: UL 1598, UL 844

• UL Listed: E10444

• CSA Standard: C22.2 No. 250, C22.2 No. 137

• CSA Certied: 025428

Fixtures are for use with Group B atmospheres only when used with Group B mounting hoods. For 26 W,32 W, and 42 W fixtures only.

496

Page 2

Code•Master™ PLT Factory Sealed Luminaires

FLUORESCENT/AREA: NEC/CEC EXPLOSIONPROOF

© May 2019

Explosionproof, Dust-Ignitionproof

Integrally Ballasted. 26 W, 32 W, 42 W, 52 W, 64 W, 84 W Compact Fluorescent. For use with Threaded Metal Conduit.

NEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 4X

Suitable for use in wet locations

CEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

CSA 4X

Catalog Numbering Guide

CJ F P 26 75 G BU L

Series:

CJ - Code•Master

Jr.

◆

C - Code•Master 2

P - Pendant

C - Ceiling

B - Bracket

S - Stanchion

PB - Group B Pendant

SB - Group B Stanchion

Lamp Type:

F - Fluorescent

Mouning:

◆

◆

Wattage:

26 - 26 Watts

32 - 32 Watts

Hub Size:

75 - 3/4”

10 - 1”

150 - 1-1/2” or 1-1/4”

G - Guard provided

Blank - Guard not provided

BU - 120-277 V 50/60 Hz

A5 - 347 V 60 Hz

Guard:

42 - 42 Watts

52 - 52 Watts

64 - 64 Watts

84 - 84 Watts

Classified Area Suitability of Code•Master™ Series PLT Fixtures — Suitability includes use of reflector

Class I, Division 1 and 2 with Globe or

Class II, Division 1 and 2 with Globe or

with Globe and Reflector

UL/NEC Temp. Ident. No.

Lamp

Type

PLT

(4-pin)

PLT

(4-pin)

PLT

(4-pin)

PLT

(4-pin)

PLT

(4-pin)

PLT

(4-pin)

Lamp

Watts

Supply

Wire

°C (°F)

26 75 (167) 40 (104) T6

32 75 (167) 40 (104) T6

42 75 (167) 40 (104) T6

52

(2 x 26)

64

(2 x 32)

84

(2 x 42)

75 (167) 40 (104) T6 C, D T4 E, F, G

75 (167) 55 (131) T5 C, D — —

75 (167) 65 (149) T5 C, D — —

75 (167) 40 (104) T6 C, D T4 E, F, G

75 (167) 55 (131) T5 C, D — —

75 (167) 65 (149) T5 C, D — —

75 (167) 40 (104) T6 C, D T4 E, F, G

75 (167) 55 (131) T5 C, D — —

75 (167) 65 (149) T5 C, D — —

Ambient

Temp

°C (°F)

Nameplate

Marking

Groups

B◆,C,D

B◆,C,D

B◆,C,D

Nameplate

Marking

Voltage:

Options:

L - Lamps Provided

F - Fused

Z - Zone 1

Exd IIB + H2

with Globe and Reflector

UL/NEC Temp. Ident. No.

Groups

T4A E, F, G

T4A E, F, G

T4A E, F, G

“T” Numbers Represent the Maximum Surface Temperature for Class I, Division 1 Locations and

Maximum Surface Temperature Under Dust Blanket for Class II, Division 1 Locations.

“T”

Number

Temp.

Range

(°˚C)

Temp

Range

(°F)

Fixtures are for use with Group B atmospheres only when used with Group B mounting hoods. For 26 W,32 W, and 42 W fixtures only.

Available only for 52, 64 and 84 watt fixtures.

Available in Codemmaster 2 Only

Certified to meet the Canadian Electrical Code (CEC) only.

T1 350 325 T2 T2A T2B T2C T2D T3 T3A T3B T3C T4 T4A T5 T6

351-

326-

301-

281-

261-

231-

216-

201-

181-

166-

161-

136-

450

664-

842

350

619-

662

325

574-

617

300

538-

572

280

502-

536

260

448-

500

230

215

200

180

165

421-

394-

358-

331-

446

419

392

356

322-

329

160

277-

320

121-

135

250-

275

101-

120

214-

248

86-100 85

187-

212

185

497

Page 3

Code•Master™ PLT Factory Sealed Luminaires

FLUORESCENT/AREA: NEC/CEC EXPLOSIONPROOF

© May 2019

Explosionproof, Dust-Ignitionproof

Integrally Ballasted. 26 W, 32 W, 42 W, 52 W, 64 W, 84 W Compact Fluorescent. For use with Threaded Metal Conduit.

NEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 4X

Suitable for use in wet locations

Pendant — One Hub, Rigid or Flexible Mounting

25° Stanchion One Hub

Mounting Hoods

Pendant — One Hub

Lamp

Watts

26 3/4 CJFPB2675BU

32 3/4 CJFPB3275BU

42 3/4 CJFPB4275BU

26 1-1/2 CJFSB26150BU

32 1-1/2 CJFSB32150BU

42 1-1/2 CJFSB42150BU

Hub Size

(Inches)

Hub Size

Inches

Catalog Number

with Globe

Catalog

Number

3/4 CAP-75B

25° Stanchion — One Hub

1-1/2 CAS-150B

NOTE: Fixture units are the same as listed on following pages.

Fixtures are for use with Group B atmospheres only when used with Group B mounting hoods. For 26 W,32 W, and 42 W fixtures only.

To order fixture with lamp(s), add suffix -L after voltage suffix.

Malleable iron sealing fittings are available in the Fittings Section.

498

Page 4

Code•Master™ PLT Factory Sealed Luminaires

FLUORESCENT/AREA: NEC/CEC EXPLOSIONPROOF

© May 2019

Explosionproof, Dust-Ignitionproof

Integrally Ballasted. 26 W, 32 W, 42 W, 52 W, 64 W, 84 W Compact Fluorescent. For use with Threaded Metal Conduit.

NEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 4X

Suitable for use in wet locations

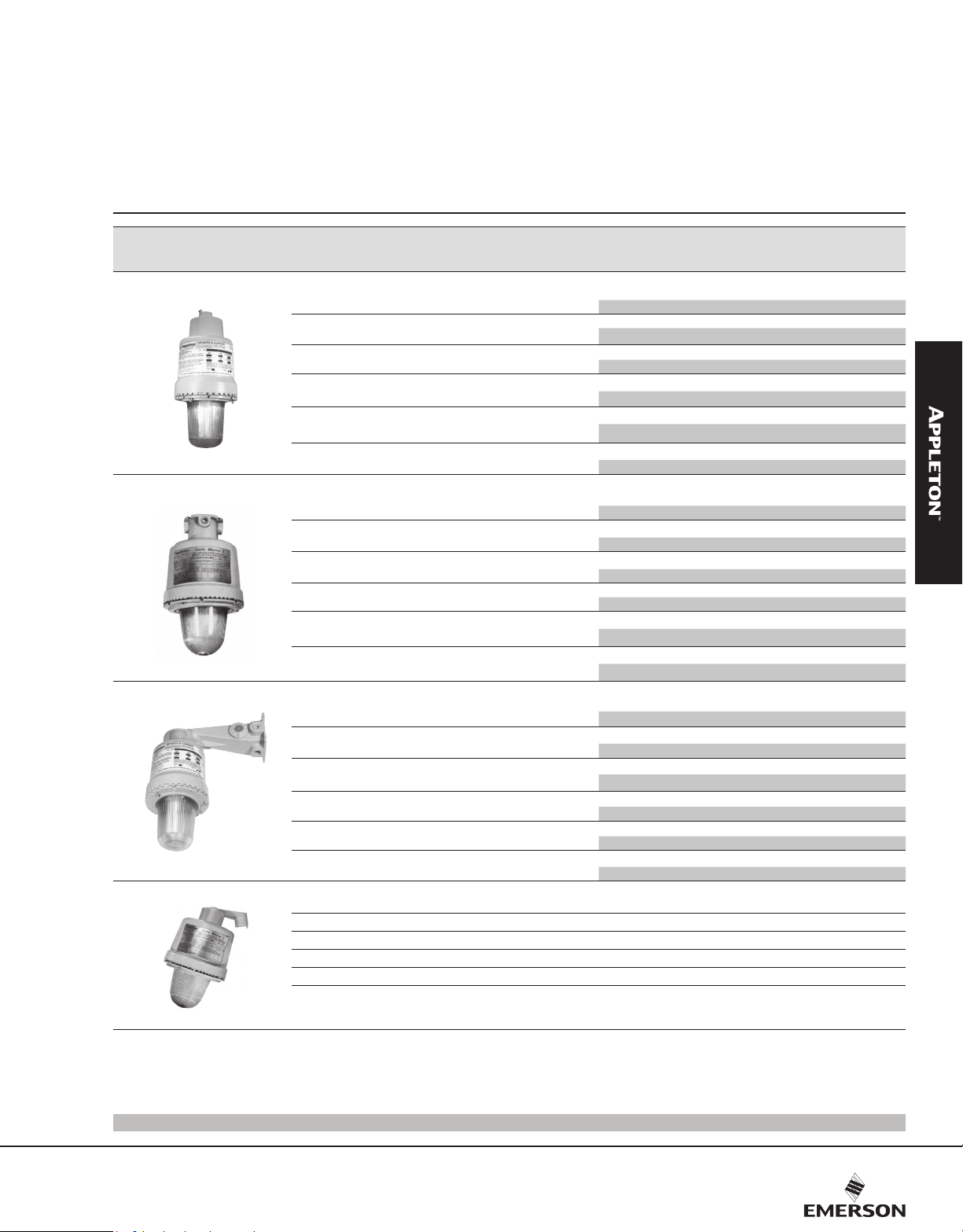

Lamp

Pendant — One Hub, Rigid or Flexible Mounting

26-42 W Shown

Ceiling — Four Hubs, Three Close-Up Plugs

52-84 W Shown

Bracket — Four Hubs, Three Close-Up Plugs

26-42 W Shown

25° Stanchion — One Hub

Watts

26 (1 x 26)

32 (1 x 32)

42 (1 x 42)

52 (2 x 26)

64 (2 x 32)

84 (2 x 42)

26 (1 x 26)

32 (1 x 32)

42 (1 x 42)

52 (2 x 26)

64 (2 x 32)

84 (2 x 42)

26 (1 x 26)

32 (1 x 32)

42 (1 x 42)

52 (2 x 26)

64 (2 x 32)

84 (2 x 42)

26 (1 x 26)

32 (1 x 32)

42 (1 x 42)

52 (2 x 26)

64 (2 x 32)

84 (2 x 42)

CEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

CSA 4X

Hub Size

(Inches)

3/4 CJFP2675BU CJFP2675A5

1 CJFP2610BU CJFP2610A5

3/4 CJFP3275BU CJFP3275A5

1 CJFP3210BU CJFP3210A5

3/4 CJFP4275BU CJFP4275A5

1 CJFP4210BU CJFP4210A5

3/4 CFP5275BU CFP5275A5

1 CFP5210BU CFP5210A5

3/4 CFP6475BU CFP6475A5

1 CFP6410BU CFP6410A5

3/4 CFP8475BU CFP8475A5

1 CFP8410BU CFP8410A5

3/4 CJFC2675BU CJFC2675A5

1 CJFC2610BU CJFC2610A5

3/4 CJFC3275BU CJFC3275A5

1 CJFC3210BU CJFC3210A5

3/4 CJFC4275BU CJFC4275A5

1 CJFC4210BU CJFC4210A5

3/4 CFC5275BU CFC5275A5

1 CFC5210BU CFC5210A5

3/4 CFC6475BU CFC6475A5

1 CFC6410BU CFC6410A5

3/4 CFC8475BU CFC8475A5

1 CFC8410BU CFC8410A5

3/4 CJFB2675BU CJFB2675A5

1 CJFB2610BU CJFB2610A5

3/4 CJFB3275BU CJFB3275A5

1 CJFB3210BU CJFB3210A5

3/4 CJFB4275BU CJFB4275A5

1 CJFB4210BU CJFB4210A5

3/4 CFB5275BU CFB5275A5

1 CFB5210BU CFB5210A5

3/4 CFB6475BU CFB6475A5

1 CFB6410BU CFB6410A5

3/4 CFB8475BU CFB8475A5

1 CFB8410BU CFB8410A5

1-1/4 or 1-1/2

1-1/4 or 1-1/2

1-1/4 or 1-1/2

1-1/4 or 1-1/2

1-1/4 or 1-1/2

1-1/4 or 1-1/2

NEC

Catalog Number

with Globe

CJFS26150BU CJFS26150A5

CJFS32150BU CJFS32150A5

CJFS42150BU CJFS42150A5

CFS52150BU CFS52150A5

CFS64150BU CFS64150A5

CFS84150BU CFS84150A5

CEC

Catalog Number

with Globe

52-84 W Shown

Fixtures are for use with Group B atmospheres only when used with Group B mounting hoods. For 26 W,32 W, and 42 W fixtures only.

To order fixture with guard, add suffix -G before adding voltage suffix. To order fixture with lamp(s), add suffix -L after voltage suffix.

1-1/2” tapped hub furnished with 1-1/2” to 1-1/4” reducer.

BU is 120 through 277 V, 50/60 Hz and 125 Vdc. A5 is 347 V, 60 Hz.

Shaded items are suitable for Class I, Group D ONLY.

499

Page 5

Code•Master™ PLT Factory Sealed Luminaires

FLUORESCENT/AREA: NEC/CEC EXPLOSIONPROOF

© May 2019

Explosionproof, Dust-Ignitionproof

Integrally Ballasted. 26 W, 32 W, 42 W, 52 W, 64 W, 84 W Compact Fluorescent. For use with Threaded Metal Conduit.

NEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 4X

Suitable for use in wet locations

Mounting Hoods

Pendant

Ceiling

Bracket

25° Stanchion

CEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

CSA 4X

Hub Size

(Inches)

3/4 CAP-75

1 CAP-100

3/4 CAC-75

1 CAC-100

3/4 CALB-75

1 CALB-100

1-1/4 or 1-1/2 CAS-150

Catalog

Number

Mounting Adapter with Connection Block

Fixture Units

Line

Voltage

Ballast body with globe

120-277 50/60

120-277 50/60

120-277 50/60

120-277 50/60 CMBF52BU

26-42 W

Electrical Specification

Lamp Wattage Line Voltage Frequency (Hz) Line Amps Input Watts Min. Starting Temp

26 (1 x 26) 120-277 50/60 0.25-0.11 28 -18 °C (0 °F)

32 (1 x 32) 120-277 50/60 0.27-0.12 36 -18 °C (0 °F)

42 (1 x 42) 120-277 50/60 0.35-0.16 48 -18 °C (0 °F)

52 (2 x 26) 120-277 50/60 0.49-0.20 55 -30 °C (-22 °F)

64 (2 x 32) 120-277 50/60 0.57-0.24 67 -30 °C (-22 °F)

84 (2 x 42) 120-277 50/60 0.73-0.31 87 -30 °C (-22 °F)

Fixtures are for use with Group B atmospheres only when used with Group B mounting hoods. For 26 W,32 W, and 42 W fixtures only.

1-1/2” tapped hub furnished with 1-1/2” to 1-1/4” reducer.

Denotes items that are suitable for Class I, Group B in addition to Class I, Groups C and D; and Class II, Groups E, F and G.

Shaded items are suitable for Class I, Group C in addition to Class I, Group D; Class II, Groups E, F and G; and Class III.

52-84 W

120-277 50/60 CMBF64BU

120-277 50/60 CMBF84BU

Hz

CMAD-1

Catalog

Number

CJB26FBU

CJB32FBU

CJB42FBU

500

Page 6

Code•Master™ PLT Factory Sealed Luminaires

FLUORESCENT/AREA: NEC/CEC EXPLOSIONPROOF

© May 2019

Explosionproof, Dust-Ignitionproof

Integrally Ballasted. 26 W, 32 W, 42 W, 52 W, 64 W, 84 W Compact Fluorescent. For use with Threaded Metal Conduit.

NEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 4X

Suitable for use in wet locations

White Polyester Reectors

Standard Dome 30° Angle Dome

Aluminum Reectors

Prismatic Glass Globe and Ring Assembly

CEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

CSA 4X

Description

For Globe Fixtures Standard Dome 26, 32, 42 W KR2-ST

30°Angle 26, 32, 42 W KR2-AN

Standard Dome 52, 64, 84 W CMR-4ST

30°Angle 52, 64, 84 W CMR-4AN

Deep Dome 52, 64, 84 W CMR-4DD

High Bay 52, 64, 84 W CMR-4HB

26, 32, 42 W CJGL-175

52, 64, 84 W CGL-400

Catalog

Number

CJGL-175

Aluminum Guards

CJGU-15

Three-Way Exit Sign

Single Sided Exit Sign

CGL-400

CGU-4

26, 32, 42 W CJGU-15

52, 64, 84 W CGU4

Epoxy enameled steel — 6”-high red lettering

Mounts to xture units in place of guard.

26, 32, 42 W CJEXRN

52, 64, 84 W EXR400

Epoxy enameled steel — 6”-high red lettering

Mounts to xture units in place of guard.

Contact your sales representative regarding hazardous location suitability.

26, 32, 42 W AEXR-15R

Fixtures when used with Deep Dome Refletors are NOT UL Listed.

Fixtures are for use with Group B atmospheres only when used with Group B mounting hoods. For 26 W,32 W, and 42 W fixtures only.

501

Page 7

Code•Master™ PLT Factory Sealed Luminaires

FLUORESCENT/AREA: NEC/CEC EXPLOSIONPROOF

© May 2019

Explosionproof, Dust-Ignitionproof

Integrally Ballasted. 26 W, 32 W, 42 W, 52 W, 64 W, 84 W Compact Fluorescent. For use with Threaded Metal Conduit.

NEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 4X

Suitable for use in wet locations

CEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

CSA 4X

Description Catalog Number

Replacement Parts – 26 W, 32 W, 42 W, 52 W, 64 W and 84 W

Socket (lampholder) G24Q-4 26 thru 84 W PLT32RS

PLT32RS CJSA42

Single Socket Bracket Assembly 26, 32, 42 W CJSA42

Double Socket Bracket Assembly 52, 64, 84 W CSA84

CSA84

Lamps

1 lamp = 26 W; 2 lamps = 52 W 26 W PLT26

1 lamp = 32 W; 2 lamps = 64 W 32 W PLT32

1 lamp = 42 W; 2 lamps = 84 W 42 W PLT42

Connection Block

For all Code•Master xtures VPT-7

Fixture and Accessory Weights kg (lb) Mounting Hood Weights kg (lb)

Fixture Size Fixture Weight Reflector Weight Guard Weight Pendant Ceiling Bracket Stanchion

26 W, 32 W, 42 W 6.6 (14.55) 1.4 (3.09) 0.5 (1.10) 0.9 (1.98) 1.8 (3.97) 2.7 (5.95) 0.9 (1.98)

52 W, 64 W, 84 W 15.9 (35.05) 1.4 (3.09) 1.1 (2.43)

Reflector Dimensions

Catalog

Number

Dimensions in mm (in)

Standard and

Deep Dome

30° AngleDescription A B C D

Standard Dome

KR2-ST 26, 32, 42 W 203.2 (8.00) 152.4 (6.00) 429.3 (16.90) —

CMR-4ST 52, 64, 84 W 284.5 (11.20) 149.9 (5.90) 475.0 (18.70) —

Deep Dome

A

B

CMR-4DD 52, 64, 84 W 268.2 (10.56) 177.8 (7.00) 515.6 (20.30) —

30° Angle

KR2-AN 26, 32, 42 W 203.2 (8.00) 69.9 (2.75) 378.5 (14.90) 258.3 (10.17)

CMR-4AN 52, 64, 84 W 268.2 (10.56) 127 (5.00) 410.5 (16.16) 247.7 (9.75)

B

C

C

A

D

Fixtures when used with Deep Dome Refletors are NOT UL Listed.

Fixtures are for use with Group B atmospheres only when used with Group B mounting hoods. For 26 W,32 W, and 42 W fixtures only.

502

Page 8

Code•Master™ PLT Factory Sealed Luminaires

FLUORESCENT/AREA: NEC/CEC EXPLOSIONPROOF

© May 2019

Explosionproof, Dust-Ignitionproof

Integrally Ballasted. 26 W, 32 W, 42 W, 52 W, 64 W, 84 W Compact Fluorescent. For use with Threaded Metal Conduit.

NEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 4X

Suitable for use in wet locations

Dimensions in Millimeters (Inches)

Mounting Hoods

Pendant Ceiling Bracket 25° Stanchion

99.3 (3.91)

250.4

304.8

(12.00)

(9.86)

447.3

(17.61)

546.1

(21.50)

520.7

(20.50)

26, 32, 42 W Fixture

116.3

(4.58) Dia.

203.2

(8.00)

95.3 (3.75)437.9

188.0

(7.40)

358.6

(14.12)

(17.22)

(17.87)

453.9

52, 64, 84 W Fixture

460.2

(18.12)

CEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

CSA 4X

101.6

(4.00)

443.7

(17.47)

203.2

(8.00)

101.6

(4.00)

150.4

(5.92)

23.9

(0.94)

114.3

(4.50)

188.0

358.6

(14.12)

101.6

(4.00)

(7.40)

125.0 (4.92) Sq.

(3.92)

99.6

188.0

(7.40)

62.9

(2.46)

(1.23)

31.2

(3.48)

88.4

406.4

(16.00)

57.9

(2.28)

292.1

(11.5)

349.3

(13.75)

396.7

(15.62)

412.8

45.7

(1.79)

(16.25)

108.0

(4.25)

60.5

(2.38) Dia.

412.28

(16.25)

241.3

(9.50)

155.0

(6.10)

114.3

(4.50) Dia.

406.4

428.8

(16.00)

(16.88)

(23.36)

(24.36)

618.7

593.3

304.8

(12.0)

(9.86)

250.4

517.1

(20.36)

250.4

(9.86)

139.7

(5.5)

444.5

(17.5)

599.7

(23.61)

625.1

(24.61)

517.1

(20.36)

444.5

(17.5)

622.3

(24.5)

596.9

(23.5)

304.8

(12.0)

99.3

(3.91)

250.4

517.1

(20.36)

(9.86)

Exit Signs

174.8

235.0

(9.25)

(6.88)

298.5 (11.75)

215.9

304.8

(12.00)

(8.50)

CJEXRN AEXR-15R

Fixtures are for use with Group B atmospheres only when used with Group B mounting hoods. For 26 W,32 W, and 42 W fixtures only.

(21.2)

538.5

(22.2)

563.9

503

Page 9

Code•Master™ PLT Factory Sealed Luminaires

FLUORESCENT/AREA: NEC/CEC EXPLOSIONPROOF

© May 2019

Explosionproof, Dust-Ignitionproof

* Photometric data is based on a fixture with a 32 W compact fluorescent PL-T lamp (2,400 lumens). For candlepower values of fixtures with 26 W PL-T lamps (1,800 lumens), multiply by 0.75. For

candlepower values of fixtures with a 42 W PL-T Lamp (3,200 lumens), multiply by 1.34.

NEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 4X

Suitable for use in wet locations

CEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

CSA 4X

Photometric Data

Total Luminaire Efficiency = 92.9%

CIE Type - Semi-Direct

Spacing

Plane

Criteria

0-180 2.76 Coefficients of Utilization - Zonal Cavity Method

90-270 2.76 Effective Floor Cavity Reflectance 0.20

Diagonal 2.72 % Ceiling Rcc 80 70 50 30 10 0

Zone Lumens 0 103 103 103 103 97 97 97 97 85 85 85 74 74 74 65 65 65 60

0-10 9.75 1 88 81 75 70 82 76 70 65 65 61 57 56 53 50 48 45 42 38

10-20 32.89 2 78 67 59 52 72 63 55 49 54 48 43 46 41 37 38 35 31 27

20-30 68.63 3 69 57 48 41 64 53 45 38 46 39 33 39 33 29 32 28 24 20

30-40 119.65 4 63 50 40 33 58 46 37 31 39 32 27 33 28 23 28 23 19 16

40-50 174.44 5 57 43 34 27 52 40 32 25 35 27 22 29 23 19 24 19 16 13

50-60 219.68 6 52 38 29 23 48 36 27 21 31 24 18 26 20 16 21 17 13 10

60-70 252.32 7 48 34 25 19 44 32 24 18 27 21 16 23 18 13 19 15 11 9

70-80 278.38 8 44 31 22 17 41 29 21 16 25 18 14 21 16 11 18 13 9 7

80-90 283.11 9 41 28 20 14 38 26 19 14 23 16 12 19 14 10 16 12 8 6

90-100 266.38 10 38 25 18 13 35 24 17 12 21 15 10 18 12 9 15 10 7 5

100-110 231.16

110-120 166.66 Zonal Lumen Summary

120-130 91.63 Zone Lumens % Lamp % Fixture Zone Lumens % Lamp % Fixture

130-140 31.38 0-30 111.27 4.6 5.0 90-120 664.20 27.7 29.8

140-150 2.95 0-40 230.92 9.6 10.4 90-130 755.83 31.5 33.9

150-160 0.19 0-60 625.05 26.0 28.0 90-150 790.17 32.9 33.9

160-170 0.00 0-90 1438.87 60.0 64.5 90-180 790.36 32.9 35.5

170-180 0.00 0-180 2229.23 92.9 100.0

Total Luminaire Efficiency = 80.7%

CIE Type - Direct

Plane

0-180 1.42 Coefficients of Utilization - Zonal Cavity Method

90-270 1.42

Diagonal 1.60

Zone Lumens

0-10 51.88 1 87 84 80 77 85 82 78 76 78 75 73 75 73 71 72 70 68 67

10-20 151.03 2 79 72 67 62 77 71 66 61 68 63 60 65 61 58 62 59 57 55

20-30 240.04 3 72 63 56 51 70 62 55 50 59 54 49 57 52 48 54 51 47 45

30-40 312.02 4 65 55 48 42 63 54 47 42 52 46 41 50 45 41 48 44 40 38

40-50 361.09 5 60 49 41 36 58 48 41 36 46 40 35 44 39 35 43 38 34 32

50-60 377.88 6 55 44 36 31 53 43 36 31 41 35 30 40 34 30 39 34 30 28

60-70 278.20 7 51 39 32 27 49 39 32 27 37 31 27 36 30 26 35 30 26 24

70-80 119.22 8 47 36 29 24 46 35 28 24 34 28 23 33 27 23 32 27 23 21

80-90 23.81 9 44 33 26 21 43 32 26 21 31 25 21 30 25 21 29 24 21 19

90-100 0.68

100-110 4.48

110-120 6.82

120-130 5.50

130-140 3.07 0-30 442.95 18.5 22.9 90-120 11.98 0.5 0.6

140-150 0.09 0-40 754.97 31.5 39.0 90-130 17.48 0.7 0.9

150-160 0.00 0-60 1493.95 62.2 77.2 90-150 20.63 0.9 0.9

160-170 0.00 0-90 1915.18 79.8 98.9 90-180 20.63 0.9 1.1

170-180 0.00 0-180 1935.81 80.7 100.0

Fixtures are for use with Group B atmospheres only when used with Group B mounting hoods. For 26 W,32 W, and 42 W fixtures only.

Maximum Candela = 265

Located at Horizontal Angle = 0, Vertical Angle = 77.5

#1 - Vertical Plane through Horizontal Angles (0-180)

(Through Max. Cd.)

#2 - Horizontal Cone through Vertical Angle (77.5)

(Through Max. Cd.)

Spacing

Criteria

Maximum Candela = 545

Located at Horizontal Angle = 0, Vertical Angle = 5

#1 - Vertical Plane through Horizontal Angles (0-180)

(Through Max. Cd.)

#2 - Horizontal Cone through Vertical Angle (5)

(Through Max. Cd.)

REPORT NUMBER: CJBF32G

32 W Fluorescent Lamp with Globe only *

% Walls Rw 70 50 30 10 70 50 30 10 50 30 10 50 30 10 50 30 10 0

REPORT NUMBER: CJBF32ST

32 W Fluorescent Lamp with Globe and Standard Dome Reflector *

Effective Floor Cavity Reflectance 0.20

% Ceiling Rcc 80 70 50 30 10 0

% Walls Rw 70 50 30 10 70 50 30 10 50 30 10 50 30 10 50 30 10 0

0 96 96 96 96 93 93 93 93 89 89 89 85 85 85 82 82 82 80

10 41 30 23 19 40 30 23 19 29 23 19 28 23 19 27 22 19 17

Zonal Lumen Summary

Zone Lumens % Lamp % Fixture Zone Lumens % Lamp % Fixture

504

Page 10

Code•Master™ PLT Factory Sealed Luminaires

FLUORESCENT/AREA: NEC/CEC EXPLOSIONPROOF

© May 2019

Explosionproof, Dust-Ignitionproof

* Photometric data is based on a fixture with a 32 W compact fluorescent PL-T lamp (2,400 lumens). For candlepower values of fixtures with 26 W PL-T lamps (1,800 lumens), multiply by 0.75. For

candlepower values of fixtures with a 42 W PL-T Lamp (3,200 lumens), multiply by 1.34. ** Photometric data is based on a fixture with two 32 W Compact Fluorescent PL-T lamps (2,400 lumens each).

For candlepower values of fixtures with two 26 W PL-T lamps (1,800 lumens each), multiply by 0.75. For Candlepower values of fixtures with two 42 W PL-T Lamps. (3,200 lumens each) multiply by 1.34.

NEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 4X

Suitable for use in wet locations

Photometric Data

Total Luminaire Efficiency = 76.6%

CIE Type - Direct

Spacing

Plane

Criteria

0-180 1.48 Coefficients of Utilization - Zonal Cavity Method

90-270 1.62 Effective Floor Cavity Reflectance 0.20

Diagonal 1.54 % Ceiling Rcc 80 70 50 30 10 0

Zone Lumens

0-10 42.08

10-20 124.46

20-30 205.20

30-40 273.31

40-50 299.53

50-60 283.93

60-70 240.60

70-80 181.91

80-90 110.47

90-100 50.28

100-110 18.05

110-120 5.01 Zonal Lumen Summary

120-130 1.80 Zone Lumens % Lamp % Fixture Zone Lumens % Lamp % Fixture

130-140 1.13 0-30 371.75 15.5 20.2 90-120 73.34 3.1 4.0

140-150 0.05 0-40 645.06 26.9 35.1 90-130 75.13 3.1 4.1

150-160 0.00 0-60 1228.52 51.2 66.8 90-150 76.32 3.2 4.1

160-170 0.00 0-90 1761.50 73.4 95.8 90-180 76.32 3.2 4.2

170-180 0.00 0-180 1837.81 76.6 100.0

Total Luminaire Efficiency = 79.8%

CIE Type - Semi-Direct

Plane

0-180 2.88 Coefficients of Utilization - Zonal Cavity Method

90-270 2.88 Effective Floor Cavity Reflectance 0.20

Diagonal 2.82 % Ceiling Rcc 80 70 50 30 10 0

Zone Lumens 0 90 90 90 90 85 85 85 85 76 76 76 68 68 68 60 60 60 57

0-10 17.70 1 76 70 65 60 71 66 61 57 58 54 51 51 48 45 45 42 40 36

10-20 61.05 2 67 58 51 45 63 55 48 42 48 43 38 42 37 34 36 32 29 26

20-30 132.44 3 60 49 41 35 56 46 39 33 40 34 29 35 30 26 30 26 23 20

30-40 236.78 4 54 43 34 28 50 40 32 26 35 28 23 30 25 21 26 21 18 15

40-50 336.66 5 49 37 29 23 46 35 27 22 31 24 19 26 21 17 23 18 15 12

50-60 421.68 6 45 33 25 19 42 31 23 18 27 21 16 23 18 14 20 16 12 10

60-70 485.34 7 41 29 22 16 38 28 20 15 24 18 14 21 16 12 18 14 10 8

70-80 517.29 8 38 26 19 14 36 25 18 13 22 16 12 19 14 10 16 12 9 7

80-90 513.72 9 35 24 17 12 33 23 16 11 20 14 10 17 12 9 15 11 8 9

90-100 468.70 10 33 22 15 11 31 21 14 10 18 13 9 16 11 8 14 10 7 5

100-110

110-120 200.85

120-130 73.54

130-140 11.28 0-30 211.19 4.4 5.5 90-120 1022.32 21.3 26.7

140-150 1.12 0-40 447.97 9.3 11.7 90-130 1095.85 22.8 28.6

150-160 0.31 0-60 1206.31 25.1 31.5 90-150 1108.26 23.1 28.6

160-170 0.06 0-90 2722.64 56.7 71.1 90-180 1108.63 23.1 28.9

170-180 0.00 0-180 3831.28 79.8 100.0

Fixtures are for use with Group B atmospheres only when used with Group B mounting hoods. For 26 W,32 W, and 42 W fixtures only.

Maximum Candela = 467

Located at Horizontal Angle = 90, Vertical Angle = 40

#1 - Vertical Plane through Horizontal Angles (90-270)

(Through Max. Cd.)

#2 - Horizontal Cone through Vertical Angle (40)

(Through Max. Cd.)

Spacing

Criteria

352.77

Maximum Candela = 493

Located at Horizontal Angle = 0, Vertical Angle = 70

#1 – Vertical Plane through Horizontal Angles (0-180)

(Through Max. Cd.)

#2 – Horizontal Cone through Vertical Angle (70)

(Through Max. Cd.)

CEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

CSA 4X

REPORT NUMBER: CJBF32AN

32 W Fluorescent Lamp with Globe and 30° Angle Dome Reflector *

% Walls Rw 70 50 30 10 70 50 30 10 50 30 10 50 30 10 50 30 10 0

90 90 90 90 88 88 88 88 83 83 83 79 79 79 75 75 75 73

0

81 76 72 69 78 74 71 67 70 67 64 67 64 62 63 61 59 58

1

73 65 59 54 70 64 58 53 60 56 52 57 53 50 54 51 48 46

2

66 57 50 44 63 55 49 44 52 47 42 50 45 41 47 43 40 38

3

60 50 42 37 58 48 42 36 46 40 35 44 39 35 42 37 34 32

4

55 44 37 31 53 43 36 31 41 35 30 39 34 30 37 33 29 27

5

50 39 32 27 49 39 32 27 37 31 26 35 30 26 34 29 25 23

6

47 36 28 23 45 35 28 23 33 27 23 32 26 22 31 26 22 20

7

43 32 25 21 42 32 25 21 30 24 20 29 24 20 28 23 20 18

8

40 30 23 18 39 29 23 18 28 22 18 27 22 18 26 21 18 16

9

38 27 21 17 36 27 21 17 26 20 16 25 20 16 24 19 16 14

10

REPORT NUMBER: CMBF64G

64 W (two 32 W lamps) Fluorescent Fixture with Globe only **

% Walls Rw 70 50 30 10 70 50 30 10 50 30 10 50 30 10 50 30 10 0

Zonal Lumen Summary

Zone Lumens % Lamp % Fixture Zone Lumens % Lamp % Fixture

505

Page 11

Code•Master™ PLT Factory Sealed Luminaires

FLUORESCENT/AREA: NEC/CEC EXPLOSIONPROOF

© May 2019

Explosionproof, Dust-Ignitionproof

** Photometric data is based on a fixture with two 32 W Compact Fluorescent PL-T lamps (2,400 lumens each). For candlepower values of fixtures with two 26 W PL-T lamps (1,800 lumens each),

multiply by 0.75. For Candlepower values of fixtures with two 42 W PL-T lamps. (3,200 lumens each) multiply by 1.34.

NEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 4X

Suitable for use in wet locations

CEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

CSA 4X

Photometric Data

Total Luminaire Efficiency = 66.5%

CIE Type - Direct

Spacing

Plane

Criteria

0-180 1.62 Coefficients of Utilization - Zonal Cavity Method

90-270 1.62 Effective Floor Cavity Reflectance 0.20

Diagonal 1.74 % Ceiling Rcc 80 70 50 30 10 0

Zone Lumens 0 79 79 79 79 77 77 77 77 74 74 74 71 71 71 68 68 68 66

0-10 73.25 1 72 69 66 63 70 67 64 62 64 62 60 62 60 58 59 58 56 55

10-20 220.57 2 65 59 54 50 63 58 53 49 55 52 48 53 50 47 51 48 46 45

20-30 368.60 3 59 51 45 41 57 50 45 40 48 43 40 46 42 39 44 41 38 37

30-40 505.61 4 53 45 38 34 52 44 38 33 42 37 33 40 36 32 39 35 32 30

40-50 603.19 5 49 39 33 28 47 39 33 28 37 32 28 36 31 28 35 31 27 26

50-60 638.42 6 45 35 29 24 43 34 29 24 33 28 24 32 27 24 31 27 23 22

60-70 497.24 7 41 32 25 21 40 31 25 21 30 25 21 29 24 21 28 24 20 19

70-80 226.17 8 38 29 23 19 37 28 22 18 27 22 18 26 22 18 26 21 18 17

80-90 57.98 9 35 26 20 16 34 26 20 16 25 20 16 24 19 16 23 19 16 15

90-100 1.64 10 33 24 18 15 32 24 18 15 23 18 15 22 18 15 22 17 14 13

100-110 0.00

110-120 0.00 Zonal Lumen Summary

120-130 0.00 Zone Lumens % Lamp % Fixture Zone Lumens % Lamp % Fixture

130-140 0.00 0-30 662.42 13.8 20.7 90-120 1.64 0.0 0.1

140-150 0.00 0-40 1168.03 24.3 36.6 90-130 1.64 0.0 0.1

150-160 0.00 0-60 2409.64 50.2 75.5 90-150 1.64 0.0 0.1

160-170 0.00 0-90 3191.04 66.5 99.9 90-180 1.64 0.0 0.1

170-180 0.00 0-180 3192.68 66.5 100.0

Total Luminaire Efficiency = 57.4%

CIE Type - Direct

Plane

0-180 1.52 Coefficients of Utilization - Zonal Cavity Method

90-270 1.70 Effective Floor Cavity Reflectance 0.20

Diagonal 1.62 % Ceiling Rcc 80 70 50 30 10 0

Zone Lumens 0 68 68 68 68 67 67 67 67 64 64 64 61 61 61 58 58 58 57

0-10 62.13 1 61 58 55 52 59 56 54 51 54 51 49 51 49 48 49 48 46 45

10-20 187.93 2 55 49 45 41 53 48 44 40 46 43 39 44 41 39 42 40 38 36

20-30 317.49 3 50 43 37 33 48 42 37 33 40 36 32 38 35 32 37 34 31 30

30-40 428.14 4 45 37 32 28 44 37 31 27 35 31 27 34 30 27 32 29 26 25

40-50 471.22 5 41 33 28 23 40 32 27 23 31 27 23 30 26 23 29 25 22 21

50-60 454.23 6 38 30 24 20 37 29 24 20 28 23 20 27 23 20 26 22 19 18

60-70 384.77 7 35 27 21 18 34 26 21 18 25 21 17 24 20 17 24 20 17 16

70-80 276.31 8 32 24 19 16 32 24 19 15 23 19 15 22 18 15 22 18 15 14

80-90 157.68 9 30 22 17 14 29 22 17 14 21 17 14 20 16 14 20 16 13 12

90-100 13.45 10 28 20 16 12 28 20 15 12 19 15 12 19 15 12 18 15 12 11

100-110 0.00

110-120 0.00 Zonal Lumen Summary

120-130 0.00 Zone Lumens % Lamp % Fixture Zone Lumens % Lamp % Fixture

130-140 0.00 0-30 567.55 11.8 20.6 90-120 13.45 0.3 0.5

140-150 0.00 0-40 995.69 20.7 36.2 90-130 13.45 0.3 0.5

150-160 0.00 0-60 1921.14 40.0 69.8 90-150 13.45 0.3 0.5

160-170 0.00 0-90 2739.90 57.1 99.5 90-180 13.45 0.3 0.5

170-180 0.00 0-180 2753.35 57.4 100.0

Fixtures are for use with Group B atmospheres only when used with Group B mounting hoods. For 26 W,32 W, and 42 W fixtures only.

Maximum Candela = 808

Located at Horizontal Angle = 0, Vertical Angle = 35

#1 – Vertical Plane through Horizontal Angles (0-180)

(Through Max. Cd.)

#2 – Horizontal Cone through Vertical Angle (35)

(Through Max. Cd.)

Spacing

Criteria

Maximum Candela = 731

Horizontal

Located at

#1 – Vertical Plane through Horizontal Angles (90-270)

(Through Max. Cd.)

#2 – Horizontal Cone through Vertical Angle (37.5)

(Through Max. Cd.)

Angle = 90, Vertical Angle = 37.5

REPORT NUMBER: CMBF64ST

64 W (two 32 W lamps) Fluorescent Fixture with Globe and

Standard Dome Reflector **

% Walls Rw 70 50 30 10 70 50 30 10 50 30 10 50 30 10 50 30 10 0

REPORT NUMBER: CMBF64AN

64 W (two 32 W lamps) Fluorescent Fixture with Globe and

30° Angle Dome Reflector **

% Walls Rw 70 50 30 10 70 50 30 10 50 30 10 50 30 10 50 30 10 0

506

Page 12

Code•Master™ PLT Factory Sealed Luminaires

FLUORESCENT/AREA: NEC/CEC EXPLOSIONPROOF

© May 2019

Explosionproof, Dust-Ignitionproof

** Photometric data is based on a fixture with two 32 W Compact Fluorescent PL-T lamps (2,400 lumens each). For candlepower values of fixtures with two 26 W PL-T lamps (1,800 lumens each),

multiply by 0.75. For Candlepower values of fixtures with two 42 W PL-T Lamps. (3,200 lumens each) multiply by 1.34.

NEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 4X

Suitable for use in wet locations

CEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

CSA 4X

Photometric Data

Total Luminaire Efficiency = 67.2%

CIE Type - Direct

Spacing

Plane

Criteria

0-180 1.44 Coefficients of Utilization - Zonal Cavity Method

90-270 1.44 Effective Floor Cavity Reflectance 0.20

Diagonal 1.60 % Ceiling Rcc 80 70 50 30 10 0

Zone Lumens 0 80 80 80 80 78 78 78 78 75 75 75 71 71 71 69 69 69 67

0-10 88.95 1 73 70 67 65 71 68 66 63 66 63 61 63 61 60 60 59 58 56

10-20 260.61 2 66 61 56 52 65 59 55 52 57 53 50 55 52 49 53 50 48 47

20-30 413.34 3 60 53 47 43 59 52 47 43 50 45 42 48 44 41 46 43 40 39

30-40 539.82 4 55 47 41 36 53 46 40 36 44 39 35 42 38 35 41 37 34 33

40-50 630.36 5 50 41 35 31 49 41 35 30 39 34 30 38 33 30 37 33 29 28

50-60 641.74 6 46 37 31 26 45 36 30 26 35 30 26 34 29 26 33 29 25 24

60-70 436.60 7 43 33 27 23 41 33 27 23 32 27 23 31 26 23 30 26 22 21

70-80 164.84

80-90 47.37

90-100 1.92 10 34 25 20 16 34 25 20 16 24 19 16 24 19 16 23 19 16 15

100-110 0.00

110-120 0.00 Zonal Lumen Summary

120-130 0.00 Zone Lumens % Lamp % Fixture Zone Lumens % Lamp % Fixture

130-140 0.00 0-30 762.91 15.9 23.7 90-120 1.92 0.0 0.1

140-150 0.00 0-40 1302.73 27.1 40.4 90-130 1.92 0.0 0.1

150-160 0.00 0-60 2574.82 53.6 79.8 90-150 1.92 0.0 0.1

160-170 0.00 0-90 3223.63 67.2 99.9 90-180 1.92 0.0 0.1

170-180 0.00 0-180 3225.55 57.4 100.0

Total Luminaire Efficiency = 58.9%

CIE Type - Direct

Plane

0-180 0.82 Coefficients of Utilization - Zonal Cavity Method

90-270 0.82 Effective Floor Cavity Reflectance 0.20

Diagonal 0.92 % Ceiling Rcc 80 70 50 30 10 0

Zone Lumens 0 70 70 70 70 68 68 68 68 65 65 65 63 63 63 60 60 60 59

0-10 239.15 1 66 64 63 61 65 63 62 60 61 59 58 58 57 57 56 56 55 54

10-20 599.67 2 62 59 56 54 61 58 55 53 56 54 52 54 52 51 52 51 50 49

20-30 645.20 3 58 54 51 48 57 53 50 47 51 49 47 50 48 46 49 47 45 44

30-40 625.54 4 55 50 46 43 54 49 45 43 48 44 42 46 44 42 45 43 41 40

40-50 452.95 5 51 46 42 39 50 45 41 39 44 41 38 43 40 38 42 39 37 36

50-60 185.71 6 48 42 38 35 47 42 38 35 41 37 35 40 37 35 39 36 34 33

60-70 58.40 7 46 39 35 32 45 39 35 32 38 35 32 37 34 32 37 34 32 31

70-80 15.26 8 43 37 33 30 42 36 32 30 36 32 30 35 32 29 34 31 29 28

80-90 4.25 9 41 34 30 28 40 34 30 28 33 30 27 33 30 27 32 29 27 26

90-100 0.69 10 38 32 28 26 38 32 28 26 31 28 26 31 28 25 30 27 25 25

100-110 0.00

110-120 0.00 Zonal Lumen Summary

120-130 0.00 Zone Lumens % Lamp % Fixture Zone Lumens % Lamp % Fixture

130-140 0.00 0-30 1484.03 30.9 52.5 90-120 0.69 0.0 0.0

140-150 0.00 0-40 2109.57 43.9 74.6 90-130 0.69 0.0 0.0

150-160 0.00 0-60 2748.23 57.3 97.2 90-150 0.69 0.0 0.0

160-170 0.00 0-90 2826.12 58.9 100.0 90-180 0.69 0.0 0.0

170-180 0.00 0-180 2628.80 58.9 100.0

Fixtures are for use with Group B atmospheres only when used with Group B mounting hoods. For 26 W,32 W, and 42 W fixtures only.

Maximum Candela = 933

Located at Horizontal Angle = 0, Vertical Angle = 7.5

#1 – Vertical Plane through Horizontal Angles (0-180)

(Through Max. Cd.)

#2 – Horizontal Cone through Vertical Angle (7.5)

(Through Max. Cd.)

Spacing

Criteria

Maximum Candela = 2540

Located at Horzonatl Angle = 0, Vertical Angle = 5

#1 – Vertical Plane through Horizontal Angles (0-180)

(Through Max. Cd.)

#2 – Horizontal Cone through Vertical Angle (5)

(Through Max. Cd.)

REPORT NUMBER: CMBF64DD

64 W (two 32 W lamps) Fluorescent Fixture with Globe and

Deep Dome Reflector **

% Walls Rw 70 50 30 10 70 50 30 10 50 30 10 50 30 10 50 30 10 0

8 40 30 24 20 38 30 24 20 29 24 20 28 23 20 27 23 20 19

9 37 28 22 18 36 27 22 18 26 21 18 26 21 18 25 21 18 16

REPORT NUMBER: CMBF64HB

64 W (two 32 W lamps) Fluorescent Fixture with Globe and High Bay Reflector **

% Walls Rw 70 50 30 10 70 50 30 10 50 30 10 50 30 10 50 30 10 0

507

Loading...

Loading...