Page 1

INSTRUCTION SHEET

Code•Master Jr.™ HID Factory Sealed Fixtures:

Explosion-Proof, Dust-Ignition-Proof.

Integrally Ballasted for H.P.S., P.S.M.H., M.H. or M.V. Lamps. For Use with Threaded Metal Conduit.

650130-004

Applications

• For use in chemical and petrochemical plants and manufacturers of plastics,

paints and thinners; in refineries; and

in other areas where ignitable vapors,

dust, moisture and corrosive elements

may be present.

• Suitable for outdoor saltwater locations and for other wet locations.

Features

• Fixtures operate safely in high ambient

temperatures.

• Patented “wireless” design. Threading

of fixture unit onto mounting hood

makes electrical connection. The only

wiring required is the attachment of

two wires to the connection block in

mounting hood.

• Connection block is easily wired: (a)

loosen two screws, (b) make wire connections, (c) re-position connection

block. (See Figure 3)

• Safe, easy servicing without disconnecting any wiring. “Wireless” fixture unit

threads off mounting hood for convenient servicing or for immediate replacement with a “stand-by” unit.

• Acme double-lead threads speed

installation and fixture removal from

mounting hood, only half as many turns

are required as for single-lead threads.

The threads do not stick or gall, eliminating problems often encountered with

single-lead threads during fixture unit

removal.

• Eight threads are always fully engaged

in an explosion-proof manner , even after

fixture unit is backed off to break the

electrical connection.

• Engineered for safety. Safe even if

current is accidentally left on because

arcing, if any, is safely confined to the

interior.

• All threaded joints are flame-tight.

• Integrally-ballasted HID lighting

fixtures; separate ballasts not required.

• Factory sealed. External seals not

required for Groups C and D.

• Fixtures for use in Group B locations

are furnished complete with UL required

sealing fitting.

• Shock-absorbing medium-base socket

mount prolongs lamp life.

CLASS I, Div. 1 & 2, Groups B,C,D

CLASS II, Div. 1, Groups E, F, G

CLASS II, Div. 2, Groups F, G

CLASS III

CAP-75B

CAS-150B

• Porcelain socket with nickel plated

phosphor bronze screw shell. Assures

trouble-free operation in high ambient

areas.

• Choice of mountings: pendant, ceiling,

bracket and stanchion.

• Fiberglass reinforced polyester reflectors in standard dome, or 30º angle

styles are ideal in installations where

luminaire is subject to exceptionally

severe corrosive atmospheres.

• Optional guards protect globes from

damage. Secured to fixture with three

stainless steel screws. (See Figure 3)

Standard Materials

• Ballast bodies and guards: copperfree aluminum (less than 4/10ths of 1%

maximum copper content).

• Pendant mounting hoods: die-cast

copper-free aluminum (less than 4/

10ths of 1%).

• Ceiling, bracket and stanchion mounting hoods: sand cast copper-free

aluminum (less than 4/10ths of 1%).

• Reflectors: fiberglass reinforced polyester.

Standard Finishes

• Ballast bodies, guards and mounting

hoods: Epoxy powder coated finish.

Two coat baked finish, electrostatically

applied for complete uniform corrosion

protection.

CLASS I, Div. 1 & 2 Groups C, D

CLASS II, Div. 1, Groups E, F, G

CLASS II, Div. 2, Groups F, G

CLASS III

CAP-75 CAP-100

CAC-75

CALB-75

CLASS I, Div. 1 & 2 Groups D

CLASS II, Div. 1, Groups E, F, G

CLASS II, Div. 2, Groups F, G

CLASS III

CAC-100

CALB-100

CAS-150

Electrical Specifications

• Wide range of wattages and voltages.

Code-Master Jr. HID fixture with in-head

ballasts available for 35 to 175 watt

medium base lamps (35W HPS in 120V

only). 50W HPS fixtures have dual-tap

ballast (120V and 277V). All other wattages have multi-tap (120V, 208V, 240V,

277V) and 480V.

• Ballasts operate at low temperatures:

MV, PSMH, and MH — minus 20

— minus 40

• 35W through 150W high pressure

sodium ballasts are high reactance, high

power factor type.

Compliances

• UL Listed.

• UL Standard 844 and 1598A.

• Suitable for use in wet locations.

• Class I, Div. 1 and 2, Class II, Div. 1

and 2. See listing pages for specific

groups.

• Appleton aluminum products are

produced from a high strength copperfree alloy (less than 4/10ths of 1%

maximum copper content).

Options

• “Hot Restart” Emergency Option: av ailable for 35W through 150W HPS only.

F.

º

F; HPS

º

Rev. C 06/08/04 Page 1

Page 2

INSTALLATION AND MAINTENANCE INSTRUCTION

WARNING

1. Do not modify unit in any way. Modification may affect safety

and reliability.

2. Improper use or failure to follow these instructions could

result in serious injury or proper ty damage.

3. Operator should be instructed in the safe and proper usage

and maintenance of this product.

WARNING

1. Disconnect electrical power before installation, adjustment

and maintenance.

2. DO NOT overload; the amperage and voltage indicated

on the name plate must not be exceeded.

3. Check continuity before connecting electrical power.

4. This fixture intended for use with ballast suitable for lamp

type and wattage shown on fixture label.

GENERAL

ELECTRICAL

Read Carefully Before Attempting To Install Fixture

Class I, Div. 1 and 2, Groups B, C, D

Class II, Div. 1, Groups E, F, G

Class II, Div. 2, Groups F, G

Class III

UL 844, 1598A (Marine)

Suitable for use in wet locations

GROUP B INSTALLATIONS:

WARNING: This fixture is designed for permanent

installation in GROUP B classified locations (as defined

by the National Electrical Code) only when installed with

appropriate Appleton Electric Company mounting hoods.

For GROUP B installations, the mounting hood, sealing

fitting and fixture must all be marked as suitable for use in

GROUP B areas. (See Figure 1)

WARNING: Only the CAP75B 3/4” pendant hood and

the CAS150B, 1-1/2” 25¡ stanchion hood, are approved

for use in Group B locations, and the Group B markings will appear on label of the mounting hood. Mounting

hoods without the Group B marking are not acceptable for

Group B installations even if sealing fittings are used.

WARNING: Both the CAP75B and the CAS150B mount-

ing hoods must have a Group B approved sealing fitting

of the appropriate trade size installed within two inches of

the hood. Any manufacturer”s Group B approved sealing

fitting may be used. Follow the manufacturers sealing

fitting instructions for proper seal installation.

Pendant and Stanchion Hood: Remove connection

block from hood by loosening two mounting screws,

Thread hood onto conduit at least five threads (conduit

should engage the internal stop) and tighten locking set

screw. Connect the ground wire to the green screw provided in hood. Connect the b lack wire to the brass colored

screw and the white wire to the silvered colored screw on

the mounting block. Replace the connection block into the

mounting hood and re-tighten the screws securely. (See

standard assembly instructions on page 3 for remainder

of fixture installation.)

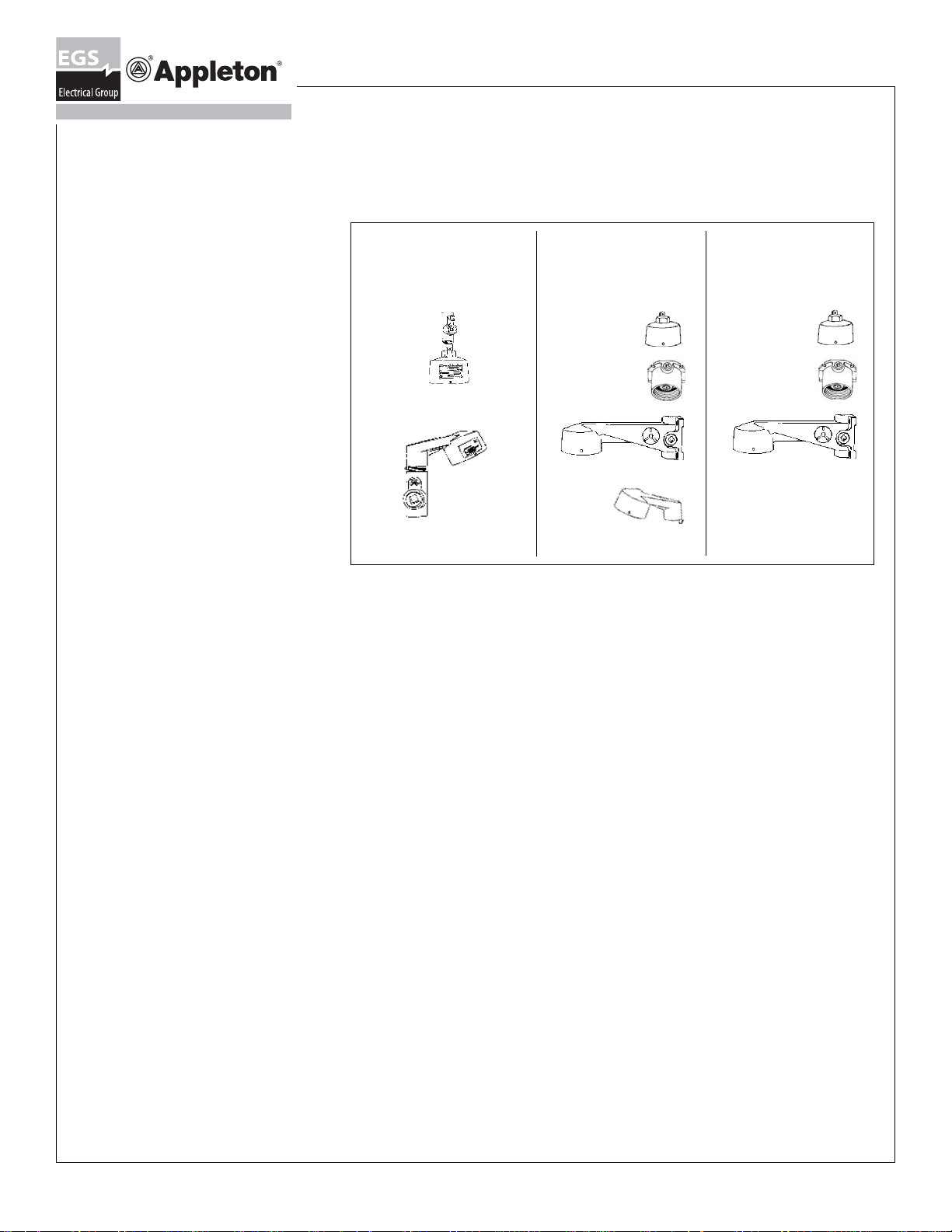

FIGURE 1

CLASS I, DIV. 1 & 2,

GROUP B INSTALLATIONS:

LABEL

NAMEPLATE

STANCHION MOUNT

CAS-150B

PENDANT MOUNT

CAP-75B

FIGURE 2

CLASS I, DIV. 1 & 2,

GROUP C, D INSTALLATIONS:

IMPORTANT: Remove all unused

CEILING

MOUNTING

HOOD

CONNECTOR

BLOCK

COLLECTOR RING

NAMEPLATE FOR

SPECIFICATIONS

IMPORTANT

FOR CORRECT CODE CLASSIFICATION AND GROUPING SEE

CHART ON PAGE 1.

AND PIN

ELECTRICAL

conduit plugs and reinstall with

pipe sealant.

SET SCREW

DOUBLE E LEAD

ACME THREADS

AS FIXTURE

UNIT IS

THREADED

INTO MOUNTING

HOOD, AN

AUTOMATIC

ELECTRICAL

CONNECTION

IS MADE

Page 2 Rev. C 06/08/04 650130-004

Page 3

INSTALLATION OF MOUNTING ACCESSORIES

(Not listed for Group B)

Read Carefully Before Attempting To Install Fixture

WARNING

• All mounting hoods using 3/4” conduit are Listed for Groups

C and D.

• All mounting hoods using 1” conduit are Listed for Group D

ONLY.

• 25

stanchion mount tapped 1-1/2” with 1-1/4” reducer

º

are rated for Groups C, D. (See listing on page 1)

PENDANT HOOD: See Figure 3

Remove connection block from hood by loosening two (2)

mounting screws. Thread hood onto conduit at least five (5)

threads (conduit should engage the inter nal conduit stop) and

tighten locking set screw. Connect the ground wire to the green

screw provided in hood. Connect the black supply wire to the

brass colored screw and the white supply wire to the silver colored screw on the connection block. Replace connection block

into the mounting hood and re-tighten the screws securely.

WALL BRACKET AND CEILING BOX

Install wall bracket or ceiling box on structural support member

with four bolts through four external mounting holes. Remove

connection block and connect electrically as described under

“Pendant Hood”.

STANCHION MOUNT

Remove connection block. Thread stanchion onto conduit at

least five (5) threads (conduit should engage the internal

conduit stop) and tighten locking set screw. Connect electrically

as described under “Pendant Hood”.

WARNING

• Disconnect power supply before servicing fixture.

• Failure to ground this fixture can result in an electric

shock which may be fatal.

• This fixture is designed for and should be used

permanently installed in accordance with the National Electr

Code and all

applicable local codes.

INSTALLATION OF FIXTURES

• Single voltage fixtures are completely wired, needing no

additional field wiring. Fixtures with multi-tap ballast (more than

one ballast voltage listed on nameplate) need to have one

ballast primary lead connected to the fixture lead.

• Verify that the supply line voltage and fixture nameplate voltages are compatible (If more than one ballast voltage is listed

on the nameplate, the fixture contains a multi-tap ballast requiring one internal connection. (See wiring diagrams Page 4)

• Verify that the hazardous groups and the fixture operating

temperatures marked on the nameplate comply with the

temperature restrictions of the hazardous area in which the

fixture is to be mounted.

• Use supply wire rated for ambient temperatures to be encountered. (See nameplate Figure 3).

ical

Install and tighten lamp (to achieve sufficient torque) to fully

depress the sockets” center contact.

RELAMPING

T o relamp , after disconnecting the power , open fixture as described

under “REMOVE GLOBE-RING ASSEMBLY”. Remove old lamp

and install new lamp as d

and “CLOSIN

G FIXTURE”. (See page 4)

escribed under “INSTALLING LAMP”

CLOSING FIXTURE

The globe-ring must be tightened to compress gasket, this

insures watertightness. Screw the globe-ring assembly into

housing by hand until gasket makes contact. Continue to

rotate additionally past three notches or for 2” of travel. To

assist in rotating globe-ring assembly, use two screwdrivers

inserted through slots on opposite sides of ring and operate

against pry bars in housing. Lock globe-ring in place by tightening locking screw until it engages the edge of the housing.

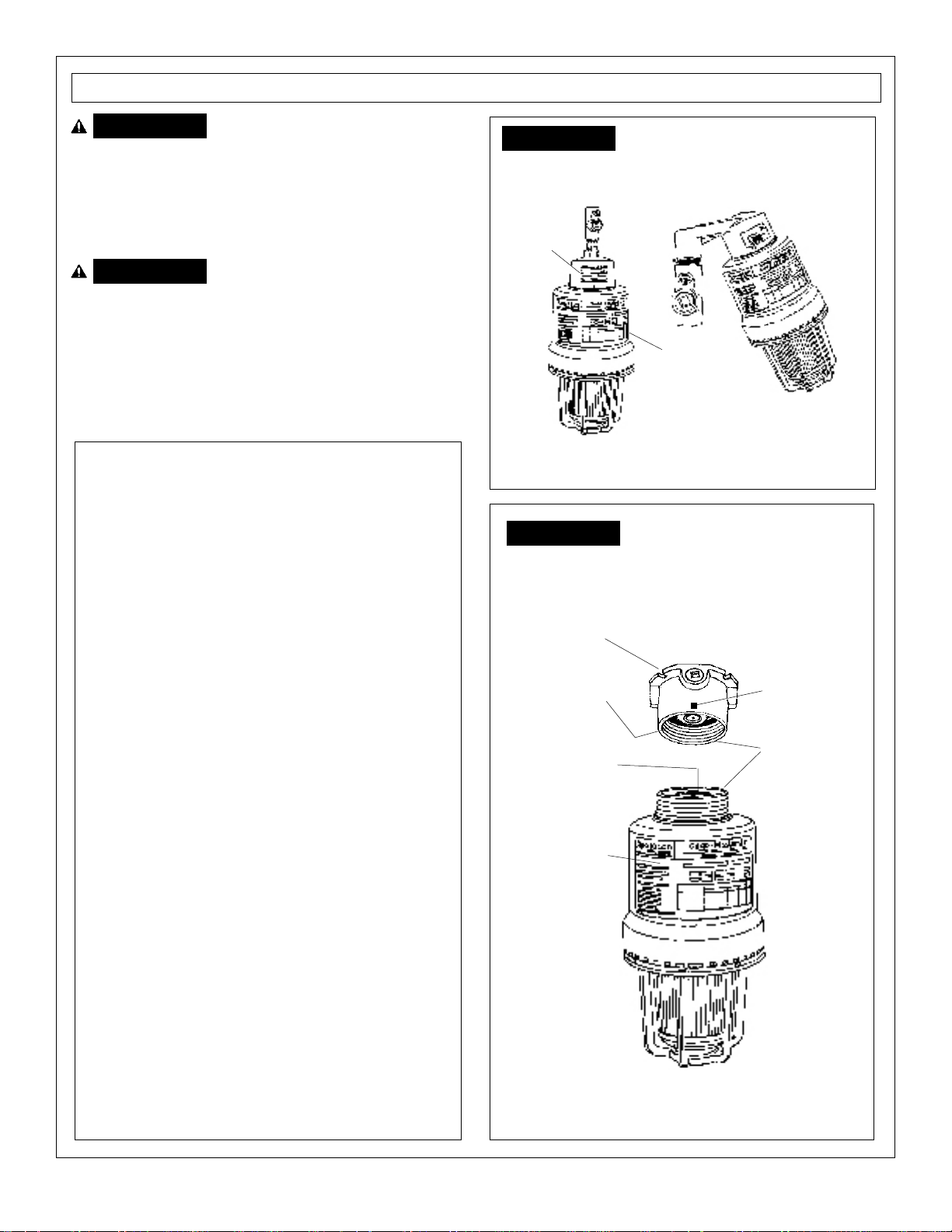

FIGURE 3

GROUND SCREW

(GREEN)

PENDANT HOOD

BLACK WIRE

CONNECTION

BLOCK SCREWS

NAMEPLATE

SOCKET PLATE

ASSEMBLY

REFLECTOR

AND GUARD

ATTACHMENT

SCREWS (3)

Pendant Mount

One Hub

SET SCREW

NAME PLATE

SET SCREW

WHITE WIRE

CONNECTION

BLOCK

DOUBLE LEAD

ACME THREADS

FIXTURE

(BALLAST)

HOUSING

MEDIUM BASE

SOCKET–35W

THRU 175W

GLOBE RING

ASSEMBLY

GUARD

Ceiling Mount

Four Hubs

Three close-up

plugs

Wall Mount

Four Hubs

Three close-up

WIRING MULTI-TAP BALLAST

• Remove globe-ring assembly. Loosen three screws securing

socket plate. Remove plate and set aside (enough slack in the

lead wires is provided). Locate fixture lead marked “line” and

connect to the ballast voltage lead corresponding to supply voltage. All other ballast v oltage leads must remain capped. Replace

socket support plate and tighten three screws. Replace globering assembly and tighten locking screw.

INSTALLING LAMP

Check lamp type and wattage against fixture nameplate.

25¡ Stanchion Mount

One Hub

CMAD-1 MOUNTING ADAPTER With Connection Block

Permits use of existing Code•Master mounting hoods(AAC

Ceiling or AALB Brackets) with the new Code•Master Jr.

fixture unit. After removing e xisting fixture unit and adapter,

screw in the CMAD-1 adapter. Then thread new fixture into

the CMAD-1. Tighten set screws.

IMPORTANT:

CMAD-1

NOT UL LISTED

Rev C 06/08/04 650130-004 Page 3

Page 4

FIGURE 4

DESCRIPTION

Nameplate

Capacitor

Capacitor

Bracket

Heat Shield

Lamp Socket

Wiring Screws

Reflector or

Guard Screw

Globe cut-away

showing lamp

Globe

Mounting Block Assembly

Ballast Housing

Ballast

Ignitor

Ignitor

Bracket

Heat Shield

Ballast Mounting

Screws #8-32

Socket Mounting

Plate

Socket Gasket

Marine Gasket

Globe Ring

Assembly

Hex Head

Locking Screw

All statements, technical information and recommendations

herein are based upon data and tests believed to be reliable.

The accuracy or completeness of such data or test results

are not guaranteed. Pursuant to Appleton Electric Company”s

“Terms and Conditions of Sale”, because Appleton Electric neither knows nor controls the applications or conditions in which

the product will be used, the purchaser must determine the

appropriateness for the intended use and the product in such

applications or conditions

WIRING DIAGRAMS:

WIRE CONNECTOR

HX-HPF

WIRING FOR HPS AND 50-100W MH MULTI-TAP

FIGURE 5 FIGURE 6

ROTATE

ADDITIONALLY

PAST THREE

NOTCHES OR

FOR TWO (2)

INCHES OF

TRAVEL.

GUARD

ANGLE

REFLECTOR

REMOVE GLOBE-RING ASSEMBLY

• Loosen hex head locking screw (longest) in globe ring until

screw clears ballast housing. Un-thread globe-ring assembly. A

screwdriver inserted in housing notches and in globe ring slots,

will assist in removing globe-ring assembly (see figure 6). DO

NOT use glass globe to un-thread globe-ring assembly as this

might loosen the globe locking ring. (Should globe locking ring be

accidentally loosened, it should be retightened.)

INSTALLATION OF REFLECTOR AND GUARD

• Reflectors and guards are provided with k e yhole slots . To install,

loosen three shorter screws in globe-ring assembly and insert

reflectors or guards over them. (Be sure slots for the locking

screw are properly located.) Tighten three screws.

• When an angle reflector is used, orient reflector to direct light

output near the desired direction. Fine tune by rotating globe-ring

assembly after loosening hex head locking screw. (See Figure 4)

• Be sure marine gasket is still under compression by slightly tightening

locking screw.

WIRE CONNECTOR

HX-HPF

WIRING FOR HPS 120V OR 480V

WIRE

CONNECTOR

CWA

WIRING FOR 100 MV AND 175W MH MULTI-TAP

WIRE

CONNECTOR

CWA

WIRING FOR 100W MV AND 175W MH 480V

Page 4 Rev. C 06/08/04 650130-004

Loading...

Loading...