Page 1

Code•Master™ Factory Sealed Strobe Luminaires

VISUAL SIGNAL: NEC/CEC EXPLOSIONPROOF

© May 2016

Explosionproof, Dust-Ignitionproof

NEC:

Class I, Division 1 and 2, Groups C, D

Class I, Division 2, Groups A, B

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 3R, 4X

NEC:

Suitable for Wet Locations

Marine Outside Type (Saltwater)

Applications

• Code•Master Explosionproof Strobe xtures are designed to

provide safe operation in the presence of hazardous gases,

vapors or dusts, dened by the National Electrical Code as

Class I, Groups C and D; and Class II, Groups E, F and G.

• For use in hazardous locations such as plants where plastics,

paints, thinners and petrochemicals are manufactured.

• Also used in areas where audible signals cannot be heard, to

warn of unsafe conditions and for other communication needs.

Features

• Fixtures operate safely in high ambient temperatures.

• Minimum operating temperature is -25 °C (-13 °F).

• Available for re alarm hearing impaired.

• 65 ashes per minute.

• Fixtures are complete with lamp.

• Patented “wireless” design. Threading of xture unit

onto mounting hood makes electrical connection. The

only wiring required is attaching two wires to connection

block in mounting hood.

• Connection block is easily wired: (a) loosen two screws, (b)

make wire connections; and (c) re-position connection block.

• Safe, easy servicing without disconnecting any wiring.

“Wireless” xture unit threads off mounting hood for convenient

servicing or for immediate replacement with a “stand by” unit.

• Acme double lead threads speed installation and xture removal

from mounting hood. Only half as many turns are required as for

single lead threads. The threads do not stick or gall, eliminating

problems often encountered with single lead threads during

xture unit removal.

• All threaded joints are ame-tight.

• Factory installed lens available in ve colors: red, amber, blue,

green and clear (factory installed).

• Factory sealed. External seals are not required.

• Heat- and impact-resistant globes have smooth dust-resistant

exterior.

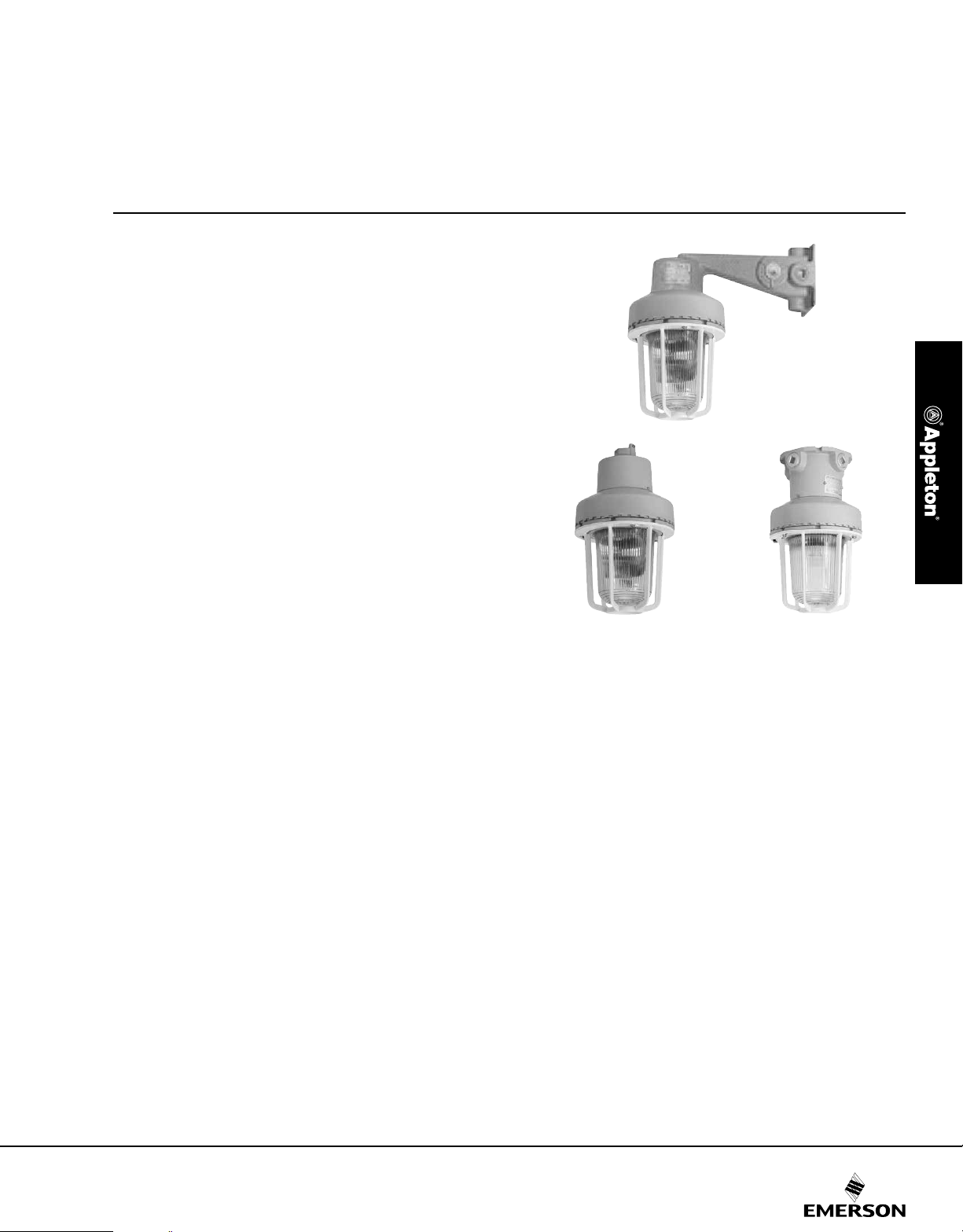

• Fixture is suitable for mounting globe up or globe down utilizing

pendant, ceiling or wall bracket type mounts.

• Optional guards protect globes from damage.

Standard Materials

• Fixture housing, mounting hoods and guards: copperfree (4/10

of 1% max.) aluminum

• Globes: prismatic glass

• Screws: Stainless steel (3)

Standard Finishes

• Fixture housing, guards and mounting hoods: epoxy power

coat nish, electrostatically applied for complete, uniform

corrosion protection

NEC Certifications and Compliances

• UL Listed: E212210

• UL Standard: 1203

• UL Standard: 1638 Visual Signaling Appliances

• UL Standard: 1971 Visual Signaling Equipment has been

investigated for re protective signaling services to alert hearing

impaired persons. This signaling equipment is intended to be

used in conjunction with Listed compatible units and devices.

Visual signaling equipment Listed in this category is intended to

be used in the “Public Operating Mode” as dened in NFPA 72

Fixture (shown with optional guard) are suitable for mounting in

any position including globe up or globe down utilizing pendant,

ceiling or wall-bracket type mounts.

577

Page 2

Code•Master™ Factory Sealed Strobe Luminaires

VISUAL SIGNAL: NEC/CEC EXPLOSIONPROOF

© May 2016

Explosionproof, Dust-Ignitionproof

NEC:

Class I, Division 1 and 2, Groups C, D

Class I, Division 2, Groups A, B

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 3R, 4X

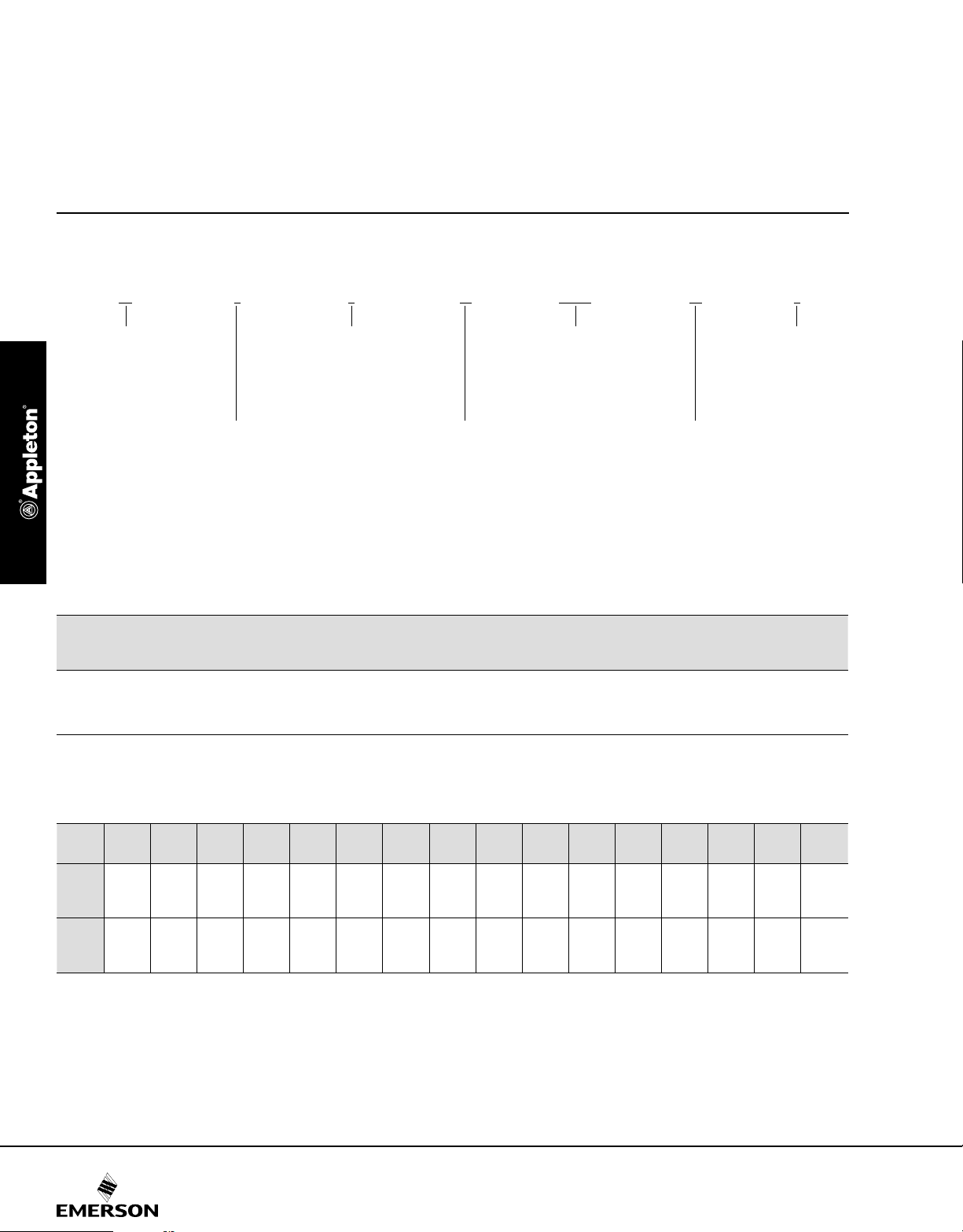

Ordering Information

Order using catalog numbering guide below or select catalog number from tables on following pages.

Catalog Numbering Guide

CS S P 75 120AC CL P

Series:

CS - Code•Master Signal

Type:

S - Strobe

NEC:

Suitable for Wet Locations

Marine Outside Type (Saltwater)

Mounting Hood:

P - Pendant

B - Wall bracket

C - Ceiling

Voltage Current:

120 AC - 120 Vac

240 AC - 240 Vac

250 DC - 250 Vdc

2030 DC - 20-30 Vdc

24 DC - 24 Vdc

Hub Size:

75 – 3/4”

Options:

P - Hearing

Impaired

(UL1971)

(Strobe Only)

G - Guard

Globe:

CL - Clear

AM - Amber

BL - Blue

GR - Green

RE - Red

Thermal Suitability of Code-Master Strobe Fixture

Ambient

Temp.

°C (°F)

40 (104) T6 T2B T4A

55 (131) T6 T2B T4A

65 (149) T6 T2A T4

Operating Temperatures

“T” Numbers Represent the Maximum Internal Temperature for Class I, Division 2 Locations; Maximum Surface Temperature for

Class I, Division 1 Locations; and Maximum Surface Temperature Under Dust Blanket for Class II, Division 1 Locations.

“T”

Number T1 350 325 T2 T2A T2B T2C T2D T3 T3A T3B T3C T4 T4A T5 T6

Temp.

351-

Range

(°C)

Temp.

Range

(°F)

NOTE: The maximum operating temperature of the fixture must not exceed the ignition temperature of the gas, vapor or dust to be encountered per the National

Electrical Code.

450

664-

842

326-

350

619-

662

Class I, Division 1 and 2

Groups C and D

301-

281-

300

538-

572

261-

280

502-

536

325

574-

617

231-

260

448-

500

216-

230

421-

446

Class I, Division 2

Groups A and B

201-

181-

215

200

394-

358-

419

392

166-

180

331-

356

161-

165

322-

329

136-

160

277-

320

Class II, Division 1 and 2

Class III

121-

135

250-

275

101-

120

214-

248

86-

100

187-

212

85

185

UL1971: Hearing-Impaired Strobe Only

Not for use with UL1971 Strobe

Diode Polarized (Current limiter supplied as standard).

578

Page 3

Code•Master™ Factory Sealed Strobe Luminaires

VISUAL SIGNAL: NEC/CEC EXPLOSIONPROOF

© May 2016

Explosionproof, Dust-Ignitionproof

NEC:

Class I, Division 1 and 2, Groups C, D

Class I, Division 2, Groups A, B

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 3R, 4X

Standard Strobes

Pendant — One Hub 3/4” NPT, Rigid Conduit

Ceiling — Four Hubs 3/4” NPT, Three Close-Up Plugs, Rigid Conduit

Bracket — Four Hubs 3/4” NPT, Three Close-Up Plugs, Rigid Conduit

Fixture Unit Only — Less Mounting Hood

NEC:

Suitable for Wet Locations

Marine Outside Type (Saltwater)

10.36 kg (4.7 lb)

Volts Catalog Number

120 Vac CSSP75120ACCL

240 Vac CSSP75240ACCL

250 Vdc CSSP75250DCCL

24 Vdc

120 Vac CSSC75120ACCL

240 Vac CSSC75240ACCL

250 Vdc CSSC75250DCCL

24 Vdc

120 Vac CSSB75120ACCL

240 Vac CSSB75240ACCL

250 Vdc CSSB75250DCCL

24 Vdc

120 Vac CSST120ACCL

240 Vac CSST240ACCL

250 Vdc CSST250DCCL

24 Vdc

CSSP7524DCCL

CSSC7524DCCL

CSSB7524DCCL

CSST24PDCCL

Weight kg (lb) Hub Size (Inches) Catalog Number

Pendant Mounting Hood — One Hub 3/4” NPT, Rigid Conduit

9.0 (19.84) 3/4 CAP-75

Ceiling Mounting Hood — Four Hubs 3/4” NPT, Three Close-Up Plugs, Rigid Conduit

1.8 (3.97) 3/4 CAC-75

Bracket Mounting Hood — Four Hubs 3/4” NPT, Three Close-Up Plugs, Rigid Conduit

2.7 (5.95) 3/4 CALB-75

Add -G suffix for optional guard.

Diode polarized (current limiter supplied as standard).

Catalog numbers shown are supplied with clear lens. To order colored lens, replace last digits of catalog number CL with AM for amber; BL for blue; GR for

green; and RE for red.

579

Page 4

Code•Master™ Factory Sealed Strobe Luminaires

VISUAL SIGNAL: NEC/CEC EXPLOSIONPROOF

© May 2016

Explosionproof, Dust-Ignitionproof

NEC:

Class I, Division 1 and 2, Groups C, D

Class I, Division 2, Groups A, B

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 3R, 4X

Strobes for the Hearing Impaired

Pendant — One Hub 3/4” NPT, Rigid Conduit

Ceiling — Four Hubs 3/4” NPT, Three Close-Up Plugs, Rigid Conduit

Fixture Unit Only — Less Mounting Hood

NEC:

Suitable for Wet Locations

Marine Outside Type (Saltwater)

Type Mounting Volts Catalog Number — UL1971: Hearing-Impaired

20-30 Vdc CSSP752030DCCLP

20-30 Vdc CSSC752030DCCLP

20-30 Vdc CSSB752030DCCLP

Fixture Unit Only — Less Mounting Hood

4.7 kg (10.36 lb) 20-30 Vdc CSST2030PDCCL

Weight kg (lb) Hub Size (Inches) Catalog Number — UL1971: Hearing-Impaired

Pendant Mounting Hood — One Hub 3/4” NPT, Rigid Conduit

Ceiling Mounting Hood — Four Hubs 3/4” NPT, Three Close-Up Plugs, Rigid Conduit

Bracket Mounting Hood — Four Hubs 3/4” NPT, Three Close-Up Plugs, Rigid Conduit

9.0 (19.84) 3/4 CAP-751971

1.8 (3.97) 3/4 CAC-751971

2.7 (5.95) 3/4 CALB-751971

Only clear globes are available for UL1971 applications.

580

Page 5

Code•Master™ Factory Sealed Strobe Luminaires

VISUAL SIGNAL: NEC/CEC EXPLOSIONPROOF

© May 2016

Explosionproof, Dust-Ignitionproof

NEC:

Class I, Division 1 and 2, Groups C, D

Class I, Division 2, Groups A, B

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 3R, 4X

Optional Aluminum Guard

Replacement Connection Block — Standard

Replacement Connection Block — UL1971: Hearing-Impaired

NEC:

Suitable for Wet Locations

Marine Outside Type (Saltwater)

Description Weight kg (lb) Catalog Number

For Non-Hearing-Impaired

CodeMaster Fixtures

For Code-Master Fixtures for the

Hearing Impaired

0.5 (1.10) CJGU-15

0.2 (0.44) VPT-7

0.2 (0.44) VPT-7P

Replacement Lamps

Fixture Type Lamp Type Voltage Base Type Catalog Number

Strobe

Xenon All Octal Socket S865

581

Page 6

Code•Master™ Factory Sealed Strobe Luminaires

VISUAL SIGNAL: NEC/CEC EXPLOSIONPROOF

© May 2016

Explosionproof, Dust-Ignitionproof

NEC:

Class I, Division 1 and 2, Groups C, D

Class I, Division 2, Groups A, B

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 3R, 4X

Pendant

One Hub, 3/4” NPT

CAP75 or CAP75-1971

NEC:

Suitable for Wet Locations

Marine Outside Type (Saltwater)

Ceiling

Four Hubs, Three Close-Up Plugs, 3/4” NPT

CAC75 or CAC75-1971

Code•Master Incandescent Fixture Unit

CSST

Four Hubs, Three Close-Up Plugs, 3/4” NPT

Bracket

CALB75 or CALB75-1971

Dimensions in Millimeters (Inches)

Pendant Ceiling Wall Bracket

Hub for .75"

NPT Conduit

114.3

95.3

(3.75)

(4.50)

334.0

(13.15)

343.7

(13.53)

198.1

(7.80)

Hub for .75" NPT

Conduit Four Sides

339.9

(13.38)

330.2

(13.00)

Optional Aluminum Guard

CJGU-15

101.6

(4.00)

101.6

(4.00)

101.6

(4.00)

150.4

(5.92)

151.3

(5.95)

198.1

(7.80)

114.3

(4.50)

125.0

(4.92)

125.0

(4.92)

99.6

(3.92)

10.4

(0.41)

62.5

(2.46)

31.2

(1.23)

87.9

(3.46)

352.6

(13.88)

57.9

(2.28)

198.1

(7.80)

Hub For

3/4” NPT

2” Wiring access

cover both sides.

292.1

(11.50)

349.3

(13.75)

314.5

(12.38)

349.3

(13.75)

45.5

(1.79)

108.0

(4.25)

UL1971: Hearing-Impaired Strobe Only

Diode polarized (current limiter supplied as standard).

582

Loading...

Loading...