EGS Electrical Group • 7770 N. Frontage Rd • Skokie, Illinois 60077

Rev. C 08/28/01 Page 1

654104-000

INSTRUCTION SHEET

A-51 SERIES INCANDESCENT LIGHTING FIXTURE

INSTALLATION AND MAINTENANCE DATA SHEET

The fixture unit must be installed with one of the following

mounting hoods for safe operation. Failure to use fixture

unit with one of the following mounting hoods voids warranty as well as the U.L. Listing and creates the risk of fire or

explosion.

Fixture unit must be installed with:

DIRECTIONS FOR FIXTURE

INSTALLATION

1.Use the installation drawing as a guide.Install mounting hood

first as all wiring connections are made in the mounting

hood.The fixture unit requires no internal wiring connections.

• Install mounting hood to conduit system (and/or wall,

ceiling or stanchion). If using pendant or stanchion

mounting hood, secure the hood to the conduit system with

the set screw.

2.Remove the connection block (VPT7) from the mounting

hood by loosening (but not removing) the two Phillips head

screws.Turn connection block counter-clockwise to remove.

3.When using ceiling bracket (AAC-), long wall bracket (AALB-), o r

short wall bracket (AASB-), mounting hoods, threaded

adapter (59064050000) can be removed by lifting

gasket (59064034000) to access set screw.

• Loosen set screw and turn adapter counter- clockwise for

easier access to junction box. If long bracket (AALB-) is

being used, bracket can be removed from junction box by

loosening set screw in flange and turning counter clockwise.

4.Pull supply wires from the conduit into the junction box.Make

connection of supply wires to the VPT-7 connection block by

attaching “HOT” voltage lead to the brass terminal and

common “neutral” lead to silver terminal.

5.Secure threaded adapter (where applicable) or long

bracket (where applicable) to junction box and tighten all set

screws.

6.Secure VPT-7 connection block to threaded adapter or

mounting hood by slipping over Phillips head screws,

turning clockwise and tightening screws.

7.Install lamp into fixture unit. See directions under “Lamp

Installation Instructions”.

8.Inspect threads of mounting hoods and the fixture unit to be

sure they are clean and free of damage.

• Inspect globe for any chips, scratches or cracks.

CAUTION GENERAL

Chipped, scratched or cracked

globes will fail.Replace any

such defective lamp housing.

9. Thread the fixture unit into mating threads of

mounting hood until tight against gasket of mounting

hood. Locking spring of fixture unit should engage with

notches on mounting hood.

10. Install guard and/or reflector if desired. Check tightness of

set screws and all threaded joints. Activate supply circuit

to test fixture.

KEEP THIS MANUAL FOR FUTURE REFERENCE

A51 Series lighting fixtures for:

Class I, Division 1, Groups C and D;

Class II, Division 1, Groups E, F, and G

WARNING GENERAL

1. DO NOT MODIFY UNIT IN ANY WAY. Modification may

affect safety and reliability.

2. Improper use or failure to follow these instructions could

result in serious injury or proper ty damage.

3. Operator should be instructed in the safe and proper

usage and maintenance of this product.

WARNING ELECTRICAL

1. Disconnect electrical power before installation, adjust-

ment and maintenance.

2. DO NOT overload; the amperage and voltage indicated

on the nameplate must not be exceeded.

3. Check continuity before connecting electrical power.

4. All installations must comply with applicable local and/or

National Electrical Code.

5. Before installing check fixture unit nameplate and carton

labels to be sure you have correct fixture and mounting

hood. Circuit must be deactivated before installing fixture.

CAUTION GENERAL

1. All A-51 Series Fixtures are to be mounted vertically

with lamp base up.

AAP-50, AAP-75 or

AAP-100

Pendant Hood

AAC-50, AAC-75 or

AAC-100

Ceiling Hood

AALB-50, AALB-75

or AALB-100

Long Wall Bracket

Hood

AASB-50, AASB-75

Short Wall Bracket

Hood

FREE OF

CHIPS OR

CRACKS

EGS Electrical Group • 7770 N. Frontage Rd • Skokie, Illinois 60077

Pag e 2

654104-000 Rev. C 08/28/01

MAINTENANCE DATA

•To relamp, see “Lamp Installation Instructions.”

•To maintain maximum light output from this fixture,

it should be cleaned periodically as follows:

1. The aluminum exterior of this fixture should be

cleaned only with a mild soap or cleaner, and

should be rinsed with water immediately.

Alkaline or acidic cleaners will attack the protective

coating of epoxy on the fixture and should not be

used. This will allow the epoxy to protect the fixture

from corrosive elements in the atmosphere and

result in longer fixture life.

2. The glass globe should be cleaned using a soft

cloth and a non-abrasive cleaner. The globe

should be regularly inspected for scratches or

chips.If the globe is scratched or chipped, it must be

replaced.

3. The porcelain enamel reflector may be cleaned with

any non-abrasive detergent or glass cleaner.

• These periodic cleaning procedures are impor tant

to prevent the accumulation of dust and dirt which

will impair the light output of the fixture.

• When relamping, be careful not to damage the

external threaded areas, since they maintain the

fixture’s explosion-proof properties.

• When removing and repairing fixture, lubricate

threads only with Appleton TLC-3 conductive, high

temperature lubricant. This should only be necessary if threads are no longer coated with the blue or

black color of the dry film lubricant.

• See attached drawing for replacement parts list

OPERATIONAL DATA

•The fixture must be operated in an environment that

does not exceed 40°C.

• The fixture may be operated on AC power only up

to 300 volts.Use lamp rated for operating voltage.

WARNING:

• To reduce the risk of fire or explosion, do not install

where the operating temperature exceeds ignition

temperature of hazardous atmospheres.

• Refer to the nameplate on the fixture for maximum

operating temperature and for proper fixture

classification.

9

NOTE:All installations must comply with applicable local

and/or National Electrical Code.

• A lamp may be safely and easily installed into

the fixture at a work bench.

1. Disconnect fixture from supply circuit.

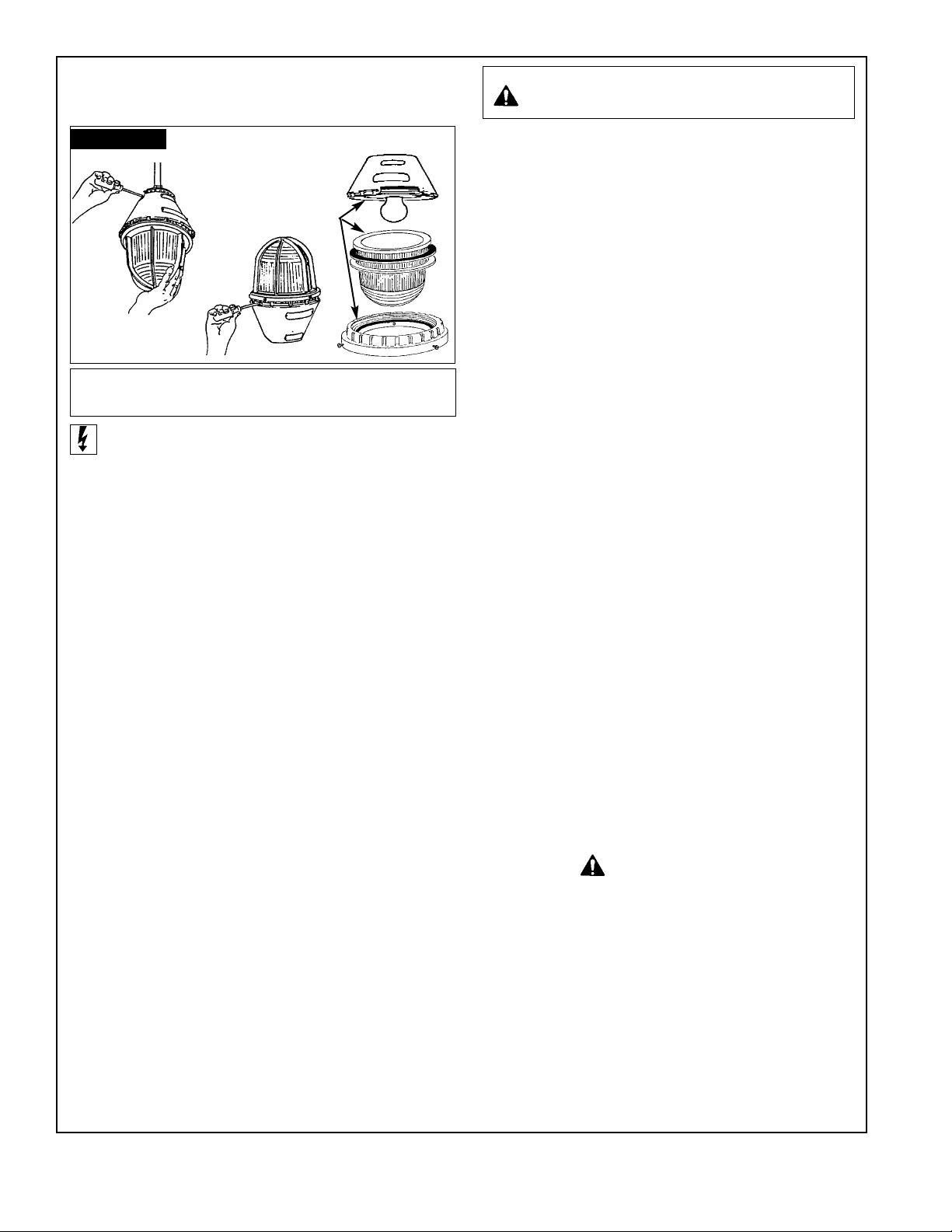

2. Remove fixture unit from mounting hood by insert-

ing screw d ri ver into canopy notches and

using release lugs for leverage.

•Once loosened from mounting hood, fixture unit can

be quic kly unscre w ed b y hand.Do not remove fixture

unit from mounting hood under load.

3. Place fixture unit on bench with globe side up.

4. Remove globe ring using pry notches if necessary.

5. Remove aluminum and fiber gaskets.

6. Lift globe carefully off of fixture and place safely on

clean surface.

7. Refer to fixture nameplate for proper lamp wattage

and types.

8. Inspect globe for chips or scratches as such def ects

will result in globe failure.

9. Wipe ground surface of globe and mating surf ace of

fixture with soft clean cloth to eliminate dust, oil or

grit.

10. Carefully place globe back on ground surface of

fixture unit.

11. Place the fiber gasket on globe flange first, then

place aluminum gasket on top of fiber gasket.

•This sequence is important for safe operation

of fixture.

12. Replace globe ring carefully and screw onto fixture

unit until globe ring is tightly in place.

13. Thread fixture unit into mounting hood as per “Directions

for Fixture Installation, Numbers 9 and 10”.

LAMP INSTALLATION

INSTRUCTIONS

CAUTION: All A-51 series fixtures are to be mounted

vertically with lamp base up.

CAUTION :

Disconnect supply circuit

before opening or relamping fixture.

➁

FIGURE 1

EGS Electrical Group • 7770 N. Frontage • Skokie, Illinois 60077

654104-000 Rev. C 08/28/01 Page 3

LONG BRACKET INSTALLATION

1. Remove bracket from junction box, pull through

leads to connector block. Attach ground wire

to grounding screw.

2. Remove Connector block from threaded adapter,

p

ull leads through to connect wires t

o cor-

rect terminal screws.

3. Push block into place and tighten screws —

Install fixture. NOTE: Plugs should be removed

and resealed with pipe sealant.

FIGURE 1

#10-24x3/8"

SL.RD.HD.

SET

SCREW

59064050000

THREADED ADAPTER

VPT-7 CONNECTOR BLOCK

SCREW #8 -32X1/2" PH. HD.

JUNCTION

BOX

TLC-3 HERE

A-51 GROUPS C & D LIGHTING FIXTURES FAMILY TREE

MOUNTING HOODS (Use of components marked “Not U.L. Listed” voids the U.L. Listing of the assembled fixture.)

Pendant Ceiling 25° Stanchion Long Bracket 15° Short Bracket

0ne Hub Three close-up plugs One close-up plug. Three close-up plug One close-up plug.

1/2" AAP-50 1/2" AAC-50 1-1/2" AAN-150 1/2" AALB-50 1/2" AASB-50

3/4" AAP-75 3/4" AAC-75 (Not U.L. Listed) 3/4" AALB-75 3/4" AASB-75

LAMP HOUSING

MED. BASE LAMP

200/300W (PS30)

AAU-2NS

LAMP HOUSING

MED. BASE LAMP

150-300 (A-

23)(PS-25)

AAU-15N

LAMP HOUSING

MED. BASE LAMP

100W(A-21)

AAU-1N

LAMP HOUSING

MOGUL. BASE LAMP

500W (PS-40)

AAU-5NS

LAMP HOUSING

MOGUL. BASE LAMP

500W (PS-40)

AAU-4MVNS

ALUMINUM GUARD

AAGU-2

ALUMINUM GUARD

AAGU-5

ALUMINUM GUARD

AAGU-4MV

PORCELAIN

REFLECTOR

STANDARD DOME

AARW-2ST

PORCELAIN

REFLECTOR

30° ANGLE

AARW-2AN

POLYESTER

REFLECTOR

STANDARD DOME

AARP-2ST

(Not U.L. Listed)

POLYESTER

REFLECTOR

30° ANGLE

AARP-2AN

(Not U.L. Listed)

PORCELAIN

REFLECTOR

STANDARD DOME

AARW-5ST

ALZAK ALUMINUM

REFLECTOR

HIGH BAY

AARE-2HB

PORCELAIN

REFLECTOR

30° ANGLE DOME

AARW5AN

ALZAK ALUMINUM

REFLECTOR

HIGH BAY

AARE-5HB

THREE-WAY EXIT SIGN

IN PLACE OF GUARD

CJEXRN

(Not U.L. Listed)

ALUMINUM GUARD

AAGU-1

PORCELAIN

REFLECTOR

STANDARD DOME

AARW-15ST

PORCELAIN

REFLECTOR

30° ANGLE

AARW-15AN

EGS Electrical Group • 7770 N. Frontage Rd • Skokie, Illinois 60077

Pag e 4

654104-000 Rev. C 08/28/01

Dimensions: A-51 Incandescent Lighting Fixtures.

A-51 Series Reflectors

STD. DOME 30° ANGLE HIGH BAY

Size Watts AB A B A B

60-100 12.00 4.50 10.00 7.63 — —

150-200 14.00 4.38 10.00 7.63 — —

200-300 16.00 5.19 12.00 7.88 12.00 6.06

300-500 20.00 6.84 18.00 13.13 18.00 9.13

STANDARD DOME 30° ANGLE HIGH BAY

Dimensions in Inches

Stanchion Pendant Ceiling Long Bracket Short Bracket

Size (Watts) A B CAB C AB CABC AB C

60-100 11.47 10.85 11.50 12.25 11.63 7.06 13.75 13.13 7.06 13.75 13.13 12.38 13.56 12.94 9.13

150-300 11.47 10.85 11.50 12.25 11.63 7.06 13.75 13.13 7.06 13.75 13.13 12.38 13.56 12.94 9.13

200-300 13.07 12.38 12.71 13.94 13.25 8.81 15.44 14.75 8.81 15.50 14.75 13.25 15.19 14.50 10.13

300-500 15.09 14.34 14.64 16.00 15.25 12.13 17.50 17.75 12.13 17.50 16.75 14.88 17.25 16.50 11.94

2.69"

(6.8cm)

B

C

Loading...

Loading...