Page 1

AFSX Speed Responsive Switch

CONTROLS: NEC/CEC EXPLOSIONPROOF CONVEYOR SWITCHES

0.1–1000 RPM.

NEC/CEC — Rated for:

Class I, Division 1 and 2, Groups C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 7CD, 9EFG

Applications

• For use in bulk material handling/processing systems to monitor

speeds of:

— Belt conveyors

— Screw conveyors

— Bucket elevators

— Rotating machinery

• Used where alarm or computer interface capabilities are

needed.

• For installation in:

— Steel mills

— Mining (ore and coal) operations

— Grain handling

— Chemical and plastic industries to protect elevators, feeders,

and conveyors from speed related damage resulting from

broken belts, overloads or belt slippage.

• For installation in mining and industrial areas where rugged

control enclosures are needed for protection from falling ores,

other heavy aggregates and from dripping water or hosedowns.

• Used in Class I and II areas where ammable vapors or highly

combustible dusts are present.

• Designed to monitor material ow by sequencing the operation

of multiple conveyors feeding a common bin or conveyor.

• Used as overspeed switches to detect motor overrun

conditions. Pickup speed should be set above normal operating

speeds. The output relay will energize if operating speed

exceeds the set point.

• Used as underspeed switches to detect slipping belts, jammed

conveyors or equipment and stalled motors: Pickup speed

setting should be below normal operating speeds. The output

relay will de-energize if operating speed falls below the set

point.

• Used as zero speed switch: When speed approaches zero

(0.1 RPM), the output relay will de-energize.

Features

• Signal range: three settings available (0.1-10 RPM; 1-100 RPM;

10-1000 RPM).

• Adjustable time delay (up to 45 seconds).

• Input power is applied to the speed responsive switch at all

times. The switch then senses input shaft speed in either

direction.

• When input shaft speed exceeds the pickup set point, the

output relay is energized.

• If shaft speed falls below 80-85% of the pickup speed the relay

will de-energize.

• Clockwise or counterclockwise rotation.

• Senses speed changes as slight as 1%.

• Operating temperatures are -45 °C to +65 °C (-49 °F to +149 °F).

• 3/4” NPT standard, two conduit openings.

• Radial load is 57 kilogram (125 pound) maximum at center of

the key.

• Axial thrust load is 45 kilogram (100 pound) maximum.

• Driving torque required is one inch-pound maximum.

• Flexible coupling accessory allows up to 7.5° misalignment,

high shock resistance and eliminates transmission of thrust

loads.

Front Back

Electrical Specifications

• Input voltage is 105-135 Vac, 50-60 Hz

• Output is a double pole, double throw relay rated 5 Amp

resistive at 120 Vac, 5 Amp at 240 Vac, 5 Amp at 30 Vdc.

• Repeatability is +/-2% maximum at constant voltage and

temperature.

• Power consumption is 3 watts maximum.

• Pulse sensor (solid state opto-electric infrared device) operating

life is 25 years if constant operation is at maximum speed.

• Pickup speed is adjustable by set point potentiometer.

• Drop-out RPM will be 10-15% lower than pickup speed to

account for normal uctuations in actual operating RPM.

• If a signal is required within 1-15% of the normal operating

speed, contact your local representative for presetting.

Standard Materials

• Housing: cast copperfree (4/10 of 1% max.) aluminum

• Shaft: stainless steel, 5/8” diameter

• #11 Woodruff key and hardware: stainless steel

• Flexible coupling: cast zinc

• Sleeve: neoprene with textile reinforcement

Standard Finishes

• Standard enclosure: shot peened

Optional Materials

• Housing: corrosion resistant epoxy powder coat

Options

• Epoxy powder coated switches, add sufx -G1.

• Mounting Bracket: AFSA1, AFSB1, AFSB2, AFSB3.

• Coupling guard: AFSG1.

352

Page 2

AFSX Speed Responsive Switch

CONTROLS: NEC/CEC EXPLOSIONPROOF CONVEYOR SWITCHES

0.1–1000 RPM.

NEC/CEC — Rated for:

Class I, Division 1 and 2, Groups C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 7CD, 9EFG

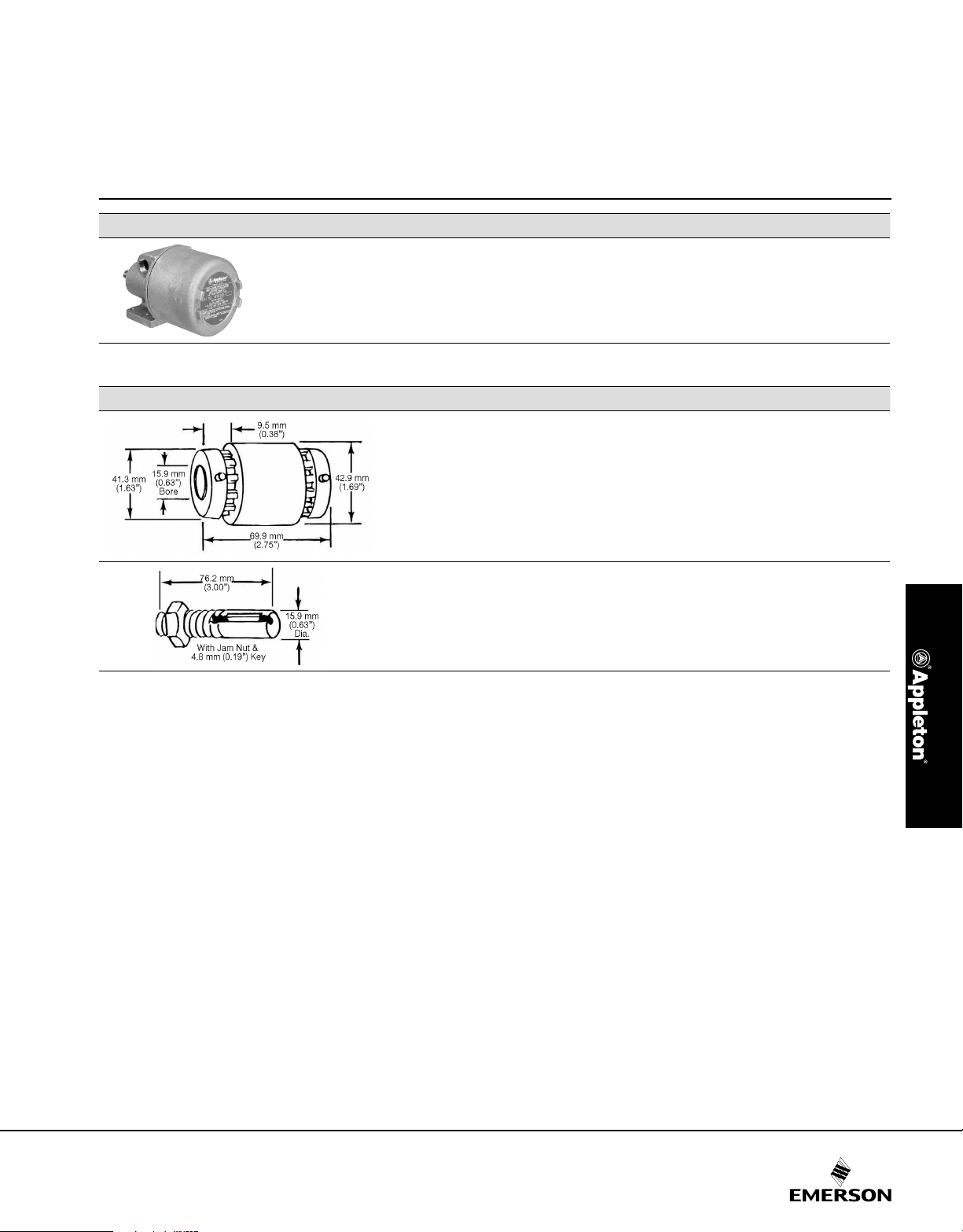

Optional Accessories

Flexible Coupling

This coupling will operate at up to a 7-1/2° axial misalignment with

no significant life reduction. This unit features high shock resistance

and eliminates transmission of lateral thrust from one shaft to the

other (no end thrust).

Sleeve: With axially molded internal teeth. Made of neoprene with

textile reinforcement. Two end fittings grooved to mate with sleeve

teeth. One fitting attached to each shaft.

Stub Shaft

Catalog Number

AFSX300

Description Catalog Number

AFSC1

76.2 mm (3”) threaded one end, keyed other end.

With jam nut and 3/16” key.

AFSS1

353

Page 3

AFSX Speed Responsive Switch Mounting

CONTROLS: NEC/CEC EXPLOSIONPROOF CONVEYOR SWITCHES

0.1–1000 RPM.

NEC/CEC — Rated for:

Class I, Division 1 and 2, Groups C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 7CD, 9EFG

Dimensions in Millimeters (Inches) and Suggested Mounting Arrangement

AFSG1 Coupling Guard

Bearing

Bracket and

Shim Plate

Part #

AFSB1 36.6 (1.44)

AFSB2

AFSB3

Mounting Dimensions in Millimeters (inches)

Rear View Side View Front View Mounting Hole Plan

Shaft

Diameter A B C D E F

31.8 - 50.8

(1.25 - 2.00)

49.3 - 62.0

(1.94 - 2.44)

74.7 - 100.1

(2.94 - 3.94)

38.1 - 65.0

(1.50 - 2.56)

76.2 - 95.3

(3.00 - 3.75)

47.8 - 54.1

(1.88 - 2.13)

57.2 - 76.2

(2.25 - 3.00)

79.5 - 104.9

(3.13 - 4.13)

Dimensions in Millimeters (Inches)

79.5

(3.13)

95.3

(3.75)

114.3

(4.50)

28.7

(1.13)

41.4

(1.63)

55.6

(2.19)

68.3

(2.69)

93.7

(3.69)

122.2

(4.81)

46.0

(1.81)

49.3

(1.94)

68.3

(2.69)

Width x Length

G H

49.2 x 25.4

(0.194 x 1.00)

49.2 x 25.4

(0.194 x 1.00)

49.2 x 25.4

(0.194 x 1.00)

14.3 x 33.3

(0.56 x 1.31)

20.6 x 50.8

(0.81 x 2.00)

27.0 x 65.1

(1.06 x 2.56)

354

Loading...

Loading...