Appleton 20 Amp U-Line® ECH Factory Sealed Receptacles, 20 Amp U-Line® ECHT Factory Sealed Receptacles Instruction Sheet

Page 1

308203

UL Listed 139L

US Patent No. 3.346.709

Other Patents Pending

INSTRUCTION SHEET

PANEL MOUNTING RECEPTACLE

®

Rev. E 11/14/05

ECHT has tapered threads

(1-1/2 — 11-1/2 NPT).

Seals must be placed adjacent

to each conduit entrance.

Class I, Groups B, C, and D

Class II, Groups F*, G

Class III

Plugs also fi t NEMA 5-15R, 5-20R, or

6-20R receptacles in non-classifi ed

areas

Plugs are 2-wire, 3-pole, for cable

diameter .427” to .625”

STG Sealing Ring Set Screw

Class I, Groups B, C, and D

Class II, Groups F*, G

Class III

U-LINE

Receptacle interlocked with switches for use in hazardous atmosphere,

do not use in Class II, Group F locations which contain electrically conductive dusts.

Note: For NEMA 4X Rating use screw cover provided.

Caution: Receptacle interlocked with switches for use in hazardous atmosphere,

do not use in Class II, Group F locations which contain electrically conductive dusts.

Receptacle 125V

Catalog Number 20 Amp

ECHT2023 250V

U-Line Model B Plugs for use with above Receptacles

ECHT20232 20 Amp

Receptacle

Catalog Number 125V

15 Amp

ECP1523

ECP2023 125V

ECP20232 20 Amp

NCP1523 250V

NCP2023 20 Amp

ECP20232

Rev. E 11/14/05

ECH/ECHT Factory Sealed Receptacles

®

for Panel Mounting: Explosionproof, Dust-Ignitionproof.

20 Amp U-Line

Dead-Front Safety Construction — Grounding thru Extra Pole and Shell. Raintight.

opening. Minimum 7 full threads of engagement required for Group B; minimum

5 threads for groups C and D.

that prevents the escape of sparks or burning materials.

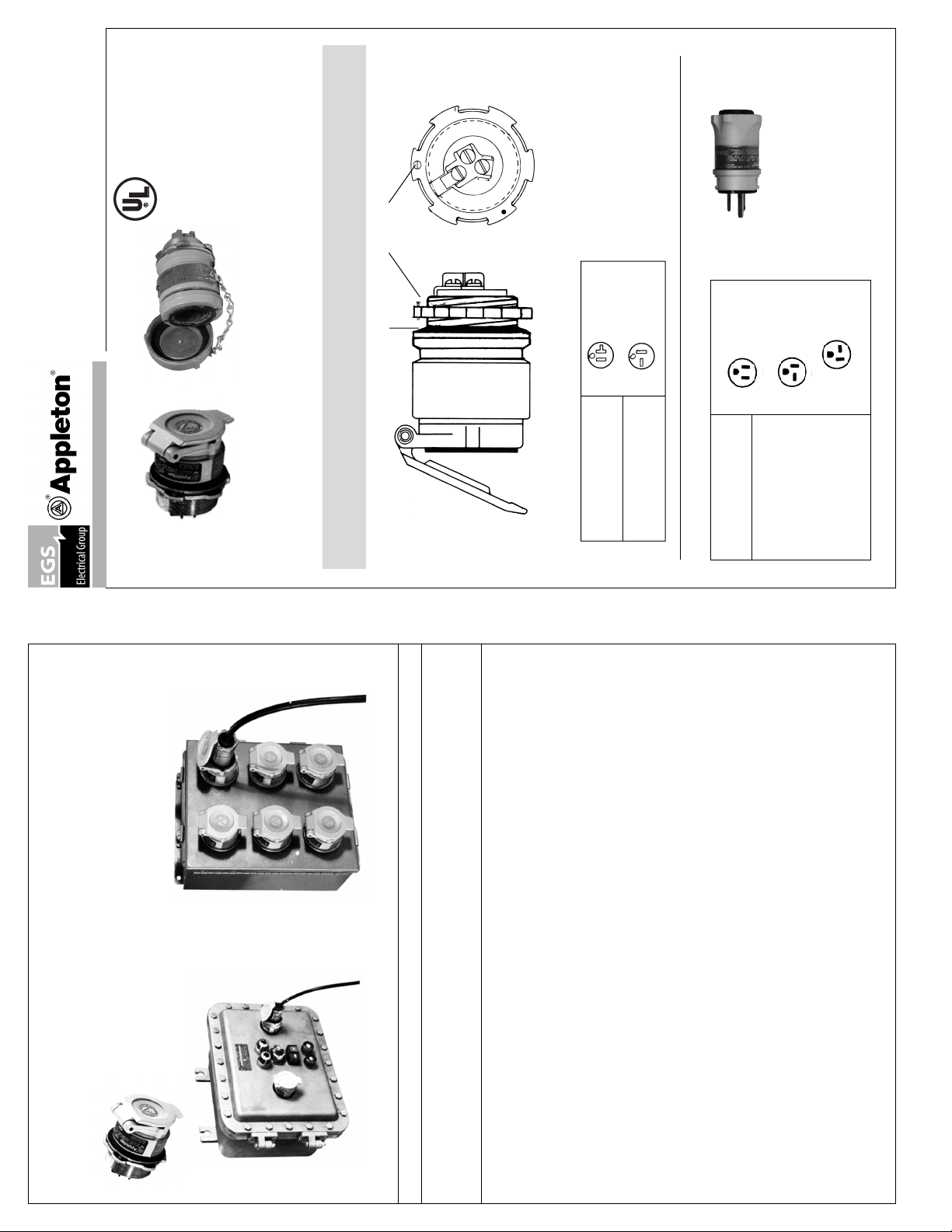

Recommended Enclosure Types for use with ECH/ECHT Receptacle

Hazardous

(Classifi ed) Suitable

Location Enclosure Type

Typical Class I, Division 1 Application Typical Class I, Division 2 Application

Class I, Div. 1 NEMA 7BCD with 1-1/2” (1-1/2—11-1/2 NPT) or 2” (2—11-1/2 NPSM) thread

Class I, Div. 2 NEMA 3, 3R, 3S, 4, 4X, 5, 12 or any suitable enclosed or gasketed enclosure

opening. Minimum 3 full threads of engagement required.

mizes entrance of dust and prevents the escape of sparks or burning materials.

(tapered) threads, such as in panelboards. The ECH is ideal for Class 1, Division 1 applications in

NPSM (straight) thread 2” openings. Class 1, Division 1 applications require a minimum of fi ve full

threads of engagement (seven for Group B).

closures having threaded or non-threaded openings for these receptacles. Where threaded en-

closures are used, they must have 1-1/2” NPT or NPSM threads to fi t the ECHT and 2” NPSM

Class II, Div. 1 NEMA 9F*, G with 1-1/2” ((1-1/2—11-1/2 NPT) or 2” (2—11-1/2 NPSM) thread

Class II, Div. 2 NEMA 3, 3S, 4, 4X, 5, 12 or any suitable enclosed or gasketed enclosure that mini-

• For Class I, Division 1 applications, the ECHT is ideal where unit is threaded into 1-1/2” NPT

(straight) threads to fi t the ECH. No thread engagement is required unless non-factorysealed de-

• For Class 1, Division 2 applications, the ECHT and ECH are suitable for use with approved en-

vices are also installed in the enclosure.

• Furnished with Steel locknut and neoprene sealing gasket assembly.

• Gasketed construction protects receptacle against moisture and dirt with plug in or out.

• Interior switch cylinder has neoprene O-ring at each end to seal out dust and moisture.

• Copper-free aluminum housing (4/10 of 1% max. copper content). Epoxy clad—two coat baked

fi nish.

Page 2

PANEL MOUNTING RECEPTACLE

®

U-LINE

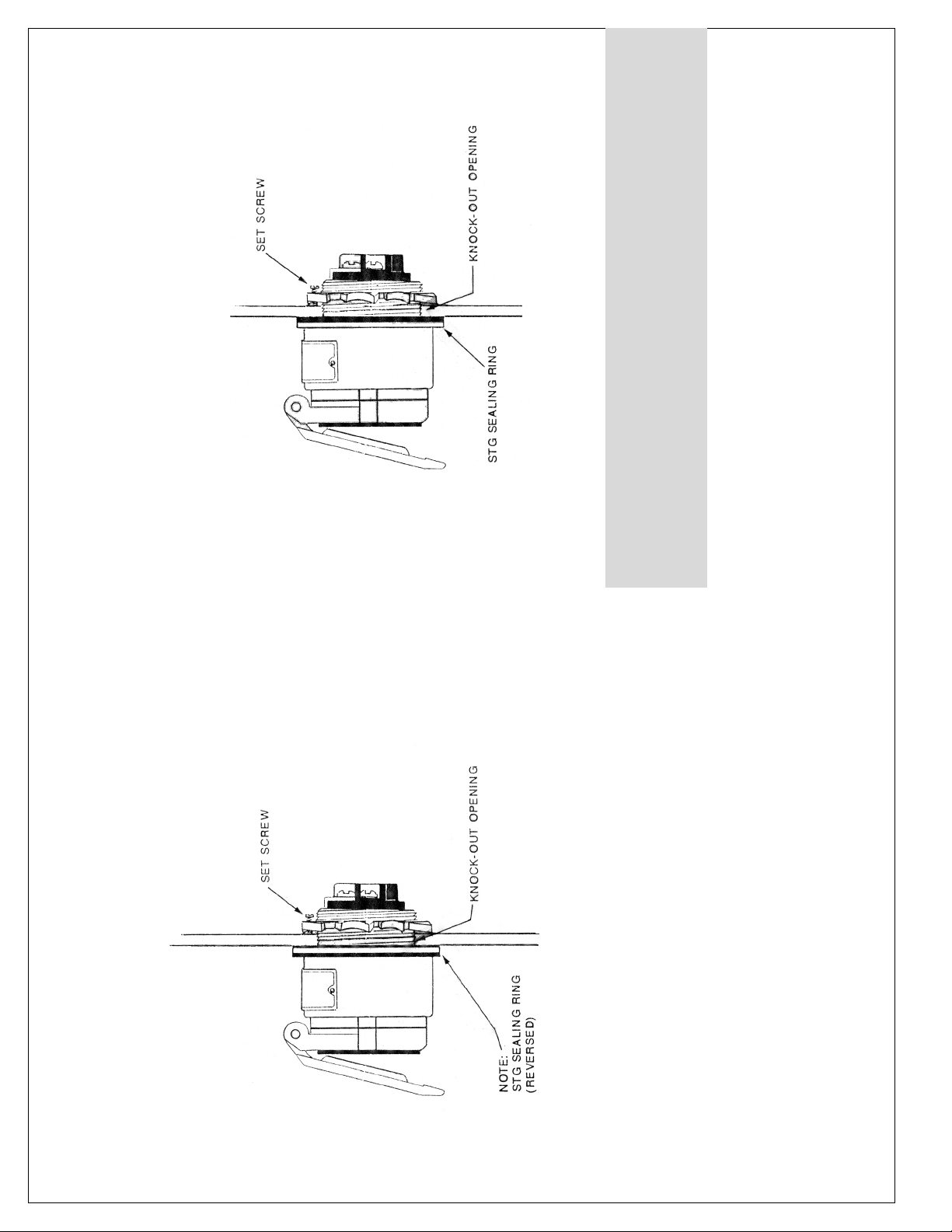

For Division 2 Location:

For Class I, receptacle must be mounted in any enclosure suitable for non-hazardous locations.

Install in 1-1/2—knock-out opening and tighten the locknut fi rmly and tighten the set screw to

prevent rotation when the receptacle is in the desired position. For Class II, a dust tight enclosure is

required.

For Raintight Location:

Receptacle must be mounted in enclosure suitable for raintight locations.

may be wired before assembly).

tacle and any live or dead metal parts of the enclosure, and between the dead metal parts of the

CAUTION

1. Attach wiring only after the receptacle has been secured in place as described above (Pigtails

2. A 1/2 inch spacing through air must be maintained between the wiring terminals of the recep-

7 FULL THREADS FOR GROUP B

5 FULL THREAD FOR GROUPS C AND D

3 FULL THREAD FOR GROUPS F AND G

receptacle and the live parts in the enclosure.

* For use only in equipment where the acceptability of the combination is determined by

Underwriters Laboratories, Inc.

Rev. E 11/14/05

For Division 1 Location:

Receptacle must be mounted in classifi ed enclosure suitable for class and group of the location.

Install in 1-1/2—11-1/2 NPT thread opening (tapered thread with at least 7 full threads engaged

for Group B, 5 full thread engaged for Groups C and D, 3 full thread engaged for Groups F and

G. Adjust receptacle to the desired position and then tighten the locknut fi rmly and tighten the set

screw to prevent rotation.

Loading...

Loading...