Aposun CHCRH700, CHCRH400 User Manual

CHCRH Series intelligent temperature and humidity controller using instruction manual

First of all, thank you for using this company's quality products. Please read this manual carefully before use so that you can fully understand and properly use the instrument

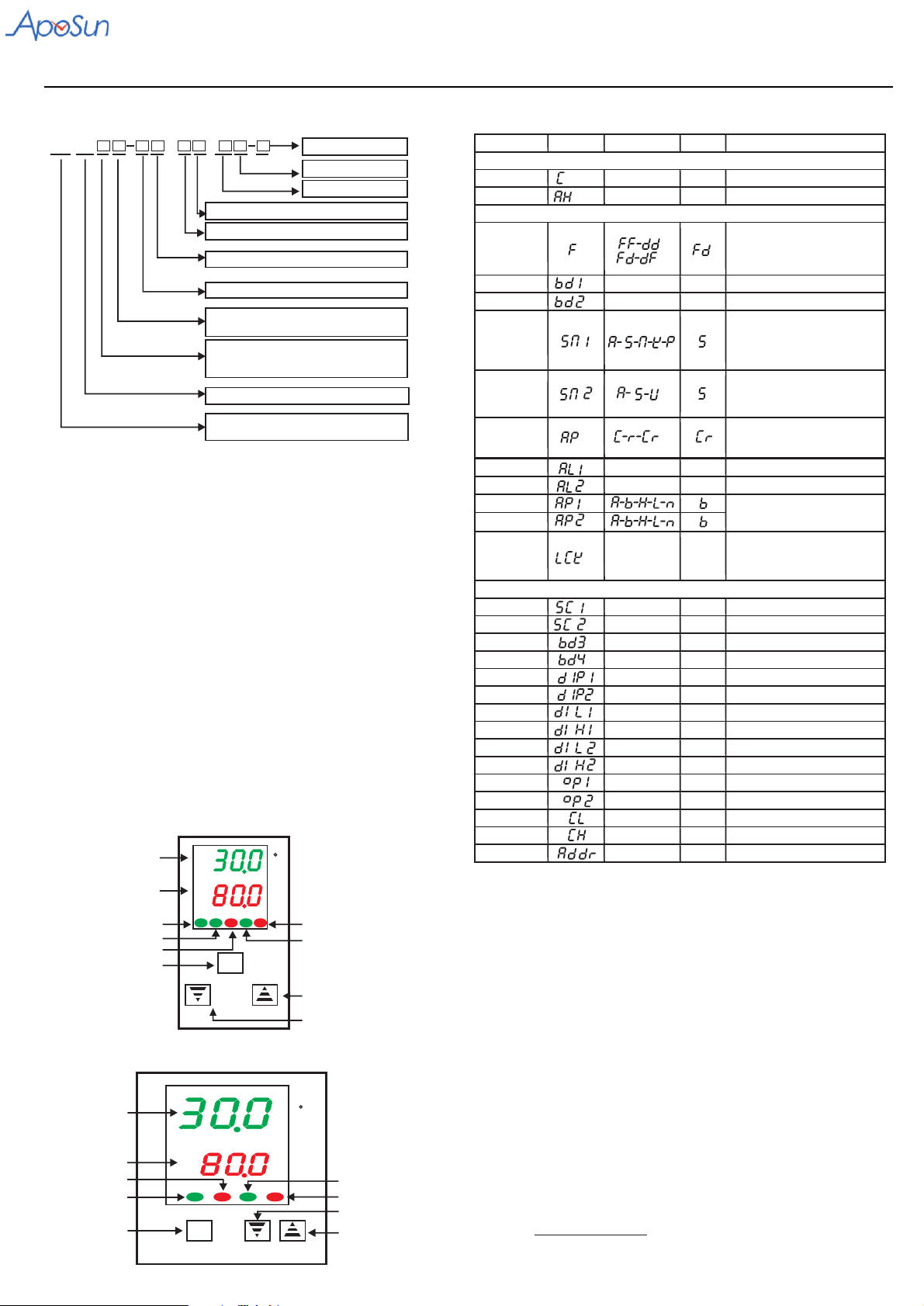

1. Description and meaning of model

CHCR H

-400

M

P

M*M

N N

N N N

*

B: AL2 alarm mode (see alarm function) N: no alarm

B: AL1 alarm mode (see alarm function) N: no alarm

Humidity output mode

Temperature output mode M:Relay V:SSR Voltage

Humidity input signal

V:0-3V S:SHT10 A:AM2305 B:AM2322B

Temperature output mode

N:NT C P:P T1 00 K :K type thermocouple

S:SH T10 A :A M2 305 B:AM2322B

Appearance of size 400:48*96mm

C:Temperature controller

CRH:Temperature and humidity controller

R:RS485 communication

X:Humidity current

changes to output

X: the temperature current

changes to the output

V:SSR Voltage

M:Relay

70 0:72* 7 2mm

RH:Humidity controller

2.Instrument technical indicators:

This instrument has the many kinds of temperature/humidity sensor signal input, the

convenient user to select different types, and a variety of combination control mode

(heating/humidification and cooling dehumidification, heating/dehumidification, cooling,

humidifying) output, convenient to users. The two auxiliary outputs are freely defined as

temperature or humidity assisted output. Multiple output options are available.

1. Temperature/humidity display resolution: 0.1 or 1 optional.

2. Temperature and humidity measurement accuracy:

K type thermocouple: 1 ℃; Pt100 platinum resistance: 0.5 ℃; NTC thermal ± ± resistor:±1 ℃

0-3v senor: ±5%RH(10%-90%RH)/

AM2305:Humity ±2%RH(10%-90%RH)/Temp. 0.3℃±

SHT10:Humity ±4.5%RH(10%-90%RH)/Temp. 0.5℃±

AM2322B:Humity ±2%RH(10%-90%RH)/Temp. 0.3℃±

4. Control mode: ON/OFF switch control mode.

5. Output of relay contact: AC250V/3A(drag) or AC250V/0.3A (inductive load)

6. Drive solid state relay signal output: 12VDC/ 30mA.

7. Working voltage: 85-265vac.

8, working environment:0~50 ℃, temperature humidity <85% RH no corrosion, no condensation

9. External dimensions (mm) : 48*96*96/72*72* 96; Installation opening: 45*92/68*68

3.Instrument panel and character

description (example) :

Temperature display window

C

4. Instrument parameter description: (non-engineering technical personnel, do

not change the engineering parameter value easily)

Parameter name

Temperature setting

Humidity setting value

Control mode

Temperature control return

Temperature control return

Temperature

input

specification

Humidity

input

specification

Alarm object

AL1 alarm value

AL2 alarm value

AL1 alarm mode

AL2 alarm mode

Parameters

of the lock

When LCK= 19, press the "SET" key to enter the engineering parameter group setting

Temperature correction

Humidity correction

Temperature alarm return

Humidity alarm return

Temperature value

Humidity value

Temperature limit

Upper temperature

display limit

Humidity display lower limit

Humidity display upper limit

Temperature transmitting output

Humidity transmitting output

Minimum temperature

setting range

Maximum temperature

setting range

Correspondence

address

characters Ranges

Press the "SET" button briefly

CL-CH

0. 0 ~9 9. 9%RH

Press the "SET" key for about 3 seconds to enter the field control parameter group setting

0. 0 ~5 0. 0

0. 0 ~5 0. 0

0. 0 ~9 9. 9

0. 0 ~9 9. 9

0~19

-2 0 . 0 ~ +50 .0

-2 0 . 0 ~ +50 .0

0~+5 0. 0

0~+5 0. 0

0~0.0

0~0.0

0.0~99 .9

0.0~40 0. 0

0.0~99 .9

0.0~99 .9

0-20/4-20

0-20/4-20

-20.0 ~1 00. 0

-2 0~400.0

0~80

initial value

Temperature control target (set value)

30 .0

Humidity control target value (set value)

80 .0

1.0

1.0

A:AM2305/AM2322B digital sensor

S:SHT10 digital sensor

V: 0-3v voltage signal humidity sensor

Cr:AL1 is the temperature alarm, AL2 is

C:AL1/AL2 is all temperature alarm.

R: AL1/AL2 is all humidity alarm.

AL 1alarm value

5. 0

AL 2alarm value

5. 0

A: lower deviation alarm.

B:Upper deviation alarm

H: upper limit alarm

L: lower limit alarm N: no alarm

LCK=0: field parameter values can be modified.

LCK=1: field parameter values cannot be

modified.

0

LCK=2-18:SV and field parameter values cannot

be modified,

LCK=19: enter engineering parameter group

Correction of measurement errors caused by temperature

0 .0

sensor problems

Correction of measurement errors caused by humidity sensor

0 .0

problems

Temperature alarm to cancel the return value

1.0

Humidity alarm to cancel the return value

1.0

Temperature display and resolution

0 .0

Humidity display and set value resolution

0 .0

0 .0

when the output is changed

100. 0

when the output is changed

0 .0

when the output is changed

100. 0

when the output is changed

The temperature current (mA) changes delivery

4-20

specification

Humidity current (mA) change delivery

4-20

specification

The limit temperature SV set the minimum

0

value

The limit temperature SV set the maximum

99.9

value

Set up the instrument communication address

1

Statement

FF: heating/humidifying control mode

Dd: cooling/pumping control mode

Fd: heating/pumping control mode

DF: cooling/humidifying control mode

Temperature control return value

Temperature control return value

A:AM2305/AM2322B digital sensor

S:SHT10 digital sensor

N: 50K NTC thermal resistance

K:K type thermocouple

P: PT100 platinum resistance

the humidity alarm.

Temperature as the minimum range value

Temperature as the maximum range value

Humidity as the minimum range value

Humidity as the maximum range value

Humidity display window

Signal lamp 1

Tem. output indicator light

Alarm indicator light 1

Function key

Temperature

display window

Humility display window

Signal lamp 1

Temperature output

indicator light

Function key

AL1 RLRH

C

COM AL2

SET

C

AL1 RH AL2

SET

%RH

Alarm indicator light 2

Humidity output indicator

light

The increasing key

The descending key

C

%RH

Humidity output

indicator light

Alarm indicator light 2

The descending key

The increasing key

5. Precautions for use and order:

1.The type and specification of the input signal of the instrument before use, and the

requirements of the installation control system shall be met in accordance with the

requirements of the installation control system.

2.Please contact the distributor or manufacturer according to the correct wiring

drawings or instructions.

3, K type thermocouple, if you want to extend the sensor lead, please use

thermocouple compensation wire,using internal automatic compensation models,

compensation conductor should be directly to the instrument of the terminal,middle can’t

into conventional wire, otherwise it will produce error of measurement.

4.When receiving the Pt100 platinum resistance, when using the compensation wire,

please use the same specification of low resistance wire,and the three-wire resistance

value is as much as possible to avoid measurement errors.

5.If the instrument sensor is connected to the wrong line or the input signal is

abnormal, the digital tube will display the fault code Err. Is the sensor damaged?

6.The instrument power line and the signal line should be separated from the large

current transmission line to reduce the influence of the electromagnetic radiation on the

instrument. In case of unavoidable,please use the shielded wire as far as possible.

7.The instrument can be energized only when the wiring is correct, especially the

power supply and output power line, which may damage the internal circuit of the instrument.

8, when ordering, please specify the instrument specific models (see the instruction

of "model meaning and expression" column) can also be note details of instrument

input signal types, specifications, measuring range, output method, instrument power

supply or other special technical requirements.

9.Accessories attached to the factory instrument:a set of mounting bracket,one copy,

and one set of temperature and humidity sensors. If there is any abnormality in the

use of instrument,please check the instruction manual or the after-sales service

hot-line email:cynthia-leung@qq.com for technical support

10.During the use of failure and unsealed, the manufacturer shall maintain free

maintenance within one year.

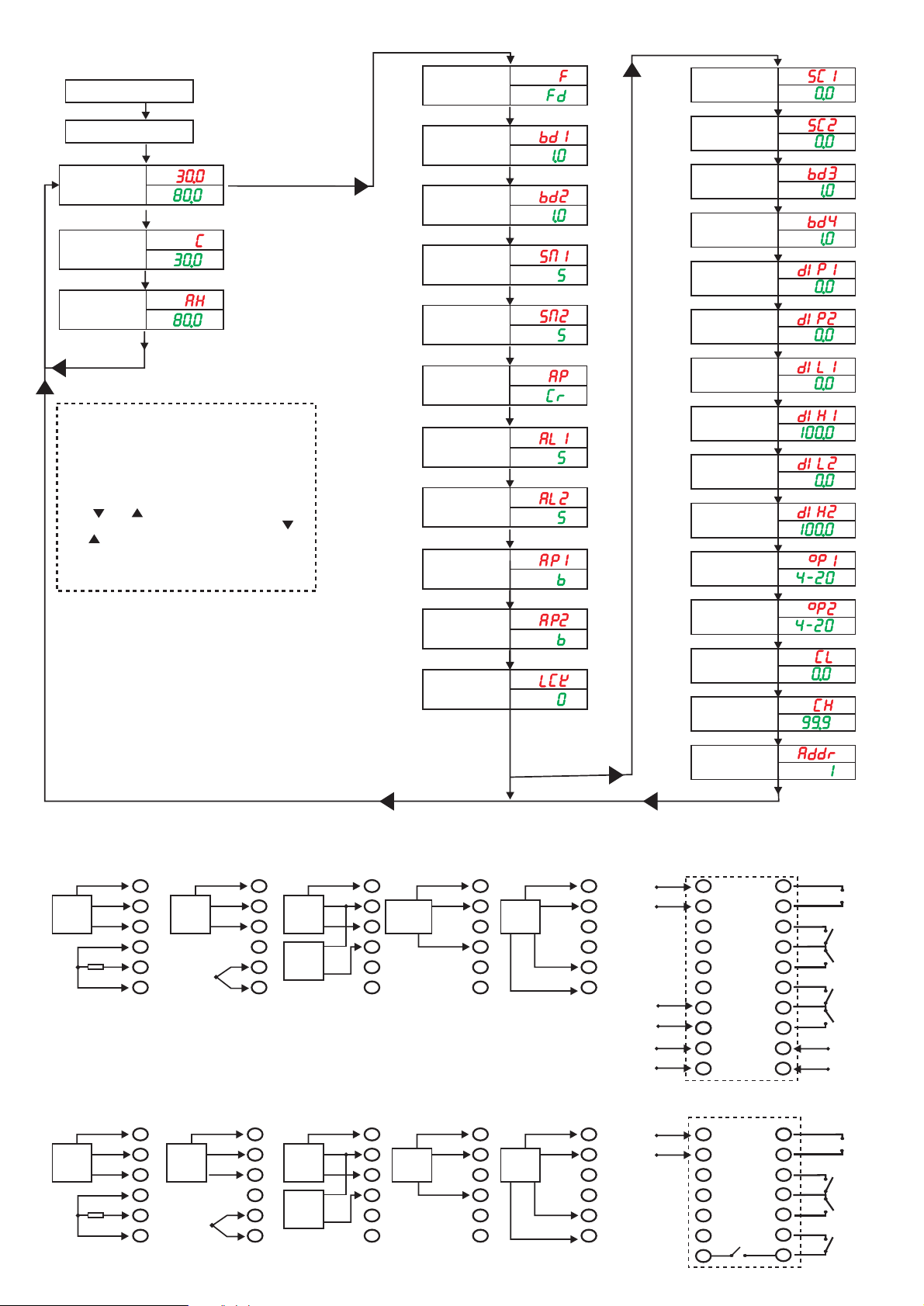

6.Procedure diagram of instrument parameter setting:

Correct connection

Electricity boot

Normal control

Press the "SET" button

for about 3 seconds to

enter the locale

parameter group setting

Status screen

Click the "SET" button

Temperature

setting

Click the "SET" button

Temperature

setting

Click the "SET" button

Precautions when setting parameters:

1. When the meter is in a set state, if no keystroke

is performed within 10 seconds, the meter will

automatically exit the set state and return to the

measurement and control operation state.

2. Press "SET" key to select the parameters, and

click " " and" "key to change the value.

3. In the setting state, the long and holding " "

and" "key can rapidly increase/decrease the value.

4.Under any parameter setting, press the "SET" key for

about 3 seconds, and immediately exit the SET state and

return to the measurement control status.

Control Type

Temperature

control

return

Humidity

control

return

Temperature input

signals

Humidity input

signal

Alarm object

Alarm set

value 1

Alarm set

value 2

AL1 alarm mode

AL2 alarm mode

Locker

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

SET LCK=19, then

press the "SET"

button

Correction of

temperature

measurement

Correction of

humidity

measurements

Temperature

alarm relieved

Humidity

alarm relieved

Temperature

resolution

Humidity

resolution

The temperature

shows the lower

limit

The temperature

shows the upper

limit

The humidity

displays the

lower limit

The humidity

displays the

upper limit

Temperature

variation

specifications

humidity

variation

specifications

Minimum

temperature

setting range

Maximum

temperature

setting

range

The communication

address

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

Click the "SET" button

7. Instrument wiring reference diagram:

0 -3 V

Pt100

platinum

resistance

sensor

Pt100

platinum

resistance

sensor

Humidity

sensor

0- 3 V

Humidity

sensor

5V

GND

OUT

5V

GND

OUT

1

0 -3 V

2

3

B

4

A

5

B

thermocouple

6

1

2

Humidity

sensor

3

B

4

A

B

5

thermocouple

6

K type

sensor

Humidity

sensor

K type

sensor

0- 3 V

GND

OUT

5V

GND

OUT

5V

1

0 -3 V

2

Humidity

sensor

3

4

50K

NTC

5

TC

+

-

sensor

6

1

0- 3 V

2

Humidity

sensor

3

4

5

TC

+

-

sensor

6

50K

NTC

5V

GND

OUT

5V

GND

OUT

1

2

3

4

5

6

1

2

3

4

5

6

brown

AM3 205

AM2 322B

brown

AM3 205

AM2 322B

black

black

GND

Blue

SDA

5V

GND

blue

SDA

CHCRH400 wiring diagram

5V

red

5V

1

2

SHT 10

3

4

yellow

5

6

blue

GND

green

SCH

DATA

1

2

3

4

5

6

Tempreature

transmitting

5V /12 V

GN D

4- 2 0MA

A

RS 485

B

+

-

1

2

3

4

5

6

7

8

9

10

1

1

2

1

1

1

3

4

1

1

1

5

1

1

6

1

1

7

1

8

9

1

20

10 0 ~26 5VA C

NO

CO M

NO

NO

alarm 1

CO M

Temperature

NO

control output

+

4- 2 0MA

-

alarm 2

Humidity

control output

Humidity

transmitting

CHCRH700 wiring diagram

red

5V

1

2

SHT 10

3

4

yellow

5

6

blue

GND

green

SCH

DATA

1

5V /12 V

2

GN D

3

4

5

6

alarm 1

1

2

3

4

5

6

7

8

10 0~26 5VA C

9

NO

10

1

1

2

1

1

113

NO

4

1

CO M

NO

NO

CO M

alarm 2

Humidity

control output

Temperature

control output

Loading...

Loading...