Page 1

60B Series

1

60B-100 Steel & 60B-700 Stainless Steel

Barstock Globe Valve

DESCRIPTION

The Apollo® 60B Series Steel & Stainless Steel Barstock Globe Valves are ideally suited for use in

instrumentation, sampling lines and ow control applications.

Job Name:

Job Location:

Engineer:

Contractor:

Tag:

PO Number:

Representative:

Wholesale Distributor:

Valve built to U.S. customary units.

Reference metric units also shown.

FEATURES

• Backseat stem design reduces pressure

exerted on the packing, prolonging

packing life. Design also prevents stem

from being accidentally turned out of

the valve.

• Integral metal-to-metal seat design.

• Externally adjustable PTFE packing is

standard, graphoil available as an

option.

• Malleable iron handle for long lasting,

reliable service.

• All valves 100% pressure tested

• Fully threaded bonnet to accommodate

optional panel mounting nut.

• Locking bonnet option available.

• All pressure retaining parts constructed

of ASTM materials.

• Meets the requirements of NACE

MR-01-75.

PERFORMANCE RATING

• Max Operating Pressure:

10,000 psig @ 100°F

689 bar @ 38°C

• Temperature Range:

-50°F to 1000°F

(-46°C to 538°C)

OPTIONS & SIZES

• -01 Standard Conguration

• -07 Tee Handle (SS)

• -09 Lock Bonnet

• -24 Graphoil Packing

• -57 Oxygen Cleaned

• -88 Panel Mount

• 07 Tee Handle (SS) not available on

3/4” (DN 20) and 1” (DN 25) sizes

• Female x Female NPT end connections

are standard.

• Socket weld end connections also

available.

STANDARD MATERIALS LIST

Part Name

Body

Hub

Material

60B-100

ASTM A108

Carbon Steel

ASTM A108

Carbon Steel

Stem ASTM A276 Stainless Steel

Stem Packing PTFE

Gland ASTM B484 ASTM B525

Gland Nut

1

Handle

ASTM A108

Carbon Steel

ASTM A47 Malleable Iron,

Zinc Phosphate Finish

Handle Nut Carbon Steel, Zinc Plated

NOTE 1:

• 1/2” (DN 15) and smaller come standard with

Cross Handle

• 3/4” (DN 20) and 1” (DN 25) sizes come standard

with Tee Handle

Material

60B-700

ASTM A276

316 Stainless Steel

ASTM A276

316 Stainless Steel

ASTM A276

316 Stainless Steel

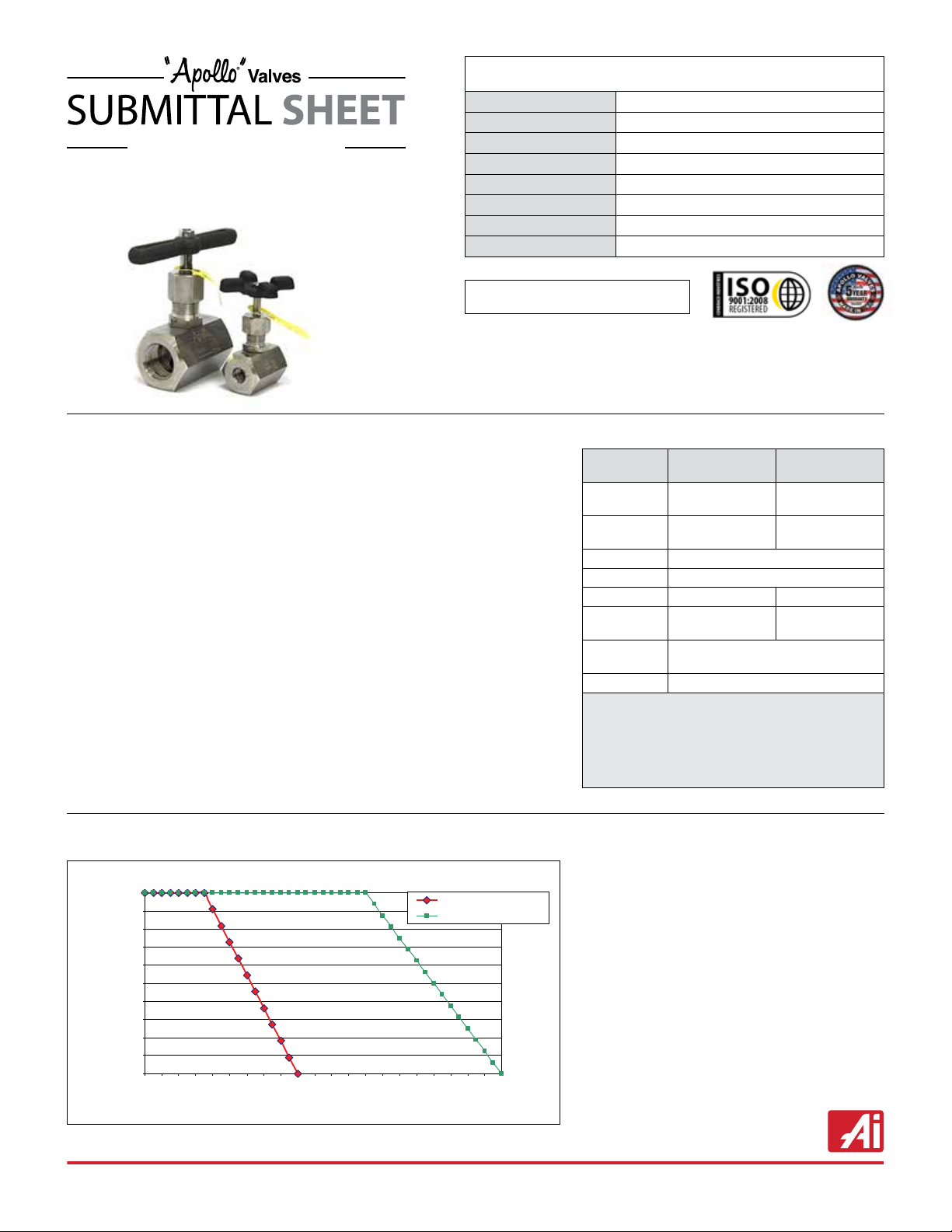

PRESSURE TEMPERATURE CURVE

P-T Curve

0000 (689)

9000 (621)

8000 (552)

7000 (483)

6000 (414)

5000 (345)

4000 (276)

Pressure in psig (bar)

3000 (207)

2000 (138)

1000 (69)

- 50 (-46)

0 (0)

0 (-18)

50 (10)

100 (38)

150 (66)

200 (93)

250 (121)

300 (149)

350 (177)

400 (204)

450 (232)

500 (260)

550 (288)

600 (316)

650 (343)

60B w/PTFE Seals

60B w/Graphoil Seals

700 (371)

750 (399)

800 (427)

850 (454)

900 (482)

950 (510)

1000 (538)

Apollo Valves, Manufactured by Conbraco Industries, Inc.

701 Matthews Mint-Hill Road, Matthews, NC 28105 USA

www.apollovalves.com | (704) 841-6000

This specication is provided for reference only. Conbraco Industries Inc. reserves the right to change any portion of this specication without notice and without incurring

obligation to make such changes to Conbraco products previously or subsequently sold. Please visit our website @ www.apollovalves.com for the most current information.

SS1324 © 05/13 Page 1 of 2

Page 2

60B Series

60B-100 Steel & 60B-700 Stainless Steel

Barstock Globe Valve

PRODUCT NUMBERING GUIDE

60 X - X X X - XX

SERIES PRESSURE RATING STYLE & MATERIAL END CONNECTIONS SIZE OPTIONS

Conbraco Barstock Globe Valves B = 10,000 PSI (689 bar) 1 = Carbon Steel Globe 0 = FNPT x FNPT 1 = 1/4” (DN 8) 01 = Standard Conguration

2 = Carbon Steel Angled Globe 2 = Socket Weld 2 = 3/8” (DN 10) 07 = Tee Handle (SS)

7 = 316 Stainless Steel Globe

8 = 316 Stainless Steel Angled 4 = 3/4” (DN 20) 24 = Grafoil Packing

Globe 5 = 1” (DN 25) 57 = Oxygen Cleaned

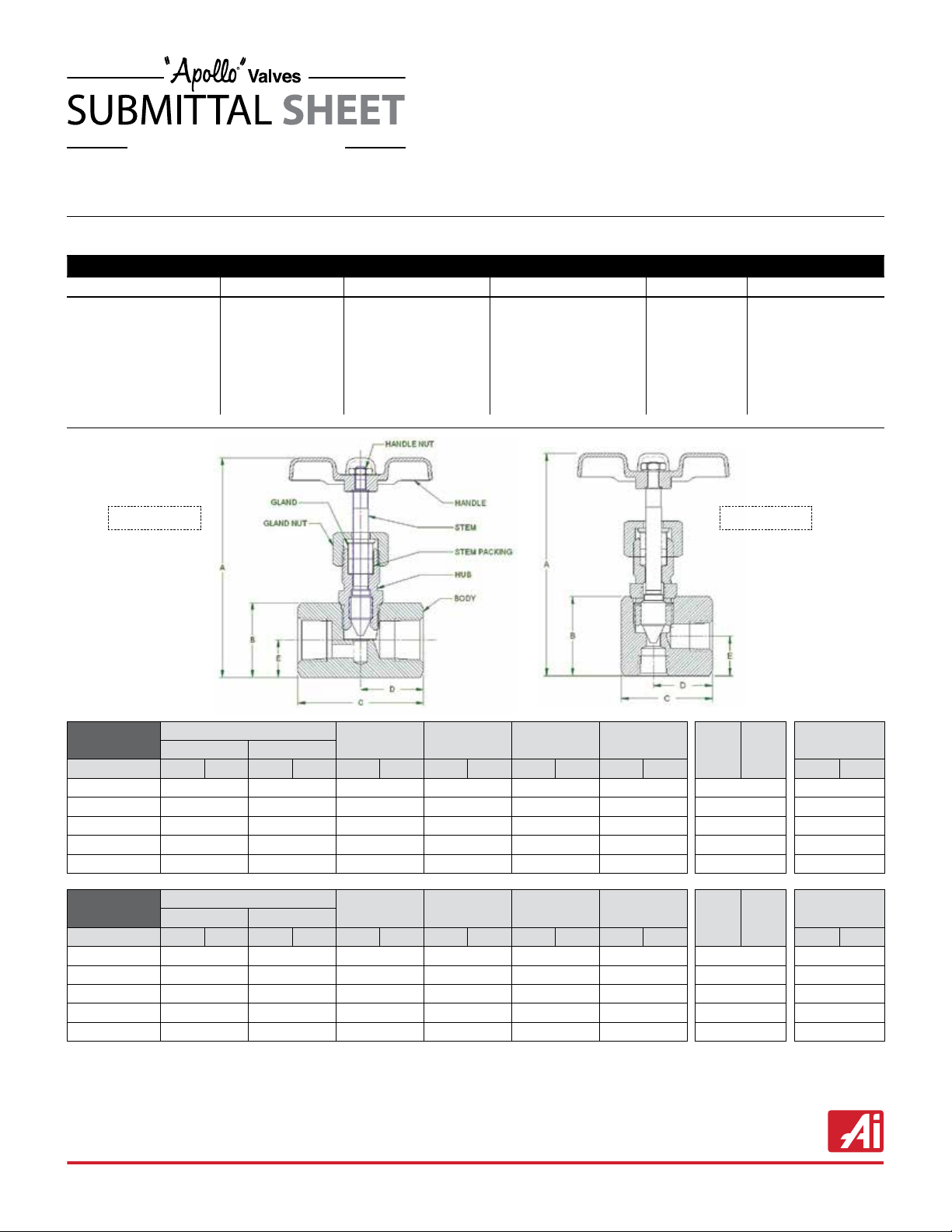

DIMENSIONS

See Table 1 See Table 2

(Not Available on Angle Valves)

3 = 1/2” (DN 15) 09 = Lock Bonnet

88 = Panel Mount

TABLE 1

Size In. (mm) In. (mm) In. (mm) In. (mm) In. (mm) In. (mm) lb. (kg)

1/4” (DN 8) 3.8 (96.5) 4.1 (104.1) 1.38 (35.1) 2.25 (57.2) 1.13 (28.7) 0.69 (17.5) 0.6 (0.5) 1.23 (0.6)

3/8” (DN 10) 3.8 (96.5) 4.1 (104.1) 1.38 (35.1) 2.25 (57.2) 1.13 (28.7) 0.69 (17.5) 0.9 (0.8) 1.19 (0.5)

1/2” (DN 15) 3.8 (96.5) 4.1 (104.1) 1.38 (35.1) 2.75 (69.9) 1.38 (35.1) 0.69 (17.5) 0.8 (0.7) 1.64 (0.7)

3/4" (DN 20) 4.9 (124.5) 5.4 (137.2) 2.00 (50.8) 3.19 (81.0) 1.60 (40.6) 1.00 (25.4) 2.7 (2.3) 3.34 (1.5)

1” (DN 25) 4.9 (124.5) 5.4 (137.2) 2.00 (50.8) 3.62 (92.0) 1.81 (46.0) 1.00 (25.4) 2.6 (2.2) 4.24 (1.9)

TABLE 2

Size In. (mm) In. (mm) In. (mm) In. (mm) In. (mm) In. (mm) lb. (kg)

1/4” (DN 8) 3.8 (96.5) 4.1 (104.1) 1.38 (35.1) 1.59 (40.4) 1.03 (26.2) 0.69 (17.5) 0.6 (0.5) 0.94 (0.9)

3/8” (DN 10) 3.8 (96.5) 4.1 (104.1) 1.38 (35.1) 1.59 (40.4) 1.06 (26.9) 0.69 (17.5) 0.9 (0.8) 0.90 (0.9)

1/2” (DN 15) 3.8 (96.5) 4.1 (104.1) 1.38 (35.1) 2.00 (50.8) 1.37 (34.8) 0.69 (17.5) 0.8 (0.7) 1.34 (0.6)

3/4" (DN 20) 4.9 (124.5) 5.4 (137.2) 2.00 (50.8) 2.50 (63.5) 1.62 (41.2) 1.00 (25.4) 2.7 (2.3) 2.79 (1.3)

1” (DN 25) 4.9 (124.5) 5.4 (137.2) 2.00 (50.8) 2.93 (74.4) 1.93 (49.0) 1.00 (25.4) 2.6 (2.2) 3.72 (1.7)

This specication is provided for reference only. Conbraco Industries Inc. reserves the right to change any portion of this specication without notice and without incurring

obligation to make such changes to Conbraco products previously or subsequently sold. Please visit our website @ www.apollovalves.com for the most current information.

SS1324 © 05/13 Page 2 of 2

Min. Max.

Min. Max.

A

A

B C D E

B C D E

Apollo Valves, Manufactured by Conbraco Industries, Inc.

701 Matthews Mint-Hill Road, Matthews, NC 28105 USA

Cv Kv

Cv Kv

www.apollovalves.com | (704) 841-6000

Weight

Weight

Loading...

Loading...