Page 1

WARNING:

VALVE MUST BE USED IN THE FULLY OPEN

POSITION FOR PROPER OPERATION OF BALL

CHECK. FAILURE TO DO SO COULD RESULT IN

BODILY INJURY AND/OR PROPERTY DAMAGE.

NOTE: NOT ALL WATER GAUGES ARE

EQUIPPED WITH BALL CHECKS.

WARNING!

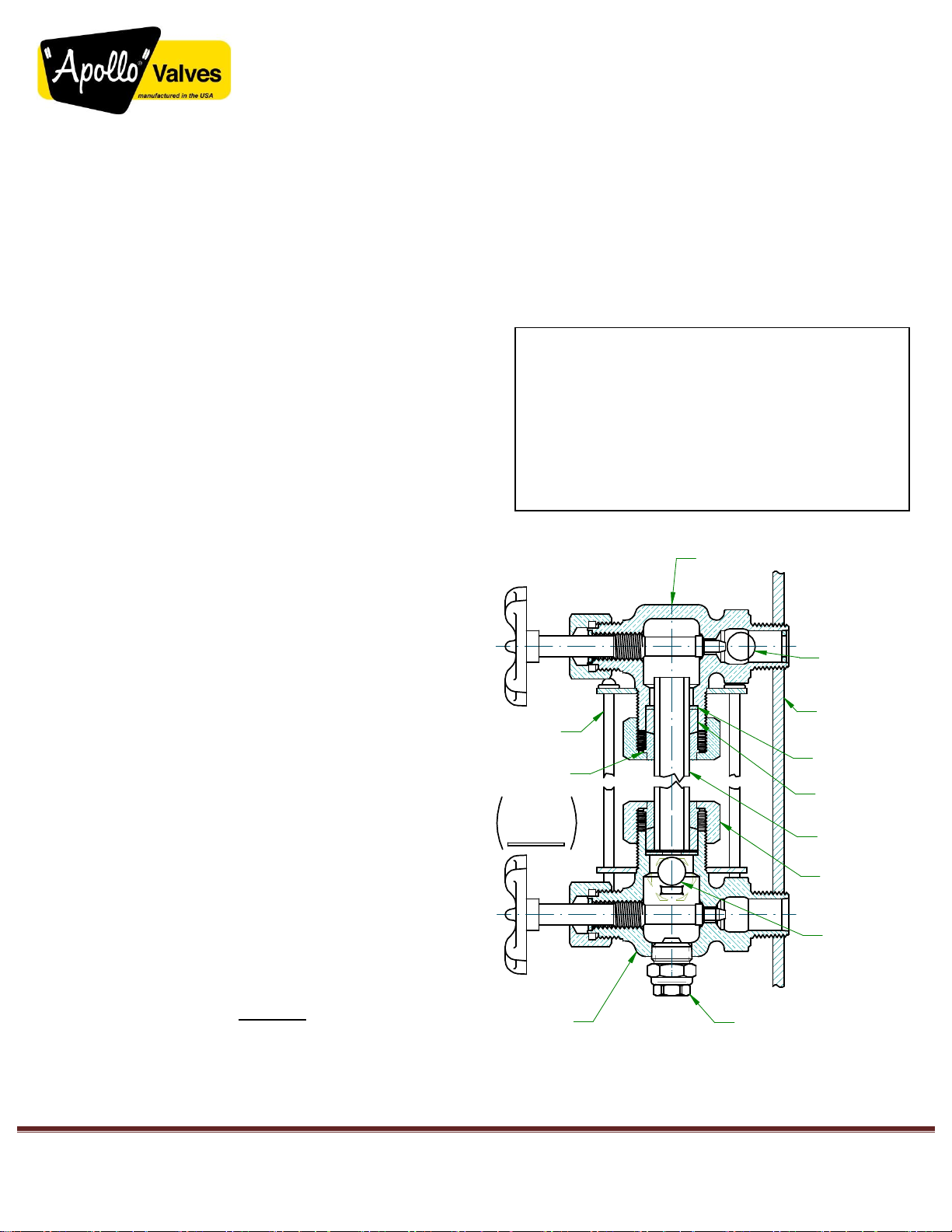

WATER GAUGE & GAUGE GLASS

TOP GAUGE FITTING

VESSEL

WALL

GAUGE

GLASS

GLASS

PACKING

NUT

GLASS

PACKING

GUARD

ROD

PACKING

GLAND

(OR

FRICTION

WASHER)

BOTTOM

GAUGE

FITTING

DRAIN

VALVE

BALL

CHECK

VALVE

ASME

AUTOMATIC

BALL

CHECK

VALVE

WASHER

INSTALLATION & MAINTENANCE GUIDE

(20, 21, 22, 23, 24, 25 Series)

INSTALLATION

Only properly trained personnel should install and

maintain water gauge glass and connections.

Remember to wear safety gloves and glasses during

installation. Before installing, make sure all parts are

free of chips and debris.

1. Read all warnings and instructions before

performing installation or maintenance.

2. Apply thread sealant or tape to pipe threads. Install

top gauge fitting (fitting without a drain valve) into

the uppermost tapping, wrench tighten the getting

until it is snug and the glass outlet is pointing at five

o’clock (about 1/8 turn from its final downward

vertical position).

8. Tighten (by hand) both glass packing nuts and then

tighten ½ turn more by wrench. Tighten only

enough to prevent leakage. DO NOT OVER

TIGHTEN! If any leakage should occur, tighten

slightly, a quarter turn at a time, checking for

leakage after each turn.

3. Install the bottom gauge fitting (the fitting with a

drain valve until it is snug and the glass outlet is

pointing directly upward.

4. Remove glass packing nut, friction washer (or

packing gland, depending on the model), and glass

packing from each gauge fitting. Slide the packing

nut, then friction washer or packing gland and then

glass packing onto each end of glass.

5. Gently insert one end of the glass into the top gauge

fitting. Keeping the glass inside the top fitting,

gently rotate the top gauge fitting clockwise until

vertically aligned with the bottom gauge fitting,

then insert glass into bottom fitting until glass

bottoms out on the shoulder inside the bottom

fitting.

6. Carefully raise glass about 1/16” and slide lower

glass packing down until the glass packing contacts

the lower gauge fitting. DO NOT allow the glass to

remain in contact with any metal!

7. Carefully slide upper glass packing up as far as

I-5334-00 REV K Page 1

possible.

Page 2

WARNING:

SAFETY GLASSES AND GLOVES SHOULD BE

WORN AT ALL TIMES WHEN WORKING WITH

OR EXAMINING WATER GAUGE GLASS AND

CONNECTIONS.

IMPROPER INSTALLATION OR MAINTENANCE

OF GAUGE GLASS AND CONNECTIONS CAN

CAUSE IMMEDIATE OR DELAYED BREAKAGE

RESULTING IN BODILY INJURY AND/OR

PROPERTY DAMAGE.

MAINTENANCE

Examine the gauge glass regularly for any signs of

clouding, scratching, erosion, or corrosion. The glass

should be inspected daily until the need for replacement

becomes apparent. This will help establish the routine

inspection and routine replacement schedules.

CLEANING

Use commercial non-abrasive glass cleaners to keep the

glass clean. Use diluted acids such as Hydrochloric

(muriatic) acid when regular cleaners do not seem to

work. Do not use wire brushes or any other abrasive

materials which could scratch the glass.

INSPECTION

Examine the surface of the glass for scratches,

corrosion, chips, cracks, surface flaws, or nicks. To do

this, shine a very bright concentrated light at an angle of

about 45 degrees. A defective glass will glisten as the

light strikes imperfections. Glass which appears cloudy

or roughened, will not respond to cleaning, and should

be replaced.

STORAGE

Keep gauge glass in original packaging until ready to

install

U.S. SAFE DRINKING WATER ACT WARNING:

It is illegal to use products that contain lead for potable water

services (Water intended for human consumption) in the

United States.

CALIFORNIA PROP 65: WARNING: Cancer and

Reproductive Harm - www.P65Warnings.ca.gov

FOR NON-LEAD FREE VALVES: It is illegal to use this product in

the United States for potable water services (water intended for

human consumption).

FOR LEAD FREE VALVES: This product complies with U.S. Safe

Drinking Water Act (SDWA). Suitable for potable water

applications intended for human consumption.

WATER GAUGE GLASS RECOMMENDATIONS

DO’s

DO verify proper gauge has been supplied.

DO examine gauge glass and packings carefully for damage

before installation.

DO install protective guards and utilize automatic ball

checks where necessary to help prevent injury in

case of glass breakage.

DO inspect the gauge glass daily, keep maintenance

records, and conduct routine replacements.

Do protect glass from sudden changes in temperatures such

as drafts, water spray, etc.

DO NOT’s

DO NOT use the glass if it contains any chips or any other

visible signs of damage.

DO NOT reuse any tubular glass or glass packings.

DO NOT subject gauge glass to bending or torsional

stresses.

DO NOT over tighten glass packing nuts.

DO NOT allow glass to touch any metal parts.

DO NOT exceed the recommended pressure of the gauge or

gauge glass.

DO NOT clean the gauge or gauge glass while pressurized

or in operation.

I-5334-00 REV K Page 2

Loading...

Loading...