SERIES

1/2009

Power Toroids Horizontal or Vertical Mount

Inductance tested at 1 kHz, <10 gauss and 0 ADC

DC Resistance at 25°C

Rated Idc based on 40°C maximum rise from 25°C ambient with

0 Arms

Windings single layered to maximize operating frequency and

minimize board space

Self leads solder coated to within 0.050" of seating plane

Other values available on request

Packaging Bulk only

Mounting Standard mounting is self-lead radial per Figure “1”.

Optional mounting methods are self-leaded horizontal per Figure

“2” or vertical base mounted per Figures “3” and “4”.

IGURE

F

1

FIGURE

3

*Complete part # must include series # PLUS the dash #

refer to www.delevanfinishes.com

PT

IGURE

F

2

STANDARD

VERTICAL HORIZONTAL

FIGURE

4

VERTICAL

2-LEAD

For surface finish information,

VERTICAL

4-LEAD

PTxxxR

D

A

S

H

N

U

IN

D

. (

µ

H

)

±1

MB

E

R

*

PT5-530

PT5-700

PT5-800

PT5-1000

PT10-530

PT10-680

PT10-820

PT10-990

PT25-680

PT25-800

PT25-900

PT25-1000

PT50-780

PT50-900

PT50-1020

PT50-1320

PT75-900

PT75-980

PT75-1260

PT75-1550

PT100-1000

PT100-1100

PT100-1260

PT100-1550

PT150-1040

PT150-1250

PT150-1500

PT150-2050

PT250-1200

PT250-1500

PT250-1800

PT300-1200

PT300-1500

PT300-1750

PT400-1200

PT400-1500

PT400-1750

PT500-1450

PT500-1750

PT500-2000

PT750-1400

PT750-1700

PT750-2050

PT1000-1400

PT1000-1750

PT1000-2050

5

% @ 1

D

C

R

MA

XIMU

M (

O

k

H

H

z

PT SERIES POWER TOROIDS

5

0.015

5

0.012

5

0.010

5

0.008

10

0.020

10

0.015

10

0.010

10

0.008

25

0.035

25

0.025

25

0.020

25

0.014

50

0.050

50

0.030

50

0.025

50

0.020

75

0.060

75

0.040

75

0.035

75

0.025

100

0.080

100

0.050

100

0.035

100

0.028

150

0.100

150

0.060

150

0.050

150

0.040

250

0.130

250

0.080

250

0.055

300

0.150

300

0.100

300

0.075

400

0.250

400

0.180

400

0.110

500

0.220

500

0.160

500

0.090

750

0.350

750

0.280

750

0.150

1000

0.620

1000

0.420

1000

0.200

MOUNTING AVAILABLE

ED

ID

C

(

A

F

IG

MPS)

6.1

7.4

10.6

12.8

4.9

6.8

9.3

13.2

4.4

6.6

7.0

10.4

3.8

5.6

7.0

11.0

3.9

5.2

7.4

10.6

3.5

5.1

7.8

10.3

3.4

5.7

7.7

12.3

3.8

6.1

9.1

3.3

5.5

7.3

2.4

4.7

6.0

3.4

5.0

8.0

2.6

3.7

6.4

1.8

3.1

5.9

R

MS)

AT

. “1

VER

IG

VER

”

. “3

T

” 2

-

IC

A

L

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

F

IG. “4” 4-LEAD

VE

RTICAL

L

EA

D

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

H

”

ST

O

A

N

T

D

IC

A

A

L

F

R

IZ

F

O

IG

N

. “2

T

R

A

D

L

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Power Inductors

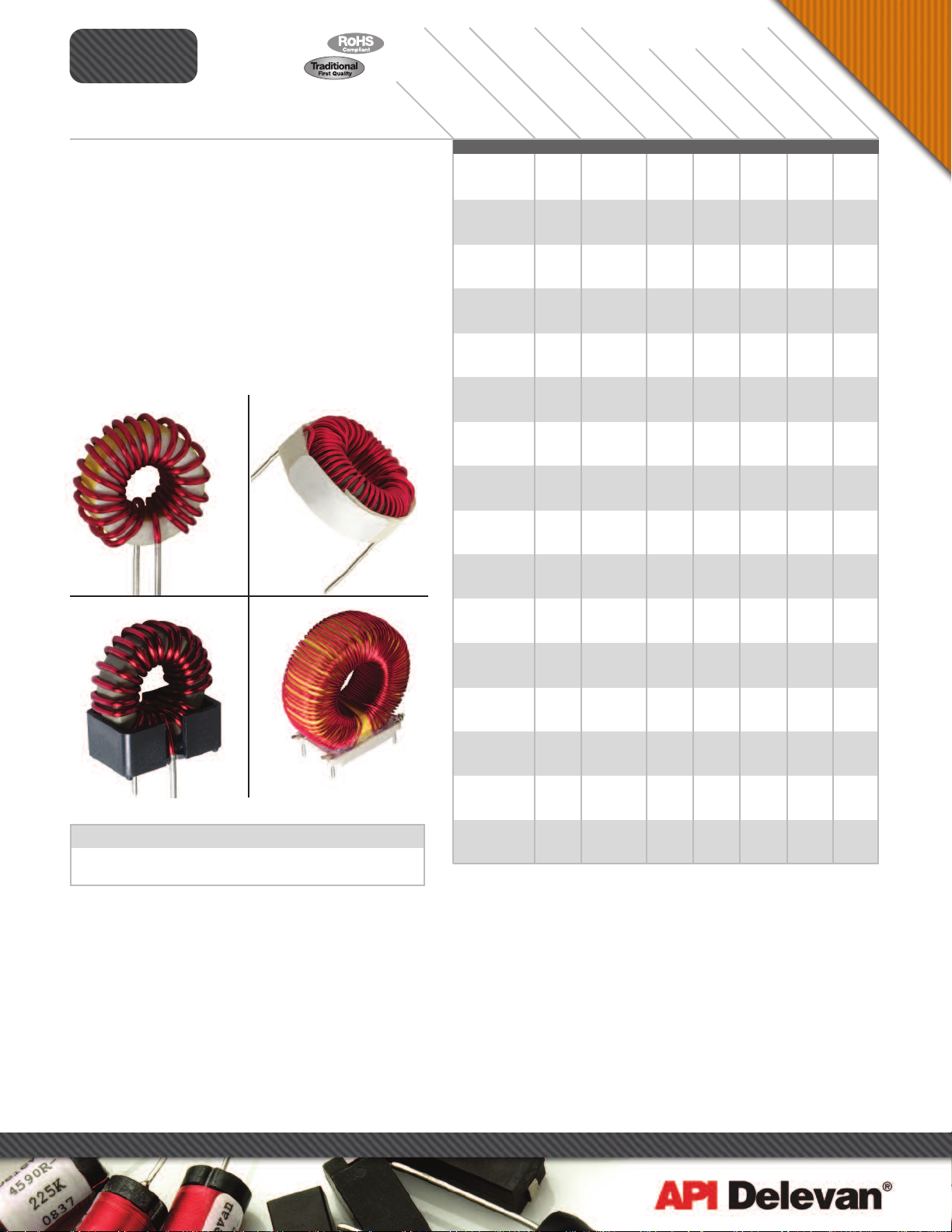

Notes to Figure 5 (Page 100) The PT Toroid Series inductance is specified at AC and DC signal levels which have no significant effect on the

permeability of the powdered iron toroidal core. Superimposed AC and DC voltages will change the permeability and therefore the inductance, under

operating conditions. Typically, DC currents will reduce the inductance, while AC signals will increase the inductance up to a point, before beginning to

decrease. Supporting information is provided, detailing the AC or DC effects upon each part. Saturation resulting from DC currents is specified with

waveform having less than a 1% ripple content. When considering the AC waveform, both the frequency and voltage level must be taken into account. As

an aid in defining what effect the alternating sine wave signal will have, the voltage/frequency factor curve can be used. To determine what change of

inductance can be expected at a given voltage level and frequency, simply divide the sinusoidal RMS voltage by the frequency. The voltage is in volts

and the frequency is in hertz. As an example, if using part number PT25-680 at a 1VRMS signal level, and a frequency of 25KHz, the voltage/frequency

factor is calculated to be: 1VRMS/25,000Hz = 40 x 10–6. Referring to the graph, a 39% increase in inductance would be expected.

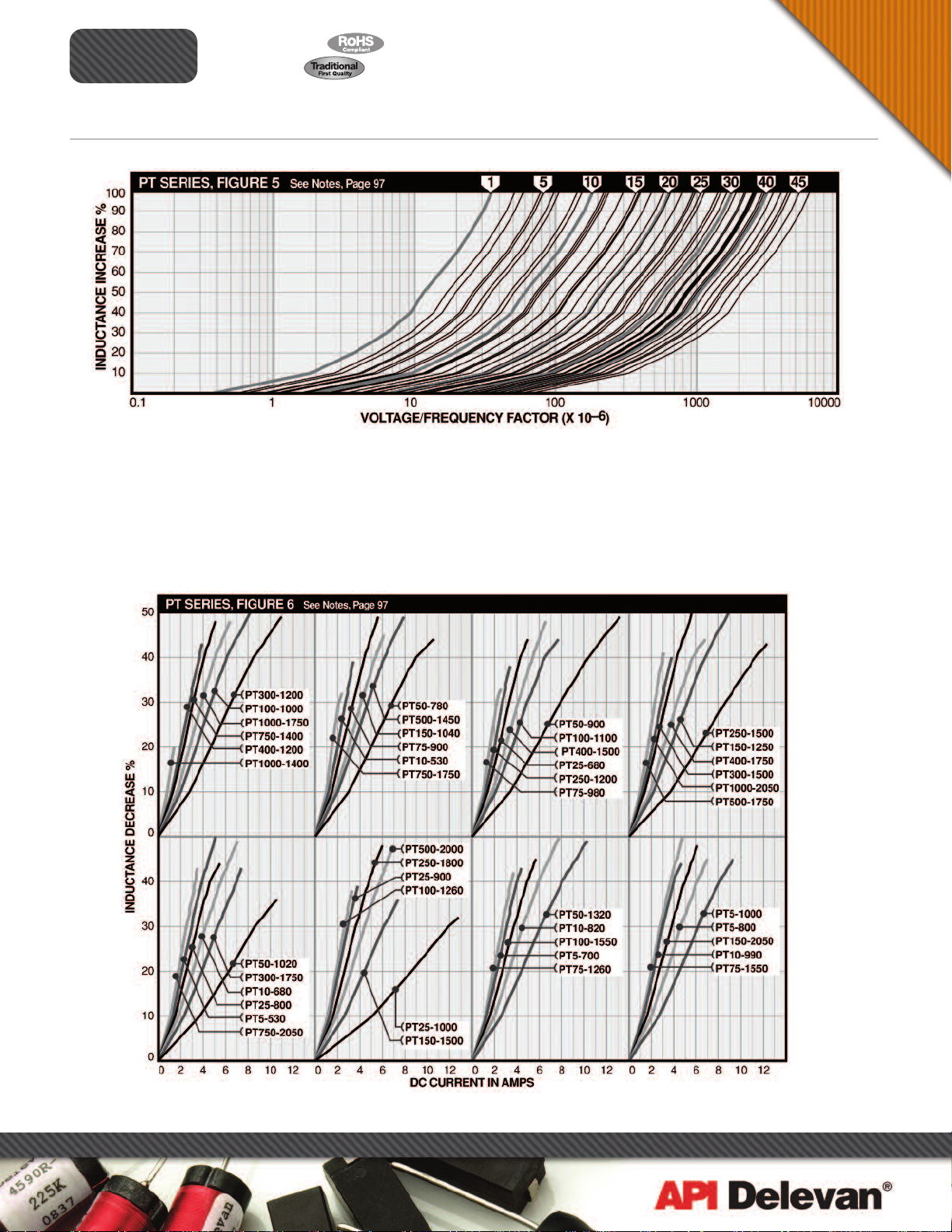

Notes to Figure 6 (Page 100) Typical saturation effects as a function of DC flowing through the part. Data is representative of a DC waveform with

less than 1% ripple, and an AC waveform less than 10 gauss.

Note This information is intended to be used in assisting the designer in part selection. Each operating application may contain other variables which

must be considered in part selection; such as temperature effects, waveform distortion, etc.…

Delevan Sales/Engin eering staff is available to provide information as needed to fit each application.

270 Quaker Rd., East Aurora NY 14052 • Phone 716-652-3600 • Fax 716-652-4814 • E-mail: apisales@delevan.com • www.delevan.com

ELECTRICAL

1/2009

IN

D

.(

µ

N

U

MB

P

A

ER

PT5-530

PT5-700

PT5-800

PT5-1000

PT10-530

PT10-680

P

T10-820

PT10-990

PT25-680

PT25-800

PT25-900

PT25-1000

PT50-780

PT50-900

PT50-1020

PT50-1320

PT75-900

PT75-980

PT75-1260

PT75-1550

PT100-1000

PT100-1100

PT100-1260

PT100-1550

PT150-1040

PT150-1250

PT150-1500

PT150-2050

PT250-1200

PT250-1500

PT250-1800

PT300-1200

PT300-1500

PT300-1750

PT400-1200

PT400-1500

PT400-1750

PT500-1450

PT500-1750

PT500-2000

PT750-1400

PT750-1700

PT750-2050

PT1000-1400

PT1000-1750

PT1000-2050

Power Inductors

(

c

o

n

t

inu

e

d

D Min.

In

c

h

4.32

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

e

)

s

Nominal

E

mm

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

In

c

h

e

s

0.025

0.032

0.040

0.051

0.025

0.032

0.040

0.051

0.025

0.032

0.040

0.051

0.025

0.032

0.040

0.051

0.025

0.032

0.040

0.051

0.025

0.032

0.040

0.051

0.025

0.032

0.040

0.051

0.025

0.036

0.051

0.025

0.032

0.045

0.020

0.025

0.040

0.025

0.036

0.045

0.020

0.025

0.036

0.016

0.025

0.032

F Nominal

mm

0.64

0.450

0.81

0.600

1.02

0.720

1.30

0.950

0.64

0.450

0.81

0.600

1.02

0.720

1.30

0.950

0.64

0.580

0.81

0.700

1.02

0.820

1.30

0.950

0.64

0.680

0.81

0.790

1.02

0.920

1.30

1.220

0.64

0.770

0.81

0.890

1.02

1.200

1.30

1.500

0.64

0.880

0.81

0.890

1.02

1.200

1.30

1.500

0.64

0.880

0.81

1.160

1.02

1.420

1.30

2.000

0.64

1.200

0.91

1.450

1.30

1.750

0.64

1.200

0.81

1.400

1.14

1.750

0.51

1.150

0.64

1.400

1.02

1.750

0.64

1.400

0.91

1.700

1.14

2.000

0.51

1.400

0.64

1.660

0.91

2.000

0.41

1.360

0.64

1.660

0.81

2.000

In

c

h

m

e

s

m

11.43

15.24

18.30

24.13

11.43

15.24

18.30

24.13

14.73

17.78

20.83

24.13

17.27

20.07

23.37

30.99

19.56

22.61

30.48

38.10

22.35

22.61

30.48

38.10

22.35

29.46

36.07

50.80

30.48

36.83

44.45

30.48

35.56

44.45

29.21

35.56

44.45

35.56

43.18

50.80

35.56

42.16

50.80

34.54

42.16

50.80

PT

S

E

RIE

S

C

mm

Nominal

In

c

h

e

0.17

0.24

0.31

0.34

0.17

0.24

0.29

0.34

0.29

0.28

0.30

0.37

0.27

0.30

0.43

0.53

0.29

0.30

0.49

0.53

0.29

0.42

0.49

0.53

0.41

0.48

0.50

0.80

0.49

0.50

0.69

0.48

0.51

0.65

0.48

0.50

0.70

0.50

0.62

0.76

0.48

0.62

0.78

0.48

0.62

0.78

s

mm

6.10

7.87

8.64

4.32

6.10

7.37

8.64

7.37

7.11

7.62

9.40

6.86

7.62

10.92

13.46

7.37

7.62

12.45

13.46

7.37

10.67

12.45

13.46

10.41

12.19

12.70

20.32

12.45

12.70

17.53

12.19

12.95

16.51

12.19

12.70

17.78

12.70

15.75

19.30

12.19

15.75

19.81

12.19

15.75

19.81

HYSICAL PARAMETERS

P

H

)

±

1

5

%

@ 1k

R

T

R

MA

H

T

X. (

O

H

z

5

0.015

5

0.012

5

0.010

5

0.008

10

0.020

10

0.015

10

0.010

10

0.008

25

0.035

25

0.025

25

0.020

25

0.014

50

0.050

50

0.030

50

0.025

50

0.020

75

0.060

75

0.040

75

0.035

75

0.025

100

0.080

100

0.050

100

0.035

100

0.028

150

0.100

150

0.060

150

0.050

150

0.040

250

0.130

250

0.080

250

0.055

300

0.150

300

0.100

300

0.075

400

0.250

400

0.180

400

0.110

500

0.220

500

0.160

500

0.090

750

0.350

750

0.280

750

0.150

1000

0.620

1000

0.420

1000

0.200

ED

M

S)

ID

C

(

A

m

p

s

)

6.1

7.4

10.6

12.8

4.9

6.8

9.3

13.2

4.4

6.6

7.0

10.4

3.8

5.6

7.0

11.0

3.9

5.2

7.4

10.6

3.5

5.1

7.8

10.3

3.4

5.7

7.7

12.3

3.8

6.1

9.1

3.3

5.5

7.3

2.4

4.7

6.0

3.4

5.0

8.0

2.6

3.7

6.4

1.8

3.1

5.9

Max.

A

In

c

h

e

0.53

0.70

0.80

1.00

0.53

0.68

0.82

0.99

0.68

0.80

0.90

1.00

0.78

0.90

1.02

1.32

0.90

0.98

1.26

1.55

1.00

1.10

1.26

1.55

1.04

1.25

1.50

2.05

1.20

1.50

1.80

1.20

1.50

1.75

1.20

1.50

1.75

1.45

1.75

2.05

1.40

1.70

2.05

1.40

1.75

2.05

s

13.46

17.78

20.32

25.40

13.46

17.27

20.83

25.15

17.27

20.32

22.86

25.40

19.81

22.86

25.91

33.53

22.86

24.89

32.00

39.37

25.40

27.94

32.00

39.37

26.42

31.75

38.10

52.07

30.48

38.10

45.72

30.48

38.10

44.45

30.48

38.10

44.45

36.83

44.45

52.07

35.56

43.18

52.07

35.56

44.45

52.07

R

D

A

C

Power Toroids

Max.

B

In

c

m

h

e

m

s

SERIES PT IRON CORE

0.23

0.33

0.36

0.40

0.23

0.33

0.37

0.40

0.37

0.35

0.40

0.40

0.36

0.38

0.62

0.63

0.36

0.38

0.60

0.64

0.36

0.50

0.60

0.64

0.50

0.58

0.62

0.92

0.55

0.60

0.77

0.55

0.60

0.76

0.55

0.60

0.78

0.58

0.75

0.88

0.55

0.70

0.85

0.55

0.70

0.85

5.84

8.38

9.14

10.16

5.84

8.38

9.40

10.16

9.40

8.89

10.16

10.16

9.14

9.65

15.75

16.00

9.14

9.65

15.24

16.26

9.14

12.70

15.24

16.26

12.70

14.73

15.75

23.37

13.97

15.24

19.56

13.97

15.24

19.30

13.97

15.24

19.81

14.73

19.05

22.35

13.97

17.78

21.59

13.97

17.78

21.59

Note: Vertical configuration is standard; add suffix “HM” for horizontal mounting

FIGURE 1: STANDARD VERTICAL MOUNT FIGURE 2: HORIZONTAL MOUNT

270 Quaker Rd., East Aurora NY 14052 • Phone 716-652-3600 • Fax 716-652-4814 • E-mail: apisales@delevan.com • www.delevan.com

ELECTRICAL

1/2009

IN

D

.(

µ

H

N

U

MB

P

A

R

ER

T

T5-530-VM

P

T5-700-VM

P

PT5-800-VM

T10-530-VM

P

PT10-680-VM

T10-820-VM

P

T25-680-VM

P

PT25-800-VM

T25-900-VM

P

PT50-780-VM

T50-900-VM

P

T50-1020-VM

P

PT75-900-VM

T75-980-VM

P

PT75-1260-VM

T100-1000-VM

P

PT100-1100-VM

PT100-1260-VM

T150-1040-VM

P

PT150-1250-VM

T150-1500-VM

P

PT250-1200-VM

PT250-1500-VM

PT300-1200-VM

PT300-1500-VM

PT400-1200-VM

PT400-1500-VM

PT400-1750-VM

PT500-1450-VM

PT500-1750-VM

PT750-1400-VM

PT750-1700-VM

PT750-2050-VM

PT1000-1400-VM

PT1000-1750-VM

PT1000-2050-VM

Power Inductors

(

c

o

n

t

inu

e

d

D Typical

In

c

h

0.025

0.032

0.040

0.025

0.032

0.040

0.025

0.032

0.040

0.025

0.032

0.040

0.025

0.032

0.040

0.025

0.032

0.040

0.025

0.032

0.050

0.025

0.050

0.025

0.050

0.020

0.050

0.050

0.050

0.050

0.050

0.050

0.050

0.050

0.050

0.050

)

e

s

Max.

E

mm

0.63

0.81

1.02

0.63

0.81

1.02

0.63

0.81

1.02

0.63

0.81

1.02

0.63

0.81

1.02

0.63

0.81

1.02

0.63

0.81

1.27

0.63

1.27

0.63

1.27

0.51

1.27

1.27

1.27

1.27

1.27

1.27

1.27

1.27

1.27

1.27

In

c

h

e

s

0.640

0.810

0.910

0.640

0.790

0.930

0.790

0.910

1.010

0.890

1.110

1.130

1.010

1.090

1.390

1.130

1.230

1.390

1.170

1.380

1.630

1.330

1.630

1.330

1.630

1.330

1.630

1.880

1.580

1.880

1.530

1.830

2.180

1.530

1.980

2.180

F Typical

In

mm

16.26

0.290

20.57

23.11

0.415

16.26

0.290

20.07

0.325

23.62

0.415

20.07

0.325

23.11

0.415

25.65

0.475

22.61

0.415

28.19

0.415

28.70

0.625

25.65

27.69

0.475

35.31

0.625

28.70

0.475

31.24

0.475

35.31

0.625

29.72

0.475

35.05

0.625

41.40

0.900

33.78

0.625

41.40

0.900

33.78

0.625

41.40

0.900

33.78

0.625

41.40

0.900

47.75

1.200

40.13

0.900

47.75

1.200

38.86

0.900

46.48

1.200

55.37

1.200

38.86

0.900

50.29

1.200

55.37

1.200

c

h

e

s

0.325

0.475

mm

7.37

8.25

10.54

7.37

8.25

10.54

8.25

10.54

12.06

10.54

10.54

15.87

12.06

12.06

15.87

12.06

12.06

15.87

12.06

15.87

22.86

15.87

22.86

15.87

22.86

15.87

22.86

30.48

22.86

30.48

22.86

30.48

30.48

22.86

30.48

30.48

PT

S

E

RIE

S

In

mm

0.220

11.43

0.300

0.220

0.300

0.300

0.300

0.300

0.450

0.300

0.300

0.500

15.24

0.450

0.500

0.450

0.450

0.500

0.450

0.500

0.600

0.500

0.600

0.500

0.600

0.500

0.600

0.700

0.600

0.700

0.600

0.700

0.700

0.600

0.700

0.700

c

h

e

s

0.300

0.450

mm

5.59

7.62

7.62

5.59

7.62

7.62

7.62

7.62

11.43

7.62

7.62

12.70

11.43

11.43

12.70

11.43

11.43

12.70

11.43

12.70

15.24

12.70

15.24

12.70

15.24

12.70

15.24

17.78

15.24

17.78

15.24

17.78

17.78

15.24

17.78

17.78

HYSICAL PARAMETERS

P

)

±

1

5

%

@ 1k

MA

H

X. (

z

100

100

100

150

150

150

250

250

300

300

400

400

400

500

500

750

750

750

1000

1000

1000

ED

ID

C

(

O

H

M

S)

5

0.015

5

0.012

0.010

5

0.020

10

0.015

10

0.010

10

0.035

25

0.025

25

0.020

25

0.050

50

0.030

50

0.025

50

7

0.060

5

0.040

75

0.035

75

0.080

0.050

0.035

0.100

0.060

0.050

0.130

0.080

0.150

0.100

0.250

0.180

0.110

0.220

0.160

0.350

0.280

0.150

0.620

0.420

0.200

F

A

m

p

s

)

6.1

7.4

10.6

4.9

6.8

9.3

4.4

6.6

7.0

3.8

5.6

7.0

3.9

5.2

7.4

3.5

5.1

7.8

3.4

5.7

7.7

3.8

6.1

3.3

5.5

2.4

4.7

6.0

3.4

5.0

2.6

3.7

6.4

1.8

3.1

5.9

Max. B Max. C Typical

A

IG

In

U

c

R

h

E#

e

s

SERIES PT VERTICAL MOUNT IRON CORE

3

0.580

3

0.650

0.830

3

0.580

3

0.650

3

0.830

3

0.650

3

0.830

3

0.950

3

0.830

3

0.830

3

1.250

3

3

0.950

0.950

3

1.250

3

0.950

3

0.950

3

1.250

3

0.950

3

1.250

3

1.500

4

1.250

3

1.500

4

1.250

3

1.500

4

1.250

3

1.500

4

1.750

4

1.450

4

1.750

4

1.400

4

1.700

4

2.050

4

1.400

4

1.750

4

2.050

4

R

D

A

C

T

R

Power Toroids

In

c

m

h

e

m

s

14.73

0.340

16.51

0.450

21.08

0.450

14.73

0.340

16.51

0.450

21.08

0.450

16.51

0.450

21.08

0.450

24.13

0.600

21.08

0.450

21.08

0.450

31.75

0.700

24.13

0.600

24.13

0.600

31.75

0.700

24.13

0.600

24.13

0.600

31.75

0.700

24.13

0.600

31.75

0.700

38.10

0.800

31.75

0.700

38.10

0.800

31.75

0.700

38.10

0.800

31.75

0.700

38.10

0.800

44.45

0.900

36.83

0.800

44.45

0.900

35.56

0.800

43.18

0.900

52.07

0.900

35.56

0.800

44.45

0.900

52.07

0.900

8.64

11.43

8.64

11.43

11.43

11.43

11.43

15.24

11.43

11.43

17.78

15.24

17.78

15.24

15.24

17.78

15.24

17.78

20.32

17.78

20.32

17.78

20.32

17.78

20.32

22.86

20.32

22.86

20.32

22.86

22.86

20.32

22.86

22.86

FIGURE 3: 2-LEAD VERTICAL BASE MOUNT FIGURE 4: 4-LEAD VERTICAL BASE MOUNT

270 Quaker Rd., East Aurora NY 14052 • Phone 716-652-3600 • Fax 716-652-4814 • E-mail: apisales@delevan.com • www.delevan.com

Power Inductors

1/2009

SERIES

Power Toroids Horizontal or Vertical Mount

KEY TO FIGURE 5 CURVE NUMBERS Graphs apply to all mounting styles. For more detailed graphs, contact factory.

1) PT5-530

2) PT10-530

3) PT5-700

4) PT5-800

5) PT10-680

6) PT5-1000

PT

7) PT10-820

8) PT10-990

9) PT25-680

10) PT25-800

11) PT25-900

12) PT25-1000

13) PT50-780

14) PT50-900

15) PT75-900

16) PT75-980

17) PT50-1020

18) PT100-1000

19) PT100-1100

20) PT50-1320

21) PT150-1040

22) PT75-1260

23) PT100-1260

24) PT75-1550

25) PT100-1550

26) PT150-1250

27) PT150-1500

28) PT250-1200

29) PT300-1200

30) PT250-1500

31) PT400-1200

32) PT300-1500

33) PT400-1500

34) PT250-1800

35) PT150-2050

36) PT300-1750

37) PT500-1450

38) PT400-1750

39) PT750-1400

40) PT500-1750

41) PT1000-1400

42) PT750-1750

PTxxxR

43) PT500-2000

44) PT1000-1750

45) PT750-2050

46) PT1000-2050

For more detailed graphs, contact factory

270 Quaker Rd., East Aurora NY 14052 • Phone 716-652-3600 • Fax 716-652-4814 • E-mail: apisales@delevan.com • www.delevan.com

Loading...

Loading...