Page 1

AUT OMATION

Operator’s Manual

PRODUCTS

GROUP, INC.

LFE Series

Industrial OEM Low Cost

Liquid Level Switches

Rev . A1, 4/07

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • E-mail: sales@apgsensors.com

Page 2

LFE Series Rev . A1, 4/07

Table of Contents

Warranty .............................................................................................................3

Introduction ......................................................................................................4

Speci cation ......................................................................................................4

Installation Location .......................................................................................6

Wiring ..................................................................................................................7

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

2

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 3

Rev . A1, 4/07 LFE Series

• Warranty and Warranty Restrictions

APG warrants its products to be free from defects of material and workmanship

and will, without charge, replace or repair any equipment found defective

upon inspection at its factory, provided the equipment has been returned,

transportation prepaid, within 24 months from date of shipment from factory.

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES

ALL OTHER WARRANTIES NOT EXPRESSLY SET FORTH HEREIN,

WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE INCLUDING BUT NOT LIMITED TO ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

No representation or warranty, express or implied, made by any sales

representative, distributor, or other agent or representative of APG which is

not specifi cally set forth herein shall be binding upon APG. APG shall not be

liable for any incidental or consequential damages, losses or expenses directly

or indirectly arising from the sale, handling, improper application or use of the

goods or from any other cause relating thereto and APG’s liability hereunder, in

any case, is expressly limited to the repair or replacement (at APG’s option) of

goods.

Warranty is specifi cally at the factory. Any on site service will be provided at

the sole expense of the Purchaser at standard fi eld service rates.

All associated equipment must be protected by properly rated electronic/

electrical protection devices. APG shall not be liable for any damage due

to improper engineering or installation by the purchaser or third parties.

Proper installation, operation and maintenance of the product becomes the

responsibility of the user upon receipt of the product.

Returns and allowances must be authorized by APG in advance. APG will

assign a Return Material Authorization (RMA) number which must appear

on all related papers and the outside of the shipping carton. All returns are

subject to the fi nal review by APG. Returns are subject to restocking charges as

determined by APG’s “Credit Return Policy”.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

3

Page 4

LFE Series Rev . A1, 4/07

• Introduction

The miniature magnetic level sensors are used for liquid level detection.

They have been designed for reliable operation in small tanks and containers.

Their rugged design and careful engineering make them the optimum

solution for OEM and large volume applications.

• Specifi cations

Operational Versions

LFE-11P-0A ........................................for water - PP, 10 VA, NC

LFE-11P-0B ......................................... for water - PP, 10 VA, NO

LFE-11P-1A ........................................for water - PP, 50 VA, NC

LFE-11P-1B ......................................... for water - PP, 50 VA, NO

LFE-11R-0A ........................................ for oil - Buna, 10 VA, NC

LFE-11R-0B .........................................for oil - Buna, 10 VA, NO

LFE-11R-1A ........................................ for oil - Buna, 50 VA, NC

LFE-11R-1B .........................................for oil - Buna, 50 VA, NO

LFE-12P-0A ......................................... for water - PP, 10 VA, NC

LFE-12P-0B .......................................... for water - PP, 10 VA, NO

LFE-12P-1A ......................................... for water - PP, 50 VA, NC

LFE-12P-1B .......................................... for water - PP, 50 VA, NO

LFE-12R-0A .........................................for oil - Buna, 10 VA, NC

LFE-12R-0B .......................................... for oil - Buna, 10 VA, NO

LFE-12R-1A .........................................for oil - Buna, 50 VA, NC

LFE-12R-1B .......................................... for oil, Buna, 50 VA, NO

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

4

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 5

Rev . A1, 4/07 LFE Series

• Specifi cations (continued)

Characteristics

Switch Rating (resistive load) (50 VA):

Max contact rating ..........................50 VA AC; 50 W DC

Max current ........................................ 0.5 A AC; 0.5 A DC

Max voltage ........................................ 300 V AC; 300 V DC

7

Life expectancy ................................. 10

operations (at 12 VDC, 5 mA)

Switch Rating (resistive load) (10 VA):

Max contact rating ..........................10 VA AC; 100 W DC

Max current ........................................ 0.2 A AC; 0.3 A DC

Max voltage ........................................ 100 V AC; 100 V DC

Life expectancy ................................. 10

7

operations (at 12 VDC, 5 mA)

Max temperature range .................-14 to 194°F (-10 to 90°C)

Max pressure ...................................... Polypropylene oat: 7 psi (0.5 bar)

Buna oat: 145 psi (10 bar)

Min SG .................................................. Polypropylene oat: 0.9

Buna oat: 0.7

Max viscosity ......................................0.5 Pa s

Max humidity ....................................95% RH

Max impact ......................................... 10 G

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

5

Page 6

LFE Series Rev . A1, 4/07

• Installation Location

Locate the LFE at the position where the liquid level variation will actually

make contact with it. DO NOT locate near liquid inlets/outlets. If there is

turbulence, use a time delay relay to dampen the switch action.

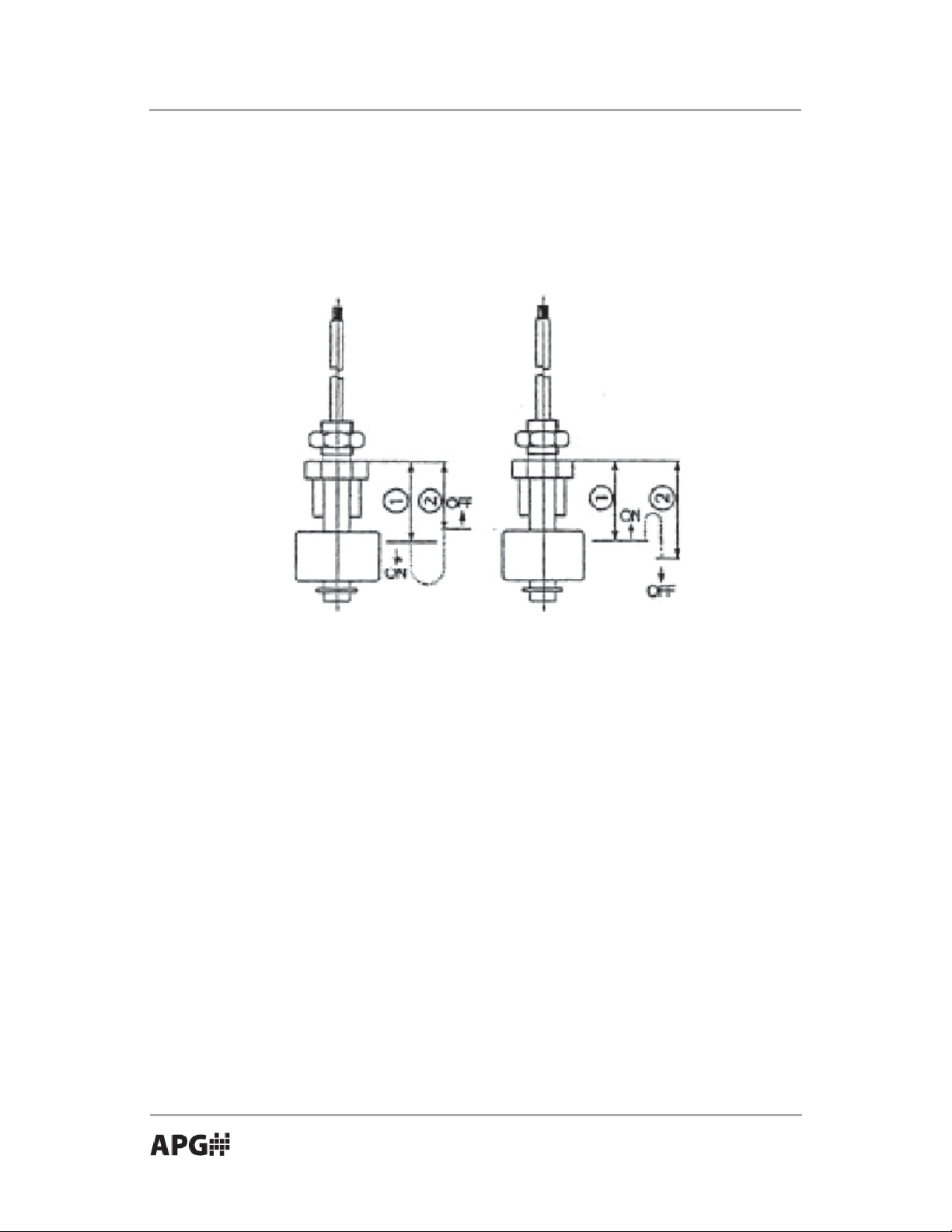

Figure A Figure B

LFE-XXX-XA (Switch closes as level falls), see Figure A

LFE-11R LFE-12R LFE-11P LFE-12P

Close as level falls 18 28 15 23

Open as level rises 16.5 26.5 13.5 21.5

LFE-XXX-XB (Switch closes as level rises), see Figure B

LFE-11R LFE-12R LFE-11P LFE-12P

Close as level rises 17 26 14 25

Open as level falls 18.5 27.5 15.5 26.5

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

6

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 7

Rev . A1, 4/07 LFE Series

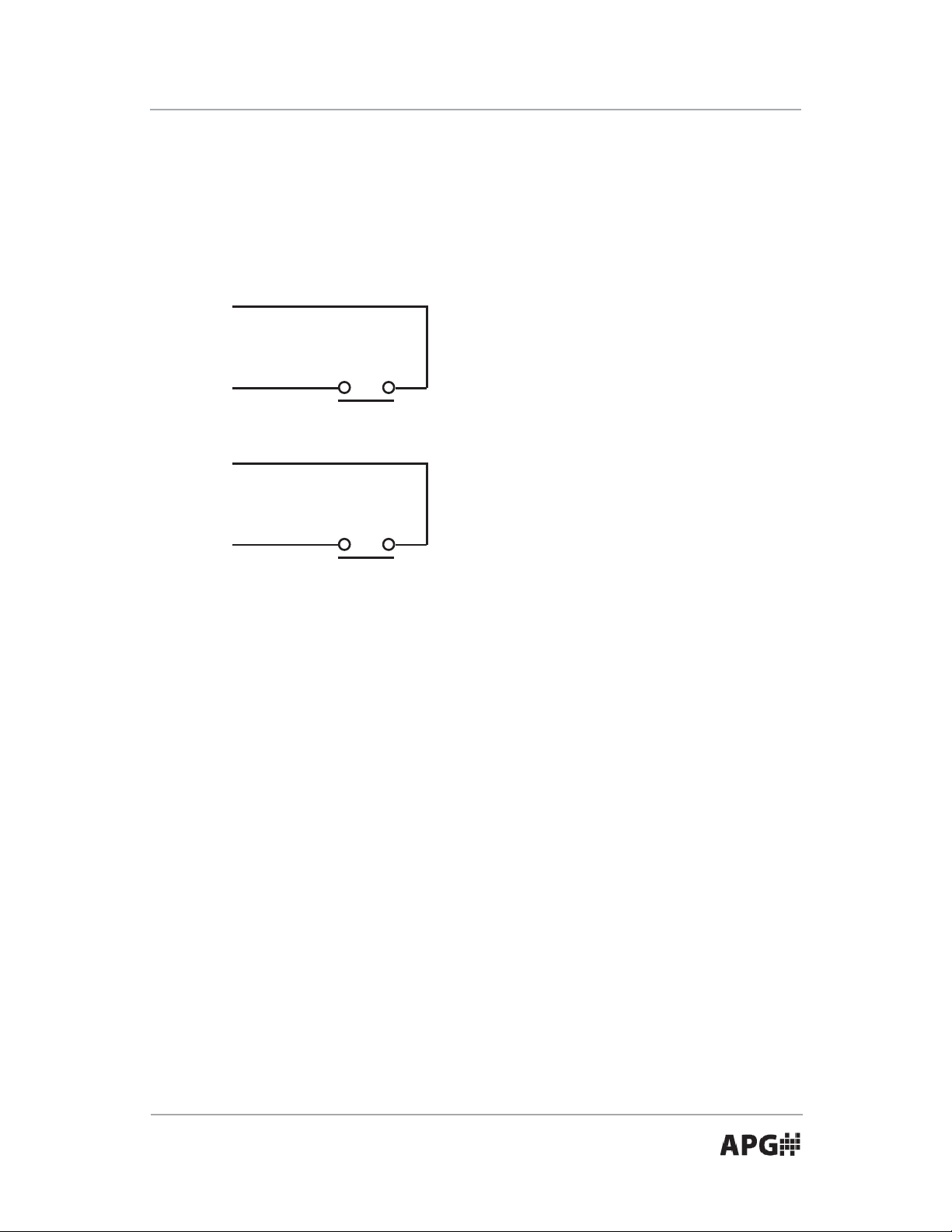

• Wiring

Wiring shall be in accordance with all local codes. Lead wires are #22

AWG, UL listed (UL1430). APG recommends the use of solderless lugs for

Black

Switch Rating (Resistive)

• Max capacity 50 VA, 50 W

• Max current 0.5 A AC, 50 A DC

Black

Yellow

• Max voltage 300 VAC, 300 VDC

Switch Rating (Resistive)

• Max capacity 10 VA, 10 W

• Max current 0.2 A AC, 0.3 A DC

Yellow

• Max voltage 3100 VAC, 100 VDC

Note: Max pull load of the lead wire is 19.6 N. Excessive pulling or kinking of

the lead wire may break the switch.

Caution!

Protection for electrical surges:

• Overvoltage

Reed switches are not designed for the direct starting of inductive

loads such as motors, contactors, solenoid valves, and so on. They are

susceptible to damage from overvoltages. DO NOT EXCEED THE CONTACT

RATINGS. Contact should be wired to miniature relays, suppressors or

similar devices. We recommend the use of our relay unit model RCU-7000.

• Overcurrent

Momentary surge current may be produced by switching lamps or stray

capacity from long cable length. Consequently reed switch is welded.

Contact should be wired to our relay unit model RCU-7000, coils in series

or suppressors.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

7

Page 8

AUT OMATION

PRODUCTS

GROUP, INC.

APG...Providing tailored solutions

for measurement applications

Automation Products Group, Inc.

Tel: 1/888/525-7300

1/435/753-7300

Fax: 1/435/753-7490

e-mail: sales@apgsensors.com

www.apgsensors.com

Automation Products Group, Inc.

1025 W. 1700 N.

Logan, UT 84321

Loading...

Loading...