Apex Dynamics AT Series Catalog

APEX DYNAMICS, INC.

AT-L

AT-FL

AT-H

AT-FH

AT-C

AT-FC

AT-4M

AT Series

AT Series

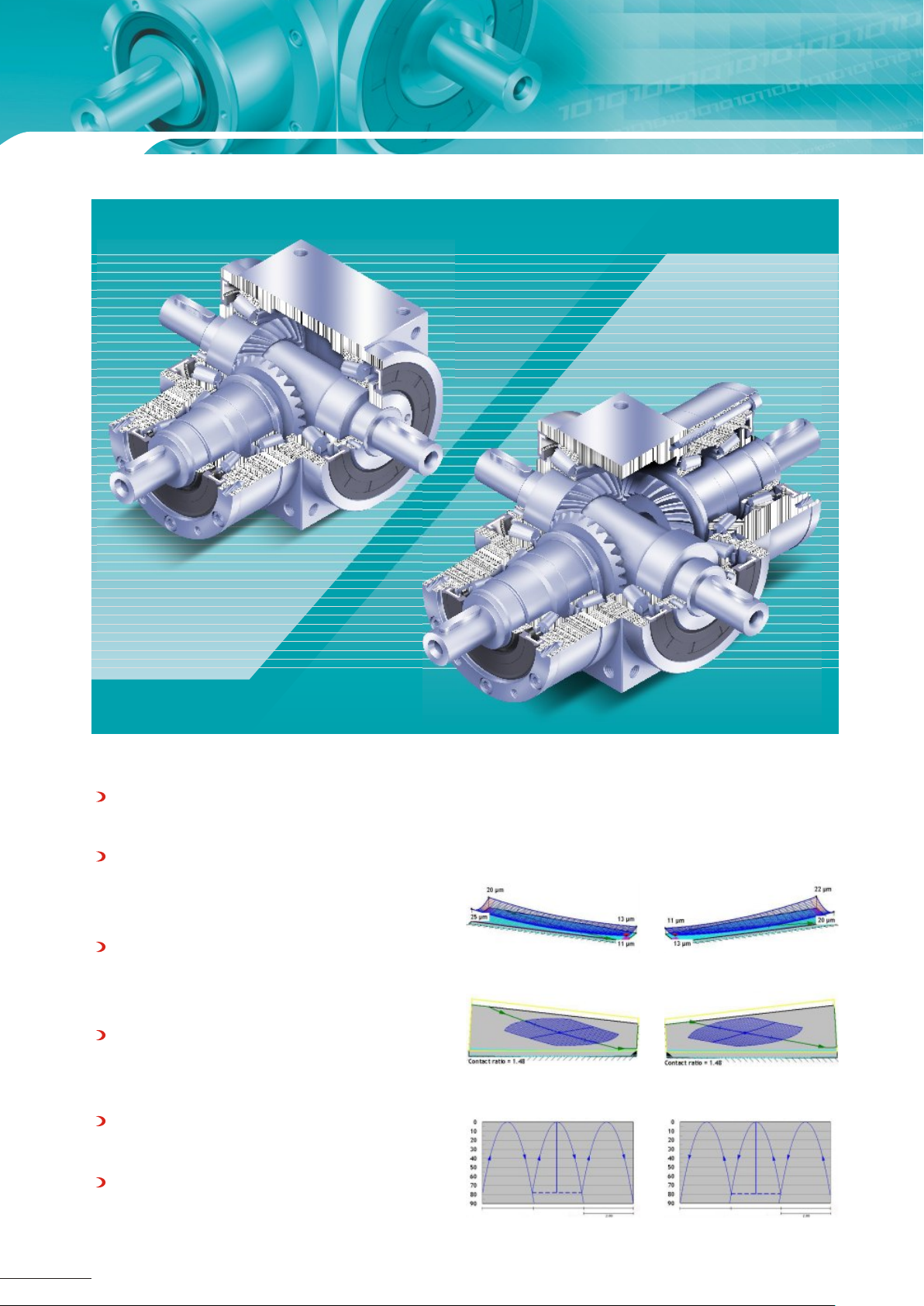

Characteristic Highlights

Characteristic Highlights

AT-4M

AT-L

Single Piece Stainless Steel housing for maximum rigidity and corrosion resistance. Multiple precision

machined surfaces for ease of installation.

Gearing design is optimized by state of the art software for highest performance. Carburized high

tensile alloy steel is precision ground to

exceed DIN 5 specifications.

Stainless steel input and output shaft with

multiple design configurations to meet all

industrial requirements.

High precision ground spiral bevel gear sets

are combined with optimized planetary

geometry to create ratios up to 500:1.

High torque. Low backlash and compact

design are ideal for all servo application.

01

Maintenance free, lubricated for life.

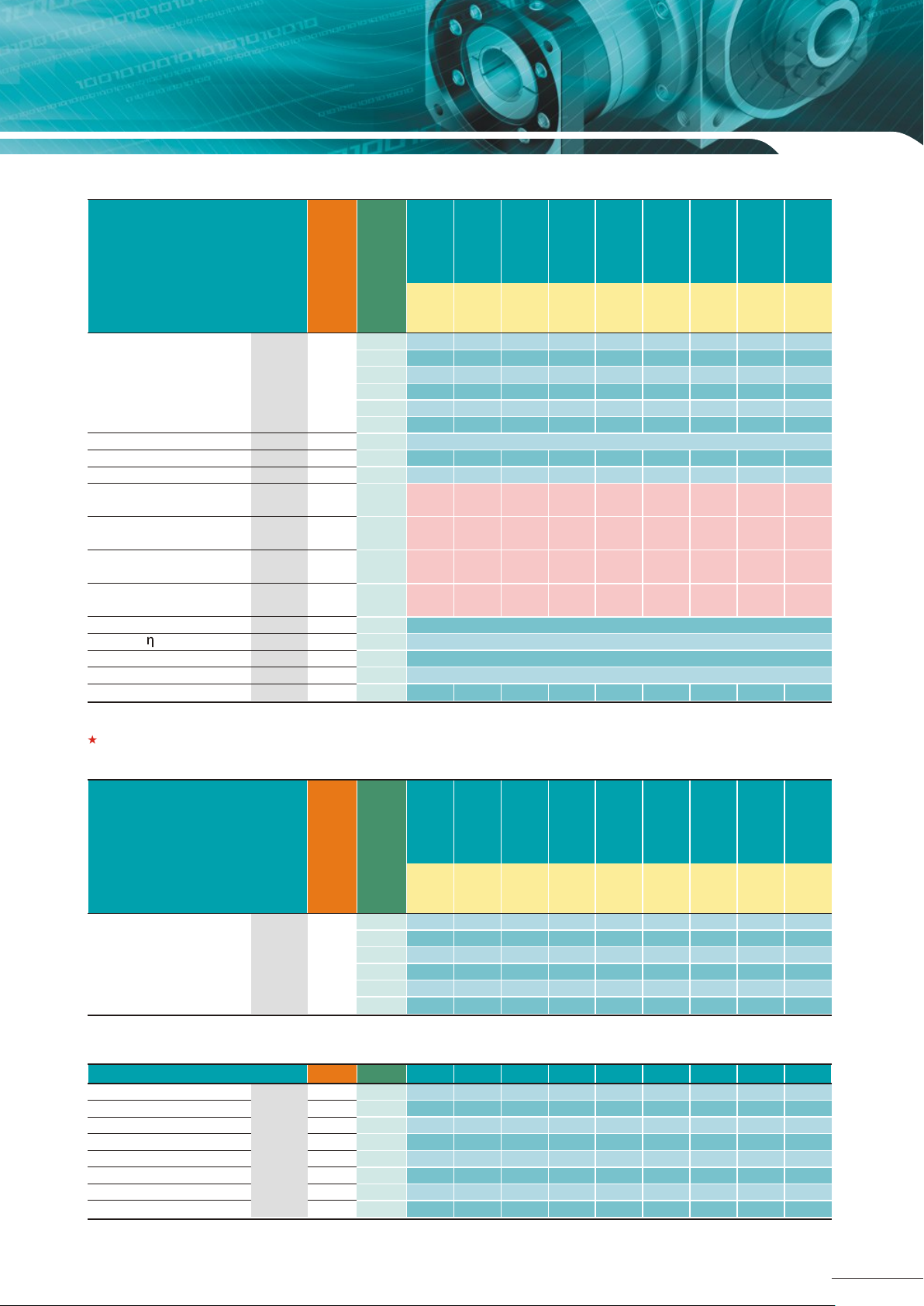

AT Shaft Type Series

AT Shaft Type Series

Specifications

Specifications

Gearbox Performance

Model No.

Nominal Output Torque T

Max. Acceleration Torque T

Acceleration

Max. Input Speed n

Standard Backlash

Max. Radial Load F

Input d1

Max. Radial Load F

Output d2

Max. Axial Load F

Input d1

Max. Axial Load F

Output d2

Service Life

Efficiency

Operating Temp

Lubrication

Noise Level (n =1500rpm, No Load)

1. Ratio ( i=N / N )

*S1 service life 10,000 hrs

1

in out

AT-LM / RM / 4M OFFER RATIO 1 : 1 ONLY.

2N

2B

*

1aB

2aB

1B

2

1rB

3

2rB

2

3

Nm

Nm

rpm

arcmin

N

N

N

N

hr

%

O

C

dB (A)

AT065 L

AT065 L1

AT065 H

AT065 C

1

Stage

Rati o

AT065 R1

AT065 LM

AT065 RM

AT065 4M

1

1.5

2

1

3

4

5

1~5

1

1~5

1

1~5

1

1

1

1

1~5

1

1~5

1

1~5

1

1~5

1

1~5

1

2. Apply to the input shaft center @ n

AT075 L

AT075 L1

AT075 H

AT075 C

AT075 R1

AT075 LM

AT075 RM

AT075 4M

25

25

24

18

13

12

7,50 0

≤6

7001~5

9001~5 11,5001,10 0 1,70 0 2,70 0 4,80 0 6,60 0 16,0 00 18,000

3501~5 3,90 0425 725 1,05 0 1,35 0 1,90 0 4,80 0 5,25 0

450

≤68

AT090 L

AT090 L1

AT090 H

AT090 C

AT090 R1

AT090 LM

AT090 RM

AT090 4M

45

45

42

33

28 48 100

AT110 L

AT110 L1

AT110 H

AT110 C

AT110 R1

AT110 LM

AT110 RM

AT110 4M

78 1 50

78 1 50

68 1 50

54

120 270 450

AT140 L

AT140 L1

AT140 H

AT140 C

AT140 R1

AT140 LM

AT140 RM

AT140 4M

360

360

330

224

AT170 L

AT170 L1

AT170 H

AT170 C

AT170 R1

AT170 LM

AT170 RM

AT170 4M

25 40 85 196

1.5 ti mes of No minal O ut put Torque

6,50 0 5,50 0 4,50 0 3,50 0 3,00 0 2,20 0

≤6 ≤6 ≤6 ≤6 ≤6 ≤6 ≤6 ≤6

950 1, 45 0 2, 10 0 2, 70 0 3, 80 0 9, 60 0 10,5 007,80 0

550 850

1,35 0 2,40 0 3,30 0 8, 005 9,000

20,000*

≥98%

O O

-10 C ~ 90 C

Synthetic lubrication oils

≤70 ≤74

1B

≤76 ≤77 ≤78 ≤8 0 ≤82 ≤83

3. Apply to the output shaft center @ n

*Backlash is measured at 2% Nominal Output Torque T

AT210 L

AT210 L1

AT210 H

AT210 C

AT210 R1

AT210 LM

AT210 RM

AT210 4M

1,30 0 2,15 0 3,20 0

585

1,30 0 2,15 0

585

1,22 0 2,01 0 3,05 0

544

1,02 0 1,65 0 2,85 0

376

320

860

740

5,75 0

AT240 L

AT240 L1

AT240 H

AT240 C

AT240 R1

AT240 LM

AT240 RM

AT240 4M

AT280 L

AT280 L1

AT280 H

AT280 C

AT280 R1

AT280 LM

AT280 RM

AT280 4M

3.20 0

1,41 0 2,30 0

1,21 0 2,00 0

2,00 0 1,70 0

1B

2N

Gearbox Inertia

Model No.

Mass Moments of Inertia J

Weight

Model No.

L Series

L1 Series

H Series

C Series

R1 Series

LM Series

RM Series

4M Series

1

kg‧cm

kg

2

Stage

1

Stage

1

1

1

1

1

1

1

1

1

Rati o

1

1.5

2

3

4

5

Rati o

1~5

1~5

1~5

1~5

1~5

1

1

1

AT065 L

AT065 L1

AT065 H

AT065 C

1

AT065 R1

AT065 LM

AT065 RM

AT065 4M

AT075 L

AT075 L1

AT075 H

AT075 C

AT075 R1

AT075 LM

AT075 RM

AT075 4M

AT090 L

AT090 L1

AT090 H

AT090 C

AT090 R1

AT090 LM

AT090 RM

AT090 4M

AT110 L

AT110 L1

AT110 H

AT110 C

AT110 R1

AT110 LM

AT110 RM

AT110 4M

AT140 L

AT140 L1

AT140 H

AT140 C

AT140 R1

AT140 LM

AT140 RM

AT140 4M

AT170 L

AT170 L1

AT170 H

AT170 C

AT170 R1

AT170 LM

AT170 RM

AT170 4M

AT210 L

AT210 L1

AT210 H

AT210 C

AT210 R1

AT210 LM

AT210 RM

AT210 4M

AT240 L

AT240 L1

AT240 H

AT240 C

AT240 R1

AT240 LM

AT240 RM

AT240 4M

0.51 1.30 3.16 7. 70 23.5 7 58.9 9 195. 40 3 69 .34 799.1 2

0.64 1.16 2.82 6. 74 19.3 7 49.2 8 155. 45 2 83 .58 595.7 8

0.44 1 .11 2.70 6. 31 17.7 5 45.3 5 140. 24 2 49 .74 5 11. 76

0.43 1.09 2.66 6. 17 17.1 8 44.0 1 134. 95 2 37 .71 483.0 6

0.43 1.09 2.65 6. 13 17.0 6 43.7 0 133. 58 2 34 .72 476.2 6

0.43 1.09 2.65 6. 12 17.0 2 43.6 0 133. 14 2 33 .67 473.5 8

1

AT065

2.6

AT075

4.2

AT090

6.8

AT110 AT140 AT170 AT210 AT240

11.6

19.8

34.8

66.2

98.1

2.6 4.1 6.7 11.5 19.5 34.2 65.1 96 .6 153. 4

2.5 3.9 6.4 11.0 18.1 31.6 60.0 89 .4 143. 4

2.8 4.2 6.9 11.4 19.6 33.7 63.3 97 .9 149. 1

2.6

3.5

3.5

3.5

4.1

5.6

5.6

5.6

6.7

9.0

9.0

9.1

11.5

15.2

15.2

15.4

19.5

24.1

24.1

24.8

34.2

42.4

42.4

42.6

65.1

81.4

81.4

82.5

96.6

122. 0

122. 0

123. 5

AT280 L

AT280 L1

AT280 H

AT280 C

AT280 R1

AT280 LM

AT280 RM

AT280 4M

AT280

155. 7

153. 4

190. 9

190. 9

193. 3

02

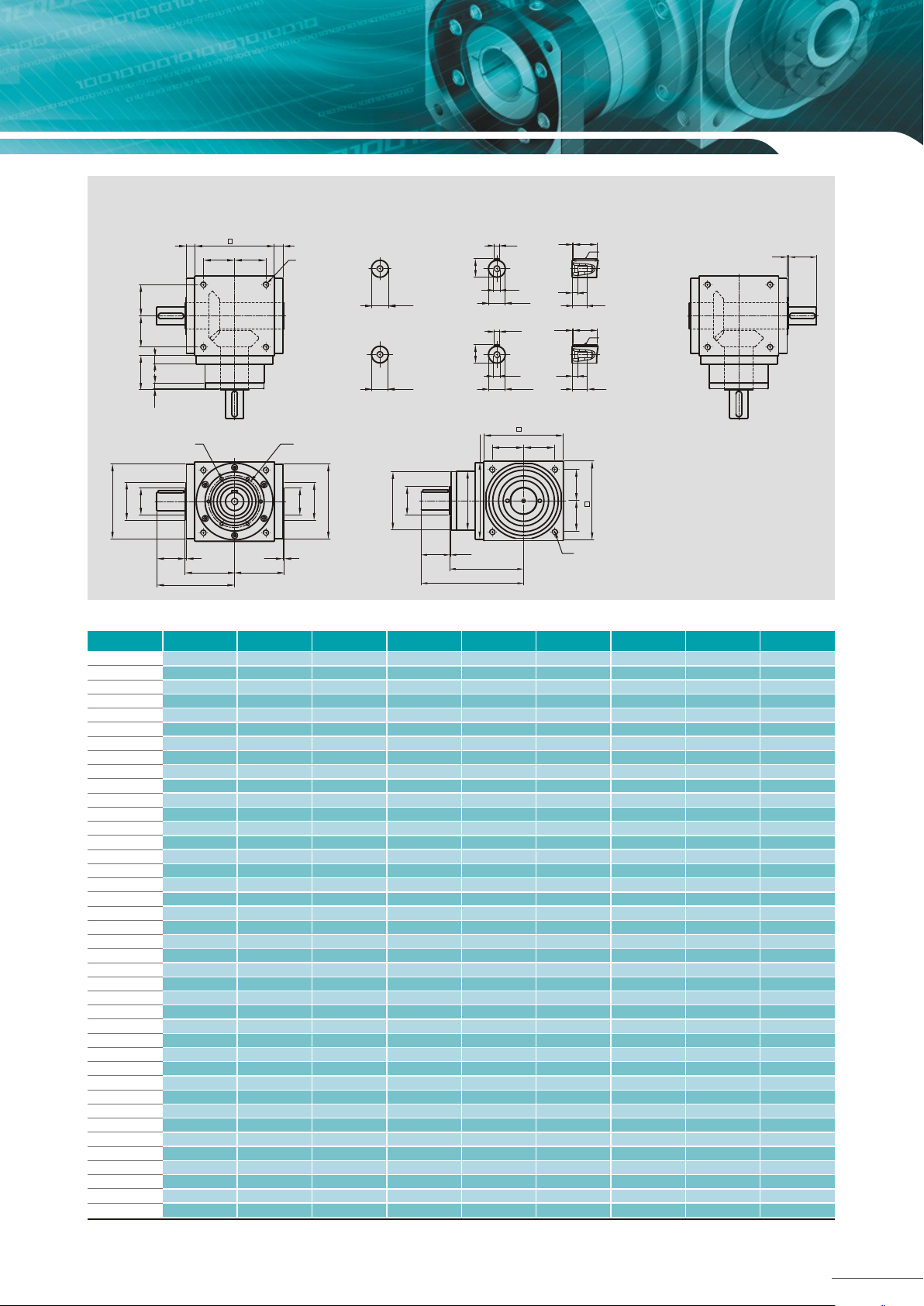

AT-L Series

AT-L Series

Dimensions (1-stage, Ratio i=1~5)

Dimensions (1-stage, Ratio i=1~5)

h7

ØD4

Dimension

D1

D3 k 6

D4 h 7

D5

D6

D7

D8

D9

D10

D11 g6

D12

D13 k6

D14 h7

D16

L1

L2

L3

L4

L5

L6

L7

L8

L9

L10

L11

L12

L13

L14

L15

L16

L17

L18

L19

L20

L21

L22

B1 h 9

B2 h 9

H1

H2

ØD5

L11L11

L13L17

L18

ØD7

AT065 L

M4

13

63

31

M4

21

53

4xM4 xL 7

15.4

62.9

62

13

63

M4

65

19.5

13

2

16

2

47.5

67

4.5

10

27

19.5

13

2

16

2

6

43

4.5

10

75.5

95

5

5

15

15

L3 L1 L3

L4L2

L7L7

L8L8

AT075 L

M6

16

73

35

M5

22

62

4xM5 xL 8

20.4

72.9

72

16

73

M5

75

30

14.5

2

25

2.5

54

84

4.8

12.5

30

30

15

2

25

2.5

8

52.5

4.8

12.5

90

120

5

5

18

18

D1L11L11

ØD8D9

L2L4

AT090 L

M6

18

88

43

M5

28

76

4xM5 xL 8

25.8

87

86

18

88

M5

90

35

15

2

28

3.5

62

97

4.8

12.5

36

35

15

2

28

3.5

8

55

4.8

12.5

100

135

6

6

20.5

20.5

L6 L5

L9

k6

L16 L15

L19

k6

L1

L11

D1

Shaft Option S2

ØD3

ØD13

g6

ØD11

k6

k6

ØD10

L12 L14

Sha ft Opti on S1

Sha ft Opti on S1 Sha ft Opti on S2

h7

ØD5

ØD7

ØD4

H1

(Output Shaft)

H2

(Input Shaft)

ØD12

L22

B1

h9

D6

ØD3

B2

h9

D16

ØD13

h7

L11

ØD14

L21

AT110 L AT140 L AT170 L AT210 L AT240 L

M8

22

108

53

M8

33

95

6xM6 xL 10

35.8

107

106

22

108

M8

110

40

15

2

32

4

72

112

7.2

19

44

40

15

2

32

4

8

60

7.2

19

115

155

6

6

24.5

24.5

M10

32

135

68

M12

47

92

6xM6xL10

49.8

103

104

32

135

M12

140

50

15

2

45

2.5

87

137

10

28

55

50

15

2

45

2.5

10

60

10

28

130

180

10

10

35

35

M12

40

165

83

M16

55

114

6xM8xL12.5

59.3

127

128

40

165

M16

170

60

15

2

50

5

102

162

12

36

67

60

15

2

50

5

10

70

12

36

155

215

12

12

43

43

M16

50

205

104

M16

75

142

6xM8xL12.5

79.3

158

160

50

205

M16

210

75

20

2

70

2.5

127

202

12

36

85

75

20

2

70

2.5

10

90

12

36

195

270

14

14

53.5

53.5

6xM8xL12.5

Key acc. to DIN6885/1

L10

Key acc. to DIN6885/1

L20

L11L11

L1

M16

55

235

124

M16

85

160

92.3

178

180

55

235

M16

240

85

25

2

80

2.5

147

232

12

36

95

85

25

2

80

2.5

10

105

12

36

225

310

16

16

59

59

[unit: mm]

AT280 L

M16

60

275

144

M20

110

176

6xM10xL15

102. 3

198

200

60

275

M20

280

110

25

2

100

5

167

277

15

42

110

110

25

2

100

5

10

120

15

42

260

370

18

18

64

64

03

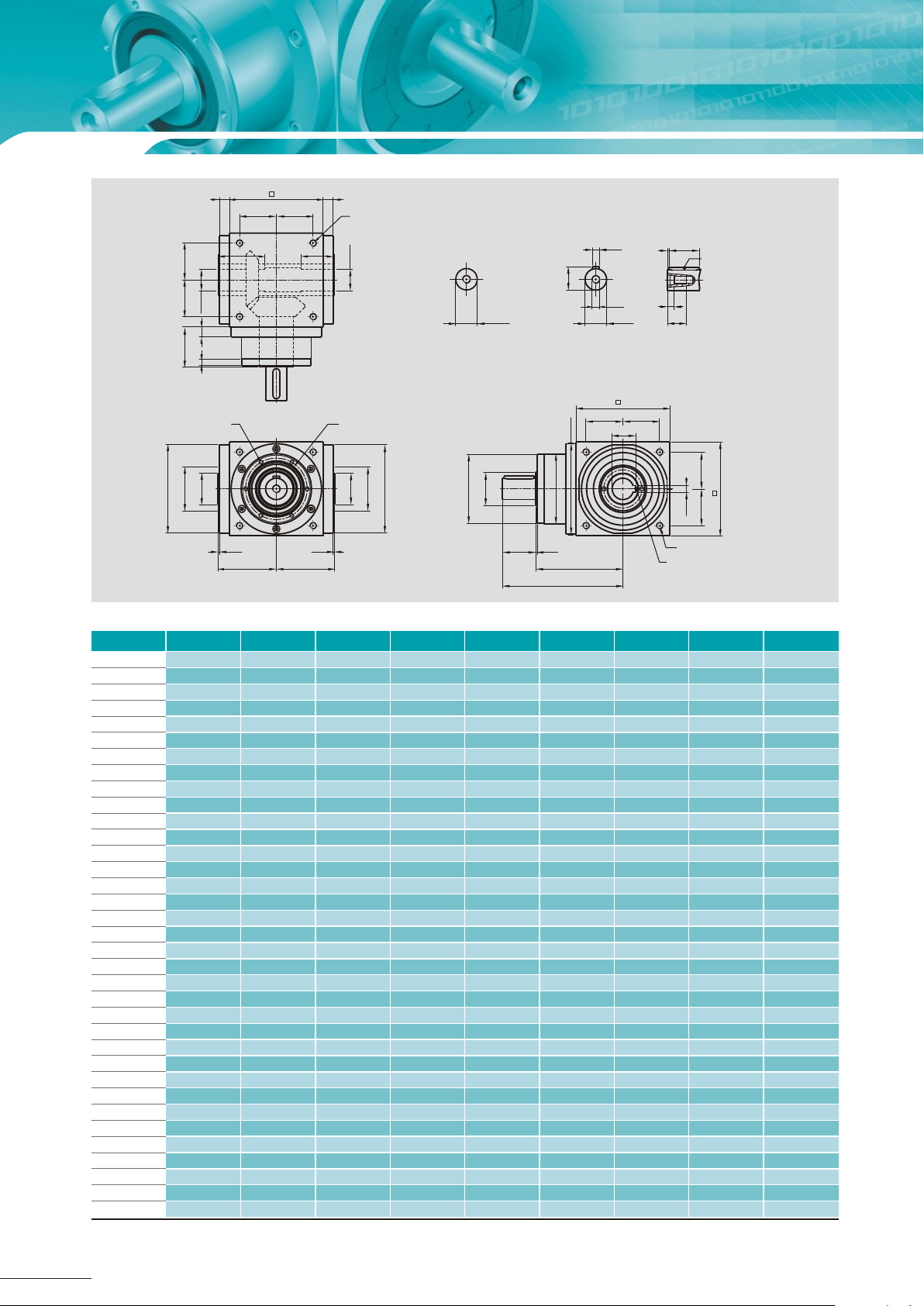

AT-L1 / R1 Series

AT-L1 / R1 Series

Dimensions (1-stage, Ratio i=1~5)

Dimensions (1-stage, Ratio i=1~5)

AT-L1 AT-R1

L11L11

L18

h7

ØD5

ØD7

ØD4

Dimension

D1

D3 k 6

D4 h 7

D5

D6

D7

D8

D9

D10

D11 g6

D12

D13 k6

D14 h7

D16

L1

L2

L3

L4

L5

L6

L7

L8

L9

L10

L11

L12

L13

L14

L15

L16

L17

L18

L19

L20

L21

L22

B1 h 9

B2 h 9

H1

H2

L3

L13L17

L4L2

L8

AT065 L1/R1

M4

13

63

31

M4

21

53

4xM4 xL 7

15.4

62.9

62

13

63

M4

65

19.5

13

16

47.5

67

4.5

10

27

19.5

13

16

43

4.5

10

75.5

95

15

15

ØD3

L6 L5

h9

k6

h9

k6

L1

L11L11

L9

L16 L15

L19

L11L1 1

D1

Key acc. to DIN6885/1

L10

Key acc. to DIN6885/1

L20

L1

L3

L1

D1

L11L11

Sha ft Opti on

ØD3

g6

ØD11

ØD13

ØD10

k6

k6

S2

Sha ft Opti on

S2

L12 L14

Sha ft Opti on

S1

Sha ft Opti on

S1

ØD8D9

h7

ØD5

ØD7

ØD4

L4

L7L7

H1

(Output Shaft)

H2

(Input Shaft)

h7

ØD14

ØD12

L21

L22

B1

D6

B2

D16

ØD13

AT075 L1/R1 AT090 L1/R1 AT110 L1/R1 AT140 L1/R1 AT170 L1/R1 AT210 L1/R1 AT240 L1/R1 AT280 L1/R1

M6

16

73

35

M5

22

62

4xM5 xL 8

20.4

72.9

72

16

73

M5

75

30

14.5

2

2

25

2

2.5

54

84

4.8

12.5

30

30

15

2

2

25

2

6

2.5

8

52.5

4.8

12.5

90

120

5

5

5

5

18

18

M6

18

88

43

M5

28

76

4xM5 xL 8

25.8

87

86

18

88

M5

90

35

15

2

28

3.5

62

97

4.8

12.5

36

35

15

2

28

3.5

8

55

4.8

12.5

100

135

6

6

20.5

20.5

M8

22

108

53

M8

33

95

6xM6 xL 10

35.8

107

106

22

108

M8

110

40

15

2

32

4

72

112

7.2

19

44

40

15

2

32

4

8

60

7.2

19

115

155

6

6

24.5

24.5

M10

32

135

68

M12

47

92

6xM6xL10

49.8

103

104

32

135

M12

140

50

15

2

45

2.5

87

137

10

28

55

50

15

2

45

2.5

10

60

10

28

130

180

10

10

35

35

M12

40

165

83

M16

55

114

6xM8xL12.5

59.3

127

128

40

165

M16

170

60

15

2

50

5

102

162

12

36

67

60

15

2

50

5

10

70

12

36

155

215

12

12

43

43

M16

50

205

104

M16

75

142

6xM8xL12.5

79.3

158

160

50

205

M16

210

75

20

2

70

2.5

127

202

12

36

85

75

20

2

70

2.5

10

90

12

36

195

270

14

14

53.5

53.5

M16

55

235

124

M16

85

160

6xM8xL12.5

92.3

178

180

55

235

M16

240

85

25

2

80

2.5

147

232

12

36

95

85

25

2

80

2.5

10

105

12

36

225

310

16

16

59

59

L4 L2

[unit: mm]

M16

60

275

144

M20

110

176

6xM10xL15

102. 3

198

200

60

275

M20

280

110

25

2

100

5

167

277

15

42

110

110

25

2

100

5

10

120

15

42

260

370

18

18

64

64

04

AT-H Series

AT-H Series

Dimensions (1-stage, Ratio i=1~5)

Dimensions (1-stage, Ratio i=1~5)

Dimension

D1

D2 H 7

D4 h 7

D5

D7

D8

D9

D10

D11 g6

D12

D13 k6

D14 h7

D16

L1

L3

L4

L7

L11

L12

L13

L14

L15

L16

L17

L18

L19

L20

L21

L22

L23

L24

B2 h 9

B3 P 9

H2

H3

L11L11

L18

h7

ØD5

ØD4

AT065 H

4xM4 xL 7

H7

ØD2

L13L17

ØD7

M4

13

63

31

21

53

15.4

62.9

62

13

63

M4

65

13

2

47.5

27

19.5

13

2

16

2

6

43

4.5

10

75.5

95

40

30

5

5

15

15.3

L3

L4

L1

L11L11

AT075 H

M6

14

73

35

22

62

4xM5 xL 8

20.4

72.9

72

16

73

M5

75

14.5

2

54

30

30

15

2

25

2.5

8

52.5

4.8

12.5

90

120

47

32

5

5

18

16.3

L24L23

L4

L7L7

L3

D1

H7

ØD2

ØD8D9

ØD7

AT090 H

M6

18

88

43

28

76

4xM5 xL 8

25.8

87

86

18

88

M5

90

15

2

62

36

35

15

2

28

3.5

8

55

4.8

12.5

100

135

52

35

6

6

20.5

20.8

B2

h9

L16 L15

H2

L19

D16

ØD13

Sha ft Opti on S1 Sha ft Opti on S2

h7

ØD5

ØD4

k6

g6

ØD10

ØD11

ØD12

L12 L14

L22

h7

ØD14

L21

(Input Shaft)

L11

ØD13

k6

L1

L11

H3

AT110 H AT140 H AT170 H AT210 H AT240 H

M8

22

108

53

33

95

6xM6 xL 10

35.8

107

106

22

108

M8

110

15

2

72

44

40

15

2

32

4

8

60

7.2

19

115

155

53

35

6

6

24.5

24.8

M10

32

135

68

47

92

6xM6 xL 10

49.8

103

104

32

135

M12

140

15

2

87

55

50

15

2

45

2.5

10

60

10

28

130

180

70

50

10

10

35

35.3

M12

40

165

83

55

114

6xM8xL12.5

59.3

127

128

40

165

M16

170

15

2

102

67

60

15

2

50

5

10

70

12

36

155

215

80

55

12

12

43

43.3

M16

50

205

104

75

142

6xM8xL12.5

79.3

158

160

50

205

M16

210

20

2

127

85

75

20

2

70

2.5

10

90

12

36

195

270

95

65

14

14

53.5

53.8

Key acc. to DIN6885/1

L20

L11L11

L1

P9

B3

D1

Key acc. to DIN6885/1

M16

55

235

124

85

160

6xM8xL12.5

92.3

178

180

55

235

M16

240

25

147

95

85

25

80

2.5

10

105

12

36

225

310

115

80

16

16

59

59.3

[unit: mm] [unit: mm]

AT280 H

M16

60

275

144

110

176

6xM10xL15

102. 3

198

200

60

275

M20

280

25

2

2

167

110

110

25

2

2

100

5

10

120

15

42

260

370

115

80

18

18

64

64.4

05

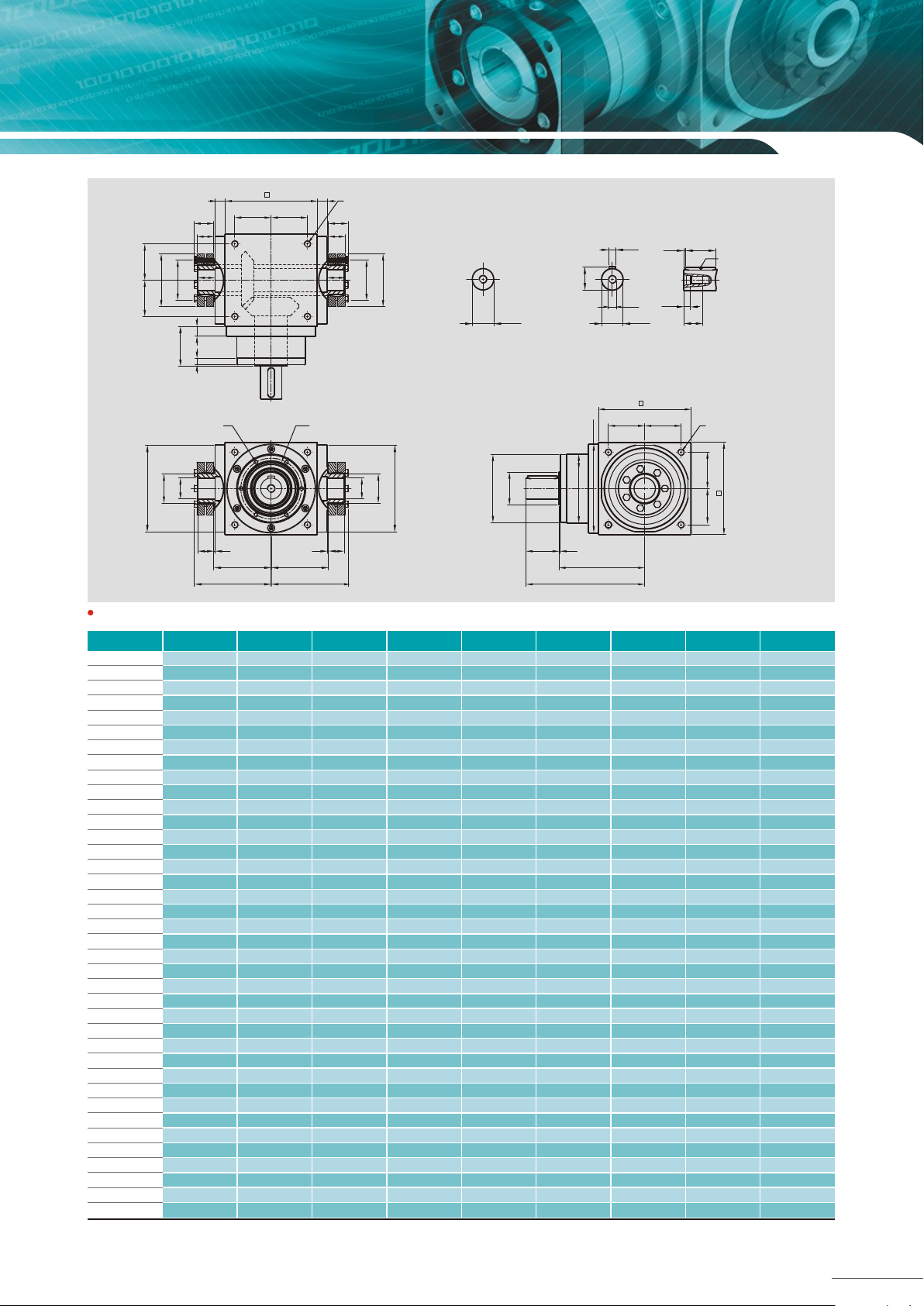

AT-C Series

AT-C Series

Dimensions (1-stage, Ratio i=1~5)

Dimensions (1-stage, Ratio i=1~5)

L11L 11

ØD4 h7ØD3

L3

L26

L25

ØD17

ØD18

L13

L18

L17

h6

h8

ØD2

L2 L4

L1

L11

L7

L8

L3

D1

L11

ØD8D9

L7

L4 L 2

L8

L26

L25

L24L23

ØD17

H6

ØD2

ØD3 h8ØD4

Standard acces sory includes 2 shrink disk power lock un its.

Dimension

D1

D2 H6

D3 h8

D4 h7

D8

D9

D10

D11 g6

D12

D13 k6

D14 h7

D16

D17

D18

L1

L2

L3

L4

L7

L8

L11

L12

L13

L14

L15

L16

L17

L18

L19

L20

L21

L22

L23

L24

L25

L26

B2 h9

H2

AT065 C

M4

13

16

63

53

4xM4xL 7

15.4

62.9

62

13

63

M4

26

41

65

14

13

2

47.5

66

27

19.5

13

2

16

2

6

43

4.5

10

75.5

95

15

15

15

18.5

5

15

AT075 C

M6

14

16

73

62

4xM5xL 8

20.4

72.9

72

16

73

M5

26

41

75

14

14.5

2

54

72.5

30

30

15

2

25

2.5

8

52.5

4.8

12.5

90

120

15

15

15

18.5

5

18

AT090 C

M6

18

22

88

76

4xM5xL 8

25.8

87

86

18

88

M5

36

50

90

18

15

2

62

85

36

35

15

2

28

3.5

8

55

4.8

12.5

100

135

20

20

19.5

23

6

20.5

B2

h9

ØD18

ØD13

Sha ft Opti on S1 Sha ft Opti on S2

h7

k6

g6

ØD10

ØD11

L12 L14

ØD12

H2

L22

(Input Shaft)

h7

ØD14

L21

L16 L15

L19

D16

ØD13

k6

L1

L11

L11

Key acc. to DIN6885/1

L20

D1

L11L11

L1

AT110 C AT140 C AT170 C AT210 C AT240 C AT280 C

M8

22

25

108

95

6xM6xL 10

35.8

107

106

22

108

M8

38

50

110

18

15

2

72

95

44

40

15

2

32

4

8

60

7.2

19

115

155

20

20

19.5

23

6

24.5

M10

32

44

135

92

6xM6xL 10

49.8

103

104

32

135

M12

61

80

140

24

15

2

87

116. 5

55

50

15

2

45

2.5

10

60

10

28

130

180

26

26

25.5

29.5

10

35

M12

40

50

165

114

6xM8xL12.5

59.3

127

128

40

165

M16

70

90

170

26

15

2

102

133.5

67

60

15

2

50

5

10

70

12

36

155

215

28

28

27.5

31.5

12

43

M16

50

62

205

142

6xM8xL12.5

79.3

158

160

50

205

M16

86

110

210

29

20

2

127

161.5

85

75

20

2

70

2.5

10

90

12

36

195

270

31

31

30.5

34.5

14

53.5

M16

55

68

235

160

6xM8xL12.5

92.3

178

180

55

235

M16

86

115

240

29

25

2

147

181.5

95

85

25

2

80

2.5

10

105

12

36

225

310

31

31

30.5

34.5

16

59

6xM10xL15

M16

60

75

275

176

102.3

198

200

60

275

M20

100

138

280

30.5

25

2

167

205

110

110

25

2

100

5

10

120

15

42

260

370

32.5

32.5

32.5

38

18

64

06

AT-LM / RM Series

AT-LM / RM Series

Dimensions (1-stage, Ratio i=1)

Dimensions (1-stage, Ratio i=1)

AT-LM AT-RM

h7

ØD5

ØD4

L3

L18

L13 L17

L11L11

L13

L18

L17

D9

ØD7

L4L2

L8

L3

L1

L11L11

h9

ØD3

L6 L5

Key acc. to DIN6885/1

L4 L2

L9

k6

h9

k6

L1

L11L 11

L16 L15

L19

h7

ØD14

L10

Key acc. to DIN6885/1

L20

ØD12

L12L14

L11L11

g6

L1

ØD10

ØD11

B1

D1

ØD3

g6

ØD11

ØD13

k6

k6

ØD10

Sha ft Opti on

S1

Sha ft Opti on

S1

ØD8

h7

ØD5

ØD7

ØD4

L4

L7L7

H1

Sha ft Opti on

S2

(Output Shaft)

H2

Sha ft Opti on

S2

(Input Shaft)

h7

ØD14

ØD12

L12 L14

L21 L21

L22 L22

D6

B2

D16

ØD13

[unit: mm]

Dimension

D1

D3 k 6

D4 h 7

D5

D6

D7

D8

D9

D10

D11 g6

D12

D13 k6

D14 h7

D16

L1

L2

L3

L4

L5

L6

L7

L8

L9

L10

L11

L12

L13

L14

L15

L16

L17

L18

L19

L20

L21

L22

B1 h 9

B2 h 9

H1

H2

AT065LM/RM

M4

13

63

31

M4

21

53

4xM4 xL 7

15.4

62.9

62

13

63

M4

65

19.5

13

2

16

2

47.5

67

4.5

10

27

19.5

13

2

16

2

6

43

4.5

10

75.5

95

5

5

15

15

AT075LM/RM AT090LM/RM AT110LM/RM AT140LM/RM AT170LM/RM AT210LM/RM AT240LM/RM AT280LM/RM

M6

16

73

35

M5

22

62

4xM5 xL 8

20.4

72.9

72

16

73

M5

75

30

14.5

2

25

2.5

54

84

4.8

12.5

30

30

15

2

25

2.5

8

52.5

4.8

12.5

90

120

5

5

18

18

M6

18

88

43

M5

28

76

4xM5 xL 8

25.8

87

86

18

88

M5

90

35

15

2

28

3.5

62

97

4.8

12.5

36

35

15

2

28

3.5

8

55

4.8

12.5

100

135

6

6

20.5

20.5

M8

22

108

53

M8

33

95

6xM6 xL 10

35.8

107

106

22

108

M8

110

40

15

2

32

4

72

112

7.2

19

44

40

15

2

32

4

8

60

7.2

19

115

155

6

6

24.5

24.5

M10

32

135

68

M12

47

92

6xM6xL10

49.8

103

104

32

135

M12

140

50

15

2

45

2.5

87

137

10

28

55

50

15

2

45

2.5

10

60

10

28

130

180

10

10

35

35

M12

40

165

83

M16

55

114

6xM8xL12.5

59.3

127

128

40

165

M16

170

60

15

2

50

5

102

162

12

36

67

60

15

2

50

5

10

70

12

36

155

215

12

12

43

43

M16

50

205

104

M16

75

142

6xM8xL12.5

79.3

158

160

50

205

M16

210

75

20

2

70

2.5

127

202

12

36

85

75

20

2

70

2.5

10

90

12

36

195

270

14

14

53.5

53.5

M16

55

235

124

M16

85

160

6xM8xL12.5

92.3

178

180

55

235

M16

240

85

25

2

80

2.5

147

232

12

36

95

85

25

2

80

2.5

10

105

12

36

225

310

16

16

59

59

M16

60

275

144

M20

110

176

6xM10xL15

102. 3

198

200

60

275

M20

280

110

25

2

100

5

167

277

15

42

110

110

25

2

100

5

10

120

15

42

260

370

18

18

64

64

07 08

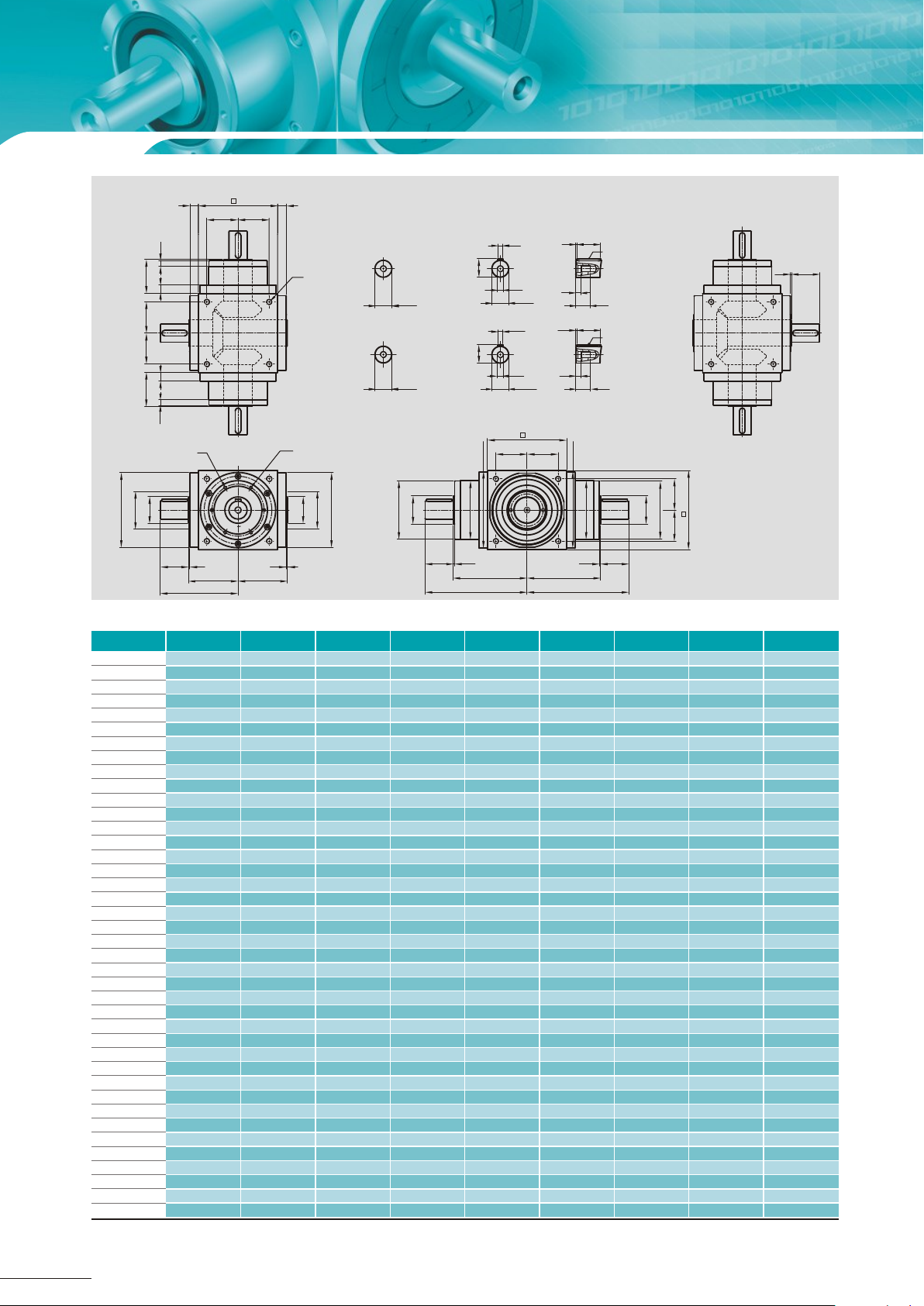

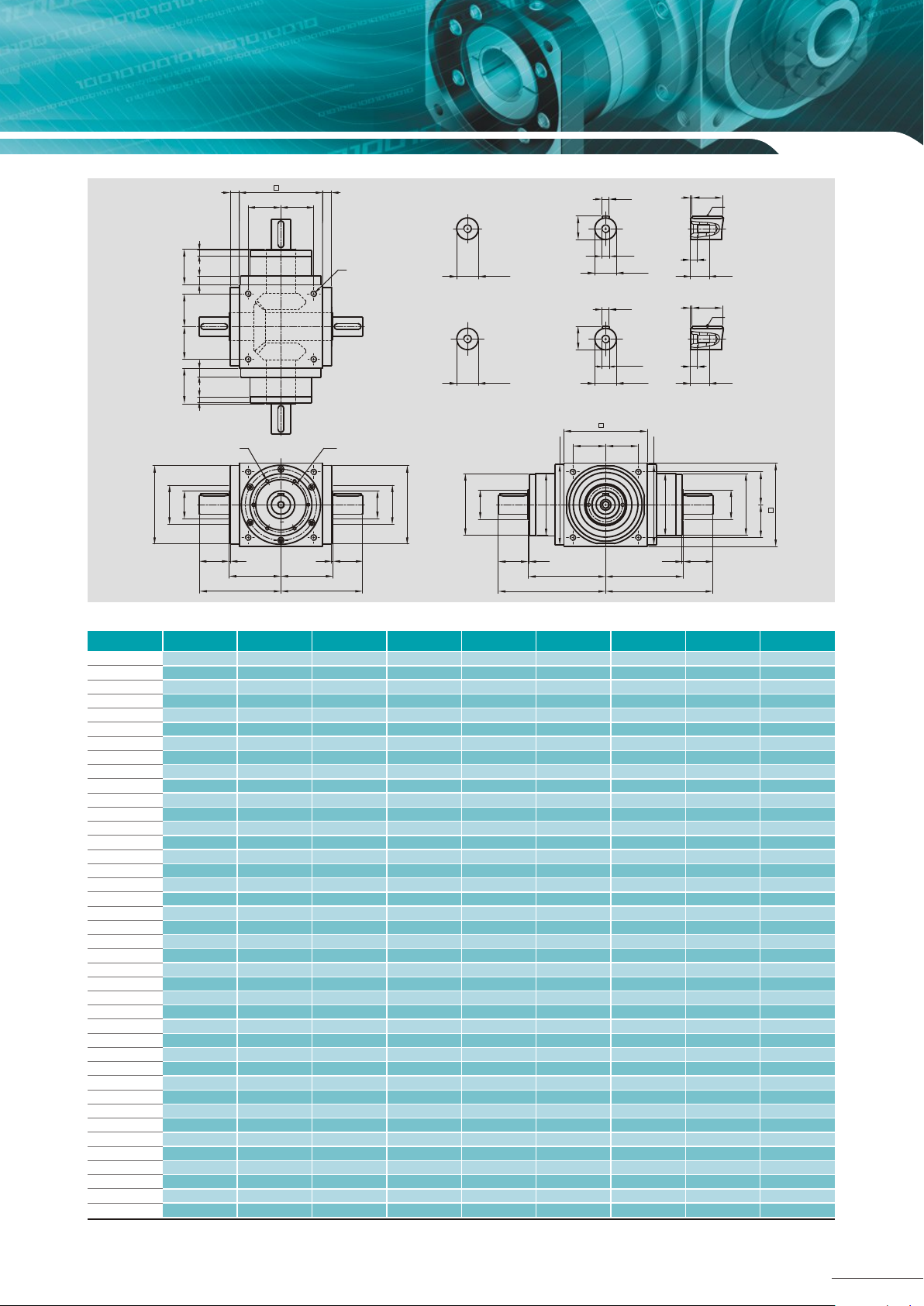

AT-4M Series

AT-4M Series

Dimensions (1-stage, Ratio i=1)

Dimensions (1-stage, Ratio i=1)

L17L13

L11L11 L8

L13L17

L8

h7

ØD5

ØD7

ØD4

L2 L4

Dimension AT065 4M

D1

D3 k 6

D4 h 7

D5

D6

D7

D8

D9

D10

D11 g6

D12

D13 k6

D14 h7

D16

L1

L2

L3

L4

L5

L6

L7

L8

L9

L10

L11

L12

L13

L14

L15

L16

L17

L18

L19

L20

L21

L22

B1 h 9

B2 h 9

H1

H2

M4

13

63

31

M4

21

53

4xM4 xL 7

15.4

62.9

62

13

63

M4

65

19.5

13

2

16

2

47.5

67

4.5

10

27

19.5

13

2

16

2

6

43

4.5

10

75.5

95

5

5

15

15

L3 L1 L3

L11L11

D9

L7L7

B1

h9

H1

(Output Shaft)

(Input Shaft)

L1

L11

D6

ØD3

B2

h9

D16

ØD13

L11

D1

ØD8

L2L 4

L8L8

Sha ft Opti on S1

Sha ft Opti on S1 Sha ft Opti on S2

h7

ØD5

ØD7

ØD4

g6

ØD10

ØD11

Shaft Option S2

ØD3

k6

H2

ØD13

k6

h7

ØD14

ØD12

L12 L14 L12L14

L21 L21

L22 L22

L6 L5

L9

k6

L16 L15

L19

k6

h7

ØD14

ØD12

Key acc. to DIN6885/1

L10

Key acc. to DIN6885/1

L20

L11L11

g6

ØD10

ØD11

L1

[unit: mm]

AT075 4M AT090 4M AT110 4M AT140 4M AT170 4M AT210 4M AT240 4M AT280 4M

M6

16

73

35

M5

22

62

4xM5 xL 8

20.4

72.9

72

16

73

M5

75

30

14.5

2

25

2.5

54

84

4.8

12.5

30

30

15

2

25

2.5

8

52.5

4.8

12.5

90

120

5

5

18

18

M6

18

88

43

M5

28

76

4xM5 xL 8

25.8

87

86

18

88

M5

90

35

15

2

28

3.5

62

97

4.8

12.5

36

35

15

2

28

3.5

8

55

4.8

12.5

100

135

6

6

20.5

20.5

M8

22

108

53

M8

33

95

6xM6 xL 10

35.8

107

106

22

108

M8

110

40

15

2

32

4

72

112

7.2

19

44

40

15

2

32

4

8

60

7.2

19

115

155

6

6

24.5

24.5

M10

32

135

68

M12

47

92

6xM6xL10

49.8

103

104

32

135

M12

140

50

15

2

45

2.5

87

137

10

28

55

50

15

2

45

2.5

10

60

10

28

130

180

10

10

35

35

M12

40

165

83

M16

55

114

6xM8xL12.5

59.3

127

128

40

165

M16

170

60

15

2

50

5

102

162

12

36

67

60

15

2

50

5

10

70

12

36

155

215

12

12

43

43

M16

50

205

104

M16

75

142

6xM8xL12.5

79.3

158

160

50

205

M16

210

75

20

2

70

2.5

127

202

12

36

85

75

20

2

70

2.5

10

90

12

36

195

270

14

14

53.5

53.5

M16

55

235

124

M16

85

160

6xM8xL12.5

92.3

178

180

55

235

M16

240

85

25

2

80

2.5

147

232

12

36

95

85

25

2

80

2.5

10

105

12

36

225

310

16

16

59

59

6xM10xL15

102. 3

M16

60

275

144

M20

110

176

198

200

60

275

M20

280

110

25

2

100

5

167

277

15

42

110

110

25

2

100

5

10

120

15

42

260

370

18

18

64

64

Loading...

Loading...