Apex Dynamics AN Series, ANR Series Catalog

AN / ANR Series

Characteristic Highlights

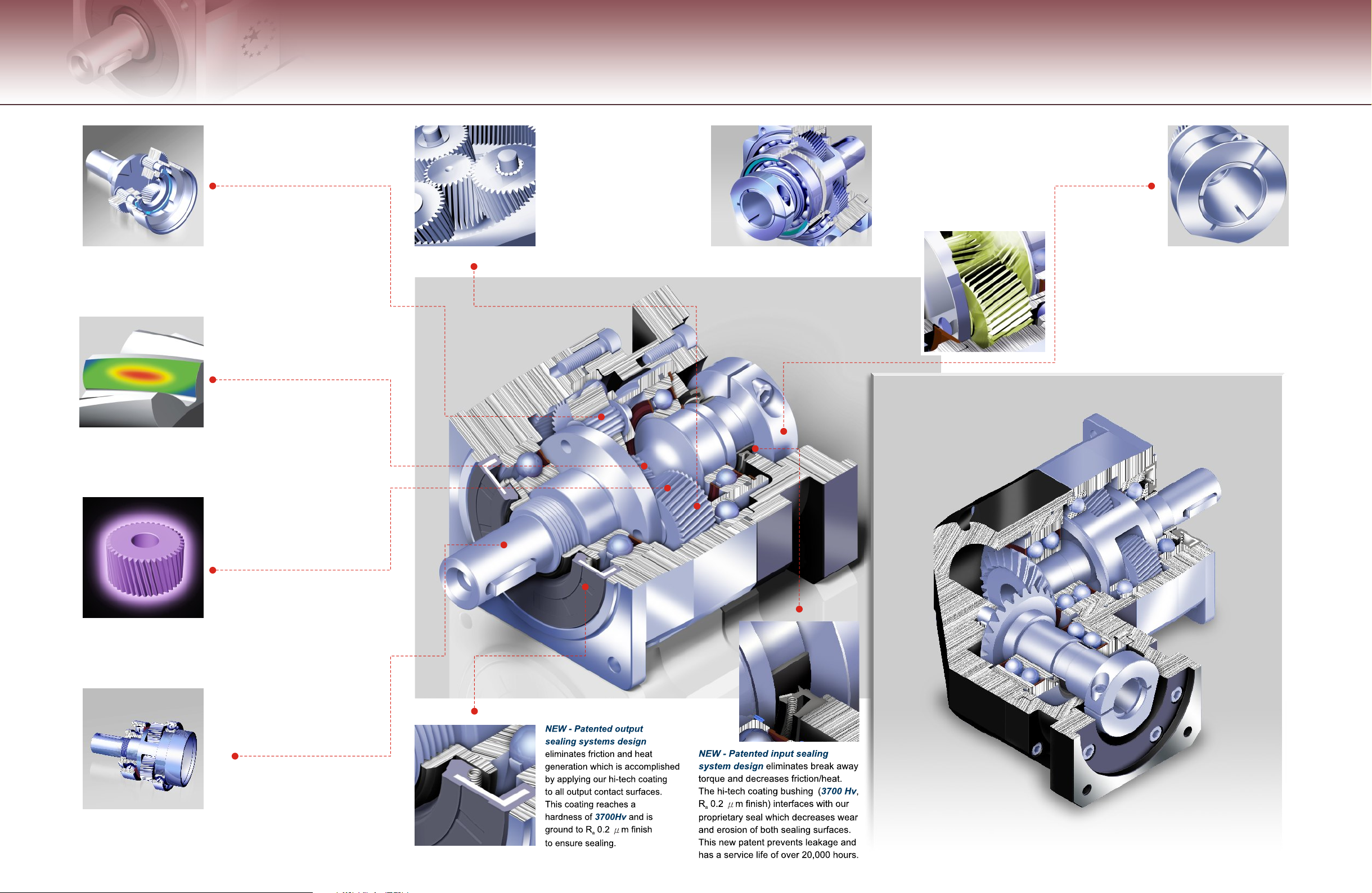

Planet gears rotate on for

increased stiffness and the maximum number of contact points.

Hardened thrust washers allow the precise control of clearances in

order to eliminate backlash.

Industry-leading gear performance is attained with our

technology. Ease off of the tooth profile and lead crowning

optimizes the gear mesh under load and achieves maximum tooth

surface contact.

solid uncaged needle roller bearings

HeliTopo

Helical gear design. Helical

gearing increases the tooth to

tooth contact ratio by as much

as 33%, Benefits include

increased torque capacity ,

ultimate smoothness, lower

backlash and decreased noise.

The helix angle is carefully

chosen to gain these

advantages while not producing

excessive axial forces.

Patented planet carrier design

mounts the sun gear bearing directly

into the planet carrier in order to

eliminate misalignment. This exclusive

design offers great advantages in

decreased noise, vibration and

transmission errors and losses.

Lubrication by synthetic grease for

smooth operation over the whole

service life, Sealed to standard

for ingress protection and can be

mounted in any orientation .

IP65

Triple split collet with dynamic balanced set

collar clamping system provides backlash free

power transmission and eliminates slippage. 100%

concentricity allows for smooth rotation and higher

input speed capability.

ANR Series

Our In-house plasma nitriding treatment process allows the

hardness of the gear flanks to reach over 900Hv for superior wear

resistance and still maintain a core hardness of 30HRc for toughness

and resistance to shock loading.

One-piece carrier and output housing ensure 100% concentricity and

alignment of all the rotating components. One-piece construction

increases strength, rigidity and system reliability.

APEX 1 APEX 2

ANR version

with 90 input via spiral bevel gear. Featuring an extremely short,

o

rigid housing with full compatibility to any motor.

AN Series

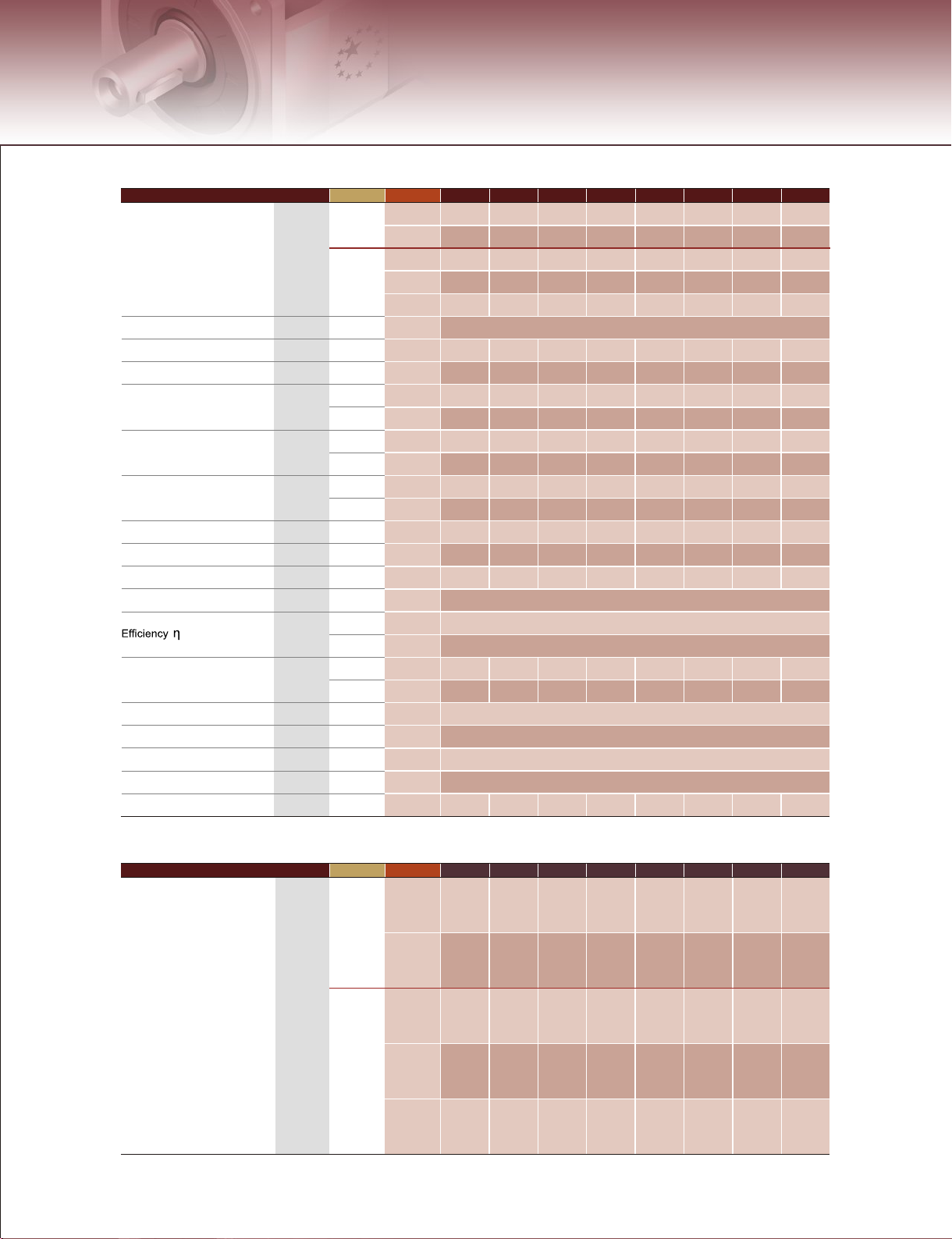

Gearbox Performance

Model No.

Nominal Output Torque T

Emergency Stop Torque T

Nominal Input Speed n

Max. Input Speed n

Micro Backlash P0

Reduced Backlash P1

Standard Backlash P2

Torsional Rigidity

Max. Radial Load F

Max. Axial Load F

Service Life

Weight

Operating Temperature

Lubrication

Degree of Gearbox Protection

Mounting Position

Noise Level (n =3000rpm, No Load)

1

1N

1B

3

2rB

3

2aB

2N

2NOT

2

arcmin

arcmin

Nm/arcmin

dB(A)

Nm

Nm

rpm

rpm

N

N

hr

%

kg

o

C

Stage

1

2

1,2

1,2

1,2

1

2

1

2

1

2

1,2

1,2

1,2

1,2

1

2

1

2

1,2

1,2

1,2

1,2

Rati o

5

10

25

50

100

5~100

5~100

5~100

5~10

25~100

5~10

25~100

5~10

25~100

5~100

5~100

5~100

5~100

5~10

25~100

5~10

25~100

5~100

5~100

5~100

5~100

1

AN023

AN023A

AN023B

AN023C

AN034

AN034A

AN034B

60 60 1 60 160 - - - -

40 40 1 00 100

- - - -

60 60 1 60 160 160 16060 60

60 60 1 60 160 160 16060 60

40 40 1 00 100 100 10040 40

3 times of Nominal Output Torque

5 000, 5 000, 5 000, 5 000, 4 000, 4 000, 4 000, 4 000,

10,000 10 000, 10 000, 10 000, 8 000, 8 000, 8 000, 8 000,

- - - - - -

- -

≤3 ≤3 ≤3 ≤3

- - - -

- - -- - -

≤1 ≤1

≤5 ≤5 ≤5 ≤5≤5 ≤5 ≤5 ≤5

≤5 ≤5 ≤5 ≤5

- - - -

≤7 ≤7 ≤7 ≤7≤7 ≤7 ≤7 ≤7

2.6

950

475

2.6 1.7 9.5

1,000

950

475

500

1.7

1,000

500

9.5

2,450

1,225

2,450

1,225

3.2

2,550

1,275

20,000*

≥97%

≥94%

1.2 1.2 3.43.4

- - - -

1.4 1.4 441.9 1.9 5.3 5.3

o

o

-10 C ~9 0 C

Synthetic lubrication oils

IP65

all directions

≤58 ≤60 ≤58 ≤60 ≤60 ≤63 ≤60 ≤63

AN034C

3.2

2,550

1,275

Gearbox Inertia

Model No.

Mass Moments of Inertia J

1. Ratio ( i=N / N )

in out

* S1 service life 10,000 hrs (Consult us)

1

kg‧cm

Stage

1

2

2

2. T = 60% of T

1

Rati o

AN023

5

10

25

50

100

2B 2NOT

AN023A

AN023B

AN023C

AN034

AN034A

AN034B

AN034C

0.13 0.13 0.47 0.47- - - -

0.13

0.03 0.03

0.03 0.03

0.03 0.03

- - - -

0.13

0.13 0.13

0.13 0.13

0.13 0.13

0.44

0.44

0.13 0.47 0.13 0.4 7

0.13 0.44 0.13 0.44

0.13 0.44 0.13 0 .4 4

3. Applied to the output shaft center @ 100 rpm

APEX 3

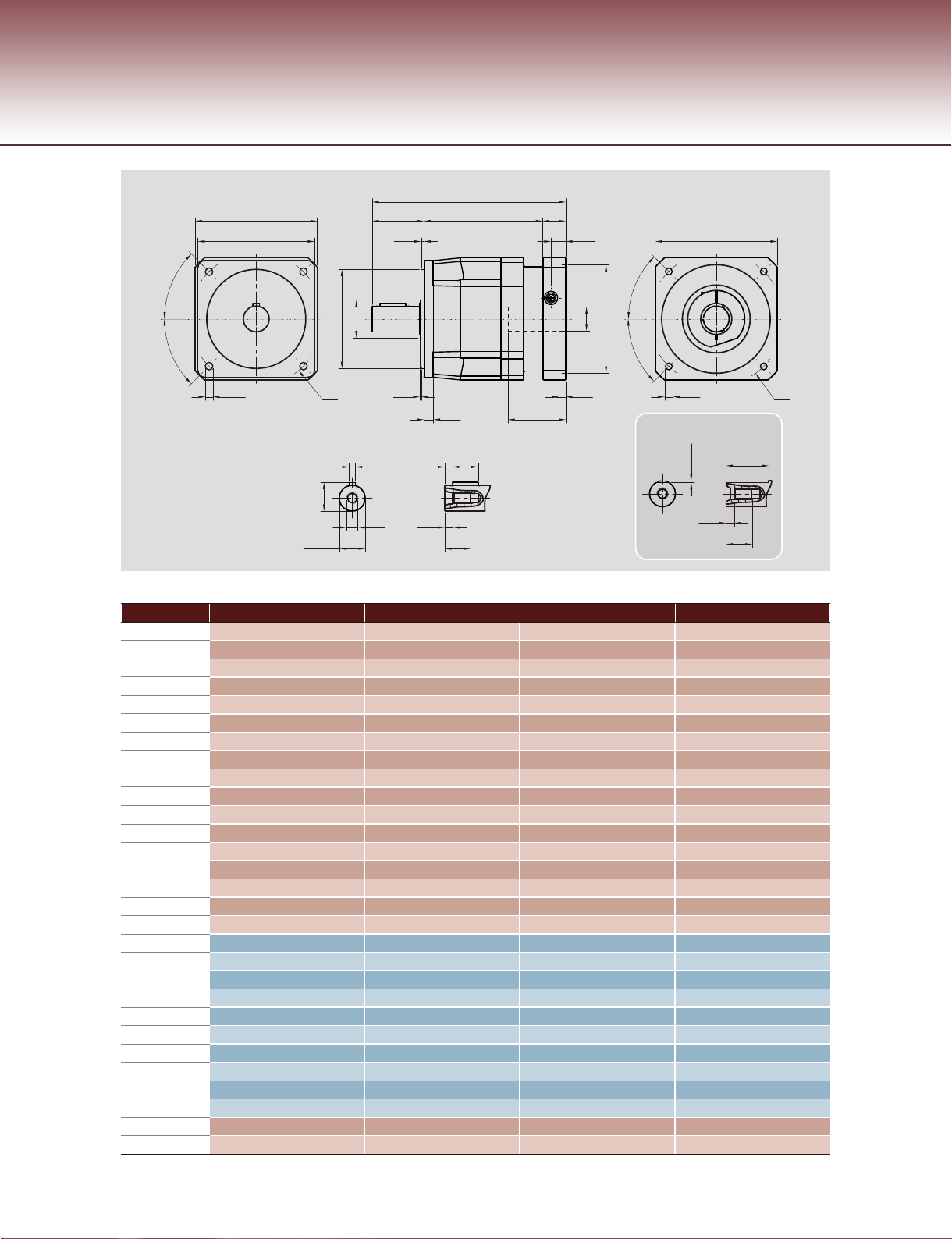

Dimensions (1-stage, Ratio i=5~10)Specifications

C9

L11

L1

L2 L8 C8

L3

C10

C7

o

45

j6

ØD5

ØD1

ØD4

L4

L7

C4

C6

45

o

ØD2

o

45

ØC3

ØC5

4

5

o

C2

ØC1

Only AN023B

19.05

L9

L10

ØD3

B1

H1

j6

L6 L5

h9

L9

D6

L10

0.381

Unit: mm (inch)

Dimension

D1

D2

D3 j6

D4 j6

D5

D6

L1

L2

L3

L4

L5

L6

L7

L8

L9

L10

L11

4

C1

4

C2

4

C3

4

C4

4

C5

4

C6

4

C7

4

C8

4

C9

4

C10

B1h9

H1

4. C1~C10 are motor specific dimensions (nema std shown). Refer to Apexdyna.com and design Tool to view your specific motor mounting system.

66.675 (2.625)

5.6 5.6

12.7 (0.50)

38.1 (1.50)

22 30

M5 x 0.8P M8 x 1.25P

60 86

31.8 (1.252)

2 2

1 1

19.05 (0.750)

3.8 (0.150)

6 7

64.5 87.5

4.8 7 .2

12.5 19

60 90

66.675 (2.625)

M5 x 0.8P

≤14 / ≤16 ≤19 / ≤24

40 (1.575)

38.15 (1.502)

4 (0.157)

58 (2.283)

25 (0.984)

121.3 (4.776)

19.5 (0.768)

3.175 (0.125)

14.125 (0.556)

66.675 (2.625)

5.6

9.525 (0.375)

38.1 (1.50)

22

M4 x 0.7P

60

25.4 (1.00)

2

1

-

-

6

64.5

4.5

10

60

66.675 (2.625)

M5 x 0.8P

≤14 / ≤16 ≤1 9 / ≤24

40 (1.575)

38.15 (1.502)

4 (0.157)

58 (2.283)

25 (0.984)

114.9 (4.524)

19.5 (0.768)

-

-

AN034AN023BAN023

98.425 (3.875)

19.05 (0.750)

73.025 (2.875)

38.1 (1.50)

19.05 (0.750)

5.7 (0.224)

98.425 (3.875)

M5 x 0.8P M5 x 0.8P

40 (1.575)

73.08 (2.877)

4 (0.157)

85 (3.346)

17 (0.669)

142.6 (5.614)

10.75 (0.423)

4.763 (0.188)

21.113 (0.831)

AN034B

98.425 (3.875)

5.6

12.7 (0.50)

73.025 (2.875)

30

M5 x 0.8P

86

31.8 (1.252)

2

1

19.05 (0.750)

3.8 (0.150)

7

87.5

4.8

12.5

90

98.425 (3.875)

40 (1.575)

73.08 (2.877)

4 (0.157)

85 (3.346)

17 (0.669)

136.3 (5.366)

10.75 (0.423)

3.175 (0.125)

14.125 (0.556)

APEX 4

Loading...

Loading...