POWER DUAL OPERATIONAL AMPLIFIERS

PA21/25/26 • PA21A/25A

MICROTECHNOLOGY

FEATURES

• LOW COST

• WIDE COMMON MODE RANGE —

Includes negative supply

• WIDE SUPPLY VOLTAGE RANGE

Single supply: 5V to 40V

Split supplies: ±2.5V to ±20V

• HIGH EFFICIENCY — |Vs–2.2V| at 2.5A typ

• HIGH OUTPUT CURRENT — 3A min (PA21A)

• INTERNAL CURRENT LIMIT

• LOW DISTORTION

APPLICATIONS

• HALF & FULL BRIDGE MOTOR DRIVERS

• AUDIO POWER AMPLIFIER

STEREO — 18W RMS per channel

BRIDGE — 36W RMS per package

• IDEAL FOR SINGLE SUPPLY SYSTEMS

5V — Peripherals

12V — Automotive

28V — Avionic

DESCRIPTION

The amplifiers consist of a monolithic dual power op amp

in a 8-pin hermetic TO-3 package (PA21 and PA25) and a 12pin SIP package (PA26). Putting two power op amps in one

package and on one die results in an extremely cost effective

solution for applications requiring multiple amplifiers per

board or bridge mode configurations.

The wide common mode input range includes the negative

rail, facilitating single supply applications. It is possible to

have a “ground based” input driving a single supply amplifier

with ground acting as the “second” or “bottom” supply of the

amplifier.

The output stages are also well protected. They possess

internal current limit circuits. While the device is well protected, the Safe Operating Area (SOA) curve must be observed. Proper heatsinking is required for maximum reliability.

This hybrid integrated circuit utilizes thick film (cermet)

resistors, ceramic capacitors and semiconductor chips to

maximize reliability, minimize size and give top performance.

Ultrasonically bonded aluminum wires provide reliable interconnections at all operating temperatures. The 8-pin TO-3

package is hermetically sealed and electrically isolated. The

use of compressible isolation washers voids the warranty.

The tab of the SIP12 plastic package is tied to –V

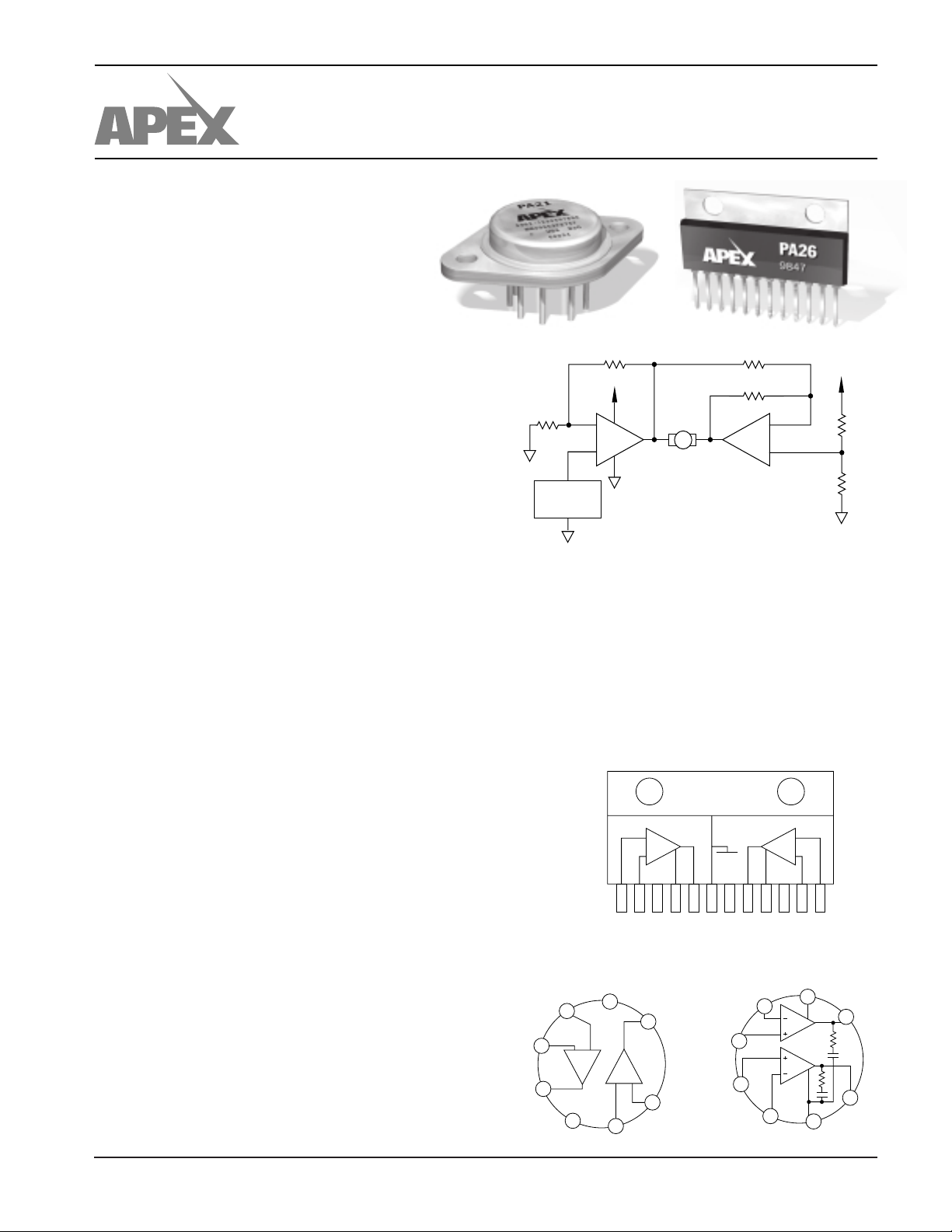

TYPICAL APPLICATION

R1 and R2 set up amplifier A in a non-inverting gain of 2.8.

Amp B is set up as a unity gain inverter driven from the output

of amp A. Note that amp B inverts signals about the reference

node, which is set at mid-supply (14V) by R5 and R6. When the

command input is 5V, the output of amp A is 14V. Since this is

equal to the reference node voltage, the output of amp B is also

14V, resulting in 0V across the motor. Inputs more positive

than 5V result in motor current flow from left to right (see Figure

1). Inputs less positive than 5V drive the motor in the opposite

direction.

HTTP://WWW.APEXMICROTECH.COM (800) 546-APEX (800) 546-2739

.

S

R1

5K

COMMAND

INPUT

0/10V

R2

9K

+28V

–

A B

+

1/2 PA21

M

R3

R4

1/2 PA21

10K

10K

+28V

–

+

R5

10K

R6

10K

FIGURE 1: BIDIRECTIONAL SPEED CONTROL FROM

A SINGLE SUPPLY

The amplifiers are especially well-suited for this application.

The extended common mode range allows command inputs

as low as 0V. Its superior output swing abilities let it drive within

2V of supply at an output current of 2A. This means that a

command input that ranges from 0V to 10V will drive a 24V

motor from full scale CCW to full scale CW at up to ±2A. A

single power op amp with an output swing capability of Vs –6

would require ±30V supplies and would be required to swing

48V p-p at twice the speed to deliver an equivalent drive.

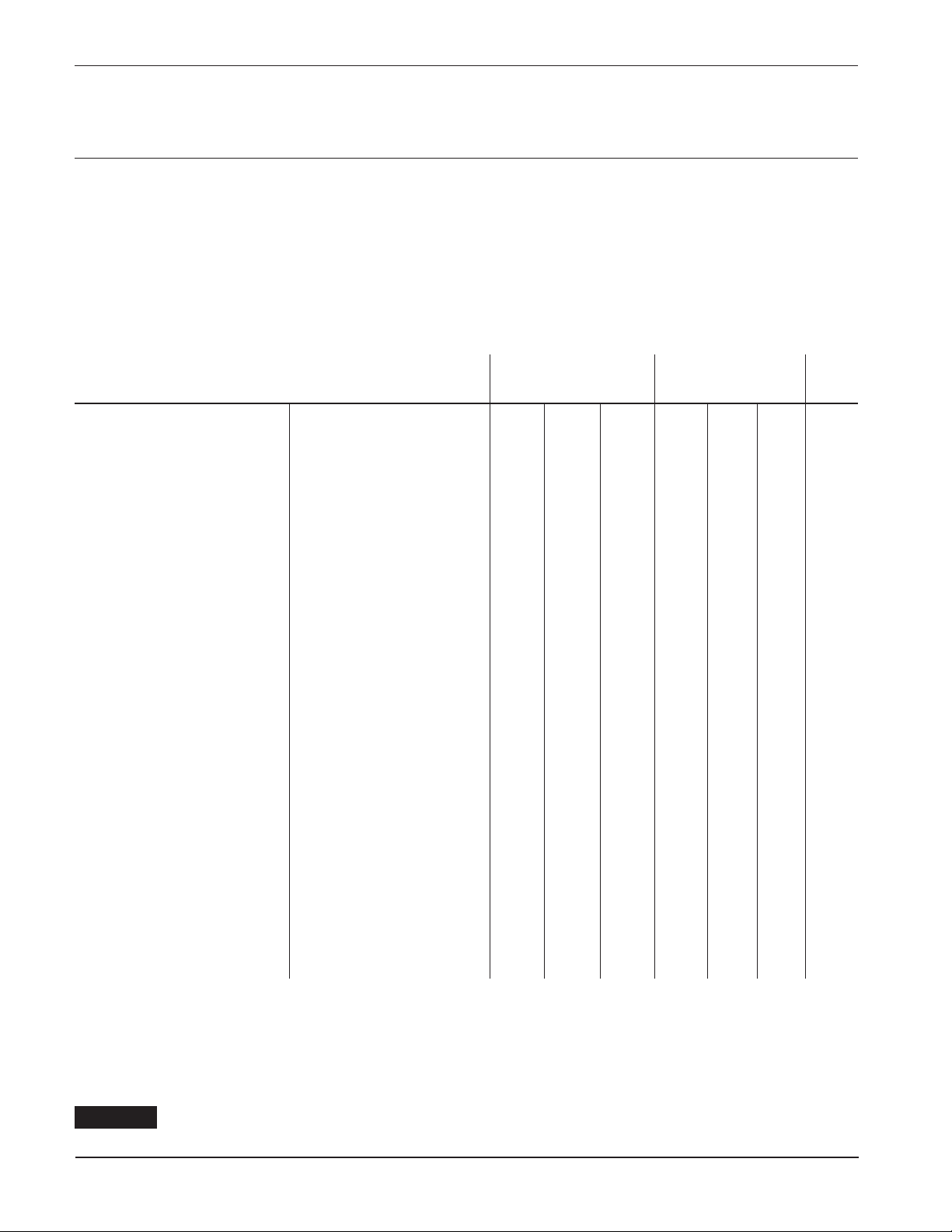

EXTERNAL CONNECTIONS

PA26

Connect pins

3 and 10 to pin 7

and connect pins

4 and 9 to pin 6

unless special

functions are required.

+IN, A

3

–IN, A

4

– +

5

OUT, A

TOP VIEW

–V

S

6

PA25

+V

A

+IN, B

+

A

–

123456789101112

S

/+V

–IN A

+IN A

BOOST

V

S

2

OUT, B

1

B

–+

8

–IN, B

7

S

/–V

SENSE

I

SUB

S+VS

–V

OUT A

–IN, A

4

+IN, A

5

+IN, B

–IN, B

/–V

OUT B

I

3

6

+

B

–

S

SENSE

S

/+V

BOOST

V

+V

A

B

PA21

2

–V

–IN B

S

7

S

+IN B

OUT, A

1

8

OUT, B

APEX MICROTECHNOLOGY CORPORATION • TELEPHONE (520) 690-8600 • FAX (520) 888-3329 • ORDERS (520) 690-8601 • EMAIL prodlit@apexmicrotech.com

PA21/25/26 • PA21A/25A

ABSOLUTE MAXIMUM RATINGS

SPECIFICATIONS

ABSOLUTE MAXIMUM RATINGS

SUPPLY VOLTAGE, total 5V to 40V

OUTPUT CURRENT SOA

POWER DISSIPATION, internal (per amplifier) 25W

POWER DISSIPATION, internal (both amplifiers) 36W

INPUT VOLTAGE, differential ±V

INPUT VOLTAGE, common mode +VS, -VS–.5V

JUNCTION TEMPERATURE, max

1

S

150°C

TEMPERATURE, pin solder—10 sec max 300°C

TEMPERATURE RANGE, storage –65°C to 150°C

OPERATING TEMPERATURE RANGE, case –55°C to 125°C

SPECIFICATIONS

PARAMETER TEST CONDITIONS

PA21/25/26

2

MIN TYP MAX MIN TYP MAX UNITS

PA21A/PA25A

INPUT

OFFSET VOLTAGE, initial 1.5 10 .5 4 mV

OFFSET VOLTAGE, vs. temperature Full temperature range 15 10 µV/°C

BIAS CURRENT, initial 35 1000 * 250 nA

COMMON MODE RANGE Full temperature range –VS–.3 +VS–2* * V

COMMON MODE REJECTION, DC Full temperature range 60 85 * * dB

POWER SUPPLY REJECTION Full temperature range 60 80 * * dB

CHANNEL SEPARATION I

= 1A, F = 1kHz 50 68 * * dB

OUT

GAIN

OPEN LOOP GAIN Full temperature range 80 100 * * dB

GAIN BANDWIDTH PRODUCT AV = 40dB 600 * kHz

PHASE MARGIN Full temperature range 65 * °

POWER BANDWIDTH V

= 28V 13.6 * kHz

O(P-P)

OUTPUT

CURRENT, peak 2.5 3 A

CURRENT, limit 3.0 4.0 A

SLEW RATE .5 1.2 * * V/µs

CAPACITIVE LOAD DRIVE AV = 1 .22 * µF

VOLTAGE SWING Full temp. range, IO = 100mA |VS| –1.0 |VS| –0.8 * * V

VOLTAGE SWING Full temp. range, IO = 1A |VS| –1.8 |VS| –1.4 * * V

VOLTAGE SWING IO = 2.5A (PA21, 25) |VS| –3.0 |VS| –2.8 V

VOLTAGE SWING IO = 3.0A (PA21A, PA25A) |VS| –4.0 |VS| –3.5 V

POWER SUPPLY

VOLTAGE, V

CURRENT, quiescent, total 45 90 * * mA

3

SS

4

5

30 40 * * * V

THERMAL

RESISTANCE, junction to case

DC, single amplifier 5.0 * °C/W

DC, both amplifiers

AC, single amplifier 3.7 °C/W

AC, both amplifiers

5

5

3.4 * °C/W

2.4 °C/W

RESISTANCE, junction to air 30 * °C/W

TEMPERATURE RANGE, case Meets full range specifications –25 85 –25 85 °C

NOTES: * The specification of PA21A/PA25A is identical to the specification for PA21/PA25 in applicable column to the left.

1. Long term operation at the maximum junction temperature will result in reduced product life. Derate internal power dissipation

to achieve high MTTF.

2. Unless otherwise noted, the following conditions apply: ±V

3. +VS and –VS denote the positive and negative supply rail respectively. VSS denotes the total rail-to-rail supply voltage.

= ±15V, TC = 25°C.

S

4. Current limit may not function properly below VSS = 6V, however SOA violations are unlikely in this area.

5. Rating applies when power dissipation is equal in the two amplifiers.

CAUTION

The internal substrate contains beryllia (BeO). Do not break the seal. If accidentally broken, do not crush, machine, or

subject to temperatures in excess of 850°C to avoid generating toxic fumes. (PA21 and PA25 only. PA26 does not contain

BeO).

APEX MICROTECHNOLOGY CORPORATION • 5980 NORTH SHANNON ROAD • TUCSON, ARIZONA 85741 • USA • APPLICATIONS HOTLINE: 1 (800) 546-2739

TYPICAL PERFORMANCE

GRAPHS

PA21/25/26 • PA21A/25A

40

POWER DERATING

35

30

25

BOTH

AMPLIFIERS

20

15

SINGLE

AMPLIFIER

10

5

0

0 25 50 75 100 125

INTERNAL POWER DISSIPATION, P(W)

100

TEMPERATURE, T (°C)

SMALL SIGNAL RESPONSE

80

60

40

20

0

OPEN LOOP GAIN, A (dB)

–20

1 100 1M

10 1K 10K 100K

FREQUENCY, F (Hz)

150

1.75

B

BIAS CURRENT

1.5

1.25

1.0

.75

.5

.25

NORMALIZED BIAS CURRENT, I (X)

–50 0 100

–25 25 50 75

CASE TEMPERATURE, T (°C)

PHASE RESPONSE

0

–30

–60

–90

–120

PHASE, (°)ϕ

–150

–180

–210

0 100 .1M

10 10K 1M

1K

FREQUENCY, F (Hz)

80

75

70

CROSSTALK

AMP 1

I = 1A

OUT

AV = –100

65

AMP 2

60

I = 0

CROSSTALK (dB)

OUT

AV = –100

55

50

125

C

10 1K

100

FREQUENCY, F (Hz)

10K

20K

POWER RESPONSE

50

40

PP

30

O

25

20

15

10

|+V | + |–V | = 40V

OUTPUT VOLTAGE, V (V )

SS

5

1K 100K

10K

FREQUENCY, F (Hz)

POWER SUPPLY REJECTION

89

86

83

80

77

74

71

69

66

63

60

0 10K

POWER SUPPLY REJECTION, PSR (dB)

HARMONIC DISTORTION

3

AV = –10

V = 16V

OUT

1

R = 8

L

.1

.01

.001

10

TOTAL HARMONIC DISTORTION, THD (%)

1K 1M

100K10 100 0

FREQUENCY, F (Hz)

PP

Ω

100 1K 40K

10K

FREQUENCY, F (Hz)

PULSE RESPONSE

10

O

5

0

–5

OUTPUT VOLTAGE, V (V)

–10

200 400 600 800 1K

TIME, t (µs)

QUIESCENT CURRENT

40

SS

35

30

25

20

15

10

5

TOTAL SUPPLY VOLTAGE, V (V)

.8 .9 1 1.1 1.2

.7 1.4

NORMALIZED QUIESCENT CURRENT, I (X)

AV = 1

R =10

L

1.3

Ω

125

100

75

50

25

0

–25

–50

Q

1.6

LIM

CURRENT LIMIT

1.4

1.2

1.0

.8

.6

.4

–50 0 75 125

–25 25 100

NORMALIZED CURRENT LIMIT, I (A)

CASE TEMPERATURE, T (°C)

OUTPUT VOLTAGE SWING

3.5

CASE TEMPERATURE, T (°C)

50

3

2.5

2

1.5

1

C

.5

0

VOLTAGE DROP FROM SUPPLY, (V)

0 1.5 2.5

12

.5 3.5

OUTPUT CURRENT, I (A)

C

3

O

APEX MICROTECHNOLOGY CORPORATION • TELEPHONE (520) 690-8600 • FAX (520) 888-3329 • ORDERS (520) 690-8601 • EMAIL prodlit@apexmicrotech.com

PA21/25/26 • PA21A/25A

GENERAL

Please read Application Note 1 "General Operating Considerations" which covers stability, supplies, heat sinking, mounting, current limit, SOA interpretation, and specification interpretation. Visit www.apexmicrotech.com for design tools that

help automate tasks such as calculations for stability, internal

power dissipation, current limit and heat sink selection. The

"Application Notes" and "Technical Seminar" sections contain

a wealth of information on specific types of applications.

Package outlines, heat sinks, mounting hardware and other

accessories are located in the "Packages and Accessories"

section. Evaluation Kits are available for most Apex product

models, consult the "Evaluation Kit" section for details. For the

most current version of all Apex product data sheets, visit

www.apexmicrotech.com.

4

3

2

SS

1

EACH, ONE LOADED

EACH, BOTH LOADED

1 ms

OPERATING

CONSIDERATIONS

* If the inductive load is driven near steady state conditions,

allowing the output voltage to drop more than 6V below the

supply rail while the amplifier is current limiting, the inductor

should be capacitively coupled or the supply voltage must be

lowered to meet SOA criteria.

NOTE: For protection against sustained, high energy flyback,

external fast-recovery diodes should be used.

MONOLITHIC AMPLIFIER

STABILITY CONSIDERATIONS

All monolithic power op amps use output stage topologies

that present special stability problems. This is primarily due to

non-complementary (both devices are NPN) output stages

with a mismatch in gain and phase response for different

polarities of output current. It is difficult for the op amp manufacturer to optimize compensation for all operating conditions.

The recommended R-C network of 1 ohm in series with

0.1µF from output to AC common (ground or a supply rail, with

adequate bypass capacitors) will prevent local output stage

oscillations.

This network is provided internally on the PA21 but must be

supplied externally on the PA25 and PA26. The amplifiers are

internally compensated for unity gain stability, no additional

compensation is required.

T = 25°C

C

.1

OUTPUT CURRENT FROM +V OR –V (A)

1 2 3 4 5 6 10 20 30 50

SUPPLY TO OUTPUT DIFFERENTIAL VOLTAGE V –V (V)

40

SO

CURRENT LIMIT

Current limit is internal to the amplifier, the typical value is

shown in the current limit specification.

SAFE OPERATING AREA (SOA)

The SOA curves combine the effect of all limits for this power

op amp. For a given application, the direction and magnitude

of the output current should be calculated or measured and

checked against the SOA curves. This is simple for resistive

loads but more complex for reactive and EMF generating

loads. The following guidelines may save extensive analytical

efforts.

Under transient conditions, capacitive and dynamic* inductive loads up to the following maximum are safe:

±Vs CAPACITIVE LOAD INDUCTIVE LOAD

20V 200µF 7.5mH

15V 500µF 25mH

10V 5mF 35mH

5V 50mF 150mH

THERMAL CONSIDERATIONS

Although R

ences in the thermal interface between case and heatsink

which will limit power dissipation capability. Thermal grease or

an Apex TW03 thermal washer, R

recommended interface for the PA21/25. The PA26 may

require a thermal washer which is electrically insulating since

the tab is tied to –V

R

of up to 1°C/W or greater.

θCS

– IN

FIGURE 2. PA26 EQUIVALENT SCHEMATIC (ONE CHANNEL)

is the same for PA21/25/26 there are differ-

θJC

= .1-.2°C/W, is the only

θCS

. This can result in thermal impedances for

S

V

BOOST

+V

+IN

I

– V

S

OUT

SENSE

R

S

S

APEX MICROTECHNOLOGY CORPORATION • 5980 NORTH SHANNON ROAD • TUCSON, ARIZONA 85741 • USA • APPLICATIONS HOTLINE: 1 (800) 546-2739

OPERATING

CONSIDERATIONS

ADDITIONAL PA26 PIN FUNCTIONS

V

BOOST

The V

second stage of the amplifier. When that terminal is connected

to a voltage greater than +V

upper output transistor, which is a darlington connected emitter follower. This will better saturate the output transistor.

When V

output can swing 0.5 Volts closer to the rail. This is as much

improvement as is possible.

V

BOOST

Dynamically it represents 1K Ω impedance. The maximum

voltage that can be applied to V

–V

. There is no limit to the difference between +VS and V

S

FIGURE 3. SIMPLE BOOTSTRAPPING IMPROVES POSITIVE

OUTPUT SWING. CONNECT PINS 3 AND 10 TO V

USED. TYPICAL CURRENTS ARE 12

Figure 3 shows a bootstrap which dynamically couples the

output waveform onto the V

swing positive from it's initial value, which is equal to +V

(one diode drop), an amount equal to the output. In other

words, if V

positive 18 Volts, the voltage on the V

-0.7 + 18 or 36.6. The capacitor needs to be sized based on a

1K Ω impedance and the lowest frequency required by the

circuit. For example, 20Hz will require > 8uF.

I

SENSE

The I

stage only. Current will flow through this pin only when negative current is being outputted. The current that flows in this pin

is the same current that flows in the output (if –1A flows in the

output, the I

in the output the I

The resistor choice is arbitrary and is selected to provide

whatever voltage drop the engineer desires, up to a maximum

of 1.0 volt. However, any voltage dropped across the resistor

will subract from the swing to rail. For instance, assume a +/–

12 volt power supply and a load that requires +/–1A. With no

current sense resistor the output could swing +/–10.2 volts. If

a 1 Ω resistor is used for current sense (which will drop 1 Volt

at 1 Amp) then the output could swing +10.2, –9.2 Volts.

pin is the positive terminal for the load of the

BOOST

it will provide more drive to the

S

is about 5 Volts greater than +VS the positive

BOOST

pin requires approximately 10–12mA of current.

is 40 volts with respect to

BOOST

BOOST

+V

≤ 20V

S

D

B1

PA26A

PA26B

was initially 19.3, and the output swings

BOOST

pin is in series with the negative half of the output

SENSE

pin will have 1A of current flow, if +1A flows

SENSE

SENSE

D

B2

37

10

C

B1

5

C

B2

8

m

A EACH.

pin. This causes V

BOOST

pin will swing to 19.3

BOOST

pin will have 0 current flow).

SPEAKER

IF NOT

S

BOOST

-0.7 V

S

to

PA21/25/26 • PA21A/25A

+V

S

PA26

R

–VS OR GND

SENSE

I

= (VIN – V

L

B

R

L

A

R

R

IN

S

R

S

TRANSCONDUCTANCE BRIDGING

SENSE

is applied to the summing network and

S

) *RIN/ RFB/ R

REF

R

I

L

R

R

FB

IN

R

FB

V

REF

feature being used to obtain

s

should be set midway between +Vs and -Vs, Vref is

V

BIAS

V

IN

.

FIGURE 4. I

AMPLIFIER

Figure 4 shows the PA26 I

a Transconductance function. In this example, amplifier "A" is

the master and amplifier "B" is the slave. Feedback from

sensing resistors R

scaled to the inverting input of amplifier "A" where it is compared to the input voltage. The current sensing feedback

imparts a Transconductance feature to the amplifiers transfer

function. In other words, the voltage developed across the

sensing resistors is directly proportional to the output current.

Using this voltage as a feedback source allows expressing the

gain of the circuit in amperes vs input voltage. The transfer

funcion is approximately:

In the illustration, resistors RIN, RFB and RS determine gain.

V

BIAS

usually ground in dual supply systems or used for level

translation in single supply systems.

MOUNTING PRECAUTIONS

1. Always use a heat sink. Even unloaded, the PA26 can

dissipate up to 3.6 watts. A thermal washer or thermal

grease should always be used.

2. Avoid bending the leads. Such action can lead to internal

damage.

3. Always fasten the tab to the heat sink before the leads are

soldered to fixed terminals.

4. Strain relief must be provided if there is any probability of

axial stress to the leads.

This data sheet has been carefully checked and is believed to be reliable, however, no responsibility is assumed for possible inaccuracies or omissions. All specifications are subject to change without notice.

APEX MICROTECHNOLOGY CORPORATION • TELEPHONE (520) 690-8600 • FAX (520) 888-3329 • ORDERS (520) 690-8601 • EMAIL prodlit@apexmicrotech.com

PA21/25/26U REV. G FEBRUARY 2000 © 2000 Apex Microtechnology Corp.

Loading...

Loading...