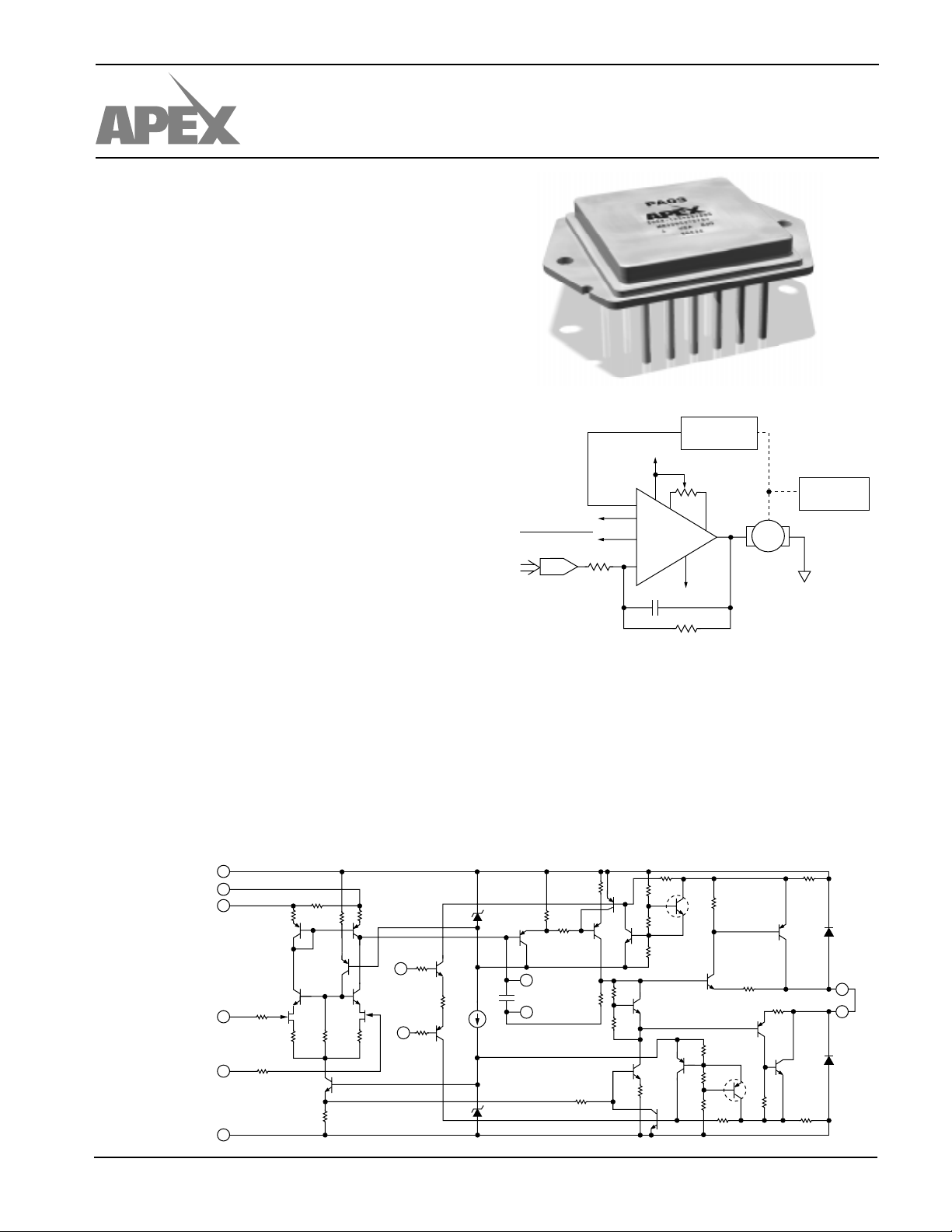

POSITION

FEEDBACK

OBJECT

TOOL

SHUT DOWN

+5V

+

+S

–S

–

–V

S

C

1

R2

R

BAL

+V

S

0/10V

R1

PA03

DESIRED

POSITION

DAC

POWER OPERATIONAL AMPLIFIERS

MICROTECHNOLOGY

HTTP://WWW.APEXMICROTECH.COM (800) 546-APEX (800) 546-2739

FEA TURES

• MO-127 COPPER POWER DIP™ PACKAGE

• HIGH INTERNAL POWER DISSIPATION

— 500 watts

• HIGH VOLTAGE OPERATION — ±75V

• VERY HIGH CURRENT — ±30 amps

• INTERNAL SOA PROTECTION

• OUTPUT SWINGS CLOSE TO SUPPLY RAILS

• EXTERNAL SHUTDOWN CONTROL

APPLICATIONS

• LINEAR AND ROTARY MOTOR DRIVES

• YOKE/MAGNETIC FIELD DEFLECTION

• PROGRAMMABLE POWER SUPPLIES to ±68V

• TRANSDUCER/AUDIO TO 1000W

DESCRIPTION

The super power PA03 advances the state of the art in both

brute force power and self protection against abnormal operating conditions. Its features start with a copper dip package

developed by Apex to extend power capabilities well beyond

those attainable with the familiar TO-3 package. The increased pin count of the new package provides additional

control features, while the superior thermal conductivity of

copper allows substantially higher power ratings.

The PA03 incorporates innovative current limiting circuits

limiting internal power dissipation to a curve approximating the

safe operating area of the power transistors. The internal

current limit of 35A is supplemented with thermal sensing

which reduces the current limit as the substrate temperature

rises. Furthermore, a subcircuit monitors actual junction temperatures and with a response time of less than ten milliseconds reduces the current limit further to keep the junction

temperature at 175°C.

The PA03 also features a laser trimmed high performance

FET input stage providing superior DC accuracies both initially

and over the full temperature range.

PA03 • P03A

TYPICAL APPLICATION

The PA03 output power stages contain fast reverse recov-

ery diodes for sustained high energy flyback protection.

This hybrid integrated circuit utilizes thick film resistors,

ceramic capacitors and silicon semiconductors to maximize

reliability, minimize size and give top performance. Ultrasonically bonded aluminum wires provide reliable interconnections at all operating temperatures. The MO-127 Copper,

12-pin Power Dip™ package (see Package Outlines), is

hermetically sealed and isolated from the internal circuits.

Insulating washers are not recommended.

IMPORTANT: Observe mounting precautions.

+V

8

BAL

11

BAL

12

Q5

Q31

Q20

B

Q3

Q18

4

+SHUT

DOWN

Q22

3

–SHUT

DOWN

Q2

Q17

–

1

+

2

–V

5

Q20

A

Q14

D1

Q12

9

COMP

10

D4

Q6

Q1

Q7

Q19

Q29

Q34

Q4

Q30

Q16

Q32

Q24

Q9

Q26

D2

+

7

6

–

D3

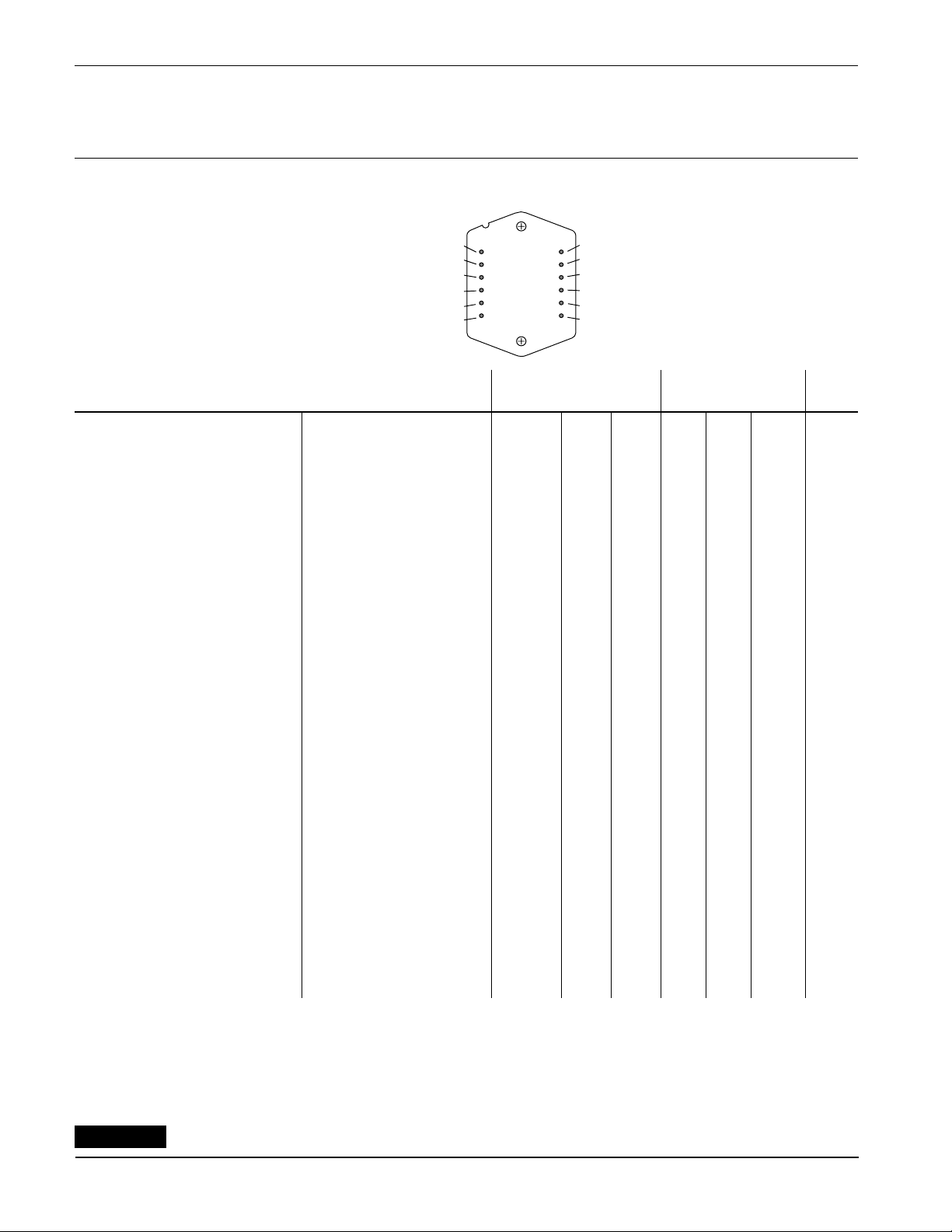

EQUIVALENT

SCHEMATIC

APEX MICROTECHNOLOGY CORPORATION • TELEPHONE (520) 690-8600 • FAX (520) 888-3329 • ORDERS (520) 690-8601 • EMAIL prodlit@apexmicrotech.com

OUT

PA03 • PA03A

ABSOLUTE MAXIMUM RATINGS

SPECIFICATIONS

ABSOLUTE MAXIMUM RATINGS

SUPPLY VOLTAGE, +VS to –V

OUTPUT CURRENT, within SOA Internally limited

S

POWER DISSIPATION, internal 500W

INPUT VOLTAGE, differential ±25V

INPUT VOLTAGE, common mode ±V

TEMPERATURE, pin solder-10s 300°C

TEMPERATURE, junction

1

TEMPERATURE RANGE, storage –65 to +150°C

OPERATING TEMP. RANGE, case –55 to +125°C

SHUTDOWN VOLTAGE, differential ±5V

SHUTDOWN VOLTAGE, common mode ±V

150V

S

175°C

S

–SHUT DN

+SHUT DN

–OUTPUT

SPECIFICATIONS

PARAMETER TEST CONDITIONS

–INPUT

+INPUT

–SUPPLY

EXTERNAL CONNECTIONS

1

2

3

4

5

6

2

12

11

TOP

10

VIEW

†

MIN TYP MAX MIN TYP MAX UNITS

BALANCE CONTROL

BALANCE CONTROL

PHASE COMP.

9

PHASE COMP.

8

+SUPPLY

7

+OUTPUT

PA03

Pins 6 & 7 must be

connected together.

If unused, tie Pins

11 & 12 to +SUPPLY.

† IMPORTANT: OBSERVE

MOUNTING PRECAUTIONS.

REVERSE INSERTION

WILL DESTROY UNIT.

PA03A

INPUT

OFFSET VOLTAGE, initial TC = 25°C ± .5 ± 2 ± .25 ± .5 mV

OFFSET VOLTAGE, vs. temperature Full temperature range 10 30 5 10 µV/°C

OFFSET VOLTAGE, vs. supply TC = 25°C8*µV/V

OFFSET VOLTAGE, vs. power Full temperature range 20 10 µV/W

BIAS CURRENT, initial TC = 25°C550310pA

BIAS CURRENT, vs. supply TC = 25°C .01 * pA/V

OFFSET CURRENT, initial TC = 25°C 2.5 50 1.5 10 pA

INPUT IMPEDANCE, DC TC = 25°C10

11

* Ω

INPUT CAPACITANCE TC = 25°C6*pF

COMMON MODE VOLTAGE RANGE3Full temperature range ± VS –10V * V

COMMON MODE REJECTION, DC Full temp. range, VCM = ±20V 86 108 * * dB

SHUTDOWN CURRENT

4

Full temperature range 100 * µA

SHUTDOWN VOLTAGE Full temp. range, amp enabled .85 * V

SHUTDOWN VOLTAGE Full temp. range, amp disabled 3.5 * V

GAIN

OPEN LOOP GAIN at 10Hz Full temp. range, full load 92 102 * * dB

GAIN BANDWIDTH PRODUCT at 1MHz TC = 25°C, full load 1 * MHz

POWER BANDWIDTH TC = 25°C, IO = 15A, VO = 88V

PHASE MARGIN Full temp. range, CC = 1.8nF 65 * °

PP

30 * kHz

OUTPUT

VOLTAGE SWING

VOLTAGE SWING

VOLTAGE SWING

3

3

3

TC = 25°C, IO = 30A ± VS –7 6.2 * * V

Full temp. range, IO = 12A ± VS –5 4.2 * * V

Full temp. range, IO = 146mA ± VS –4 3.5 * * V

CURRENT, peak TC = 25°C30*A

SETTLING TIME to .1% TC = 25°C, 10V step 8 * µs

SLEW RATE TC = 25°C, CC - open 8 * V/µs

CAPACITIVE LOAD Full temp. range, AV = 1 2 * nF

SHUTDOWN DELAY TC = –25°C, disable 10 * µs

TC = –25°C, operate 20 * µs

POWER SUPPLY

VOLTAGE Full temperature range ± 15 ± 50 ± 75 * * * V

CURRENT, quiescent

6

TC = 25°C 125 300 * * mA

CURRENT, disable mode Full temperature range 25 40 * * mA

THERMAL

RESISTANCE, AC junction to case

5

Full temp. range, F>60Hz .22 .28 * * °C/W

RESISTANCE, DC junction to case Full temp. range, F<60Hz .25 .3 * * °C/W

RESISTANCE, junction to ambient Full temperature range 14 * °C/W

TEMPERATURE, junction Sustained operation 150 * °C

TEMPERATURE RANGE, case Meets full range specification – 25 85 * * °C

NOTES: * The specification of PA03A is identical to the specification for PA03 in applicable column to the left.

1. Long term operation at the maximum junction temperature will result in reduced product life. Derate power dissipation to

achieve high MTTF.

2. The power supply voltage for all specifications is the TYP rating unless noted as a test condition.

3. +VS and –VS denote the positive and negative supply rail respectively. Total VS is measured from +VS to –VS.

4. Rating applies if both shutdown inputs are least 1V inside supply rails. If one of the shutdown inputs is tied to a supply rail, the

current in that pin may increase to 2.4mA.

5. Rating applies if the output current alternates between both output transistors at a rate faster than 60Hz.

6. The PA03 must be used with a heatsink or the quiescent power may drive the unit into thermal shutdown.

CAUTION

APEX MICROTECHNOLOGY CORPORATION • 5980 NORTH SHANNON ROAD • TUCSON, ARIZONA 85741 • USA • APPLICATIONS HOTLINE: 1 (800) 546-2739

The internal substrate contains beryllia (BeO). Do not break the seal. If accidentally broken, do not crush, machine, or

subject to temperatures in excess of 850°C to avoid generating toxic fumes.

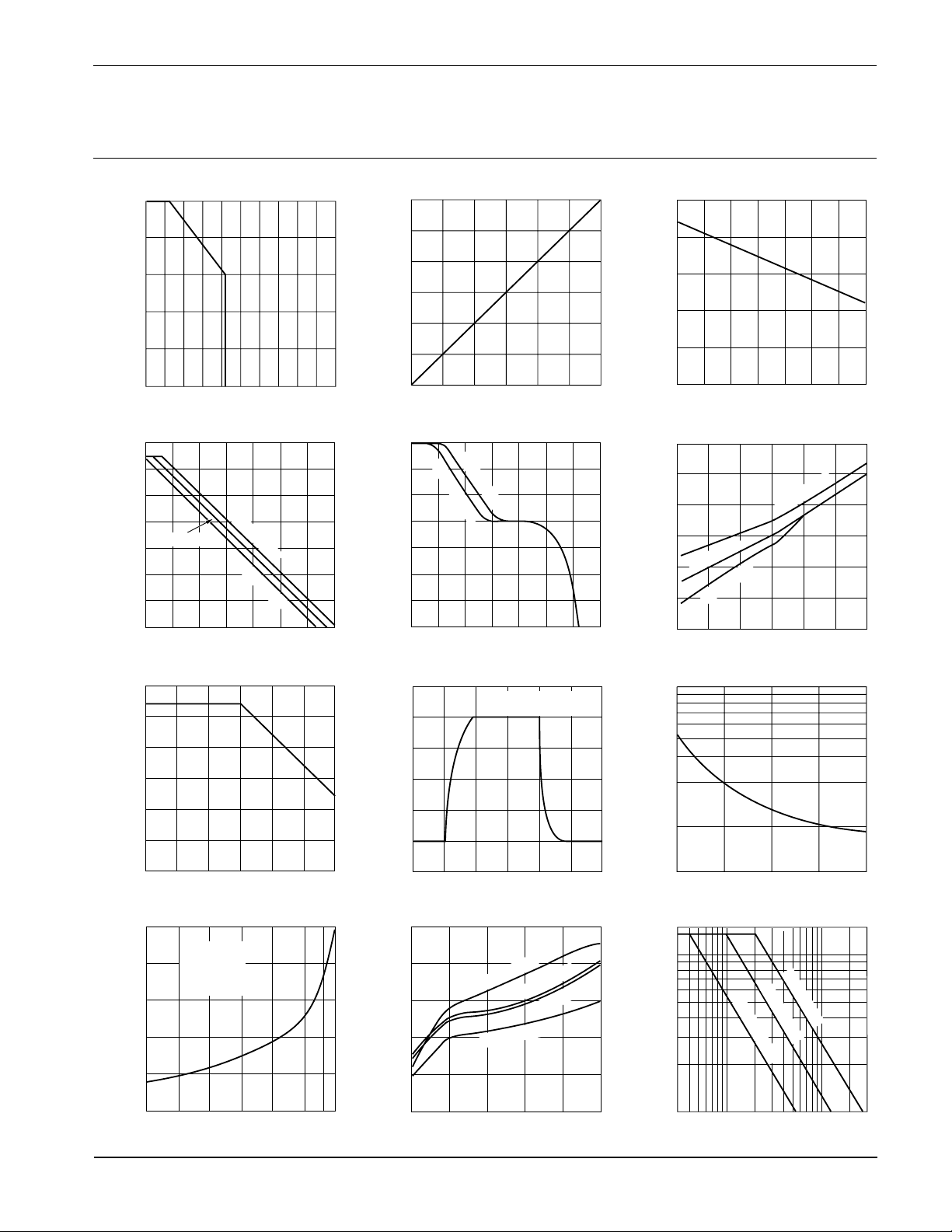

TYPICAL PERFORMANCE

GRAPHS

PA03 • PA03A

500

POWER DERATING

400

300

200

100

0

0

INTERNAL POWER DISSIPATION, P(W)

40 80 120 160 200

CASE TEMPERATURE, T (°C)

C

SMALL SIGNAL RESPONSE

120

100

80

C

C

60

CC = 470pF

40

20

OPEN LOOP GAIN, A (dB)

0

–20

1 100 10M

10 1K 10K .1M 1M

FREQUENCY, F (Hz)

COMMON MODE REJECTION

120

100

80

= OPEN

C

C

= 1800pF

BIAS CURRENT

B

256

64

16

4

1

.25

.06

NORMALIZED BIAS CURRENT, I (X)

5456585

–15 105

25

CASE TEMPERATURE, T (°C)

C

PHASE RESPONSE

0

–30

–60

Φ

–90

–120

PHASE, (°)

–150

–180

–210

1 100 .1M 10M

7.5

5.0

2.5

C

C

C

= OPEN

C

= 1800pF

10 10K 1M

1K

FREQUENCY, F (Hz)

PULSE RESPONSE

VIN = ±.5V, AV = 10

RL =.5Ω

50

CURRENT LIMIT

40

LIM

30

20

10

CURRENT LIMIT, I (A)

0

–50 –25 0

CASE TEMPERATURE, T (°C)

OUTPUT VOLTAGE SWING

7

25 75

50 100

C

6

5

= –55°C

C

T

4

= 25°C

C

T

3

= 125°C

C

T

2

1

VOLTAGE DROP FROM SUPPLY (V)

0 5 20 25

20

10

OUTPUT CURRENT, I

INPUT NOISE

O

√

(nV/ Hz)

10

N

125

3015

(A)

60

0

6

VOLTS

40

–2.5

4

20

0

1 10K

COMMON MODE REJECTION, CMR (dB)

1.0

0.3

FREQUENCY, F (Hz)

HARMONIC DISTORTION

VS = ±50V

A

P

R

0.1

1K 1M

= 10

V

= 200W

O

= 4 Ω

L

.1M10 100

.03

DISTORTION, (%)

.01

.003

30 100 300 1K 3K 10K 30K

FREQUENCY, F (Hz)

–5.0

–7.5

1.4

51015202530

0

TIME, t (µS)

QUIESCENT CURRENT

1.2

C

(X)

Q

1.0

.8

NORMALIZED, I

.6

.4

40

T

T

60 80 100 120 140

TOTAL SUPPLY VOLTAGE, V

= 125°C

= 85°C

C

C

T

= 25°C

= –25°C

C

T

2

INPUT NOISE VOLTAGE, V

10 100 10K .1M

1K

FREQUENCY, F (Hz)

150

)

100

PP

(V

O

POWER RESPONSE

50

40

C

C

C

C

= 1800pF

C

C

= OPEN

= 470pF

30

20

OUTPUT VOLTAGE, V

10

5K

3K

10K 50K 100K

(V)

S

FREQUENCY, F (Hz)

300K

APEX MICROTECHNOLOGY CORPORATION • TELEPHONE (520) 690-8600 • FAX (520) 888-3329 • ORDERS (520) 690-8601 • EMAIL prodlit@apexmicrotech.com

PA03 • PA03A

OPERATING

CONSIDERATIONS

GENERAL

Please read the “General Operating Considerations” section,

which covers stability, supplies, heatsinking, mounting, current

limit, SOA interpretation, and specification interpretation. Additional information can be found in the application notes. For

information on the package outline, heatsinks, and mounting

hardware, consult the “Accessory and Package Mechanical Data”

section of the handbook.

MOUNTING PRECAUTIONS

The PA03 copper base is very soft and easily bent. Do not put

any stress on the mounting ears of this package. This calls for

caution when pushing the amplifier into certain types of packaging

foam and particularly when inserting the device into a socket.

Insert the amplifier into the socket only by pushing on the perimeter

of the package lid. Pushing the unit into the socket by applying

pressure to the mounting tabs will bend the base due to the high

insertion force required. The base will then not contact the heatsink

evenly resulting in very poor heat transfer. To remove a unit from

a socket, pry the socket away from the heatsink so that the

heatsink will support the amplifier base evenly. Recommended

mounting torque is 8–10 in.-lbs. (.9–1.13 N•m).

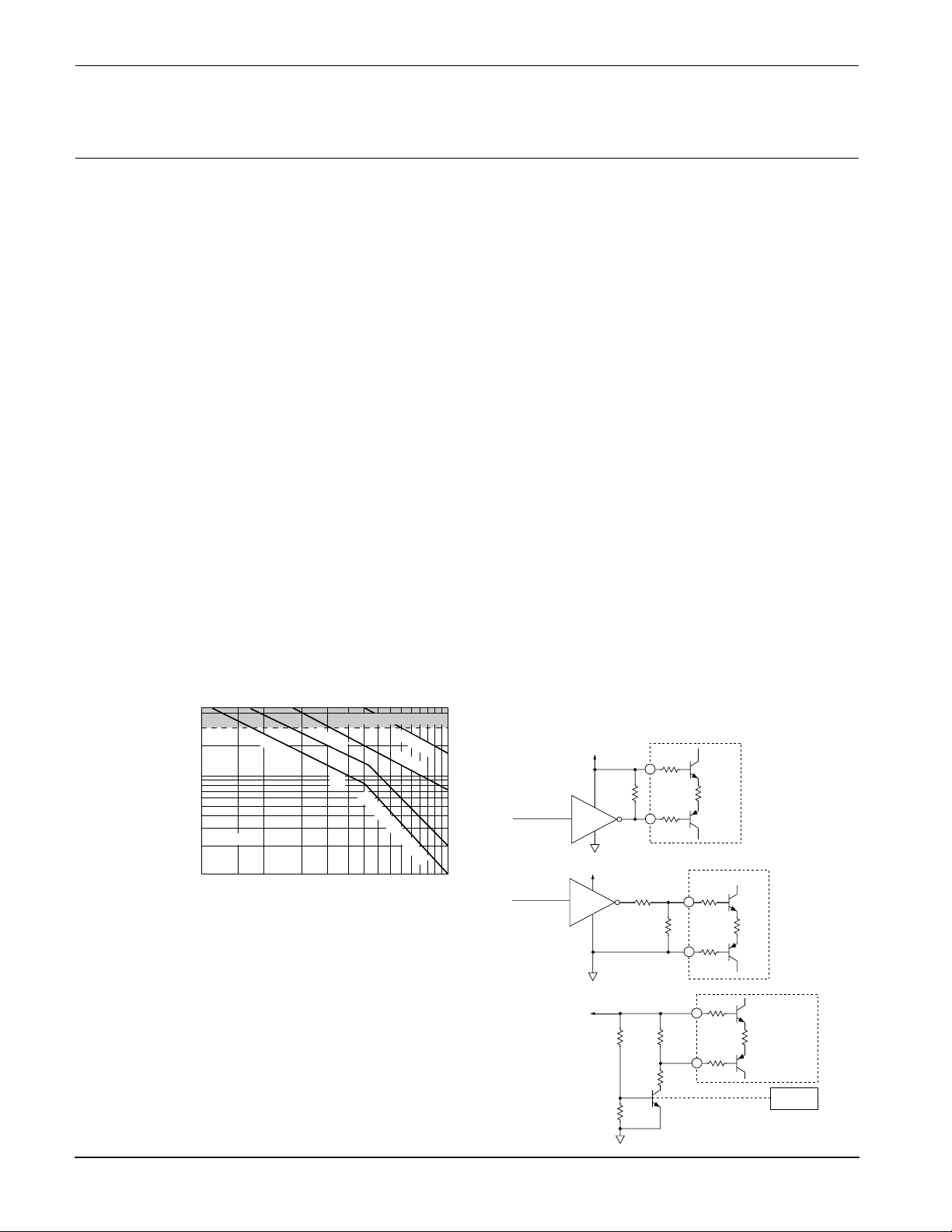

SAFE OPERATING AREA (SOA)

Due to the internal (non-adjustable) current limit of the PA03,

worst case power dissipation calculations must assume current

capability of 46 amps. Application specific circuits should be

checked against the SOA curve when relying upon current limit for

fault protectio

n.

SAFE OPERATING AREA CURVES

Second breakdown limitations do apply to the PA03 but are

less severe, since junction temperature limiting responds

within 10ms. Stress levels shown as being safe for more than

10ms duration

will merely

cause thermal

shutdown.

Under normal operating

conditions, activation of the

)

40

(A

S

30

OR –V

S

10

5

THERMAL

CURRENT LIMIT ZONE

100mS

dc

SECOND BREAKDOWN

1.0mS

10mS

thermal shutdown is a sign

that the internal junction

temperatures

have reached

approximately

TC = 25°C

1

10 20 50 100 150

SUPPLY TO OUTPUT DIFFERENTIAL VS –VO (V)

OUTPUT CURRENT FROM +V

175°C. Thermal shutdown is a short term safety feature. If the

conditions remain that cause thermal shutdown, the amplifier

will oscillate in and out of shutdown, creating peak high power

stresses, destroying useful signals, and reducing the reliability

of the device.

BALANCE CONTROL

The voltage offset of the PA03 may be externally adjusted to

zero. To implement this adjustment install a 100 to 200 ohm

potentiometer between pins 11 and 12 and connect the wiper arm

to the positive supply. Bypass pins 11 and 12 each with at least a

.01µF ceramic capacitor.

If the optional adjust provision is not used, connect both pins 11

and 12 to the positive supply.

OUTPUT STAGE SHUTDOWN

The entire power stage of the PA03 may be disabled using one

of the circuits shown in Figure 1. There are many applications for

this function. One is a load protection based on power delivered to

the load or thermal rise. Another one is conservation of power

when using batteries. The control voltage requirements accommodate a wide variety logic drivers.

1. CMOS operating at +5V can drive the control pins directly.

2. CMOS operating at greater than 5V supplies need a voltage

divider.

3. TTL logic needs a pull up resistor to +5V to provide a swing to

the fully disabled voltage (3.5V). When not using the shutdown

feature, connect both pins 3 and 4 to common.

PHASE COMPENSATION

At low gain settings an external compensation capacitor is

required to insure stability. In addition to the resistive feedback

network, roll off or integrating capacitors must also be considered.

A frequency of 1 MHz is most appropriate to calculate gain.

Operation at gains below 10, without the external compensation

capacitor opens the possibility of oscillations near output saturation regions when under load, the improper operation of the

thermal shutdown circuit. This can result in amplifier destruction.

At gains of 10 or more:

1. No external components are required.

2. Typical slew rate will be 8V/µs.

3. Typical phase margin will be 70°.

At a gain of 3:

1. Connect a 470pF compensation capacitor between pins 9 and

10.

2. Typical slew rate will be 5V/µs.

3. Typical phase margin will be 45°.

At unity gain:

1. Connect a 1.8nF compensation capacitor between pins 9 and

10.

2. Typical slew rate will be 1.8V/µs.

3. Typical phase margin will be 65°.

FIGURE 1a.

DIRECT DRIVE

OF SHUTDOWN

0 = OPERATE

1 = SHUT DN

0 = SHUT DN

1 = OPERATE

FIGURE 1b.

HIGH VOLTAGE

LOGIC INTERFACE

FIGURE 1c.

THERMALLY

ACTIVATED

SHUTDOWN

** SELECT SHUTOFF

TEMPERATURE

SELECT R4 FOR 5V

DROP ON R2

+5V

+15V

CMOS 4

+V

S

360–

400mV

R3

360

Ω

500

Ω

4

*

500

Ω

3

2R

R

R2

R1

4.7K

**

R4

30K

THERMAL SENSE

TRANSISTOR

PA03

Q14

1K1K

Q22

500

500

3

4

3

500

500

Ω

Ω

Ω

Ω

* NOT REQUIRED

WHEN USING

CMOS LOGIC

PA03

Q14

1K

Q22

Q14

1K

Q22

LOAD

PA03

This data sheet has been carefully checked and is believed to be reliable, however, no responsibility is assumed for possible inaccuracies or omissions. All specifications are subject to change without notice.

PA03U REV. I FEBRUARY 1998 © 1998 Apex Microtechnology Corp.

Loading...

Loading...