POWER OPERATIONAL AMPLIFIERS

MICROTECHNOLOGY

HTTP://WWW.APEXMICROTECH.COM (800) 546-APEX (800) 546-2739

FEATURES

• LOW COST, ECONOMY MODEL — PA01

• SECOND SOURCEABLE — PA73

• HIGH OUTPUT CURRENT — Up to ±5A PEAK

• EXCELLENT LINEARITY — PA01

• HIGH SUPPLY VOLTAGE — Up to ±30V

• ISOLATED CASE — 300V

APPLICATIONS

• MOTOR, VALVE AND ACTUATOR CONTROL

• MAGNETIC DEFLECTION CIRCUITS UP TO 4A

• POWER TRANSDUCERS UP TO 20kHz

• TEMPERATURE CONTROL UP TO 180W

• PROGRAMMABLE POWER SUPPLIES UP TO 48V

• AUDIO AMPLIFIERS UP TO 50W RMS

DESCRIPTION

The PA01 and PA73 are high voltage, high output current

operational amplifiers designed to drive resistive, inductive

and capacitive loads. For optimum linearity, the PA01 has a

class A/B output stage. The PA73 has a simple class C output

stage (see Note 1) to reduce cost for motor control and other

applications where crossover distortion is not critical and to

provide interchangeability with type 3573 amplifiers. The safe

operating area (SOA) can be observed for all operating conditions by selection of user programmable current limit resistors.

These amplifiers are internally compensated for all gain settings. For continuous operation under load, a heatsink of

proper rating is recommended.

This hybrid integrated circuit utilizes thick film (cermet)

resistors, ceramic capacitors and semiconductor chips to

maximize reliability, minimize size and give top performance.

Ultrasonically bonded aluminum wires provide reliable interconnections at all operating temperatures. The 8-pin TO-3

package is hermetically sealed and electrically isolated. The

use of compressible thermal washers and/or improper mounting torque will void the product warranty. Please see “General

Operating Considerations”.

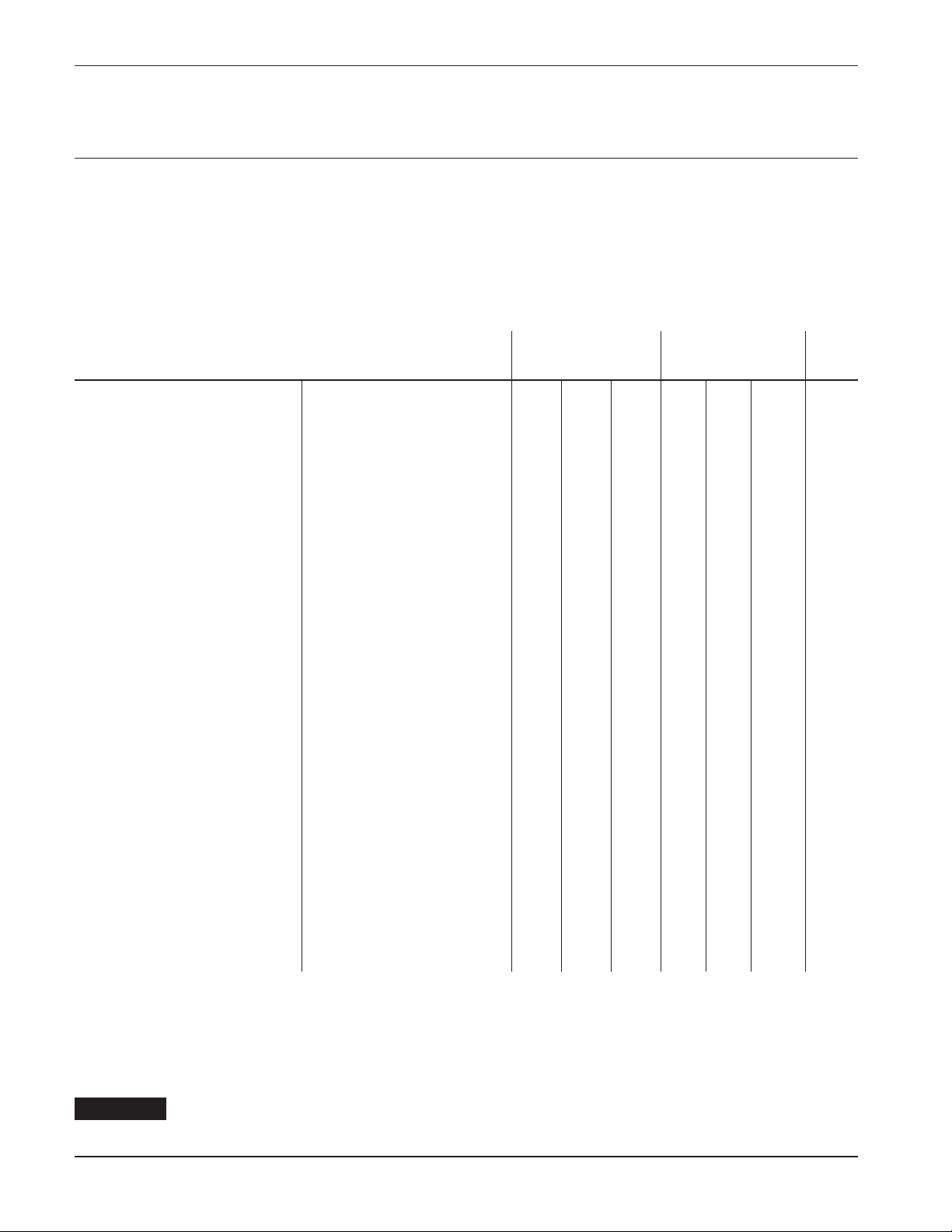

EXTERNAL CONNECTIONS

R

CL+

OUTPUT

R

CL–

+IN

–IN

+V

4

5

S

–V

3

S

TOP VIEW

6

2

7

N.C.

CL+

OUT

1

8

CL–

PA01 • PA73

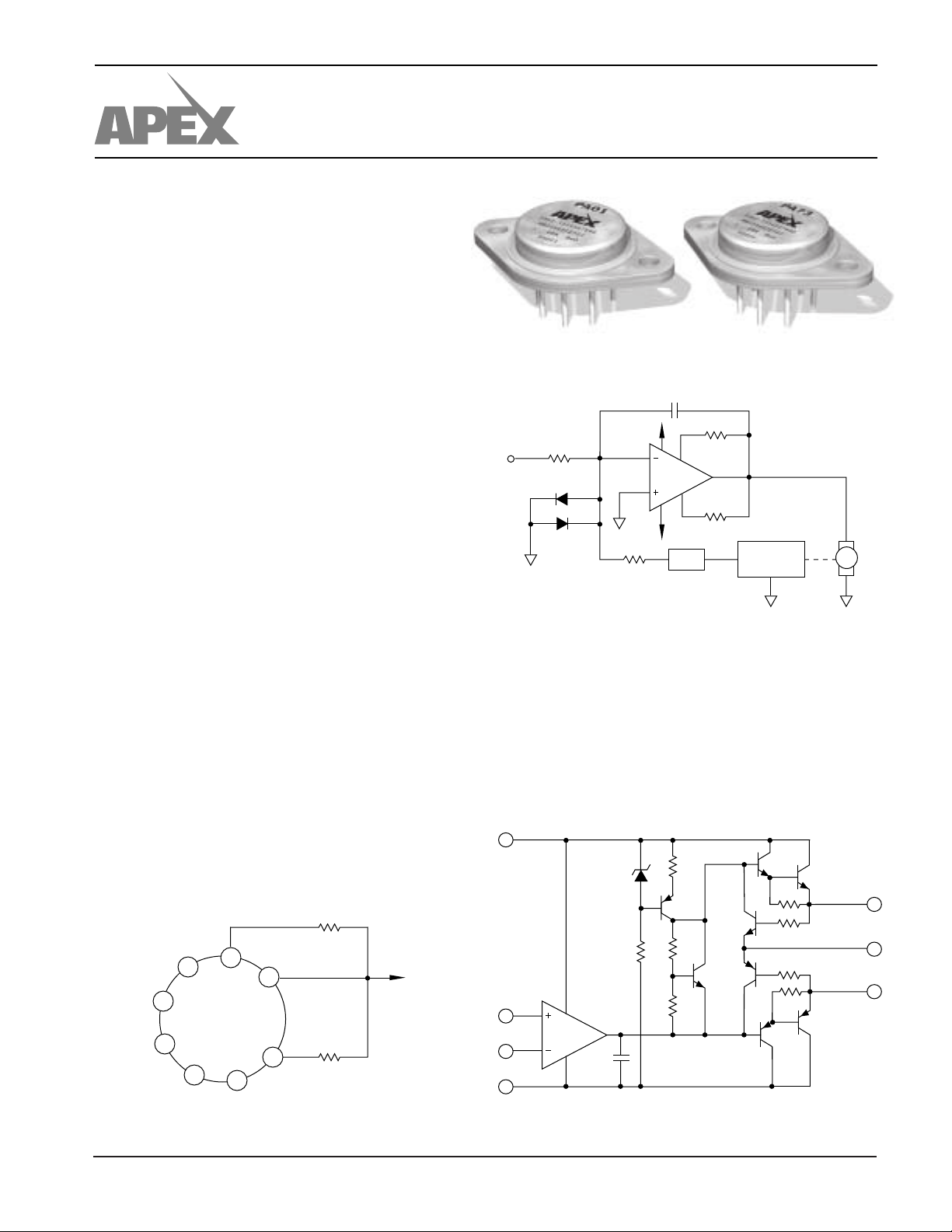

TYPICAL APPLICATION

C

F

R

F/V

0/–5V

*

Q1

*

CL+

.33

Ω

3W

R

CL–

.33

Ω

3W

*

Q4

OPTO

PULSE

GEN.

Q2A

Q3

Q5

*

Q6A

+6V

IN

1N4148

R

IN

PA01

–30V

R

F

V

0/+5V

UNSYMMETRICAL SUPPLIES FOR EFFICIENCY

Unidirectional Optical Speed Control

The pulse output of a non-contact optical sensor drives a

voltage-to-frequency converter which generates feedback for

the op amp. With the loop closed in this manner, the op amp

corrects for any variations in the speed due to changing load.

Because of operation in only one direction, an unsymmetrical

supply is used to maximize efficiency of both power op amp

and power supply. High speed diodes at the input protect the

op amp from commutator noise which may be generated by

the motor.

EQUIVALENT SCHEMATIC

3

D1

*

*

4

A1

5

C1

6

NOTE 1: * Indicates not used in PA73. Open base of Q2A connected to

output of A1.

Q2B

Q6B

24V

M

2

1

8

APEX MICROTECHNOLOGY CORPORATION • TELEPHONE (520) 690-8600 • FAX (520) 888-3329 • ORDERS (520) 690-8601 • EMAIL prodlit@apexmicrotech.com

PA01 • PA73

ABSOLUTE MAXIMUM RATINGS

SPECIFICATIONS

PA01 PA73

ABSOLUTE MAXIMUM RATINGS

SUPPLY VOLTAGE, +VS to –V

OUTPUT CURRENT, within SOA 5A 5A

S

60V 68V

POWER DISSIPATION, internal 67W 67W

INPUT VOLTAGE, differential ±VS –3V ±VS –3V

INPUT VOLTAGE, common-mode ±V

TEMPERATURE, junction

1

200°C 200°C

S

±V

S

TEMPERATURE, pin solder -10s 300°C 300°C

TEMPERATURE RANGE, storage –65 to +150°C –65 to +150°C

OPERATING TEMPERATURE RANGE, case –25 to +85°C –25 to +85°C

SPECIFICATIONS

PARAMETER TEST CONDITIONS

PA01

2

MIN TYP MAX MIN TYP MAX UNITS

PA73

INPUT

OFFSET VOLTAGE, initial TC = 25°C ±5 ±12 * ±10 mV

OFFSET VOLTAGE, vs. temperature Full temperature range ±10 ±65 * * µV/°C

OFFSET VOLTAGE, vs. supply TC = 25°C ±35 * ±200 µV/V

OFFSET VOLTAGE, vs. power TC = 25°C ±20 * µV/W

BIAS CURRENT, initial TC = 25°C ±15 ±50 * ±40 nA

BIAS CURRENT, vs. temperature Full temperature range ±.05 ±.4 * * nA/°C

BIAS CURRENT, vs. supply TC = 25°C ±.02 * nA/V

OFFSET CURRENT, initial TC = 25°C ±5 ±15 * ±10 nA

OFFSET CURRENT, vs. temperature Full temperature range ±.01 * nA/°C

INPUT IMPEDANCE, common-mode TC = 25°C 200 * MΩ

INPUT IMPEDANCE, differential TC = 25°C10*MΩ

INPUT CAPACITANCE TC = 25°C3*pF

COMMON MODE VOLTAGE RANGE3Full temperature range ±VS–6 ±VS–3** V

COMMON MODE REJECTION, DC

3

TC = 25°C, VCM = VS –6V 70 110 * * dB

GAIN

OPEN LOOP GAIN at 10Hz Full temp. range, full load 91 113 * * dB

GAIN BANDWIDTH PRODUCT @ 1MHz TC = 25°C, full load 1 * MHz

POWER BANDWIDTH TC = 25°C, IO = 4A, VO = 40V

PHASE MARGIN Full temperature range 45 * °

PP

15 23 * * kHz

OUTPUT

VOLTAGE SWING

VOLTAGE SWING

VOLTAGE SWING

3

3

3

TC = 25°C, IO = 5A ±VS–10 ±VS–5 ±VS–8* V

Full temp. range, IO = 2A ±VS–6 ±VS–5** V

Full temp. range, IO = 46mA ±VS–5* V

CURRENT, peak TC = 25°C ±5* A

SETTLING TIME to .1% TC = 25°C, 2V step 2 * µs

SLEW RATE TC = 25°C, RL = 2.5Ω 1.0 2.6 * * V/µs

CAPACITIVE LOAD, unity gain Full temperature range 3.3 * nF

CAPACITIVE LOAD, gain > 4 Full temperature range SOA *

POWER SUPPLY

VOLTAGE Full temperature range ±10 ±28 ±28 * * ±30 V

CURRENT, quiescent TC = 25°C 20 50 2.6 5 mA

THERMAL

RESISTANCE, AC, junction to case

4

F > 60Hz 1.9 2.1 * * °C/W

RESISTANCE, DC, junction to case F < 60Hz 2.4 2.6 * * °C/W

RESISTANCE, junction to air 30 * °C/W

TEMPERATURE RANGE, case Meets full range specifications –25 25 +85 * * * °C

NOTES: * The specification of PA73 is identical to the specification for PA01 in applicable column to the left.

1. Long term operation at the maximum junction temperature will result in reduced product life. Derate internal power dissipation

to achieve high MTTF.

2. The power supply voltage specified under the TYP rating applies unless otherwise noted as a test condition.

3. +V

4. Rating applies if the output current alternates between both output transistors at a rate faster than 60Hz.

CAUTION

APEX MICROTECHNOLOGY CORPORATION • 5980 NORTH SHANNON ROAD • TUCSON, ARIZONA 85741 • USA • APPLICATIONS HOTLINE: 1 (800) 546-2739

and –VS denote the positive and negative supply rail respectively. Total VS is measured from +VS to –VS.

S

The internal substrate contains beryllia (BeO). Do not break the seal. If accidentally broken, do not crush, machine, or

subject to temperatures in excess of 850°C to avoid generating toxic fumes.

TYPICAL PERFORMANCE

GRAPHS

PA01 • PA73

70

POWER DERATING

60

50

40

30

T = T

C

20

10

0

0 20 40 60 80 100 120

INTERNAL POWER DISSIPATION, P(W)

SMALL SIGNAL RESPONSE

120

100

(dB)

OL

80

T = T

A

TEMPERATURE, T(°C)

60

40

20

0

OPEN LOOP GAIN, A

–20

1 100 10M

10 1K 10K .1M 1M

FREQUENCY, F (Hz)

140

2.8

B

BIAS CURRENT

2.5

2.2

1.9

1.6

1.3

1.0

.7

NORMALIZED BIAS CURRENT, I (X)

–25 25 50 75

–50 0 100

CASE TEMPERATURE, T (°C)

PHASE RESPONSE

0

–30

–60

–90

–120

PHASE, (°)ϕ

–150

–180

–210

10 10K 1M

1 100 .1M 10M

1K

FREQUENCY, F (Hz)

3.5

CURRENT LIMIT

3.0

2.5

LIM

2.0

1.5

R = 0.6CLΩ

R = 0.3CLΩ

1.0

CURRENT LIMIT, I (A)

.5

0

125

C

–50 –25 50 100

025 75

CASE TEMPERATURE, T (°C)

C

125

POWER RESPONSE

100

68

PP

46

O

32

22

15

10

6.8

OUTPUT VOLTAGE, V (V )

4.6

10K 20K 50K .1M

|+V | + |-V | = 60V

SS

30K

FREQUENCY, F (Hz)

70K

COMMON MODE REJECTION

120

100

80

60

40

20

0

1 10K

COMMON MODE REJECTION, CMR (dB)

3

FREQUENCY, F (Hz)

HARMONIC DISTORTION

1

.3

PA73 @

.1

.03

DISTORTION (%)

.01

PA73 @ P

.003

PA01 @ P

100 1K 3K .1M

300 10K 30K

1K 1M

W

= 50mW

= 50m

O

O

P

PA01 @ P

= 32W

O

= 32W

O

FREQUENCY, F (Hz)

.1M10 100

VS = ±28V

RL = 8

Ω

AV = 10

O

–2

–4

OUTPUT VOLTAGE, V (V)

–6

–8

1.3

1.2

(X)

Q

1.1

1.0

NORMALIZED, I

PULSE RESPONSE

8

6

4

V = ±5V, t = 100ns

IN r

PA01

2

0

for PA73∆

0

2 4 6 8 10 12

TIME, t (µs)

QUIESCENT CURRENT

PA01 @ 85

PA01 @

.9

PA73 @

.8

.7

20 80

30 40 50 60 70

TOTAL SUPPLY VOLTAGE, V

°C

–25 to +25

–25 to +85

°C

°C

S

(V)

100

INPUT NOISE

√

70

N

50

40

30

20

10

INPUT NOISE VOLTAGE, V (nV/ Hz)

10 100 10K .1M

1K

FREQUENCY, F (Hz)

+6

OPEN LOOP GAIN

+4

(dB)

+2

OL

0

T = 85

C

–2

NORMALIZED, A

–4

–6

30 80

20 40 50

TOTAL SUPPLY VOLTAGE, V

°C

T =

C

T = 25

C

–25°C

°C

60

70

S

(V)

APEX MICROTECHNOLOGY CORPORATION • TELEPHONE (520) 690-8600 • FAX (520) 888-3329 • ORDERS (520) 690-8601 • EMAIL prodlit@apexmicrotech.com

PA01 • PA73

GENERAL

Please read Application Note 1 "General Operating Considerations" which covers stability, supplies, heat sinking, mounting, current limit, SOA interpretation, and specification interpretation. Visit www.apexmicrotech.com for design tools that

help automate tasks such as calculations for stability, internal

power dissipation, current limit and heat sink selection. The

"Application Notes" and "Technical Seminar" sections contain

a wealth of information on specific types of applications.

Package outlines, heat sinks, mounting hardware and other

accessories are located in the "Packages and Accessories"

section. Evaluation Kits are available for most Apex product

models, consult the "Evaluation Kit" section for details. For the

most current version of all Apex product data sheets, visit

www.apexmicrotech.com.

SAFE OPERATING AREA (SOA)

The output stage of most power amplifiers has three distinct

limitations:

1. The current handling capability of the transistor geometry

and the wire bonds.

2. The second breakdown effect which occurs whenever the

simultaneous collector current and collector-emitter voltage

exceeds specified limits.

3. The junction temperature of the output transistors.

5.0

4.0

3.0

2.0

1.5

1.0

Tc = 85°C

Tc = 125°C

THERMAL

.8

steady state SECOND BREAKDOWN

t = 5ms

t = 0.5ms

t = 1ms

OPERATING

CONSIDERATIONS

1. For sine wave outputs, use Power Design

Make sure the load line does not cross the 0.5ms limit and

that excursions beyond any other second breakdown line

do not exceed the time label, and have a duty cycle of no

more than 10%.

For other waveform outputs, manual load line plotting is

recommended. Applications Note 22, SOA AND LOAD

LINES, will be helpful. A Spice type analysis can be very

useful in that a hardware setup often calls for instruments or

amplifiers with wide common mode rejection ranges.

2. EMF generating or reactive load and short circuits to the

supply rail or shorts to common are safe if the current limits

are set as follows at T

±V

S

C, L, OR EMF LOAD COMMON

= 85°C.

C

SHORT TO ±V

S

34V .58A 1.1A

30V .46A 1.4A

25V .61A 1.7A

20V .86A 2.1A

15V 1.3A 2.9A

3. The output stage is protected against occaisional transient

flyback. However, for protection against sustained, high

energy flyback, external fast-recovery diodes should be

used.

1

to plot a load line.

SHORT TO

CURRENT LIMIT

Proper operation requires the use of two current limit resistors, connected as shown, in the external connection diagram.

The minimum value for R

reliability it should be set as high as possible. Refer to the

“General Operating Considerations” section of the handbook

for current limit adjust details.

is 0.12 ohm; however, for optimum

CL

.6

.4

PA01 LIMIT

.3

10 15 20 25 30 35 40 50 60

The SOA curves combine the effect of these limits. For a

given application, the direction and magnitude of the output

current should be calculated or measured and checked against

the SOA curves. This is simple for resistive loads but more

complex for reactive and EMF generating loads.

1

Note 1. Power Design is a self-extracting Excel spreadsheet

APEX MICROTECHNOLOGY CORPORATION • 5980 NORTH SHANNON ROAD • TUCSON, ARIZONA 85741 • USA • APPLICATIONS HOTLINE: 1 (800) 546-2739

This data sheet has been carefully checked and is believed to be reliable, however, no responsibility is assumed for possible inaccuracies or omissions. All specifications are subject to change without notice.

PA01, 73U REV. O FEBRUARY 2001 © 2001 Apex Microtechnology Corp.

available free from www.apexmicrotech.com

Loading...

Loading...