Page 1

PC60 Premium Multi-Parameter Tester

(pH/EC/TDS/Salinity/Temp.)

Instruction Manual

APERA INSTRUMENTS, LLC

www.aperainst.com

V6.4

Page 2

!

2!

Thank!you!for!purchasing!Apera!Instruments!PC60!Premium!Multi-Parameter!Tester.!Please!

carefully!read!this!instruction!manual!before!using!the!product!in!order!to!have!an!accurate!and!

reliable!test!result,!and!avoid!unnecessary!damages!to!the!meter!or!probe.!

!

For!video!tutorials,!please!go!to!support.aperainst.com!

Contents!

1.!Battery!Installation!.................................................................................................................................!3!

2.!Keypad!Functions!....................................................................................................................................!3!

3.!Complete!Kit!...........................................................................................................................................!4!

4.!Preparation!Before!Use!..........................................................................................................................!4!

5.!pH!Calibration!.........................................................................................................................................!5!

6.!pH!Measurement!....................................................................................................................................!6!

7.!Conductivity!Calibration!.........................................................................................................................!7!

8.!Conductivity!Measurement!....................................................................................................................!7!

9.!Parameter!Setting!...................................................................................................................................!9!

10.!Technical!Specifications!......................................................................................................................!10!

11.!Icons!and!Functions!............................................................................................................................!11!

12.!Probe!Replacement!............................................................................................................................!11!

13.!Warranty!.............................................................................................................................................!12!

Page 3

!

3!

1. Battery Installation

Please install batteries according to the following steps. *Please note direction of batteries: All

POSITIVE SIDES (“+”) FACING UP. (Wrong installation of batteries will cause damage to the

tester and potential hazards)

2. Keypad

Functions

■ Short press------ < 2 seconds ,Long press------- > 2 seconds

1.Short press to turn on the tester and long press to

turn off the tester.

2.When turned off, long press to enter parameter

setting.

3. In measurement mode, short press to turn on

backlight.

1.In measurement mode, short press to switch

parameter pH→COND→TDS→SAL

2.In mode setting, short press to change parameter

(Unidirectional)

1. Long press to enter calibration mode.

2. In calibration mode, short press to confirm

calibration.

3.When measured value is locked, short press to

unlock;

① Pull!the!battery!cap!up!

② Slide!the!battery!cap!along!to!the!direction!of!arrow!

③ Open!the!battery!cap!

④ Insert!the!batteries!(ALL$POSITIVE$SIDES$FACING$UP)!(see!graph)!

⑤ Close!the!battery!cap!

⑥ Slide!and!lock!the!battery!cap!along!to!the!direction!of!arrow!

⑦ Fit!the!tester’s!cap!while!making!sure!to!push!all!the!way!down.!The!!tester’s!

waterproof!design! may !be!compromised!if!the!cap!is!not!fitted!correctly.!

Battery!

Buttons

Probe!

Probe

Probe!Cap

LCD!

pH!Sensor

BPB!Sensor

!

+

+ + +

- - -

-

Page 4

!

4!

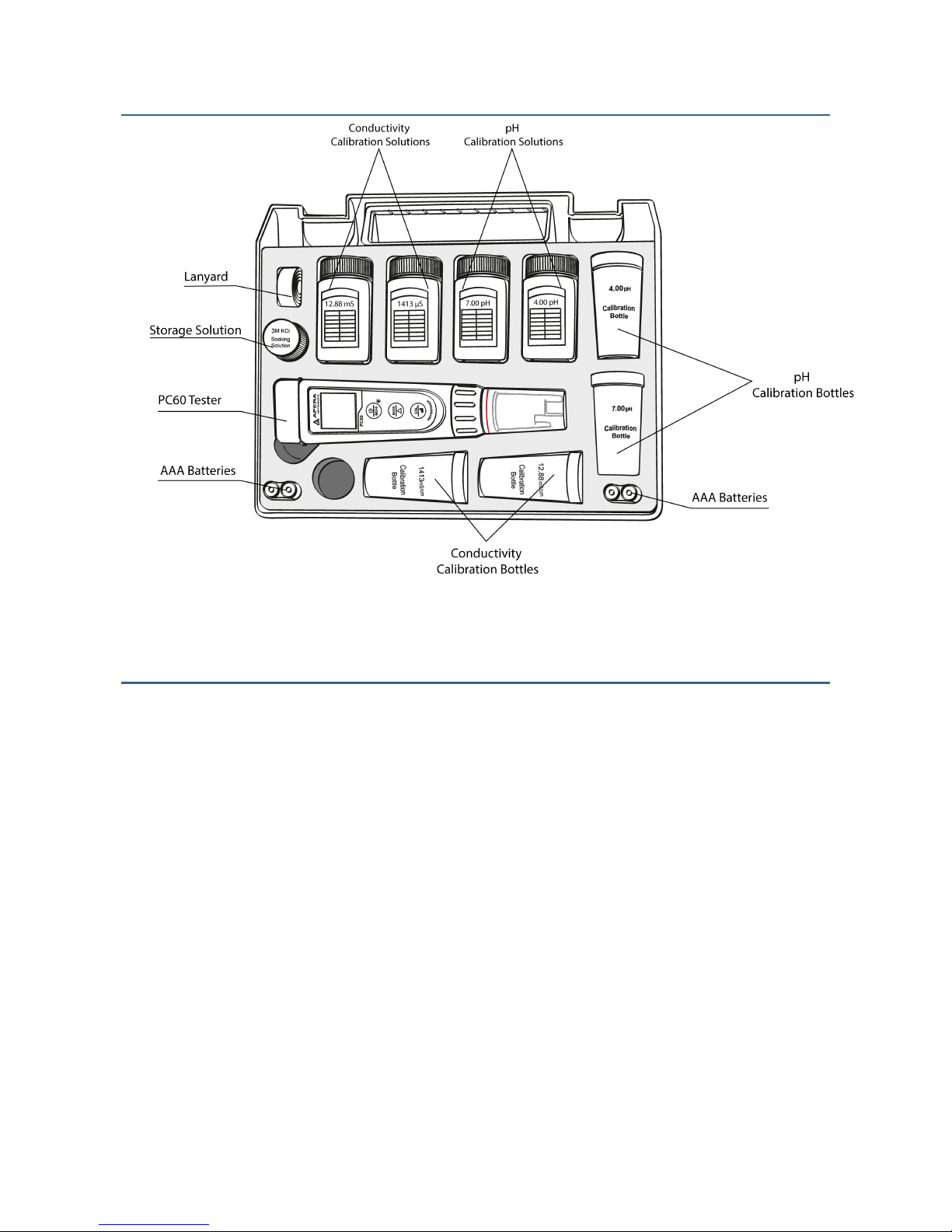

3. Complete Kit

4. Preparation Before Use

If it is first-time use or the tester hasn’t been used for a long time, pour some 3M KCL solution in

the probe cap (about 1/5 of the probe cap) and soak the probe for 15-30 minutes.

When not in use, we recommend store the pH probe in the storage 3M KCL solution in the probe

cap to keep the sensor’s accuracy. But even if stored dry, it won’t do any permanent damage to

the sensor. It will only temporarily cause the probe to lose its sensitivity, which can always be

restored by soaking in the storage solution.

The!storage!solution!is!3M!KCL!(potassium!chloride).!One!bottle!of!10mL!storage! solution! comes! w ith! the!

tester!kit.!If!the!soaking!solution!was!contaminated ,!pleas e!rep lace!w ith!n ew!ones!timely.!

*!DO!NOT!use!any!other!brand’s!storage!solutions!because!different!chemicals!may!be!used!and!

potential!permanent!damage!could!be!caused!to!the!meter.!

Diagram!-!2!

Page 5

!

5!

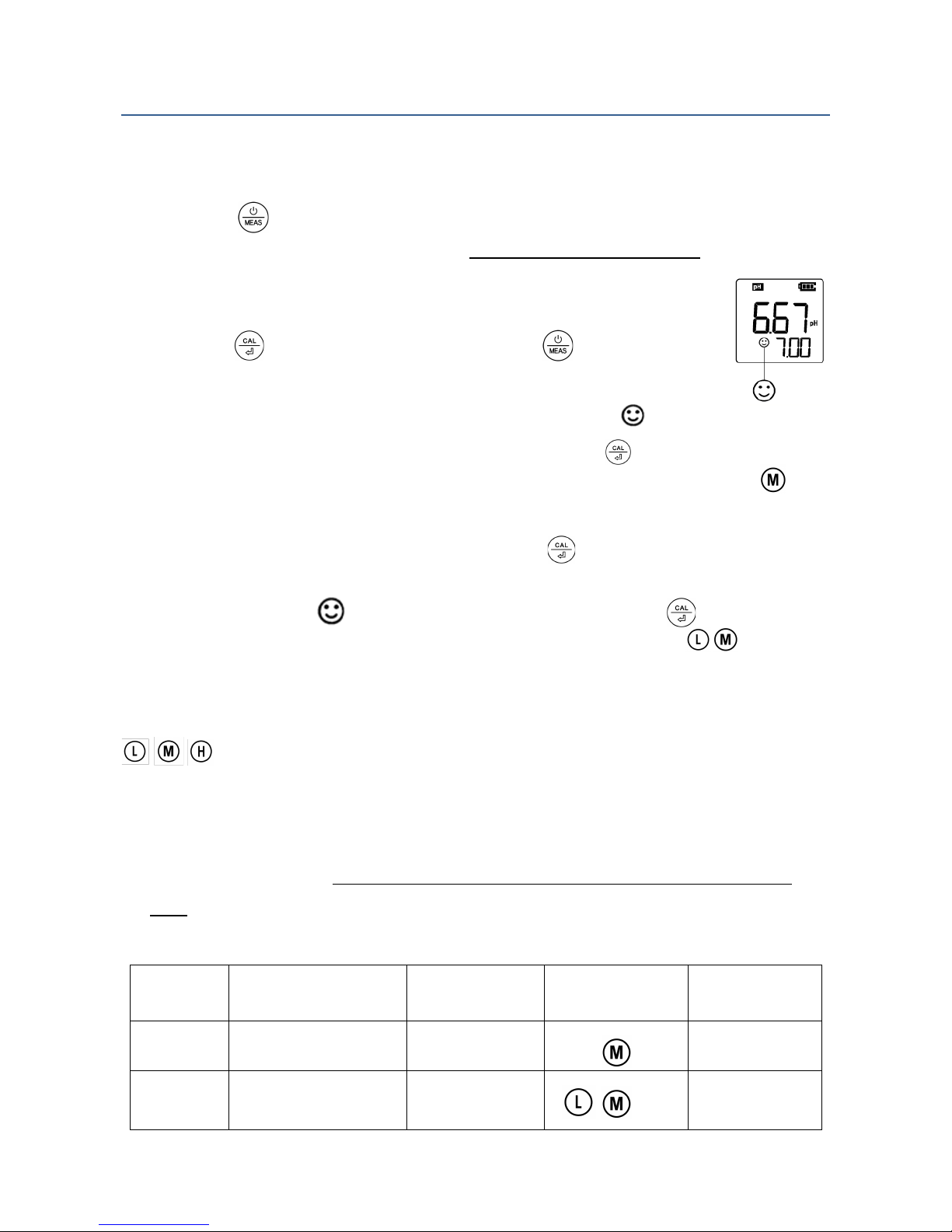

5. pH Calibration

Things needed in addition to what’s in the box:

A clean cup, distilled water (8-16oz), and tissue papers for rinsing and drying the probe.

5.1 Short press to turn on the meter; rinse the probe in distilled water, shake the meter in the

air and use tissue paper to dap off excess water (never rub or wipe the sensor).

5.2 Pour certain amount (about half volume of the calibration bottle) of pH 7.00 and

pH 4.00 buffer solution in separate calibration bottles;

5.3 Long press to enter calibration mode; Short press to exit.

5.4 Dip the probe in pH7.00 buffer solution, stir gently, and allow it to stand still in

the buffer solution until a stable reading is reached. When stable icon is

displayed on the LCD screen (as shown in Diagram 3), short press to

complete 1-point calibration and the tester returns to measurement mode. Indication Icon will

appear at the bottom left of the LCD screen.

5.5 Rinse the probe in distilled water and dry it. Long press to enter calibration mode.

Dip the probe in pH 4.00 buffer solution, stir gently, and allow it to stand still in the buffer

solution. When stable icon is displayed on the LCD screen, short press to complete

2-point calibration and the tester returns to measurement mode. Indication icon will

appear at the bottom left of the LCD screen.

5.6 If necessary, rinse the probe in distilled water and dry it, and dip the probe in 10.01 buffer

solution (sold separately) to complete 3rd point of calibration according to the steps in 5.5,

will appear at the bottom left of the LCD.

■ Notes

a) Tester will automatically recognize pH buffer solution. Users can perform one-point, two-point,

or three-point calibration. But for the 1st point calibration, only 7.00 pH solution can be

used. Then use other buffer solutions to conduct 2nd or 3rd point calibration. Tester!will!

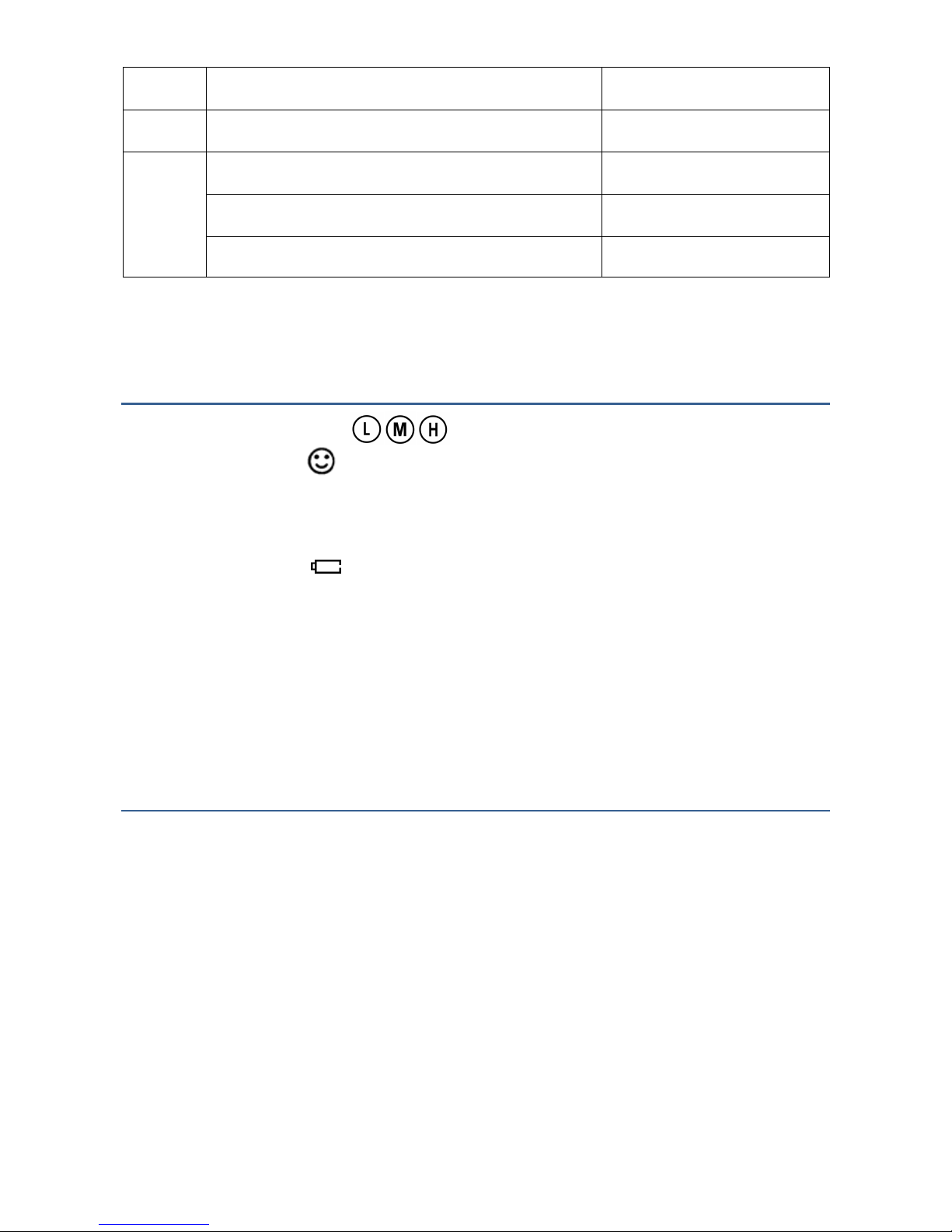

automatically!recognize!5!kinds!of!pH!buffer!solutions. Refer to the table below:

Calibration

USA Series

NIST Series

Calibration

Indication Icon

Recommended

Accuracy and

Range

1-point

1) 7.00 pH

1) 6.86 pH

Accuracy ≥ 0.1

pH

2-point

1) 7.00 pH

2) 4.00 or 1.68 pH

1) 6.86 pH,

2) 4.01 pH or

1.68 pH

Measurement

Range<7.00

pH

Diagram!-!3!

Page 6

!

6!

1) 7.00 pH

2) 10.01 or 12.45 pH

1) 6.86 pH,

2) 9.18 pH or

12.45 pH

Measurement

Range>7.00pH

3-point

1) 7.00 pH

2) 4.00 or 1.68 pH

3) 10.01 or 12.45 pH

1) 6.86pH

2) 4.01 or

1.68pH,

3) 9.18 pH or

12.45 pH

Wide

Measurement

Range

b) For pH Calibration buffer solutions, we recommend that users replace new buffer solution

after 10 to 15 times of use to keep the standard buffer’s accuracy. Do NOT pour the used

calibration solutions back into the solution bottles in case of contamination.

c) This pH probe will NOT give accurate and stable readings for distilled or deionized water.

This is because distilled and deionized water do not have enough ions present for the

electrode to function properly. Specialized pH probes need to be used for

distilled/deionized water measurement. Contact us at info@aperainst.com for more details.

d) When%testing%purified%water%like%spring%water%or%drinking%water,%it%will%take%longer%for%the%readings%

to%get%stabilized%(typically%3-5%minutes)%because%there%is%very%few%ions%left%to%be%detected%by%the%

sensor%in%those%purified%water.

e) Do NOT store pH probe in distilled water to prevent permanent damage to the probe.

f) For the self-diagnosis information, please refer to the table below:

Symbol

Self-Diagnosis information

Checking and methods to fix

Wrong calibration solution or the range of

calibration solution exceeds standard.

a) Check if calibration solution is correct (1st point

of pH calibration must be pH 7.00)

b) Check if electrode is damaged.

c) Check if there is any air bubble in the glass

bulb pH sensor

Is pushed before measurement is stable

( comes up and stays)

Wait for the smile icon to come up and stay,

then press

* If you find any air bubble in the glass bulb of the pH sensor, simply shake the probe for a few times

to remove it. The existence of an air bubble in the glass bulb will cause instable measurements.

* The 1st point calibration must be 7.00 pH. Perform the 2nd point calibration (4.00 pH) immediately

after the 1st point. Do NOT turn off the meter before you conduct 2nd point calibration. If the meter is

turned off after 1st point calibration, users will need to restart the calibration process with the 7.00 pH

first and the 4.00 pH following after. Calibrating directly in pH 4.00 after turning meter off and back on

will cause Er1.

Page 7

!

7!

6.pH Measurement

Short press to turn on the tester. Rinse the probe in distilled water and dry it. Dip the probe in

sample solution, stir gently, and allow it to stand still in the solution. Get readings after

comes up and stays.

7. Conductivity Calibration

7.1 Press key to switch to conductivity measurement mode. Rinse the probe in distilled water

and dry it.

7.2 Pour certain amount (about half volume of the calibration bottle) of 1413μS/cm and 12.88

mS/cm conductivity calibration solution into accordant calibration bottles.

7.3 Long press key to enter calibration mode, short press to exit.

7.4 Dip the probe in 1413 μS/cm conductivity calibration solution, stir gently and

allow it to stand still in the solution until a stable reading is reached. When stable

icon appears and stays on the LCD screen, short press key to complete one-point

calibration, the tester returns to measurement mode and indication icon will

appear at the bottom left of the LCD screen.

7.5 After calibration, dip the probe in 12.88 mS/cm conductivity calibration solution. If the value is

accurate, it is not necessary to conduct 2nd point calibration. If it is inaccurate, follow the steps

in 7.3 to 7.4 to complete the 2nd point of calibration using 12.88 mS/cm buffer solution.

* 1000 µS/cm = 1 mS/cm

8. Conductivity Measurement

Press key to turn on the tester. Rinse the probe in distilled water and dry it.

Dip the probe in sample solution, stir gently, and allow it to stand still in the solution until a stable

reading is reached. Get readings after comes up and stays. Press to switch from

Conductivity to TDS, and Salinity

■ Notes

a) The TDS and Salinity measurements are converted from the conductivity

measurements via a certain conversion factor.

b) The tester can calibrate 84μS, 1413 μS/cm and 12.88 mS/cm conductivity calibration

solution. User can conduct 1 to 3 points calibration. Refer to the table below. Usually

calibrating the tester with 1413 μS/cm conductivity buffer solution alone shall meet the

testing requirement.

Page 8

!

8!

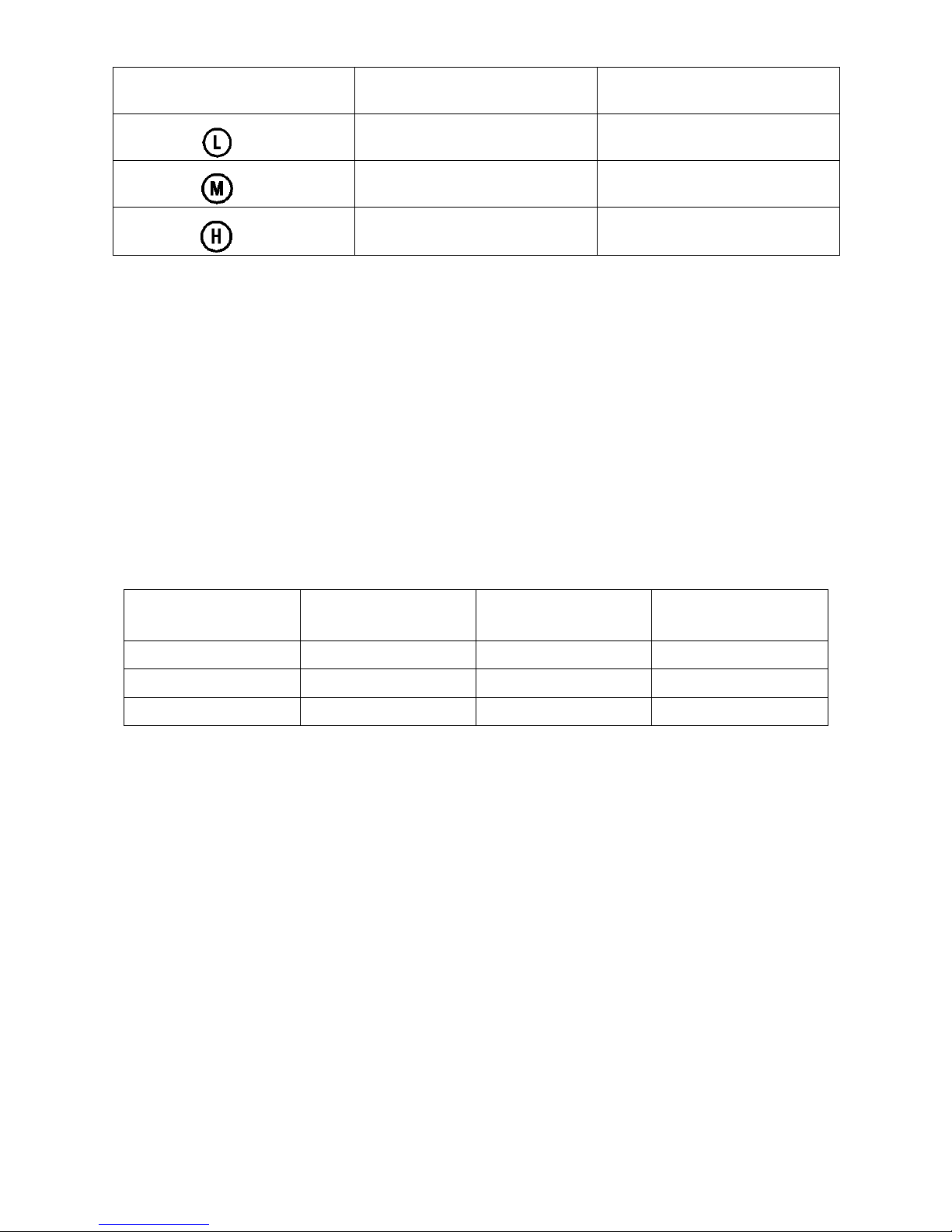

Calibration Indication Icon

Calibration Standards

Measuring Range

84 μS/cm

0 - 200 μS/cm

1413 μS/cm

200 - 2000 μS/cm

12.88 mS/cm

2 - 20 mS/cm

c) The tester has been calibrated before leaving the factory. Generally, users can use the tester

directly or users can test conductivity buffer solutions first. If the error is large, then calibration is

needed.

d) For conductivity calibration solutions, we recommend that users replace new solutions after 5 to

10 times of use to keep the standard solution’s accuracy. Do NOT pour the used calibration

solutions back into the solution bottles in case of contamination.

e) Temperature compensation factor: The default setting of the temp. compensation factor is

2.0%/℃. User can adjust the factor based on test solution and experimental data in parameter

setting P4.

Solution

Temperature

compensation factor

Solution

Temperature

compensation factor

NaCl

2.12%/˚C

10% Hydrochloric acid

1.32%/˚C

5% NaOH

1.72%/˚C

5% Sulfuric acid

0.96%/˚C

Dilute ammonia

1.88%/˚C

f) 1000 ppm = 1 ppt

g) TDS and conductivity is linear related, and its conversion factor is 0.40-1.00. Adjust the factor

in parameter setting P5 based on the requirements in different industries. The factory default

setting is 0.71. Salinity and conductivity is linear related, and its conversion factor is 0.5. The

tester only needs to be calibrated in Conductivity mode, then after calibration of conductivity,

the meter can switch from conductivity to TDS or salinity.

h) Conversion Example: if conductivity measurement is 1000µS/cm, then the default TDS

measurement will be 710 ppm (under the default 0.71 conversion factor), and the salinity be

0.5 ppt.

Page 9

!

9!

i) For the self-diagnosis information, please refer to the table below:

Symbol

Self-Diagnosis information

How to fix

Wrong conductivity buffer solution, which

exceeds the recognizable range of the

meter.

1. Check if buffer solution is correct

2. Check if electrode is damaged.

Is pushed before measurement is stable

( comes up and stays)

Wait for the smile icon to come up and then press

!

9. Parameter Setting

9.1 Setting Chart

9.2 Parameter Setting

When turned off, long press to enter parameter setting →short press

to switch P1-P2… →P8. Short Press , parameter flashes → short press

to choose parameter, → short press to confirm →Long press

to turn off.

9.3 Parameter Setting Instruction

a) Select standard pH buffer solution (P1): There are two options of standard buffer solutions:

USA series and NIST series. Refer to following chart:

Symbol

Parameter Setting Contents

Code

Factory

Default

P1

Select pH buffer standards

USA – NIST

USA

P2

Select automatic lock

Off – On

Off

P3

Select backlight

Off - 1 - On

1

P4

Temperature compensation factor

0.00 - 4.00%

2.00%

P5

TDS factor

0.40 - 1.00

0.71

P6

Salinity unit

ppt - mg/L

ppt

P7

Select temperature unit

˚C - ˚F

˚F

P8

Back to factory default

No – Yes

No

Page 10

!

10!

Icons

pH Standard Buffer Solution Series

USA series

NIST series

Three-point

calibration

1.68 pH and 4.00 pH

1.68 pH and 4.01 pH

7.00 pH

6.86 pH

10.01 pH and 12.45 pH

9.18 pH and 12.45 pH

b) Automatic lock (P2):

Select “On” to activate auto lock function. When reading is stable for more than 10

seconds, the tester will lock the value automatically, and HOLD icon will display on LCD.

Press key to cancel auto hold.

c) Backlight (P3)

“Off”-turn off backlight, “On”-turn on backlight, 1- backlight will last for 1 minute.

d) Factory default setting(P7)

Select “Yes” to recover instrument calibration to theoretical value (pH value in zero

potential is 7.00, slope is 100%), parameter setting return to initial value. This function can

be used when instrument does not work well in calibration or measurement. Calibrate and

measure again after recover the instrument to factory default status.

10. Technical Specifications

pH

Range

-2.00 to 16.00 pH

Resolution

0.01 pH

Accuracy

±0.01 pH ±1 digit

Calibration Points

1 to 3 points

Automatic Temperature Compensation

0 – 50˚C (32 – 122˚F)

Cond.

Range

0 to 200.0 μS, 0 to 2000 μS,

0 to 20.00 mS/cm

Resolution

0.1/1 μS, 0.01 mS/cm

Accuracy

±1% F.S

Calibration Points

1 to 3 points

TDS

Range

0.1 ppm to 10.00 ppt

Page 11

!

11!

TDS Factor

0.40 to 1.00

Salinity

Range

0 to 10.00 ppt

Temp.

Range

0 to 50˚C (32-122˚F)

Resolution

0.1˚C

Accuracy

±0.5˚C

11. Icons and Functions

① Calibration points indication:

② Stable Measurement:

③ Reading value Auto. Lock: HOLD

④ Self-Diagnostic Information: Er1, Er2

⑤ Low-Voltage warning: flashes, reminder of battery replacement

⑥ Three-Color backlight:

Blue—Measurement Mode; Green—Calibration Mode; Red—Alarm;

⑦ Auto. Power off in 8 minutes if no operation.

12. Probe Replacement

Screw off the probe ring, unplug the probe, plug in the new replacement probe (pay attention to the

probe’s position), and screw on the probe ring. The model numbers of replacement probes that are

compatible with PC60 are:

• PC60-E

• PH60-E (Regular pH glass bulb probe)

• PH60S-E (Spear pH probe for solids/semi-solids pH testing)

• PH60F-E (Flat pH probe for surface pH testing)

• EC60-E (Conductivity probe)

Page 12

!

12!

13. Warranty

We!warrant!this!instrument to be free from defects in material and workmanship and agree to repair

or replace free of charge, at option of APERA INSTRUMENTS, LLC, any malfunctioned or

damaged product attributable to responsibility of APERA INSTRUMENTS, LLC for a period of TWO!

YEARS!(SIX!MONTHS!for!the!probe) from the delivery.

This limited warranty does not cover any damages due to:

Transportation, storage, improper use, failure to follow the product instructions or to perform any

preventive maintenance, modifications, combination or use with any products, materials,

processes, systems or other matter not provided or authorized in writing by us, unauthorized

repair, normal wear and tear, or external causes such as accidents, abuse, or other actions or

events beyond our reasonable control.

APERA INSTRUMENTS, LLC

Address: 6656 Busch Blvd, Columbus Ohio 43229

Tel: 1-614-285-3080

Email: info@aperainst.com

Website: www.aperainst.com

Loading...

Loading...