Page 1

Solar

control

SGS

Condensing High Efficiency

Gas-Solar Water Heater

SGS - 28/30/50/60/80/100

Storage

Tank

SGS

Fully room sealed condensing high efficiency gas-solar water

heater (95 % gross) • Maximum solar contribution through fully

integrated intelligent solar controller • 1 control and display unit

for the complete installation • Extra solar contribution possible up

to 40 % compared to standard solar systems • Suitable in combination

with storage tanks up to 3000 liters • Flexible ue options (maximum

lenght 115m) • Thermocontrol for easy exible control / fault

diagnosis • Programmable for legionella purge cycle • All models

suitable for natural or LP gas • Meets latest EPC standards:

SGS 28-60 : 0,902 • Scale formation is reduced through the improved

design and location of the heat exchanger • Very easy maintenance

and installation • SGS 80 - SGS 100 standard applied with powered

anodes • Remote control connection • Voltage-free contact for

general fault indication • Unvented kits are optional

Innovation has a name.

Page 2

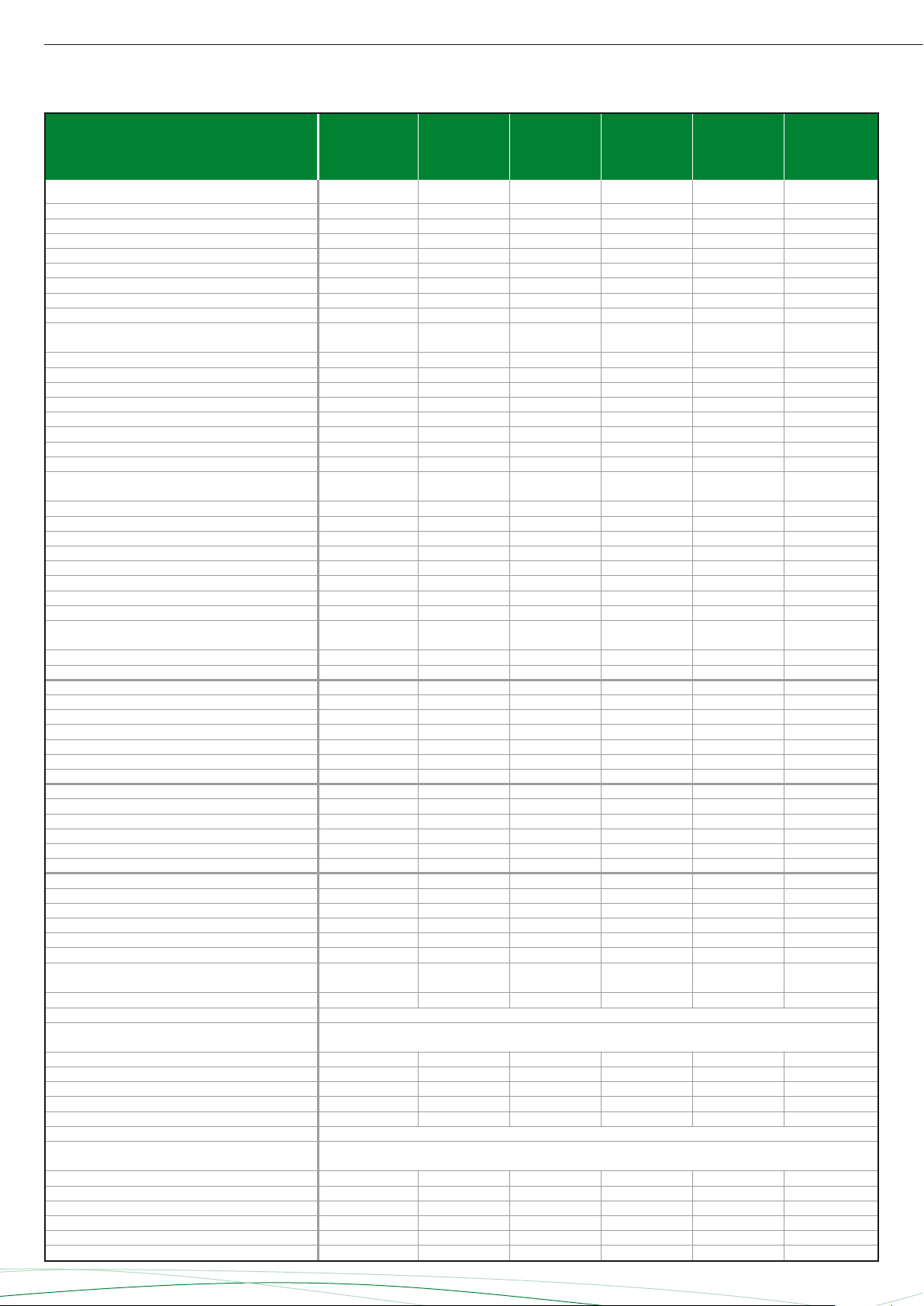

SGS

Technical specifications

SGS 28

SGS 30

SGS 50

SGS 60

SGS 80

SGS 100

Gas data natural gas 2H (G20)

Input* kW 32.1 34.5 52.6 63.2 86.6 105.5

Output kW 30.5 32.7 48.8 59.6 81.9 99.8

Inlet pressure mbar 20 20 20 20 20 20

Burner pressure mbar 8.5 8.5 8.5 11.5 6.0 6.0

Gas consumption ** m

Diameter injector mm 4.90 5.10 7.00 7.10 6.30 6.80

Max. flue gas temperature °C 70 50 75 75 50 50

Flue gas discharge kg/h 56.8 61.1 85.4 101.4 141.9 164.3

3

/h 3.1 3.3 5.0 6.0 8.3 10.1

Gas data butane gas 3+ G30

Input* kW 30.7 32.8 50.6 59.4 - Output kW 29.8 31.8 48.1 56.9 - Inlet pressure mbar 30 30 30 30 - Burner pressure mbar - - - - - Gas consumption ** kg/h 2.2 2.4 3.7 4.3 - Diameter injector mm 2.50 2.60 3.40 3.80 - Max. flue gas temperature °C 70 50 75 75 - Flue gas discharge kg/h 60.0 62.2 86.0 101.9 - -

Gas data propane gas 3+ G31

Input* kW 29.0 30.9 50.3 59.1 84.8*** 103.3***

Output kW 28.1 29.8 47.7 56.9 81.9*** 99.8***

Inlet pressure mbar 37 37 37 37 30*** 30***

Burner pressure mbar - - - - 13.0*** 13.0***

Gas consumption ** kg/h 2.1 2.2 3.6 4.2 6.1*** 7.4***

Diameter injector mm 2.50 2.60 3.40 3.80 4.70*** 5.10***

Max. flue gas temperature °C 70 50 75 75 50*** 50***

Flue gas discharge kg/h 54.3 56.5 85.1 101.0 142.1*** 176.4***

Draw-off capacity

Storage capacity l 217 368 368 368 460 460

Max. temperature setting °C 80 80 80 80 80 80

T

= 10ºC / T

cold

30 min ∆T=44°C l 457 642 784 897 1139 1296

60 min ∆T=44°C l 755 961 1261 1461 1939 2270

90 min ∆T=44°C l 1053 1280 1738 2043 2737 3245

120 min ∆T=44°C l 1350 1599 2215 2625 3540 4220

Continuous ∆T=44°C l/h 595 638 954 1164 1601 1950

Heating-up time ∆T=44°C min 22 35 23 19 17 14

30 min ∆T=50°C l 402 565 690 773 1002 1140

60 min ∆T=50°C l 664 846 1110 1286 1706 1998

90 min ∆T=50°C l 926 1126 1530 1798 2411 2856

120 min ∆T=50°C l 1188 1407 1950 2310 3115 3714

Continuous ∆T=50°C l/h 524 562 840 1025 1409 1716

Heating-up time ∆T=50°C min 25 39 26 22 20 16

30 min ∆T=55°C l 366 513 627 703 911 1036

60 min ∆T=55°C l 604 769 1009 1169 1551 1816

90 min ∆T=55°C l 842 1024 1391 1634 2191 2596

120 min ∆T=55°C l 1080 1279 1772 2100 2832 3376

Continuous ∆T=55°C l/h 476 511 763 932 1281 1560

Heating-up time ∆T=55°C min 27 43 29 24 22 18

set

= 65ºC

Electrical data

Power consumption W 275 275 275 275 600 690

Power supply VAC/Hz 230(-15% / +10 % VAC)

General

Fan rotational speed at ignition r.p.m. 4500 4500 4500 4500 2790 3120

Working speed fan r.p.m. 5000 5400 6000 6660 5100 5700

Pressure differential Pa 635/605 855/825 885/855 1085/1055 1005/975 1145/1115

Diameter of air restrictor mm 23 23 28 29 36 38

Anodes - 4 4 4 4 2-electric 2-electric

Maximum working pressure bar 8

Shipping data

Empty weight kg 177 214 214 214 480 480

Max. weight kg 394 582 582 582 940 940

Weight incl. packaging kg 197 234 234 234 491 491

Width packaging mm 870 870 870 870 920 920

Height packaging mm 1550 2080 2080 2080 2060 2060

Depth packaging mm 950 950 950 950 1020 1020

*** 3p (G31)

* Gas data on gross value

** Gas consumption at 15°C en 1013,25 mbar

Page 3

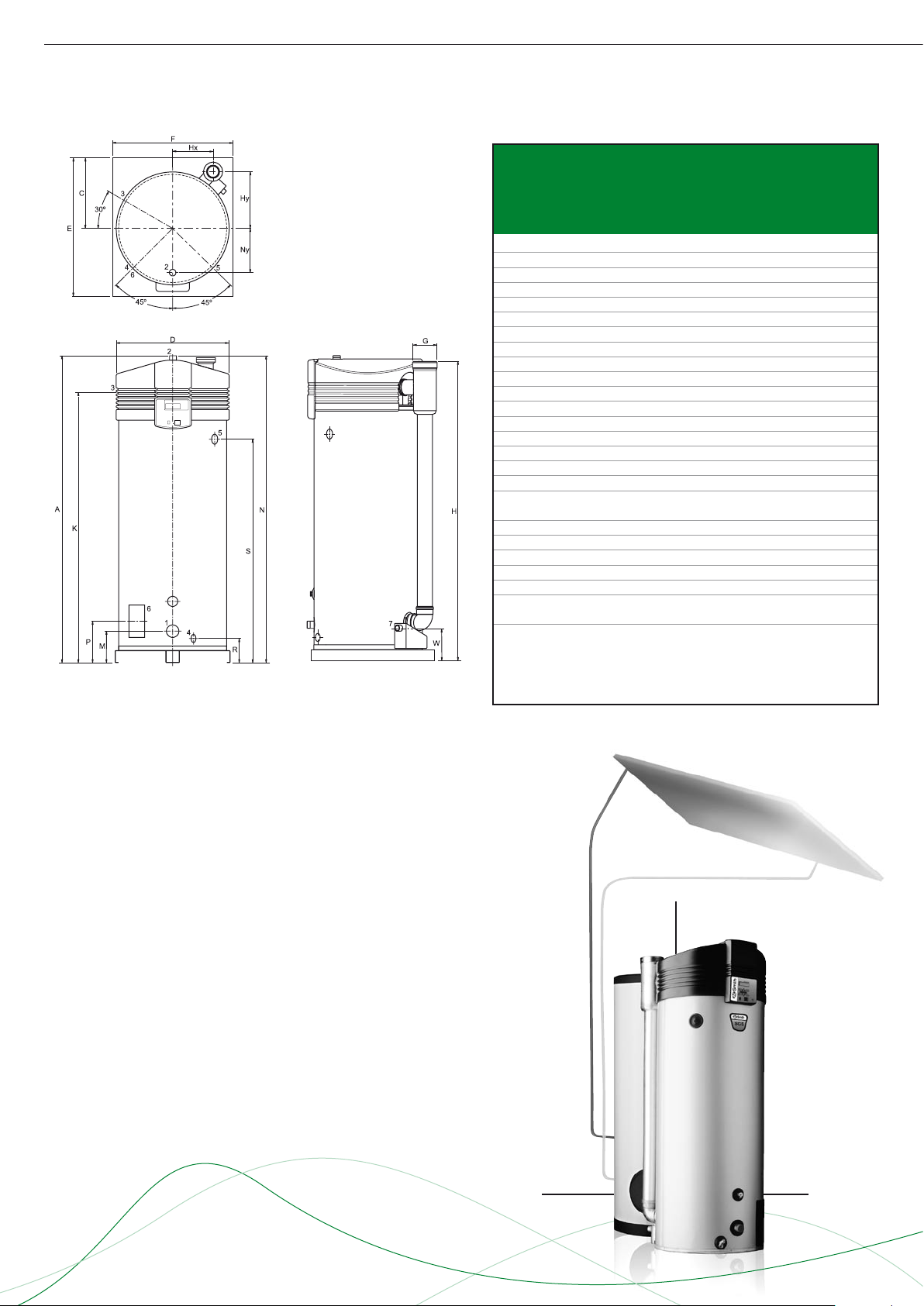

SGS

Dimensions SGS 28-60

SGS 28

SGS 30

SGS 50

SGS 60

A 1485 2005 2005 2005

C 490 490 490 490

D 705 705 705 705

E 925 925 925 925

F 850 850 850 850

G 80/125 100/150 100/150 100/150

H 1460 2000 2000 2000

Hx 265 265 265 265

Hy 375 375 375 375

K 1365 1895 1895 1895

M 265 255 255 255

N 1485 2005 2005 2005

Ny 205 205 205 205

P 265 270 270 270

R 180 170 170 170

S 995 1505 1505 1505

W 220 240 240 240

1 Cold water connection R11/2

2 Hot water connection R1

3 Gas valve connection Rp

4 Drain valve connection

5 Temperature and pressure valve 1 / 11.5 NPT

6 Inspection flange 95x70

7 Condensate drain Ø40 (SGS 28)

Rp1 (SGS 30-60)

1

/2

3

/4

3

/4

On all SGS units 3 year warrranty is appliccable on the tank

and 1 year on all parts.

Storage

Tank

Solar

control

SGS

Page 4

SGS

Dimensions SGS 80-100

SGS 80

SGS 100

A 2060 2060

C 530 530

D 850 850

E 1000 1000

F 900 900

G 130/200 130/200

H 2015 2015

Hx 310 310

Hy 440 440

K 1855 1855

M 225 225

N 2060 2060

Ny 205 205

P 290 290

R 225 225

S 1425 1425

W 240 240

1 Cold water connection R11/2

2 Hot water connection R1

3 Gas valve connection Rp

4 Drain valve connection

5 Temperature and pressure valve 1 / 11.5 NPT

6 Inspection flange 95x70

7 Condensate drain Rp1

1

/2

3

/4

3

/4

On all SGS units 3 year warrranty is appliccable on the tank

and 1 year on all parts.

Storage

Tank

Solar

control

SGS

Page 5

SGS

Installation diagrams

Vented

Unvented

1 Pressure reduce valve

2 Inlet security group

3 Temperature and pressure valve

4 Stop valve

5 Non-return valve

6 Circulation pump

9 Drain valve

10 Gas cock

11 Isolating valve

12 Temperature gauge

13 Condense drain

14 Hot water outlets

16 Expansion vessel

17 Three way valve

18 Water cistern

19 Float valve

23 Over pressure security group

26 Air bleed

37 Flowmeter

38 Pompmodule solar

S1 T-collector

S2 T-tank

S3 T-top tank

S4 T-return solar

A Cold water supply

B Hot water outlet

C Circulation pipe

D Gas supply

E Water overflow

F Coil inlet

G Coil outlet

H Expansion pipe

Page 6

SGS

Electrical diagram SGS 28-60

COMPONENTS CONTROLLER

A Controller

B Ionisation rod

C Glow ignitor

D Gas control

E Burner earth connection

F Extra ON-mode switch

G Continuous pump

H Program controlled pump

J Extra error signal

K Isolating transformer

L Double-pole mains switch

M On/Off switch control

N Display

O Fan

P Temperature sensor

(T2 - bottom of tank)

Q Dummy

R Temperature sensor

(T1 - top of tank)

S Selection resistor

T Pressure switch

U Controller solarsystem (BUS-link)

F1 Fuse

F3 Fuse

CONNECTIONS MAIN CONTROLLER

1 X5

2 X

3 - n.a.

4 - n.a.

5 X

6 X

7

8 L

9 N

10 N

11 L

12

13 X

14 X

15

16 N

17 L

18

19 N

20 L

21

22

23 L

24 N

BUS-link

6

3

External ON / OFF

4

5 Continuous pump

4 Program controlled pump

2

1 Extra error signal

Isolating transformer

2

(primary side)

Isolating transformer

3

(secundary side)

1 Power supply

COMPONENTS SOLAR CONTROLLER

AA Controller

BB Pump solar system (ON / OFF)

CC Pumps solar system (modulating)

DD Temperature sensor

(S1 - solar collector)

EE Temperature sensor (S2 - tank)

FF Q/T-measuring (incl. temperature sensor S4 - return solar collector)

GG Controller (BUS-link)

HH Temperature sensor

(S3 - top tank)

F2 Fuse

CONNECTIONS SOLAR CONTROLLER

1

2 L Power supply

3 N

4 - n.a.

5 - n.a.

6 - n.a.

7

8 L

9 N

10 N

11 L

12 - (modulating)

13

14 - n.a.

15 - n.a.

16 - n.a.

17 - n.a.

18 - n.a.

19 - n.a.

20 - n.a.

1 n.a.

2 n.a.

J3

3 n.a.

4 n.a.

1 Power supply 5V

2 Sensor return

J12 solar collector (S4)

3 Earth

4 Flow signal

1 n.a.

J13

3 n.a.

4 Sensor solar collector (S1)

1 Sensor top tank (S3)

J14

3 Sensor top tank (S3)

4 Sensor tank (S2)

J15

2 n.a.

J16

2

1 n.a.

J17 2 n.a.

3 n.a.

Pump solar system

1

(ON / OFF)

2 Pump solar system

2 Sensor solar collector (S1)

2 Sensor tank (S2)

1 n.a.

1

BUS-link

Page 7

SGS

Electrical diagram SGS 80-100

COMPONENTS CONTROLLER

A Control

B Ionisation rod

C Glow ignitor

D Gas control

E Burner earth connection

F Program controlled pump

G Continuous pump

H Extra error signal

J Isolating transformer

K Double-pole mains switch

L ON / OFF switch control

M Display

N Fan

O Temperature sensor

(T2 - bottom of tank)

P Dummy

Q Temperature sensor

(T1 - top of tank)

R Selection resistor

S Pressure switch

T Potentiostat

U Frequency controller

V RS-485 interface

W Electric anodes

X Signaling for electric anodes

Y Mains choke and EMC-filter

Z Solar control system (BUS-link)

F1 Fuse

F3 Fuse

CONNECTIONS MAIN CONTROLLER

1 X5

2 X

3 L

4 N

5

6 L

7 N

8 X

9 X

10 N

11 L

12

13 X

14 X

15

16 N

17 L

18

19 N

20 L

21

22

23 L Power supply

24 N

BUS-link

6

5

Potentiostat

4 Frequency controller

3

External ON / OFF

4

3 Program controlled pump

1

2 Extra error signal

Isolating transformer

2

(primary side)

Isolating transformer

1

(secundary side)

COMPONENTS SOLAR CONTROLLER

AA Control

BB Pump solar system (ON / OFF)

CC Pump solar system (modulating)

DD Temperature sensor

(S1 - solarcollector)

EE Temperature sensor (S2 - tank)

FF Q/T-measuring (incl. temperature

sensor S4 - return solar collector)

GG Control (BUS-link)

HH Temperature sensor

(S3 - top tank)

F2 Fuse

CONNECTIONS SOLAR CONTROLLER

1

2 L Power supply

3 N

4 - n.a

5 - n.a

6 - n.a

7

8 L

9 N

10 N

11 L

12 - (modulating)

13

14 - n.a

15 - n.a

16 - n.a

17 - n.a

18 - n.a

19 - n.a

20 - n.a

1 n.a

2 n.a

J3

3 n.a

4 n.a

1 Power supply 5V

2 Sensor return

J12 solar collector (S4)

3 Earth

4 Flow signal

1 n.a

J13

3 n.a

4 Sensor solar collector (S1)

1 Sensor top tank (S3)

J14

3 Sensor top tank (S3)

4 Sensor tank (S2)

J15

2 n.a

J16

2

1 n.a

J17 2 n.a

3 n.a

Pump solar system

1

(ON / OFF)

2 Pump solar system

2 Sensor solar collector (S1)

2 Sensor tank (S2)

1 n.a

1

BUS-link

Page 8

X

Y

V

W

X

Y

V

W

W

Y

V

X

Z

Y

T

X

Flue systems SGS

Installation options

B23

C33

C13

A SGS water heater should be installed according category B23,

C13, C33, C43 or C53*.

SGS 28

SGS 30

SGS 50

SGS 60

SGS 80

Concentric

Diameter (mm) 80/125 100/150 100/150 100/150 130/200 130/200

Max. length (m) 40 40 40 15 15 15

Max. 45/90° bends 7 7 7 4 3 3

Parallel (standard diameter)

Diameter (mm) 80 100 100 100 130 130

Max. length (m) 25 80 45 25 115 60

L

/bend 90° (m) 3,9 4,6 4,6 4,6 2,4 2,4

equivalent

L

/bend 45º (m) 1,1 1,2 1,2 1,2 1,4 1,4

equivalent

Parallel (larger diameter for more length)

Diameter (mm) 100 130 130 130 150 150

Max. length (m) 100 100 100 100 100 100

L

/bend 90º (m) 4,6 2,4 2,4 2,4 2,6 2,6

equivalent

L

/bend 45º (m) 1,2 1,4 1,4 1,4 1,6 1,6

equivalent

* All SGS are also approved for installations where the unit is supplied

without venting materials (C63).

SGS 100

Concentric flues

It is not permitted to use more than the specified number of

bends, even when the duct is shorter than the maximum

length. A 45° bend is equivalent to a 90° bend.

C53

C43

Flue systems SGS

Minimum space requirements

SGS 28-60

SGS 80-100

Parallel flues

- The maximum permissible length should be reduced by the

equivalent length of each bend. (Note: for a parallel installation

this means that 3 changes in direction amount to 6 bends

(3 in the supply duct and 3 in the flue).

- The maximum length also applies if a parallel installation has

different supply and flue duct lengths (B23, C53).

- Combined flues (C43) shall be fitted with a condensate drain.

Note: horizontal flue runs must be installed with a fall of at least

5 mm per metre.

SGS 28

SGS 30

SGS 50

SGS 60

SGS 80

Minimal space for wall duct (mm)

Ø80/125 Ø100/150 Ø100/150 Ø100/150 Ø130/200 Ø130/200

V 550 550 550 550 640 640

W 725 790 790 790 940 940

X 1630 2170 2170 2170 2230 2230

Y 1460 1480 1480 1480 1620 1620

Y * 1010 1030 1030 1030 1170 1170

Minimal space for roof duct (mm)

V 1305 1500 1500 1500 1730 1730

W 680 1035 1035 1035 1120 1120

X 3060 3420 3420 3420 3620 3620

X ** 2110 2470 2470 2470 2670 2670

Y 1575 1415 1415 1415 1560 1560

Y ** 625 465 465 465 610 610

SGS 100

For the parts numbers of components and flue gas ducts, etc.

please refer to the “Maintenance and accessories” chapter.

* Distance without concentric pipe between bend and wall duct.

** Distance without concentric pipe between appliance and roof duct.

Data subject to change INT/1108/SGS/02

Terms and conditions apply, please refer to our website.

www.aosmithinternational.com

Loading...

Loading...