A.O. Smith PCG6240T403NOV, PCG250T403NOV, PCG2J5040T3NOV, PCG2J4040T3NOV, 12 40GPC T 100 User Manual

...

SERVICE HANDBOOK FOR

STANDARD RESIDENTIAL

HIGH EFFICIENCY ATMOSPHERIC VENT

(FVIR) GAS WATER HEATERS

MODELS:

GAHH 40 100,

GP 6 40YPC T 100,

PCG6240T403NOV 100,

PCG2J4040T3NOV 100,

12 40GPC T 100,

PCG2J4040T3NOV 100,

GAHH 50 100,

GP 6 50YPC T 100,

PCG250T403NOV 100,

PCG2J5040T3NOV 100,

12 50GPC T 100,

PCG2J5040T3NOV 100

Printed in U.S.A. 10/10 318181-000

1

ALL TECHNICAL AND WARRANTY QUESTIONS

SHOULD BE DIRECTED TO THE LOCAL DEALER FROM WHOM THE WATER HEATER WAS PURCHASED.

IF YOU ARE UNSUCCESSFUL, CONTACT A. O. SMITH WATER HEATERS RESIDENTIAL TECHNICAL ASSISTANCE

AT 1-800-527-1953 OR WWW.HOTWATER.COM.

2

SERVICE HANDBOOK

Your safety and the safety of others is extremely important in the servicing of this water heater. Many

safety-related messages and instructions have been provided in this handbook and on the water heater

to warn you and others of a potential hazard. Read and obey all safety messages and instructions

throughout this handbook. It is very important that the meaning of each safety message is understood

by you and others who service this water heater.

The information contained in this handbook is designed to answer commonly faced situations encountered in the operation of the standard Residential Gas product line and is not meant to be all-inclusive.

If you are experiencing a problem not covered in this handbook, please contact the Technical Information Center listed on the back of this handbook for further assistance. Additional information is also

available on the web site listed on the back of this handbook. This handbook is intended for use by

licensed plumbing professionals and reference should be made to the Installation Instructions and Use

& Care Guide accompanying the product. This handbook contains supplemental information to the

Installation Instructions and Use & Care Guide.

When servicing residential water heaters, it is essential that you return the unit to a safe condition

before you leave the site. All original components must be re-installed and all safety measures must be

implemented. In addition, the recommended water temperature setting is 120° F.

IMPORTANT: It is recommend that on every service call an inspection & cleaning of the air

intake chamber screen and combustion chamber and air diverter assembly be performed. See

page 24.

Tools Required (for servicing gas models):

• phillips head screw driver

• 3/8, 7/16, & 3/4 inch open end wrenches

• 3/16 inch Allen wrench

• 1-1/16 inch – 6 point – socket – for anode removal

• 5/16” nut driver

• pliers

• electrical multimeter (with alligator leads)

• digital or analog manometer

• gas pressure gauge

• Teflon

• hose – to drain tank

®

tape

Digital manometer shown.

®

is a registered trademark of E.I. Du Pont De Numours and Company.

Tef lo n

3

Fire or Explosion Harzard

Do not operate water heater if flood damaged.

Install in location with drainage.

Fill tank with water before operation.

Be alert for thermal expansion.

Refer to instruction manual for installation and service.

Improper installation and use may result

in property damage.

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

Avoid all ignition sources if you smell Natural or LP gas.

Do not expose water heater control to excessive gas

pressure.

Use only gas shown on rating plate.

Maintain required clearances to combustibles.

Keep ignition sources away from faucets after extended

period of non-use.

Read instruction manual before

installing, using or servicing

water heater.

Breathing Hazard - Carbon Monoxide Gas

Install vent system in accordance with

codes.

Do not operate water heater if flood

damaged

Heater should not be installed for High

Altitude operation above 10,100 feet

(3,078 m).

Do not operate if soot buildup.

Do not obstruct water heater air intake

with insulating jacket.

Do not place chemical vapor emitting

products near water heater.

Gas and carbon monoxide detectors

are available.

Breathing carbon monoxide can cause brain damage or death.

Always read and understand instruction manual.

4

TABLE OF CONTENTS

INTRODUCTION:

Service Handbook Introduction ...........................................................................................................................3

Warnings and Cautions .......................................................................................................................................4

Table Of Contents ...............................................................................................................................................5

INSTALLATION / OPERATION:

Basic Installation & Operation .............................................................................................................................6

Combustion Air and Vent System Requirements .......................................................................................... 7-10

KNOW YOUR WATER HEATER:

Know the Water Heater’s Component Parts ................................................................................................11-13

Water Heater Operation ....................................................................................................................................14

Filling and Draining the Water Heater ...............................................................................................................15

Lighting Instructions ..........................................................................................................................................16

ADJUSTING TEMPERATURE CONTROL:

Adjusting the Temperature on the Electronic Control Display ...........................................................................17

Using the Electronic Control Display ........................................................................................................... 18-19

Electronic Control Display Troubleshooting ................................................................................................ 20-23

COMPONENTS REMOVAL / REPLACING:

External Inspection and Cleaning .....................................................................................................................24

Electronic Control Display Removal / Replacement .........................................................................................25

Powered Anode Removal / Replacement ................................................................................................... 26-27

Pressure Switch Removal / Replacement .........................................................................................................28

Transformer Removal / Replacement ......................................................................................................... 29-30

Air Intake Chamber Box Removal / Replacement ...................................................................................... 31-33

Wiring Harnesss Removal / Replacement .................................................................................................. 34-36

Air Intake Chamber Fan Removal / Replacement ...................................................................................... 37-38

Pressure Tubing Removal / Replacement .................................................................................................. 39-40

Inner Door/Manifold/Burner Assembly Removal / Replacement ................................................................. 41-42

Flame Sense/Hot Surface Igniter Removal / Replacement ..............................................................................43

Burner Removal / Replacement .................................................................................................................. 44-46

Burner Orifi ce Removal / Replacement ...................................................................................................... 47-49

Gas Control Valve/Thermostat Removal / Replacement............................................................................. 50-52

CHECKPOINTS / GENERAL INFORMATION:

Checking the Gas Supply Pressure ..................................................................................................................52

Gas Water Heater Sizing Guide -and- Leakage Checkpoints .........................................................................53

General Information .................................................................................................................................... 54-55

5

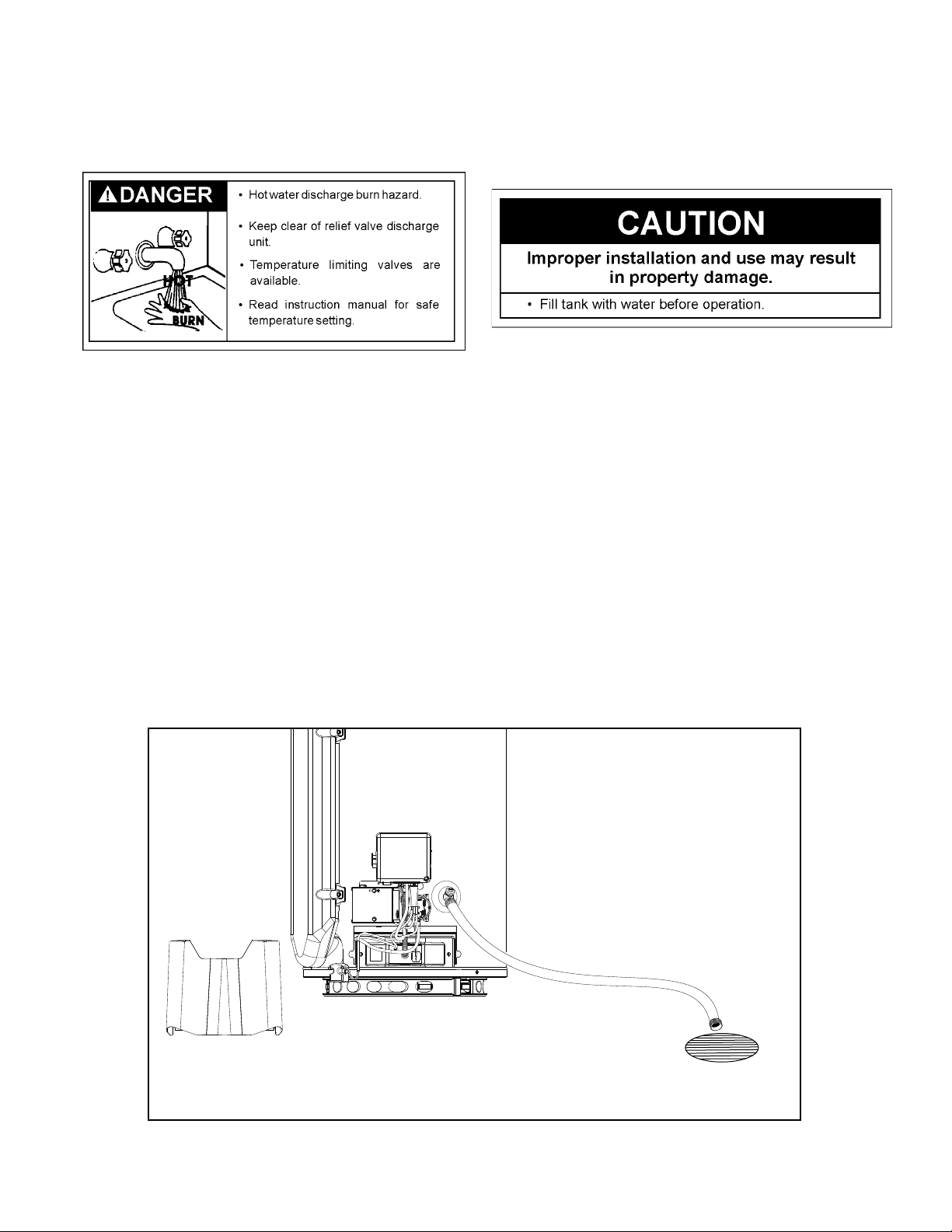

BASIC INSTALLATION & OPERATION

INSTALLATION OF RESIDENTIAL GAS WATER HEATER

See Labels and

Installation Instructions

and Use & Care Guide

for clearances.

Use Draft Hood

supplied with unit

Exhaust Vent to

Ouside of Building

Union

Water

Shut-Off

Valve

Water

Supply- Cold*

*Massachusett: Install

a vacuum relief in cold

water line per section

19 MGL 142.

To Fixtures - Hot

Untempered

Hot Water

Hot

Water

Outlet

Mixing Valve

(Set to 120°F)

Follow the Mixing Valve

Manufacturer’s Instructions

Union

Tempered Water

To Fixtures

Cold

Water

Inlet

Gas

Supply

Control

Display

Expansion Tank

Pressurize to Equal

Supply Water Pressure*

(Relieve water pressure

on the expansion tank

before adjusting air

pressure.)

Temperature-Pressure Relief Valve

with discharge piped to an

adequate drain. Do not cap or plug.

Manual Gas Shut-off Valve

Air Intake Chamber

Air is drawn in for combustion.

Keep area clean and free from

flammables and flammable vapors.

Gas Control Valve/Thermostat

Recommended setting of 120°F.**

Do not cap or plug.

6” Maximum Air Gap

Union

Sediment Trap

(Drip Leg) 3” Minimum.

NOTE: Local codes

may vary.

Drain

Electrical Plug

Metal Drain Pan piped to an adequate drain.

FV Sensor

Bracket

NOTE: Drain pan diameter must be at least

2 inches wider than the diameter of the

water heater.

The water heater must be installed according to all local and state codes or in the absence of local

and state codes, the “National Fuel Gas Code”’ ANSI Z223.1(NFPA 54)- current edition.

* NOTE: If on a well system the expansion tank should be set to the maximum pressure of the pump tank.

** White-Rodgers® gas control valve/thermostat shown in this figure.

Figure 1

6

COMBUSTION AIR AND VENT SYSTEM REQUIREMENTS

Combustion Air Requirements:

WARNING

Carbon Monoxide Warning

Water heater must be vented to outdoors.

Vent must be installed by a qualified technician using

the local and state codes or, in the absence of local

and state codes, the National Fuel Gas Code,

ANSI Z223.1 (NFPA 54) - current edition, and/or the

installation instructions.

Examples of a qualified technican include: gas

technicians, authorized gas company personel, and

authorized service persons.

Failure to so do can result in death or carbon monoxide

poisoning.

IMPORTANT: Air for combustion and ventilation

must not come from a fl ammable or corrosive at-

mosphere. Any failure due to fl ammable or corro-

sive elements in the atmosphere is excluded from

warranty coverage.

The following types of installation (not limited to

the following) will require outdoor air for combustion due to chemical exposure and may reduce

but not eliminate the presence of corrosive chemicals in the air:

• beauty shops

• photo processing labs

• buildings with indoor pools

• water heaters installed in laundry, hobby, or

craft rooms

• water heaters installed near chemical storage

areas

• water softeners

Combustion air must be free of acid-forming

chemicals such as sulfur, fl uorine, and chlorine.

These elements are found in aerosol sprays, detergents, bleaches, cleaning solvents, air fresheners, paint, and varnish removers, refrigerants, and

many other commercial and household products.

When burned, vapors from these products form

highly corrosive acid compounds. These products should not be stored or used near the water

heater, air inlet, or air intake path.

Combustion and ventilation air requirements are

determined by the location of the water heater.

The water heater may be located in either an

open (unconfi ned) area or in a confi ned area or

small enclosure such as a closet or small room.

Confi ned spaces are areas with less than 50 cubic

feet for each 1,000 BTUH of the total input for all

gas-using appliances.

Unconfi ned Space: A water heater in an uncon-

fi ned space uses indoor air for combustion and

requires at least 50 cubic feet for each 1,000

BTUH of the total input for all gas appliances. The

table below shows a few examples of the minimum square footage (area) required for various

BTUH inputs.

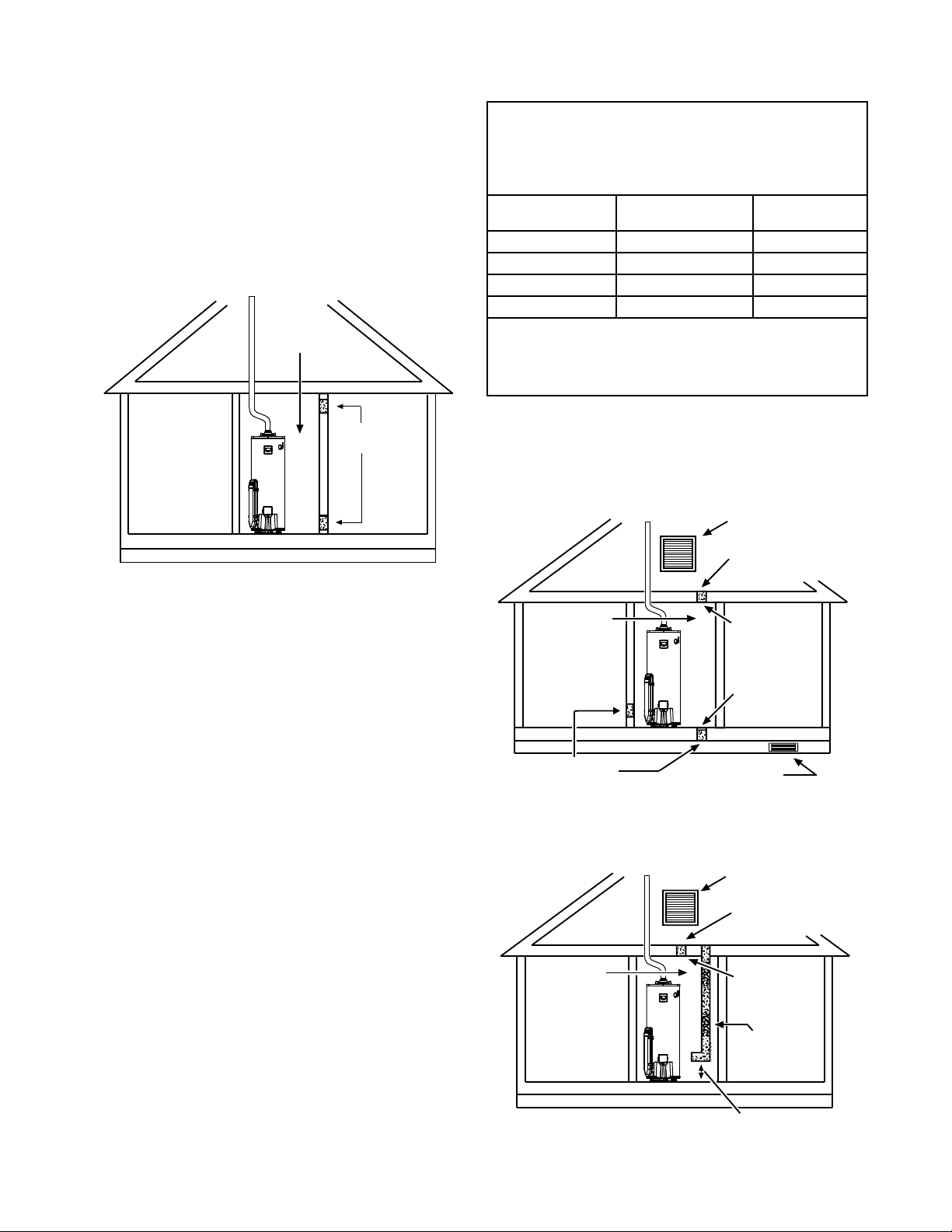

Table 1:

BTUH Input

30,000 188 9 x 21

45,000 281 14 x 20

60,000 375 15 x 25

75,000 469 15 x 31

90,000 563 20 x 28

105,000 657 20 x 33

120,000 750 25 x 30

135,000 844 28 x 30

Minimum Square

Feet with

8’ Ceiling

Typical Room

with 8’ Ceiling

IMPORTANT:

• The area must be open and be able to provide

the proper air requirements to the water

heater. Areas that are being used for storage

or contain large objects may not be suitable

for water heater installation.

• Water heaters installed in open spaces in

buildings with unusually tight construction may

still require outdoor air to function properly. In

this situation, outside air openings should be

sized the same as for a confined space.

• Modern home construction usually requires

supplying outside air into the water heater

area.

• Room exhaust fans may effect air

requirements.

Confi ned Space: For the correct and proper

operation of this water heater, ample air must be

supplied for the combustion, ventilation, and dilution of fl ue gases. Small enclosures and confi ned

areas must have two permanent openings so that

suffi cient fresh air can be drawn from outside of

the enclosure. One opening shall be within 12

inches of the top and one within 12 inches of the

bottom of the enclosure.

The size of each opening (free area) is determined by the total BTUH input of all gas utilization

equipment (i.e., water heaters, furnaces, clothes

dryers, etc.) and the method by which the air is

provided. The BTUH input can be found on the

water heater rating plate. Additional air can be

provided by two methods:

1. All air from inside the building.

2. All air from outdoors.

12” MAXIMUM

CLOSET

OR

OTHER

PERMANENT

OPENINGS TO

THE OUTSIDE OR

ADDITIONAL

ROOMS WITHIN

THE BUILDING

CONFINED

SPACE

12” MAXIMUM

Figure 2.

7

COMBUSTION AIR AND VENT SYSTEM REQUIREMENTS

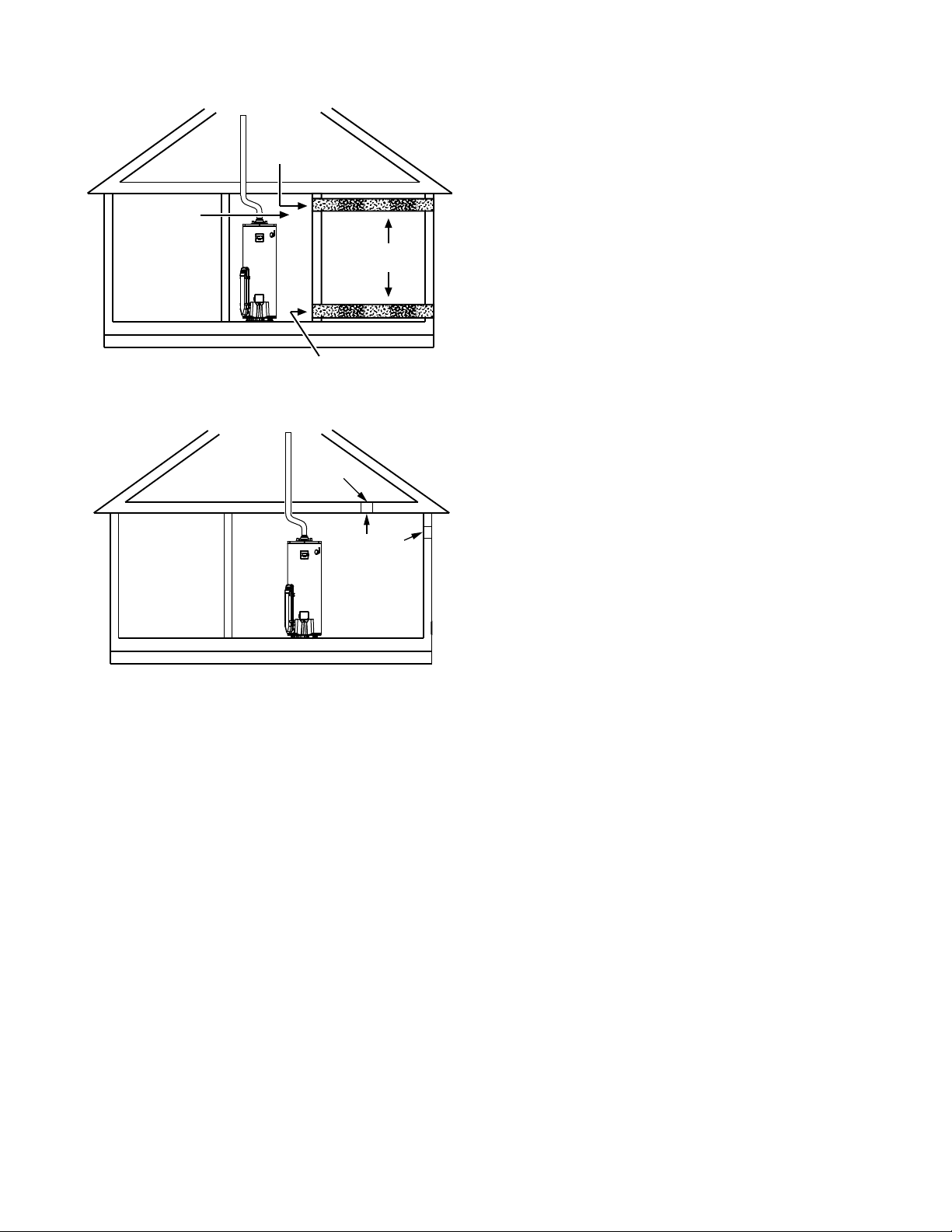

All Air from Inside the Building: When

additional air is to be provided to the confi ned

area from additional room(s) within the building,

the total volume of the room(s) must be of

suffi cient size to properly provide the necessary

amount of fresh air to the water heater and other

gas utilization equipment in the area. Each of the

two openings shall have a minimum free area

of 1 square inch per 1,000 BTUH of the total

input rating of all gas utilization equipment in

the confi ned area, but not less than 100 square

inches for each opening.

CONFINED

SPACE

PERMANENT

OPENINGS

1 SQUARE

INCH/1000

BTUH

(MINIMUM

100 SQ. IN.

FOR EACH

OPENING)

Figure 3.

All Air from Outdoors: Outdoor fresh air can be

provided to a confined area either directly or by

the use of vertical and horizontal ducts. The fresh

air can be taken from the outdoors or from crawl

or attic spaces that freely communicate with the

outdoors. Attic or crawl spaces cannot be closed

and must be properly ventilated to the outside.

Ductwork must be of the same cross-sectional

area as the free area of the opening to which

they connect. The minimum dimension of

rectangular air ducts cannot be less than three

inches. The size of each of the two openings is

determined by the method in which the air is to

be provided. Refer to the table below to calculate

the minimum free area for each opening.

Minimum Free Area of Permanent Openings for

Ventilation and Combustion Air Supply - All Air from

Outdoors Only.

Based on total BTUH input rating for all utilizing

equipment within the confi ned space.

Opening Source

*D irect t o outdo or s 1 sq. in, per 4000 BTUH Fi gu re 4

Ver tic al D uct s 1 sq. in, per 4000 BTUH Fi gu re 5

Ho rizon tal Duc ts 1 sq. in, per 2000 BTUH Figu re 6

Si ng le Op ening 1 sq. in, per 3000 BTUH Fi gu re 7

Example: A water heater with an input rating of 50,000 BTUH

using horizontal ducts would require each opening to have a

minimum free area of 25 square inches.

Minimum free area = 50,000 BTUH x 1 sq. in. / 2000 BTUH = 25

sq. in.

These openings connect directly with the outdoors

*

Minimum Free Area

Per Opening (sq. in.)

Reference

Drawing

through a ventilated attic, a ventilated crawl space, or

through an outside wall.

Consult the local codes of your area for specific

ventilation and combustion air requirements

ABLE VENT

TO OUTDOORS

INSTALL ABOVE

INSULATION

CONFINED

SPACE

ALTERNATE

AIR INLET

1 SQ. INCH PER

100 SQ. INCH MINIMUM (EACH)

ALL AIR FROM OUTDOORS: INLET AIR FROM VENTILATED

4000 BTUH

CRAWL SPACE/OUTLET AIR TO VENTILATED ATTIC

OUTLET

AIR TO

ATTIC 1 SQ.

INCH PER

4000 BTUH

THE CRAWL SPACE

FOUNDATION

INLET AIR FROM

OPEN

VENT

Figure 4.

Louvers and Grilles: In calculating free

area for ventilation and combustion air supply

openings, consideration must be given to the

blocking effect of protection louvers, grilles, and

screens. These devices can reduce airflow, which

in turn may require larger openings to achieve the

required minimum free area. Screens must not be

smaller than 1/4” mesh. If the free area through

a particular design of louver or grille is known, it

should be used in calculating the specified free

area of the opening. If the design and free area

are not known, it can be assumed that most wood

louvers will allow 20 - 25% of free area while

metal louvers and grilles will allow 60 - 75% of

free area. Louvers and grilles must be locked

open or interconnected with the equipment so that

they are opened automatically during equipment

operation. Keep louvers and grilles clean and free

of debris or other obstructions.

GABLE VENT

TO OUTDOORS

INSTALL ABOVE

INSULATION

CONFINED

SPACE

ALL AIR FROM OUTDOORS THROUGH VENTILATED ATTIC

OUTLET AIR TO

ATTIC 1 SQ. INCH

PER 4000 BTUH 100 SQ. INCH MIN.

(EACH)

INLET AIR DUCT

1 SQ. INCH PER

4000 BTUH - 100

SQ. INCH MIN.

(EACH)

12” MAXIMUM

Figure 5.

8

COMBUSTION AIR AND VENT SYSTEM REQUIREMENTS

1 SQ. INCH PER

2000 BTUH

100 SQ. INCH

MINIMUM (EACH)

CONFINED

SPACE

ALL AIR FROM OUTDOORS USING HORIZONTAL DUCTS

OUTLET

OUTDOOR

AIR DUCTS

INLET

1 SQ. INCH PER

2000 BTUH 100 SQ. INCH

MINIMUM (EACH)

Figure 6.

ALTERNATIVE

OPENING

LOCATION

CONFINED

SPACE

ALL AIR FROM OUTDOORS - USING A SINGLE PERMANENT OPENING

1 SQ. INCH

PER 3000 BTUH

100 SQ. INCH

MINIMUM (EACH)

Figure 7.

Vent Pipe System: This water heater must be

properly vented for the removal of exhaust gases

to the outside atmosphere. Correct installation of

the vent pipe system is mandatory for the proper

and effi cient operation of this water heater and is

an important factor in the life of the unit.

The vent pipe must be installed according to all

local and state codes or, in the absence of local

and state codes, the “National Fuel Gas Code”,

ANSI Z223.1(NFPA 54)-current edition. The vent

pipe installation must not be obstructed so as

to prevent the removal of exhaust gases to the

outside atmosphere.

U.L. recognized fuel gas and carbon monoxide

(CO) detectors are recommended in all

applications and should be installed using the

manufacturer’s instructions and local codes, rules,

or regulations.

Vent Pipe Size: It is important that you follow the

guidelines in these instructions for sizing a vent

pipe system. If a transition to a larger vent size is

required, the vent transition connection must be

made at the draft hood outlet. DO NOT reduce

the vent size to less than the draft hood outlet

diameter.

Vent Connectors:

1. Type B, Double wall, U.L. Listed Vent Pipe.

2. Single wall Vent Pipe.

Maintain the manufacturer’s specifi ed minimum

clearance from combustible materials when using

type B double wall vent pipe.

Vent connectors made of type B, double wall

vent pipe material may pass through walls or

partitions constructed of combustible material if

the minimum listed clearance is maintained.

Maintain a one inch minimum clearance from all

combustible materials when using single wall vent

pipe.

IMPORTANT: Single wall vent pipe cannot be

used for water heaters located in attics and may

not pass through attic spaces, crawl spaces or

any confi ned or inaccessible location. A single wall

metal vent connector cannot pass through any

interior wall.

When installing a vent connector, please note the

following

• Install the vent connector avoiding

unnecessary bends, which create resistance

to the flow of vent gases.

• Install without dips or sags with an upward

slope of at least 1/4-inch per foot.

• Joints must be fastened by sheet metal

screws or other approved means. It must be

supported to maintain clearances and prevent

separation of joints and damage.

• The length of the vent connector cannot

exceed 75% of the vertical vent height.

• The vent connector must be accessible for

cleaning, inspection, and replacement.

• Vent connectors cannot pass through any

ceiling, floor, firewall, or fire partition.

• It is recommended (but not mandatory) that

a minimum 12 inches of vertical vent pipe be

installed on the draft hood prior to any elbow

in the vent system.

IMPORTANT: Existing vent systems must be

inspected for obstructions, corrosion, and proper

installation.

Chimney Connection: IMPORTANT: Before

connecting a gas vent to a chimney, make sure

the chimney passageway is clear and free of

obstructions. The chimney must be cleaned if

previously used for venting solid fuel appliances

or fireplaces. Also consult local and state codes

for proper chimney sizing and application or, in the

absence of local and state codes, the “National Fuel

Gas Code”, ANSI Z223.1(NFPA 54)-current edition.

• The connector must be installed above the

extreme bottom of the chimney to prevent

potentially blocking the flue gases.

9

COMBUSTION AIR AND VENT SYSTEM REQUIREMENTS

• The connector must be firmly attached and

sealed to prevent it from falling out.

• To aid in removing the connector, a thimble or

slip joint may be used.

• The connector must not extend beyond the

inner edge of the chimney as it may restrict

the space between it and the opposite wall of

the chimney

2 FT. Minimum Above Any Object

Within 10 FT. Horizontally

Do Not Extend

Vent Beyond Edge

Of Chimney

Maintain

Clearance*

Vent

Connector

Support Strap

3 FT.

Minimum

Seal

Slope Up

1/4 Inch

Per Foot

Minimum

Chimney Termination Vent System

Figure 8.

Do not reduce the vent to less than the draft

hood outlet diameter. Do not terminate the vent

connector in a chimney that has not been certified

for this purpose. Some local codes may prohibit

the termination of vent connectors in a masonry

chimney.

Vertical Exhaust Gas Vent: Vertical exhaust

gas vents must be installed with U.L. listed type

B vent pipe according to the vent manufacturer’s

instructions and the terms of its listing.

It must be connected to the water heater’s draft

hood by a listed vent connector or by directly

originating at the draft hood opening.

Vertical gas vents must terminate with a listed cap

or other roof assembly and be installed according to

their manufacturer’s instructions.

Gas vents must be supported to prevent damage,

joint separation, and maintain clearances to

combustible materials.

IMPORTANT: This gas vent must be terminated in a

vertical position to facilitate the removal of the burnt

gases.

An unused chimney fl ue or masonry enclosure

may be used as a passageway for the installation

of a gas vent. NOTE: The chimney fl ue or masonry

enclosure size may be too large to allow proper

venting.

Common (combined) venting is allowable with

vertical type B vent systems and lined masonry

chimneys as long as proper draft for the water

heater is established under all conditions of

operation. CAUTION: DO NOT common vent this

water heater with any power vented appliance.

The following fi gures are examples of vent pipe

system installations and may or may not be typical

for your specifi c application. Consult the “National

Fuel Gas Code”, NFPA 54, ANSI Z223.1-current

edition and the guidelines set forth by prevailing

local codes.

2 FT. Minimum Above

Any Object Within

3 FT.

Minimum

Support Strap

Maintain

Clearance*

Vent

Connector

Slope Up

1/4 Inch

Per Foot

Minimum

Venting Gas Vent System With Type B Double Wall Vent Pipe.

10 FT. Horizontally

Type B Double

Wall Vent Pipe

**Maintain

Specified

Clearance

Figure 9.

Consult the table found in the “National Fuel Gas

Code”, NFPA 54, ANSI Z223.1-current edition to

determine the minimum height from roof to lowest

discharge opening.

Listed Vent Cap

**Maintain

Specified

Clearance

Vent Connector

Unused Chimney

Flue Or Masonry

Enclosure

Maintain Manufacturer’s

Specified Minimum Clearance

Support Strap

Maintain

Clearance*

Venting Through Chimney With Type B Double Wall Vent Pipe.

Seal

Vent

Connector

Slope Up

1/4 Inch

Per Foot

Minimum

Figure 10.

Maintain vent pipe clearance requirements to local,

*

state and/or the “National Fuel Gas Code”, ANSI

Z223.1(NFPA 54)-current edition.

NFPA 211, Standard for Chimneys, Fireplaces,

**

Vents, and Solid Fuel-Burning Appliances states

that these chimneys are intended to be installed

in accordance with the installation instructions

provided with each chimney support assembly.

Minimum air space clearance to combustible

materials should be maintained as marked on the

chimney sections.

10

KNOW THE WATER HEATER’S COMPONENT PARTS

Electronic Control Display (Upper Control)

The Electronic Control Display panel used on this water heater provides an easy-to-read, eye level display

for temperature adjustment, fault code diagnostics and recall, powered anode rod operation and setting the

temperature scale for either Fahrenheit (°F) or Celsius (°C).

Figure 11.

Electronic Control Display

(Upper Control)

Gas Control Valve/Thermostat (Lower Control)

The gas control valve/thermostat is where the incoming gas supply is connected to the water heater. It is

used in conjunction with the electronic control display to start or stop main burner operation. There is an

On/Off switch located on the right-hand side of the control. The gas control valve/thermostat is energized

by a 24 VAC power supply transformer and uses a temperature sensing probe to open or close the flow

of gas to the main burner. The gas control valve has an inlet filter built into its body to prevent impurities in

the gas system from contaminating the internal valves and a LED diagnostic light located in the lower right

hand corner of the valve to display any micro-computer fault experienced by the control. On the bottom of

the control is where electrical connections to the other component parts are attached along with the gas

supply (manifold tube) to the main burner. The gas control/valve thermostat of this water heater is suitable

for use on Natural gas only.

Figure 12.

Gas Control Valve/ Thermostat

On/Off Switch

located on

the right side.

Pressure

Switch / Fan,

1

FV Sensor

Connector

2

Control Display,

Anode Rod

Connector

Bottom View

3

4

2 Pin Power

Connector

2

5 Pin Communications

Connector

3 Pin Ignitor

Connector

1

8 Pin Systems

Connector

Gas Supply- Inlet

Temperature Probe

/High Limit Probe

Power Supply

Transformer

Connector

Manifold Tube

4

3

Igniter/Flame

Sense

Connector

11

KNOW THE WATER HEATER’S COMPONENT PARTS

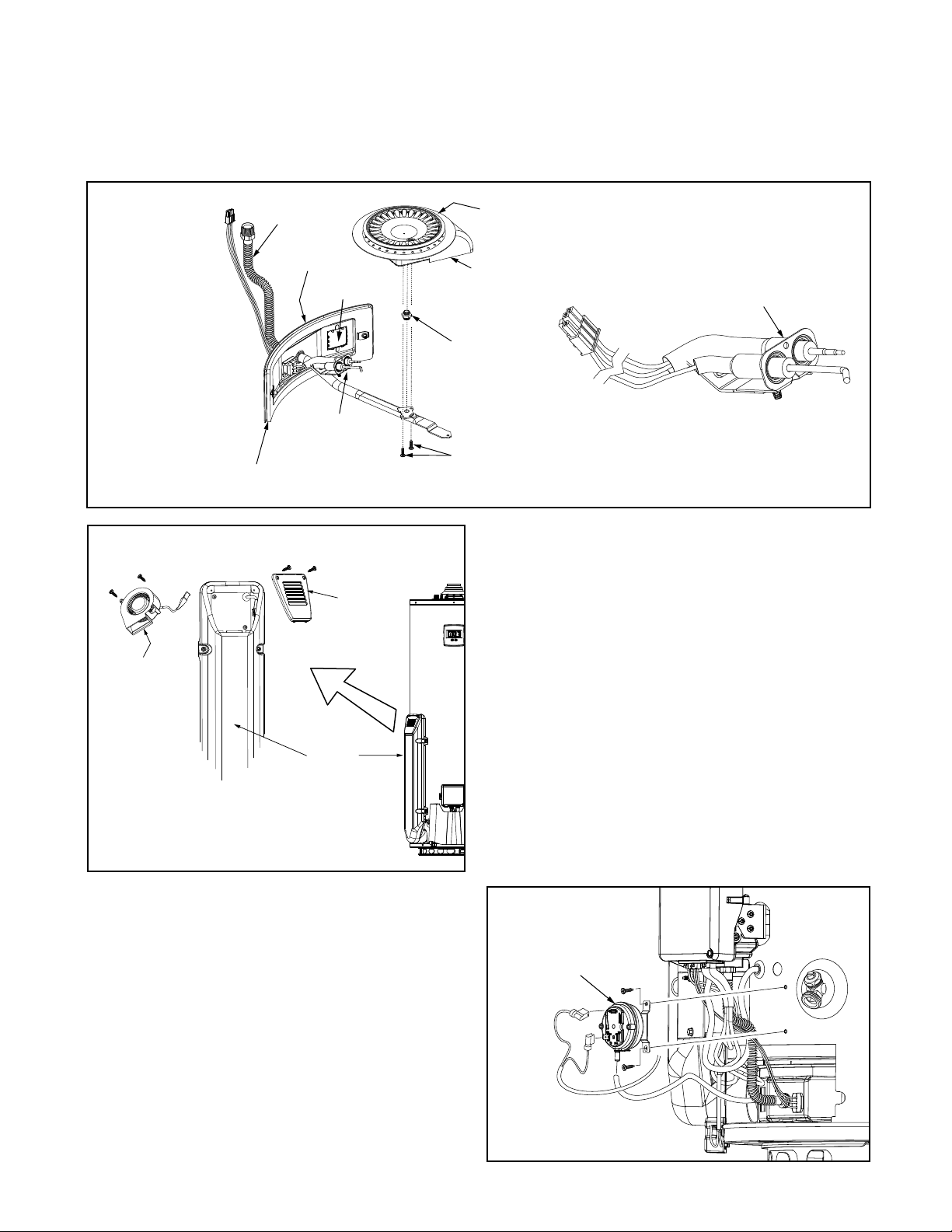

Burner/Manifold Door Assembly

The burner/manifold door assembly consists of several components such as: main burner, burner orifice,

manifold tube and flame sense / hot surface igniter. See figure below for the complete list of components

(Figure 13).

Figure 13.

Figure 14.

Air intake

Chamber

Fan

Door Gasket

Manifold

Tube

Manifold

Door

View

Port

Flame Sense/

Hot Surface

Igniter Assembly

*DO NOT operate the water heater without the burner orifices installed.

Air intake

Chamber

Air intake

Chamber

Screen

Main Burner

Scoop side to be placed

on the same side as

View Port.

Burner Orifice*

Burner Screws

Flame Sense / Hot Surface

Igniter Assembly

Air Intake Chamber Fan

The small fan at the top of the air intake chamber

on the side of the water heater is used to draw in

necessary combustion air for the efficient operation

of the main burner. The fan pressurizes the sealed

combustion chamber which in turn allows the flue

baffle inside the center flue tube to slow down the

hot exhaust gases so heat can be extracted into the

water before exiting into the vent system. The air

intake chamber fan runs for about 5 seconds to prepurge the combustion chamber before the beginning

of an ignition sequence when there is a call for

heat. The fan will continue to operate while the main

burner is in operation and for about 5 seconds after

the temperature set point has been achieved. The

air intake chamber screen covering the fan should

be inspected and cleaned periodically to assure it is

not limiting air flow into the chamber (Figure 14).

Pressure Switch

A pressure switch in the control string of this water

heater is used to verify there is an adequate flow of

combustion air into the combustion chamber before

and during main burner operation. It is electrically

connected to the gas control valve/thermostat and

controls the opening and closing of the gas valve.

If there is an insufficient air supply being delivered

to the combustion chamber the pressure switch will

not allow the water heater to operate (Figure 15).

Figure 15

Pressure

Switch

12

KNOW THE WATER HEATER’S COMPONENT PARTS

Flammable Vapor Cut Off Switch (FV Sensor)

The water heater is equipped with a FV sensor, for

detecting the presence of flammable vapors (e.g.

spilled gasoline). When the sensor detects those

vapors, the heater will shut down and not operate.

If flammable vapors are detected or the sensor

is inoperative, an icon will flash on the electronic

control display and the heater will go into a lockout

mode. The water heater will not function again until

the flammable vapors have been eliminated and the

control is manually reset using a special Flammable

Vapor sensor reset sequence. (Figure 16).

Figure 17.

Powered

Anode

Rod

Figure 16.

FV Sensor

Power Anode Rod

To protect the glass-lined water tank from corrosion

through electrolysis, this water heater is equipped

with a non sacrificial powered anode rod. Unlike

conventional magnesium or aluminum anode rods

used in water heaters, the powered anode does

not deteriorate and is less likely to contribute to

the occurrence of “Smelly (Rotten Egg) Water”

(Figure 17).

HOW THE WATER HEATER’S COMPONENT PARTS ARE CONNECTED

Figure 18.

Air Intake

Chamber Fan

Gas Control

Valve / Thermostat

Pressure

Switch

Igniter/Flame

Sense Connector

FV

Sensor

CAUTION:

LABEL ALL WIRES PRIOR TO

DISCONNECTION WHEN SERVICING

CONTROLS. WIRING ERRORS CAN CAUSE

IMPROPER AND DANGEROUS OPERATION.

VERIFY PROPER OPERATION AFTER SERVICING.

Control Display

CAUTION:

DO NOT USE AN EXTENSION

CORD TO CONNECT THE

TRANSFORMER TO AN

ELECTRICAL OUTLET.

Power Supply

Transformer

Anode

Rod

13

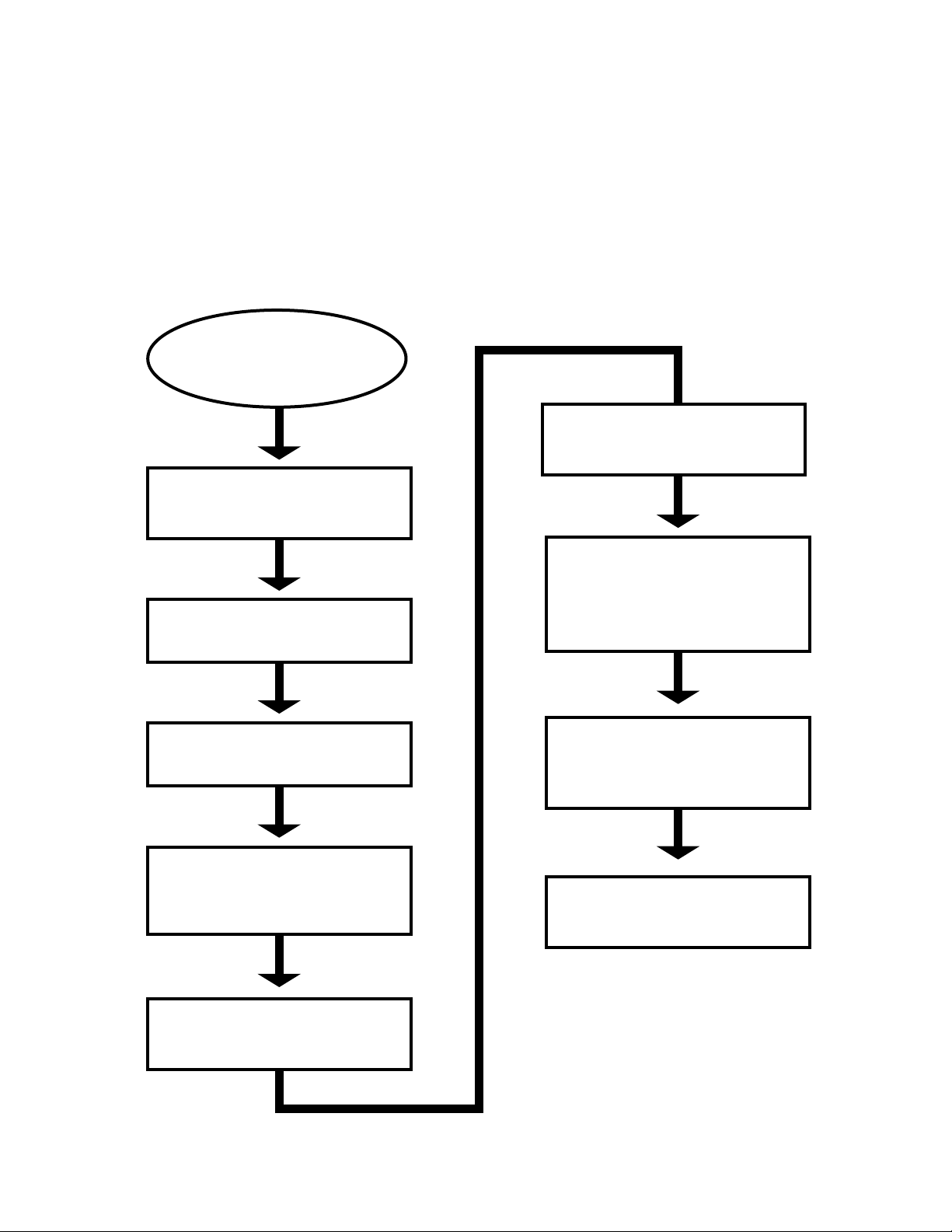

WATER HEATER OPERATION

The figure below shows the water heater’s sequence of operation when a call for heat is initiated. The gas

control valve/thermostat will attempt to light the burner three times. If the flame sense rod in the burner/

manifold assembly does not detect ignition, the control will enter lockout mode indicated by the electronic

control display’s flashing of the appropriate status code.

SEQUENCE OF OPERATION

Call for heat indicated by

flashing of display screen

status codes.

Gas valve/thermostat will open

for 4 second trial for ignition

and fan will turn on.

Gas valve/thermostat will do a

relay check (relay clicks will be

heard).

Display will show temperature

set point during call for heat.

Draft Blower is energized.

System will verify pressure

switch operation and start a

5 second pre-purge, then air

intake fan will turn off.

Main burner flame is detected by

flame sense rod. Air intake fan

and main burner will continue to

operate until water temperature

inside the tank reaches

temperature set point.

Gas valve/thermostat is deenergized and air intake fan

continues for a post purge time

of approximately 5 seconds.

Water heater returns to standby

mode.

Ignitor will start a 12 second

warm up period. “IGN” will

show on display.

14

FILLING, DRAINING AND FLUSHING THE WATER HEATER TANK

It is recommended that the tank be drained and flushed every 6 months to remove sediment which

may build up during operation. The water heater should be drained if being shut down during freezing

temperatures. To drain the tank, perform the following steps:

1. Turn off the gas to the water heater at the manual gas shut-off valve and turn off the electrical power to

the gas control/thermostat valve.

2. Open a nearby hot water faucet until the water is no longer hot.

3. Close the cold water inlet valve.

4. Remove the outer door and connect a hose to the drain valve and terminate it to an adequate drain or

external to the building (Figure 19).

5. Open the water heater drain valve and allow all the water to drain from the tank. Flush the tank with

water as needed to remove sediment.

6. Close the drain valve, refill the tank, and restart the heater as directed in the lighting instructions on the

front of the heater.

IMPORTANT: Condensation may occur when refilling the tank and should not be confused with a tank leak.

NOTE: If the water heater is going to be shut down for an extended period,

the drain valve should be left open.

Figure 19.

Hose

Outer Door

Adequate Drain

15

LIGHTING INSTRUCTIONS

Read and understand these directions thoroughly before attempting to operate the water heater. Make sure

the view port is not missing or damaged. Make sure the tank is completely filled with water before operating

the water heater. The gas control valve/thermostat has an “On/Off Switch” and needs to be turned on

before the water heater is operational. Check the label on the front of the water heater near the gas control

valve/thermostat for the correct gas. Do not start this water heater with any gas other than the one listed on

the label. If you have any questions or doubts, consult the gas supplier or gas utility company. The following

Lighting Instruction label appears on the front of the water heater.

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING:

explosion may result causing property damage, personal injury

or loss of life.

BEFORE OPERATING: ENTIRE SYSTEM MUST BE FILLED WITH WATER AND AIR PURGED FROM ALL LINES.

This appliance does not have a pilot. It is equipped with

A.

an ignition device that will

burner.

B.

BEFORE OPERATING smell all around the appliance

area for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light the burner by hand.

Do not try to light any appliance.

Do not touch any electric switch;

do not use any phone in your building.

Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

If you do not follow these instructions exactly, a fire or

automatically

light the

If you cannot reach your gas supplier, call the

fire department.

Use only your hand to push in the electronic display

C.

buttons and gas control switch. Never use tools.

If the control buttons will not push in, don't try to

repair them, call a qualified service technician. Force

or attempted repair may result in a fire or explosion.

Do not use this appliance if any part has been

D.

under water. Immediately contact a qualified

installer or service agency to replace a flooded

water

heater. Do not attempt to repair the unit.

be replaced!

It must

FLAMMABLE

OPERATING INSTRUCTIONS

ON

OFF

ON/OFF

SWITCH

"GAS CONTROL"

1.

2.

Turn on all electrical power to the appliance.

3.

Set the ON/OFF switch on the gas control to the

"ON" position.

Set the Electronic Display to the lowest

4.

setting by first

HOTTER but

second. Then press

the lowest setting.

5.

Set the ON/OFF switch on the gas control to the

"OFF" position.

6.

This appliance is equipped with a device

which automatically lights the burner.

DO NOT TRY TO LIGHT THE BURNER BY HAND.

Wait five (5) minutes to

7.

If you then smell gas,

the safety information above on this label. If you

don't smell gas, go to the next step.

Read the safety information

STOP!

above on the label.

pressing the COOLER and

tons together and holding for 1

the COOLER button to

clear out any gas.

STOP! Follow "B" in

"ELECTRONIC DISPLAY"

8.

Set the ON/OFF switch on the gas control to the

"ON" postition.

Set the Electronic Display to the desired setting by first

9.

pressing the COOLER and HOTTER buttons together and holding for 1 second. Then press

the HOTTER button until the desired setting

is reached.

DANGER:

risk of scald injury. Consult the instruction

manual before changing temperature.

If the appliance will not operate, follow the instruc-

10.

tions "TO TURN OFF GAS TO APPLIANCE" and

call your technician or gas supplier.

Hotter water increases the

WARNING: TURN OFF ALL

ELECTRIC POWER BEFORE SERVICING.

TO TURN OFF GAS TO APPLIANCE

Set the Electronic Display to the lowest setting by first

1.

pressing the COOLER and HOTTER but-

tons together and holding for 1 second. Then press

the COOLER button to the lowest setting.

Figure 20.

2.

Set the ON/OFF switch on the gas control to the

"OFF" postition.

3.

Turn off all electrical power to the appliance if

service is to be performed.

16

185741-000

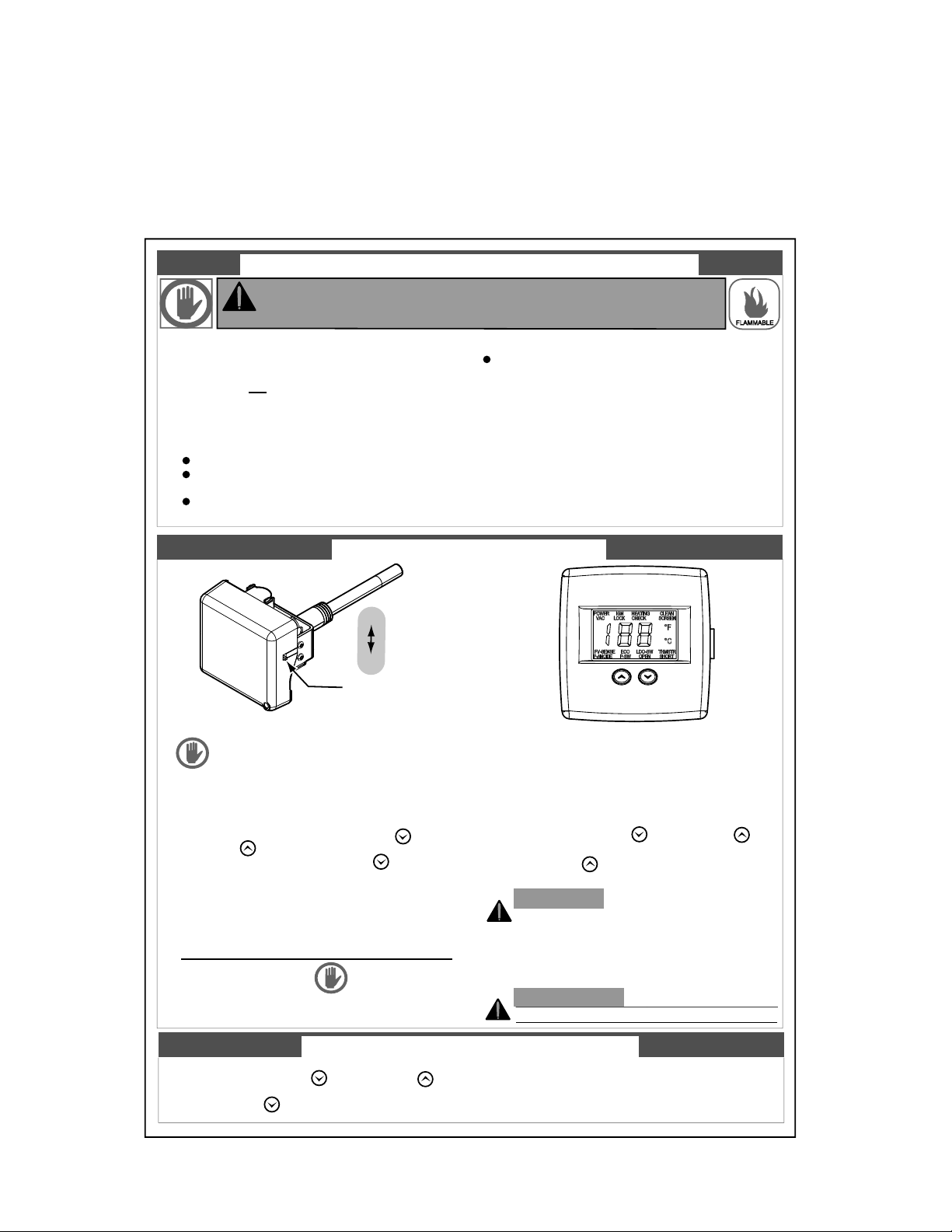

ADJUSTING THE TEMPERATURE ON THE

ELECTRONIC CONTROL DISPLAY

Adjusting the Temperature Set Point - The thermostat of this water heater has been factory set at its

lowest position. It is adjustable and must be reset to the desired temperature setting to reduce the risk of

scald injury. The electronic control display temperature should be set at approximately 120°F (49°C) and

this is the preferred starting point, see Figure 21 Some states have a requirement for a lower setting. If you

need hotter water, follow directions for temperature adjustment, but beware of the warnings in this section.

Pressing the “COOLER” button decreases temperature and pressing the “HOTTER” button increases

the temperature.

To avoid any unintentional changes in water temperature settings, the control has a tamper resistant

feature for changing the temperature setting. To change the temperature setting follow these instructions:

1. “Unlock” the temperature indicators by holding down both “COOLER” and “HOTTER” temperature

adjustment buttons at the same time for one second (See Figure 21). The temperature indicators will light

up and will only remain on for 30 seconds if no further buttons are pressed. After 30 seconds the control

will go back to “Lock” mode (“Lock” mode indicates a temperature setting is locked into the control

memory).

2. Release both of the temperature adjustment buttons.

A. To decrease the temperature press and release the “COOLER”

b ut to n unt il th e de si red s et ti ng is re ach ed .

B. To increase the temperature press and release the “HOTTER”

button until the desired setting is reached.

NOTE: Should overheating occur or the gas supply fail to shut off, turn off the manual gas control valve to

the heater.

Figure 21.

HOTTER

Water

Temperature

°F

110 (normal shower temp.)

116 (pain threshold)

116 35 minutes 45 minutes

122 1 minute 5 minutes

131 5 seconds 25 seconds

140 2 seconds 5 seconds

149 1 second 2 seconds

154 instantaneous 1 second

(U.S. Government Memorandum, C.P.S.C., Peter L. Armstrong, Sept. 15,1978)

Gas Control Valve/Thermostat Settings

Electronic Control Display

Time for 1st

Degree Burn

(Less Severe Burns)

COOLER

Time for Permanent Burns

2nd & 3rd Degree

(Most Severe Burns)

Table 2

17

Loading...

Loading...