Page 1

CUSTOM-LINE SINGLE-WALL

COPPER TUBE TANK HEATERS

®

STEAM AND HOT WATER HEATING COIL SELECTION

Single wall copper tube tank heaters

are designed for heating potable

water with both steam or hot water.

DESIGN AND CONSTRUCTION

FEATURES

Tank heating units are used for heating

water and are specifically engineered

for installation in water storage tanks.

The heating medium may be either steam

or hot water.

Heating units are manufactured from

3/4" OD 20 gauge seamless deoxidized

drawn copper tubing, formed into "U"

shapes with ends expanded into a steel

or brass tube sheet. Where necessary,

the assemblies are installed with tube

bundle supports and with spacers to keep

tubes in alignment. The collar is made

from steel pipe. Heater heads are constructed of gray cast iron or optional

methods, depending upon working pressure.

Other non-standard gauges, tubing sizes

and materials are available; consult the

factory.

EXPLANATION OF MODEL NUMBERS

Example: NS6-24

NS = Steam, NW = water

6 = diameter of tube

bundle in inches.

24 = length of tube bundle

in inches.

SELECTION

For the best performance, tank heating

units should extend into the tank as far

as possible (minimum one half the tank

diameter or length).

NOTE: The heat transfer rate can be

drastically reduced in hard water areas

with age and the build up of scale. Thus,

consideration should be given to fouling

factors and the square footage increased

accordingly. In order to increase the

fouling factor from 0.001 to 0.002 increase the square footage of heating

surface by 20%.

September 2010R

July 2008R

Revised June 1999

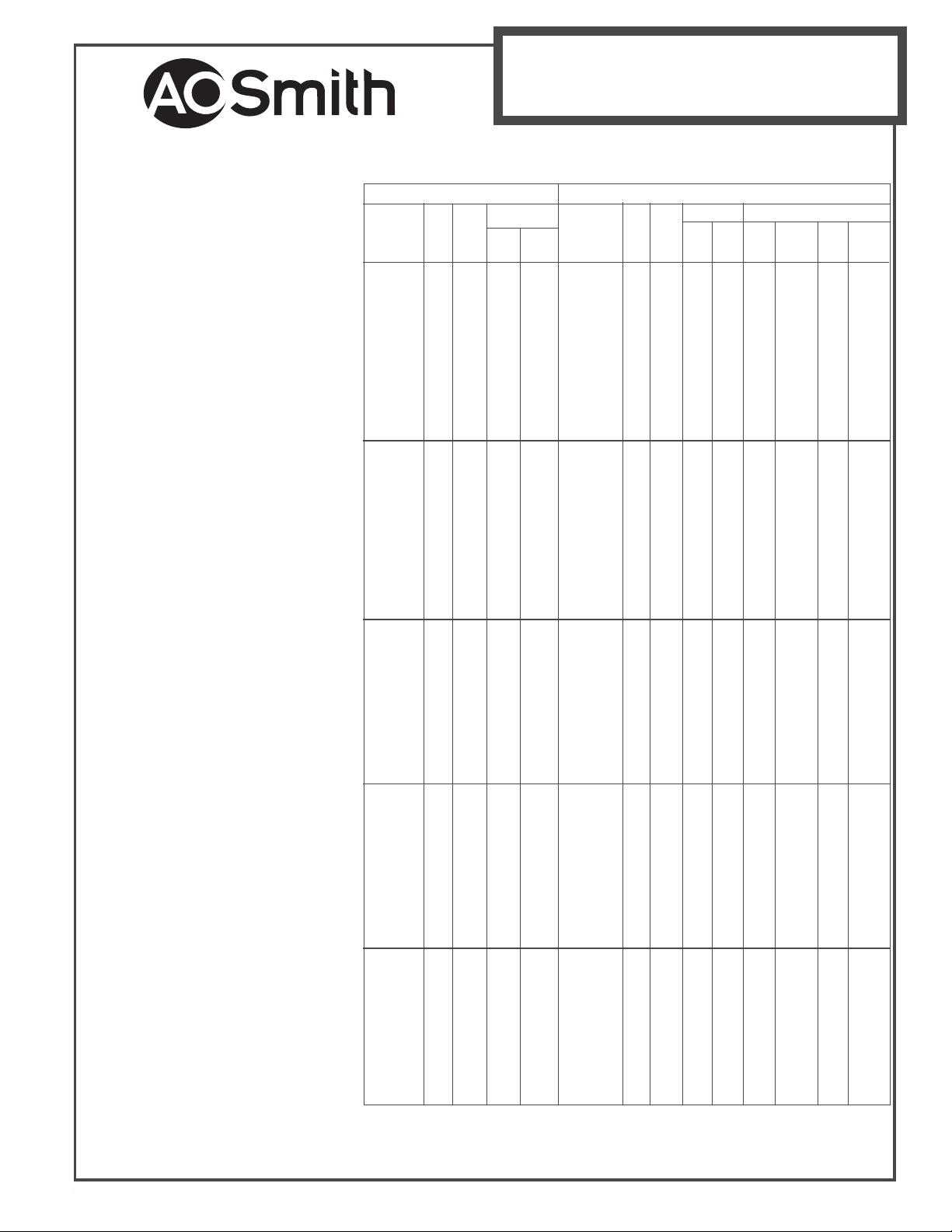

Model Ft. Ship. Number Ft. Ship Flow P res s GPH @

Number Ht. Wt. GPH@ GPH@ Type Ht. Wt. Rate Drop Rec.@ BW Flow Rec.@ BW Flow

Type NS Surf. (lbs.) 0 lbs. 10 lbs. NW Surf. (lbs.) GPM PSI 18 0°F GPM 210°F GPM

NS 4-12 0.9 29 20 26

NS 4-18 1.7 31 37 50 NW 4-18 1.0 31 0.90 10 1 19 2

NS 4-24 2.5 3 2 55 73 NW 4-24 1.7 32 1.20 17 1 33 3

NS 4-30 3.3 34 72 97 NW-4-30 2.7 34 1.50 27 2 52 4

NS 4-36 4.135 90120NW 4-36 3.635 1.8036 3 69 6

NS 4-42 4.9 3 7 107 14 3 NW 4-42 4.6 37 2.10 4 6 4 8 9 7

NS 4-48 5.7 3 8 125 16 7 NW 4-48 5.6 38 34 2.4 0 56 5 108 9

NS 4-54 6.5 4 0 142 19 0 NW 4-54 6.5 40 2.70 6 5 5 125 10

NS 4-60 7.3 4 1 160 21 4 NW 4-60 7.3 41 3.00 7 3 6 141 12

NS 4-66 8.1 4 3 178 23 7 NW 4-66 8.1 43 3.30 8 1 7 156 13

NS 4-72 8.9 4 4 195 26 0 NW 4-72 8.9 44 3.60 8 9 7 172 14

NS 4-84 10.5 47 230 307 NW 4-84 10.5 47 4.20 105 9 202 17

NS 4-96 12.1 50 265 354 NW 4-96 12.1 50 4.80 121 10 233 19

NS 6-12 3.3 5 1 7 2 9 7

NS 6-18 5.6 5 6 124 16 5 NW 6-18 3.1 56 0.90 3 1 3 6 0 5

NS 6-24 8.0 6 1 175 23 4 NW 6-24 5.8 61 1.20 5 8 5 112 9

NS 6-30 10.3 66227 303NW 6-30 8.566 1.50 85 7 164 4

NS 6-36 12.7 71 2 78 372 NW 6-36 11.4 71 1.80 114 9 22 0 18

NS 6-42 15.0 76 330 441 NW 6-42 14.2 76 2.10 142 12 274 23

NS 6-48 17.4 8 1 381 509 NW 6-48 17.3 81 7 8 2.40 172 14 334 2 8

NS 6-54 19.7 86 433 578 NW 6-54 19.7 86 2.70 197 16 381 32

NS 6-60 22.1 91 484 647 NW 6-60 22.1 91 3.00 220 18 426 36

NS 6-66 24.4 96 536 716 NW 6-66 24.4 96 3.30 244 20 471 39

NS 6-72 26.8 101 587 784 NW 6-72 26.8 101 3.60 267 22 517 43

NS 6-84 31.5 111 690 922 NW 6-84 31.5 111 4.20 314 26 607 5 1

NS 6-96 36.2 121 793 1060 NW 6-96 36.2 121 4.80 361 30 698 58

NS 8-18 11.2 97 2 47 329 NW 8-18 6.6 9 7 0.90 6 6 5 12 7 11

NS 8-24 15.5 107 340 454 NW 8-24 11.0 107 1.20 110 9 212 18

NS 8-30 19.7 117 433 578 NW 8-30 15.7 117 1.50 156 13 303 2 5

NS 8-36 24.0 127 526 702 NW 8-36 20.7 127 1.80 206 17 399 33

NS 8-42 28.2 137 619 827 NW 8-42 25.7 137 2.10 256 21 495 41

NS 8-48 32.5 147 712 951 NW 8-48 31.9 147 175 2.40 318 26 615 51

NS 8-54 36.7 157 806 1076 NW 8-54 36.7 157 2.70 366 31 709 59

NS 8-60 41.0 167 899 1200 NW 8-60 41.0 167 3.00 409 34 790 66

NS 8-66 45.2 177 992 1324 NW 8-66 45.2 177 3.30 451 38 872 73

NS 8-72 49.5 187 1085 1449 NW 8-72 49.5 187 3.60 493 4 1 954 30

NS 8-84 58.0 207 1271 1698 NW 8-84 58.0 207 4.20 578 4 8 1118 9 3

NS 8-96 66.5 227 1458 1946 NW 8-96 66.5 227 4.80 663 5 5 1282 107

NS 10-24 26 220 5 70 761 NW 10-24 2 0 220 1.20 20 2 1 7 391 3 3

NS 10-30 34 231 7 34 981 NW 10-30 2 9 231 1.50 28 8 2 4 557 4 6

NS 10-36 41 242 899 1 200 NW 10-36 3 8 242 1.80 38 1 3 2 736 6 1

NS 10-42 49 253 1063 142 0 NW 10-42 4 8 253 2.10 473 3 9 91 6 7 6

NS 10-48 56 264 1227 163 9 NW 10-48 5 6 264 2.40 554 4 6 107 2 8 9

NS 10-54 64 275 1392 185 9 NW 10-54 6 4 275 2.70 633 5 3 122 4 102

NS 10-60 71 286 1556 2078 NW 10-60 71 286 310 3.00 708 59 1369 114

NS 10-66 79 297 1721 2298 NW 10-66 7 9 297 3.30 782 65 1513 126

NS 10-72 86 308 1885 2517 NW 10-72 8 6 308 3.60 857 71 1658 138

NS 10-84 101 330 2214 2956 NW 10-84 101 330 4.20 1007 84 1947 162

NS 10-96 116 35 2 2 543 3395 NW 10-96 116 352 4.80 1156 96 2 23 6 186

NS 10-108 13 1 374 28 71 38 34 NW 10-108 131 374 5.40 13 05 109 2526 210

NS 12-36 60 297 1315 1756 NW 12-36 5 6 297 1.80 554 46 1072 89

NS 12-42 71 321 1556 2078 NW 12-42 6 9 321 2.10 689 57 1332 111

NS 12-48 82 345 1797 240 0 NW 12-48 8 3 345 2.40 823 6 9 159 2 133

NS 12-54 93 369 2038 272 2 NW 12-54 9 3 369 2.70 927 7 7 179 3 149

NS 12-60 104 393 2280 3044 NW 12-60 104 393 310 3.00 1036 86 2005 167

NS 12-66 115 417 2521 3366 NW 12-66 115 417 3.30 1146 96 2217 185

NS 12-72 126 441 2762 3688 NW 12-72 126 441 3.60 1256 105 2429 202

NS 12-84 148 489 3244 4332 NW 12-84 148 489 4.20 1475 123 2853 238

NS 12-96 170 537 3726 4976 NW 12-96 170 537 4.80 1694 141 3277 273

NS 12-108 19 2 585 42 08 56 20 NW 12-108 192 585 5.40 19 13 159 3702 308

NS 12-120 21 4 633 46 91 62 64 NW 12-120 214 633 6.00 21 33 178 4126 344

All recovery capacities (GPH) figures include a .001 fouling factor for average water conditions.

Hard water areas should consider an increase to this factor.

*Effective heating surface for water to water calculation (Actual NW heating surface is equal to

NS heating surface).

+Minimum boiler water (b.w.) required.

40° TO 140°F ALL RECOVERIES SHOWN ARE FOR 3/4" TUBES

NS COIL -- STEAM TO WATER

Sq. Approx. Mode l Sq. * Approx.

TABLE A

WATER HEATED -- GALLONS PER HOUR --

NW COIL -- WATER TO WATER

Using Steam As

Heating Medium

Maximum

Using Forced Circulation of Boiler

Water As Heating Medium

+

Min. GPH @+Min.

AOSTT35600

A 412.1

Page 1 of 2

Page 2

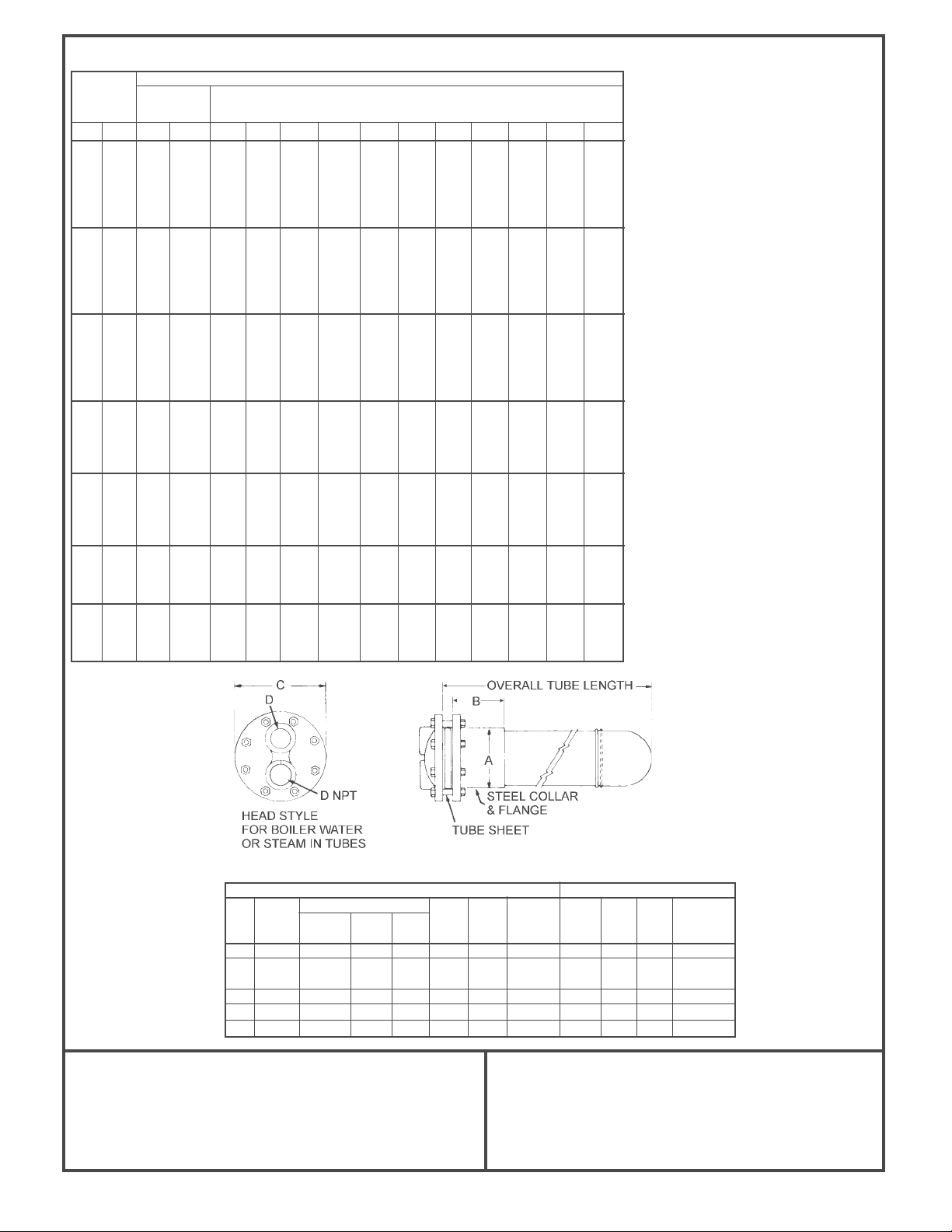

TABLE B TANK COIL RECOVERY DATA (Various Temperature Rises)

TEMP.

RISE

Inlet Outlet 180°F 210°F 0 lbs 2 lbs 5 lbs 10 lbs 15 lbs 20 lbs 30 lbs 40 lbs 50 lbs 75 lbs 100 lbs

40140101922242629 32 343943 465358

50140112024262832 35 374246 505764

60140112226283135 38 414651 556370

70140122428313438 42455257617179

80140132731343843 48515965708190

90 160 8 19 22 25 28 32 36 39 45 51 55 64 72

1001608 2025283136 41445157627382

* Based on 20° F drop.

FORCED

BOILER

WATER*

80 38 63 72 77 83 91 98 104 116 126 133 151 166

100233944485257 626673808597106

120152631333640 43465257606977

160 6 14 16 17 19 22 25 26 30 33 36 42 46

180-- 1011131417 19212427293438

80 48 81 93 99 107 118 128 136 151 164 174 198 217

100264552556066 72778694100114125

120162934364044 48525863687886

160 7 14 17 18 21 23 26 28 32 36 38 45 50

180-- 1012131518 20222528303540

80 65 112 135 145 156 172 187 198 221 241 256 291 320

100315463677381 8894105115122139154

12018333841 4550 55 596672 778998

160 7 15 18 20 22 25 28 30 35 38 71 48 54

180-- 1012141618 21232630323842

100 39 69 80 86 94 104 114 122 137 149 159 182 201

120203844475258 6468778591104116

160 7 16 19 21 23 27 30 32 37 41 45 52 58

180-- 1113141719 22242831344045

100 52 95 116 125 136 152 166 177 200 219 233 268 296

120244553576371 778394103111128142

160 7 17 20 23 25 29 33 35 41 45 49 57 64

180-- 1113151721 23263034374349

120 30 57 68 73 81 91 100 108 122 134 144 167 185

140153036404450 556069768295106

180-- 1214161922 25283236404753

120 39 78 97 105 116 132 145 156 178 196 211 244 272

140173643475360 6772839299116130

180-- 1215172024 27303540435258

GALLONS PER HOURS/SQ.FT. OF HEATING SURFACE

STEAM PRESSURE - POUNDS PER SQUARE INCH

HOW TO SIZE TABLE B

1. Locate temperature rise desired in

left-hand column.

2. Move to the right, until you reach

the column labeled with the appro

priate heating medium. This figure

represents the recovery capacity of

one square foot of heating surface.

3. Divide the total GPH requirement of

the installation by the recovery

of 1 sq. ft. to determine the number

of sq. ft. required.

4. Select the coil with adequate sq. ft.

of heating surface from table A.

In most cases, more than one

coil will meet the system requirements. Maximum efficiency for hot

water coils will normally be

obtained when the coil extends into

the tank as far as a possible

(minimum of halfway required).

Consideration should be given to insure adequate condensate drainage

for steam coils.

Vertical tank: Maximum coil length determined by tank diameter.

Horizontal tank: Maximum coil length

determined by tank length.

NOTE: The heat transfer rate can be

drastically reduced with age

and build-up of scale. Thus,

consideration should be given

to fouling factors and the

square footage increased accordingly, in hard water areas.

The recovery capacity (GPH/

sq. ft.) already includes a .001

fouling factor for average water conditions.

TABLE C DIMENSIONS

Material Test Work Max.

Unit Tube Tube Press. Press. Oper.

Dia. Tubing Supports Heads Sheet PSI PSI Temp. °F. A B C D

6 3/4" Cast 225 150 375 6 5/ 8 6 1 /8 11 2

O.D. Steel Iron Steel

A.O. Smith Water Products Co., Inc. On Line

AOSTT35600

A 412.2 © A.O. Smith Corp., 1999 PRINTED IN THE U.S.A.

Page 2 of 2

www.hotwater.com

For Technical Information and

Automated Fax Service,

Phone: 800-527-1953

A. O. Smith Corporation reserves the right to make product changes

or improvements at any time without notice.

Water Products Company

Ashland City, TN

A Division of A. O. Smith Corporation

sehcnI ni snoisnemiDataD lacinhceT

4/1 198/1 62/1 45730515224

32/1 3188/5 8573051522reppoC8

4614/1 84/3 0157305152201

egnalF "4914/1 014/3 2157305152221

A. O. Smith

Loading...

Loading...