Page 1

Commercial Gas Boilers

®

®

90% EFFICIENT, LOW-NOx HOT WATER SUPPLY BOILER

The Legend 2000® series delivers an exceptional 90% thermal efficiency by combining

advanced pre-mix burner design and an extruded, self-baffling copper heat exchanger for

outstanding efficiency and unsurpassed performance. The heat-exchanger design exposes

more surface area to the combustion system to maximize heat transfer. Each model features

a small footprint with zero side clearance for outstanding adaptability that is perfect for

retrofits. The exclusive Dia-Scan® solid-state self-diagnostic system helps make operation

and troubleshooting quick and easy.

ADVANCED COMBUSTION TECHNOLOGY

• Advanced burner design precisely pre-mixes gas and air increasing

combustion efficiency and reducing emissions

• Delivers optimum burner performance for 90% thermal efficiency

LOW-NOx OPERATION

• Meets or exceeds Texas and California SCAQMD Rule 1146.2 air

quality standards

LW-500

through

LW-1000

NEW STAINLESS STEEL BURNER

• Features metal fiber alloy sheath for consistent heat distribution and reliable

performance under all conditions

ALL-BRONZE FACTORY MOUNTED PUMP

• Integrally mounted and wired

• Factory sized for proper flow between boiler and storage tank

• Allows 50 equivalent feet of piping between boiler and tank

EXCLUSIVE NO-BAFFLE HEAT EXCHANGER DESIGN

• Extruded copper manufacturing process exposes more surface area to the

combustion system for increased heat-transfer efficiency

• Unique self-baffling design (patent pending) is a significant improvement over

traditional heat-transfer systems

100% ALL NON-FERROUS WATERWAYS

• All waterways 100% copper, brass or bronze for years of reliable performance

• Impervious to thermal shock

STANDARD-VENT OR DIRECT-VENT FLEXIBILITY

• Standard-vent configuration, vertical or horizontal sidewall

• Two-pipe direct-venting vertical and/or horizontal sidewall, with all combustion

makeup air drawn from outside the building

COMPACT, LOW-PROFILE DESIGN

• Zero clearance on sides, ideal for multiple boiler installations

• Fits through 30" doors and into elevators for hard-to-get retrofit applications

ASME

January 2006

Page 1 of 4

ACMSS00705

Page 2

®

®

90% EFFICIENT, LOW-NOx HOT WATER SUPPLY BOILER

CATEGORY IV LISTED

• A condensing gas appliance that

operates with a positive vent pressure

PROFESSIONAL START-UP SERVICE

FURNISHED

• Assures optimum performance for each

installation

MEETS ASHRAE/IESNA 90.1-1999

• Five-year heat exchange warranty

®

OTHER LEGEND 2000

FEATURES:

• ASME 160# W.P.

• ASME PRESSURE RELIEF VALVE 125#

• FACTORY MOUNT FLOW SWITCH

• BRASS DRAIN VALVE

• LOW GAS PRESSURE SWITCH

• INLET/OUTLET

DIGITAL THERMOMETERS

• MANUAL RESET HI-LIMIT

®

LEGEND 2000

FM APPROVED OPTIONS:

❑ CSD-1 CODE

❑ I.R.I. CODE

❑ SEQUENCING PANEL

❑ ALARM BELL

❑ SIDEWALL VENT KITS

❑ VERTICAL AND HORIZONTAL

DIRECT VENT KITS

❑ SKID-MOUNTED SYSTEMS

❑ DRY CONTACTS FOR ANY

BOILER FAILURE

❑ LOW WATER CUTOFF

❑ LP GAS

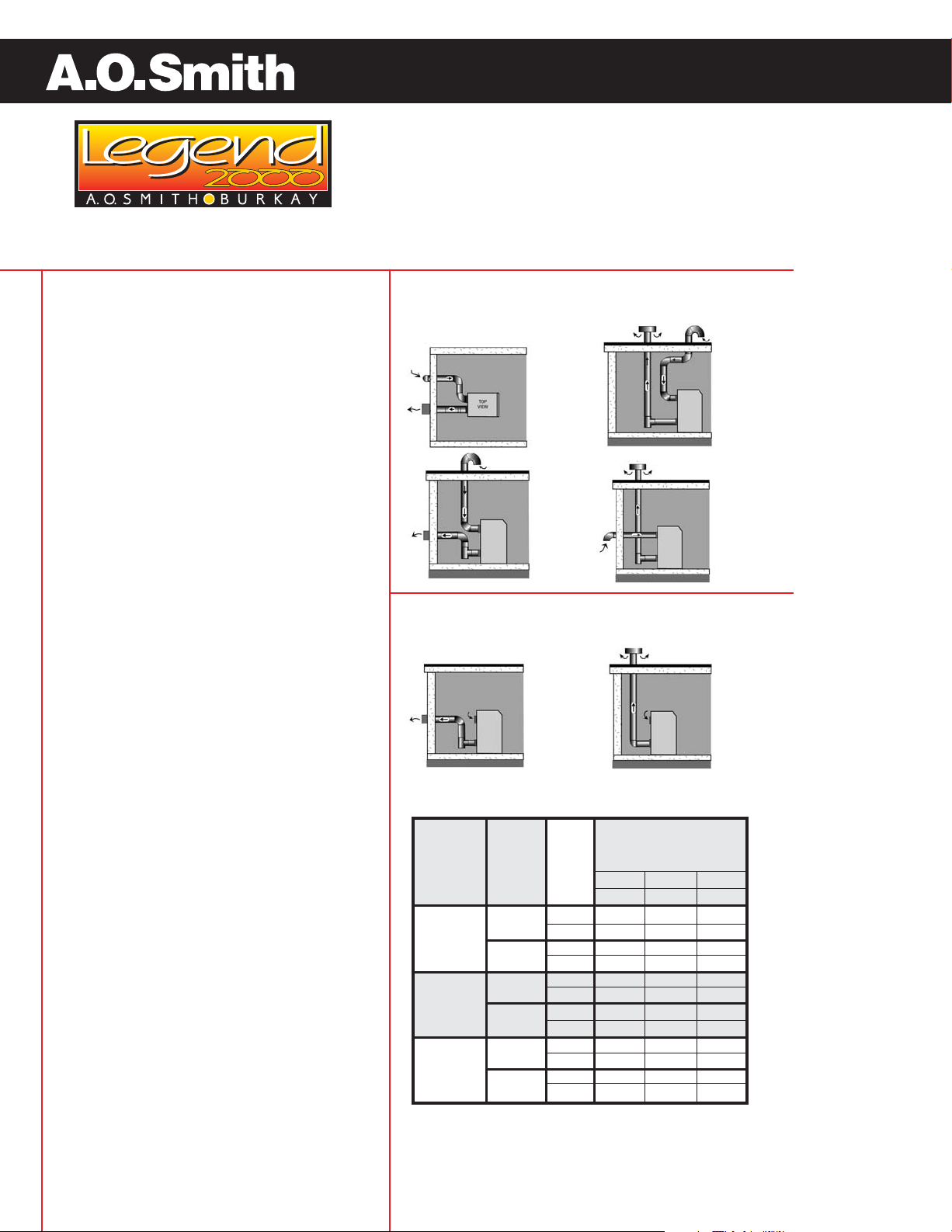

VERSATILE MULTI-VENTING CONFIGURATIONS

DIRECT-VENTING

90 Equivalent Feet Exhaust

90 Equivalent Feet Intake

90 Degree Elbows = 10 Feet

45 Degree Elbows = 5 Feet

Boot Tee = 5 Feet

SIDEWALL VENTING CONVENTIONAL

SIDEWALL VENTING CONVENTIONAL

VENTING

VENTING

180 Equivalent Feet Max

90 Degree Elbows = 10 Feet

45 Degree Elbows = 5 Feet

Boot Tee = 5 Feet

INPUT AND RECOVERY

BTU

MODEL INPUT

NUMBER PER

40°F 100°F 140°F

HOUR

22°C 56°C 78°C

Natural LPH 5162 2065 1475

450,000 GPH 1227 491 351

Propane LPH 4646 1858 1327

Natural LPH 7743 3097 2212

LW-750

675,000 GPH 1841 736 526

Propane LPH 6968 2787 1991

Natural LPH 10,324 4129 2950

LW-1000

860,000 GPH 2345 938 670

Propane LPH 8878 3551 2537

Maximum gas supply pressure (natural and propane gas): 13.8" w.c.

Minimum gas supply pressure, natural gas: 7" w.c.

Minimum gas supply pressure, propane gas: 11" w.c.

The LEGEND 2000

independent line source that is: 120 Volts, 60 Hertz, 30 Amps.

NOTE: For proper boiler performance, it is important that the

LEGEND 2000

Do not put other applications on the same breaker as the boiler.

500,000 GPH 1364 545 390

LW-500

750,000 GPH 2045 818 584

1,000,000 GPH 2727 1091 779

®

must be connected to a single-phase

®

is on its own separate breaker.

RECOVERY – GALLONS OR

GPH

OR

LPH

LITRES PER HOUR AT

DEGREE RISE

Page 2 of 4

ACMSS00705

Page 3

DIMENSIONS AND SHIPPING WEIGHTS

MODEL

NUMBER

INCHES

OR

CM

A B C D E F G H J K L M N P Q R

Commercial Gas Boilers

DIMENSIONS

SHIPPING

WEIGHT

LW-500

CM 134.6 58.4 81.3 34.3 11.1 8.3 16.2 19 8.9 48.3 36.8 12.7 13.3 29.2 5.1 2.5 193.2 Kg

LW-750

CM 134.6 58.4 81.3 34.3 11.1 8.3 16.2 19 8.9 48.3 28.6 12.7 13.3 29.2 5.1 2.5 240 Kg

CM 153.7 68.9 97 34.9 39.4 8.3 20.6 21 8.9 91.4 30.5 17.1 10.5 34 5.7 3.2 424.5 Kg

Inches 53 23 32 13-1/2 4-3/8 3-1/4 6-3/8 7-1/2 3-1/2 19 11-1/4 5 5-1/4 11-1/2 2 1 528 Lbs.

LW-1000

Inches 60-1/2 27-1/8 38-3/16 13-3/4 15-1/2 3-1/4 8-1/8 8-1/4 3-1/2 36 12 6-3/4 4-1/8 13-3/8 2-1/4 1-1/4 934 Lbs.

Vent Size on LW-500 and LW-750: 6"/15.2 CM

Vent Size on LW-1000: 7"/17.8 CM

BOILER INPUT, OUTPUT AND PRESSURE DROP

FLOW RATE @ 20°F/

Inches 53 23 32 13-1/2 4-3/8 3-1/4 6-3/8 7-1/2 3-1/2 19 14-1/2 5 5-1/4 11-1/2 2 1 425 Lbs.

LW-1000

LP 860,000 774,000

TYPE

MODEL

NUMBER

OF

GAS

Natural 500,000 450,000

LW-500

LW-750

LP 450,000 405,000

Natural 750,000 675,000

LP 675,000 607,500

BTUH BTUH

INPUT OUTPUT

Natural 1,000,000 900,000

11°C TEMPERATURE RISE

GPM

PD-FT/

HD

LPM

PD-M/

45 10 170.3 3.0

68 10.1 257.4 3.1

91 8.9 344.4 2.7

HD

R

B

A

C

E

D

K

(NPT GAS INLET)

F

4"

(10.16 CM)

BLOWER

INLET

4" x 4"

(10.16 x 10.16 CM)

JUNCTION BOX

CONNECTION

2" (5.08 CM)

WATER

INLET

Q

P

CONDENSATE

DRAIN TUBE

(3/8" I.D., 5/8" O.D.)

(.9525 CM I.D., 1.5875 CM O.D.)

F

N

2" (5.08 CM)

WATER

OUTLET

G

6" (15.24 CM)

VENT

EXHAUST

LK

M

D

E

H

6" BLOWER

INLET

4" x 4"

(10.16 x 10.16 CM)

JUNCTION BOX

CONNECTION

J

F

2" (5.08 CM)

R (NPT

GAS INLET)

WATER

INLET

Q

P

CONDENSATE

DRAIN TUBE

(3/8" I.D., 5/8" O.D.)

(.9525 CM I.D., 1.5875 CM O.D.)

N

G

N

2" (5.08 CM)

WATER

OUTLET

7" (17.78 CM)

VENT

EXHAUST

L

M

Models LW-500, 750 Model LW-1000

Page 3 of 4

ACMSS00705

Page 4

COMMERCIAL

®

®

90% EFFICIENT, LOW-NOx HOT WATER SUPPLY BOILER

SUGGESTED SPECIFICATION

The gas-fired hot water supply boiler(s) shall be A. O. Smith Legend 2000® model LW ______ having an input

rating of _______ BTU/hr and capable of supplying no less than ______ GPH at a 100°F temperature rise when

fired with Natural/Propane gas. The boiler shall: 1) Bear the ASME "H" stamp and shall be National Board

registered for 160 PSI working pressure. 2) Be test certified at 90% thermal efficiency by CSA International.

3) Meet SCAQMD Rule 1146.2 for low-NOx emissions and air quality standards.

The heat exchanger shall: 1) Incorporate 5/8" I.D. finned copper tubing with 9 fins per inch and an integrated

self-baffling tube design. No “V” baffles are acceptable. 2) Be circular, encompassing the entire burner and

forming the combustion chamber. No gaskets are acceptable in the combustion chamber, burner assembly,

or the ASME wet section. Combustion chamber tube shall be glass-coated steel to prevent damage by

condensation.

The hot water supply boiler(s) shall be supplied with a factory supplied, sized and wired boiler-circulating pump.

™

The gas burner shall be constructed of Inconel

360-degree flame pattern. Fuel and gas mixture shall take place in the stainless steel pre-mix tube for safety.

Pressurized cabinets are unacceptable. Gas orifices shall be replaceable without removal of the burner.

Boiler shall have an inner steel frame, and jacket panels shall have a baked-on enamel finish. The unit must

be capable of operating with jacket panels removed for inspection and maintenance. Control panel shall permit

easy access and have a protective cover, removable with no tools. All units shall utilize an approved AL29-4C

stainless steel vent system to handle condensation. The Dia-Scan

control 15 operating and safety functions. Indicating lights will monitor and include air, transformer, ignition, gas

pressure, water flow, gas valves, pre-purge, post-purge and safety lockouts.

CSA International certified for installation on combustible floor. Standard operating controls and equipment

shall include: hot surface electronic ignition, operating aquastat, manual reset hi-limit, automatic main and

redundant gas valve, master switch with pilot light, digital inlet/outlet temperature gauges, ASME safety

relief valve, flow switch, heat-resistant glass viewing port, and Dia-Scan

The boiler shall be equipped for 120V, single-phase, 60 Hz current. Complete operating and start-up

instructions are to be furnished with unit. Units shall meet or exceed ASHRAE/IESNA 90.1-1999.

Controls shall be 24 VAC, including slow-opening main gas valve for soft ignition, redundant safety shutoff

gas valve, main and pilot pressure regulators, recycling intermittent pilot system with one-second shutdown

in the event of pilot flame failure, automatic recycling high limit, manual reset ECO limit, main and pilot manual

cocks and manual firing valve, and an ASME-rated pressure relief valve. The boiler shall be approved by

Factory Mutual (FM).

The boiler shall comply with ASHRAE/IESNA 90.1-1999 standards. The boiler manufacturer must supply

complete factory start-up by a factory approved start-up agent.

625 stainless steel, warranted for 5 years, and fire in a radial

®

solid-state control system shall monitor and

®

control system.

w w w. hotwater. c o m

For Technical Information and Automated Fax Service, call 800-527-1953.

A. O. Smith reserves the right to make product changes or improvements without prior notice.

500 Tennessee Waltz Parkway, Ashland City, TN 37015

©2006 A. O. Smith Corporation Printed in U.S.A AOSC-108133-10M

Page 4 of 4

ACMSS00705

Loading...

Loading...