Page 1

Innovation has a name.

LILY

Reverse Osmosis User Manual

Ters Osmoz Kullanma Kılavuzu

Page 2

Page 3

ENG 1

Dear customer,

Thank you for purchasing a "A.O. Smith" branded water purier!

You are now the owner of water treatment equipment produced by the world’s leading

manufacturer of water treatment systems. This equipment produces pure water that can

be consumed directly, providing you with a cleaner and healthier source of drinking water.

Please read this user manual carefully before you install and operate your

"A.O. Smith branded" water purier. To achieve maximum efciency this user manual

provides detailed instructions regarding the installation of your water purier as well as

information related to the proper operation and maintenance of your water purier.

The installation should only be handled by professionals authorized by A.O. Smith

Su Teknolojileri A.Ş.

Spare parts used for maintenance and replacement lter should be approved

by A.O. Smith Su Teknolojileri A.Ş. before they are installed.

Any degradation of performance caused by the use of spare parts or lters that have not

been approved by A.O. Smith Su Teknolojileri A.Ş. will not be covered by our warranty.

If you experience any difculties during installation or operation, please contact your local

distributor to have them carry out repairs or maintenance on your equipment.

Page 4

ENG 2

CONTENTS

İÇİNDEKİLER

Page 5

ENG

SAFETY CONSIDERATIONS 4

PRODUCT DESCRIPTION 7

Brief Introduction 7

Description of Components 7

Electrical Diagram 8

Water Route Map 8

Technical Specications 9

Functions of Main Components 9

Functions of Accessories 10

Water Puriter Features 10

TRANSPORTATION 10

INSTALLATION METHODS 11

Pre-Installation Preparations 11

Instructions for Proper Installation 11

ADJUSTMENT METHODS 14

LED DISPLAY FUNCTIONS 15

SIDE STREAM R.O. MEMBRANE 17

OPERATION WARNINGS 18

MAINTENANCE AND REPAIR 19

Flushing the RO Membrane 19

Filter Replacement Interals 19

PACKING LIST 21

AFTER-SALES SERVICE 21

TROUBLESHOOTING GUIDE 22

TR

GÜVENLİK UYARILARI 26

ÜRÜN TANITIMI 29

Kısa Tanıtım 29

Su Arıtma Cihazının Ayrıntılı Proli 29

Elektrik Şeması 30

Su Akış Şeması 30

Teknik Bilgiler 31

Ana Bileşenlerin İşlevleri 31

Aksesuarların İşlevleri 32

Su Arıtma Cihazının Özellikleri 32

NAKLİYE 32

KURULUM TALİMATLARI 33

Kurulum İçin Ön Hazırlık 33

Doğru Kurulum için Uyulması Gereken Talimatlar 33

AYARLAMA YÖNTEMLERİ 36

LED EKRANIN İŞLEVLERİ 37

SIDE STREAM R.O. MEMBRAN 39

KULLANIM UYARILARI 40

BAKIM VE ONARIM 41

RO Membranın Yıkanması 41

Filtre Değişim Aralıkları 41

Filtre Değişim Yöntemleri 42

Genel Bilgiler 42

ÜRÜN KONTROL LİSTESİ 43

SATIŞ SONRASI SERVİS 43

ARIZA GİDERME KILAVUZU 44

YETKİLİ SERVİSLER 46

MONTAJ KONTROL KARTI 48

BAKIM KARTI 49

GARANTİ BELGESİ 50

Page 6

ENG 4

Safety Considerations

(Be sure to read and remember these safety considerations)

Make note of the following safety precautions In order to avoid property damage and harm to you and others.

•Ignoring the following safety precautions could result in risky situations for you, your water purier and your environment.

Warnings

If you ignore contents in this section, it may cause permanent damage to the water purier or cause serious property damage.

Do not disassemble or modify this water

purier on your own!

Unauthorized disassembly or modication

of the machine could lead to machine

malfunctions or leakage accidents. Please

check with the store where you purchased

this product for product consultation in order

to arrange for repairs.

Do not put the water purier close

to a source of ames!

Do not put the water purier near a source

of ames or a place where the temperature

is too high as this may cause deformation or

melting of the machine, causing damage or

leakage, which could lead to serious bodily

and property damage.

Do not put heavy objects on the water

purier!

Placing heavy objects on the water purier

may cause damage to the water purier’s

external cover or internal components, which

in turn could lead to leakage, equipment

malfunctions or even serious property

damage.

Do not place any objects on top of your

water purier!

Obstructing the heat dissipation may lead to

machine damage or res.

This appliance can be used by 8 years and

older children and persons with reduced

physical and sensory capabilities only

when they have been given supervision or

instruction concerning use of the appliance by

a person responsible for their safety and they

have fully comprehend the possible risks of

the appliance.

As this appliance functions with electricty

and water, using the device by mentally

handicapped people is not advised.

Children should not be allowed to play with

the unit.

Cleaning and maintenance of the unit should

not be made by children without supervision.

Page 7

ENG 5

Do not use this water purier under high

water pressure conditions!

Operating under high pressure conditions

may cause the water purier pipes to rupture,

resulting in leakage, the machine working

improperly, or even serious property damage.

Recommended inlet pressure is

0.1-0.35 MPa (1 Bar to 3,5 Bars)

In places where inlet water pressure is

more than 0.35 MPa (3,5 Bars), it is

recommended to use a pressure reducer

before the unit.

Do not touch the power plug with wet hands!

It may lead to electric shock.

Do not damage the power cord

or the outlet!

Doing so may lead to electric shock, short

circuiting or re.

The equipment must be disconnected from

the power supply during installation

and repairs!

Otherwise it may lead to electric shock.

Do not use a power source exceeding

the equipment’s specied value. Use only

230V AC power!

The electrical current supplied to your

equipment by the outlet must not be greater

than the specied value; otherwise it may

lead to the overheating of your equipment

or re.

230 V

Unit should be installed and connected to

the water mains by new hose-set that was

included in the product package. Old

hose-sets should not be reused with the unit.

Otherwise water leakages may occur or

the unit’s performance may be affected

negatively.

Use only power supply unit (the supply cord

and the plug) that was provided with the unit!

Using the non-original power supply unit may

affect the performance of the unit negatively

and using unqualied parts may damage to

the unit.

If the supply cord is damaged, supply an

original cord from your A.O.Smith Sales Agent

or A.O.Smith Authorized Service!

Using the non-original supply cord unit may

affect the performance of the unit negatively

and using unqualied parts may damage to

the unit.

Do not use the water purier when the sewer

is blocked up!

If the purier is used while the sewer is

blocked, it may cause waste water to back

up into the purier and pollute the water

and parts inside.

Page 8

ENG 6

Do not place the water purier under direct

sunlight!

Placing the water purier under direct

sunlight for a certain period of time may

create a breeding ground for microorganisms;

decreasing the output water quality

and potentially causing the internal

components of the water purier

to become contaminated.

The waste water discharge pipe and

waste water rationing device cannot be

blocked!

When the waste water discharge pipes and

waste water rationing devices are obstructed

or clogged, it may lead to high levels of TDS

efuent, the RO membrane may get blocked

or the water purier may not work.

Do not use in conditions under 5°C!

If the ambient temperature falls below 5°C,

please be sure to take measures to prevent

freezing, such as turning on a heater or air

conditioner to prevent leakage or cracked

pipes caused by water freezing inside

the equipment.

Water purier inlet water temperature

should not exceed 38°C!

If the inlet water temperature is over 38°C,

it will damage the reverse osmosis membrane

leading to membrane failure.

Do not use this water purier outdoors!

If this water purier is used outdoors, it can

lead to accelerated aging of the

water purier pipes and parts, which can

cause leaking or machine failure.

Do not let the machine come in contact with

corrosive materials!

These materials could corrode the outer cover

and adversely affect various parts of the

equipment. Toxic and hazardous compounds

could penetrate the water purier pipes,

causing contamination of the water or

leakage, which in turn may cause personal

damage or property damage.

Do not use force on the glass panel and place

the water purier atly!

The reinforced glass panel needs to be put

lightly and atly. Otherwise it may lead to the

glass panel damage.

Do not remove the UV Protector

unauthorized!

• Wear protective goggles and gloves

while maintaining UV disinfection unit.

• Do not look directly to UV lamps while

they are on.

• During maintenance and repair, be sure

that UV unit is not active.

Otherwise UV light might lead damage to

the eyes and skin.

Page 9

ENG 7

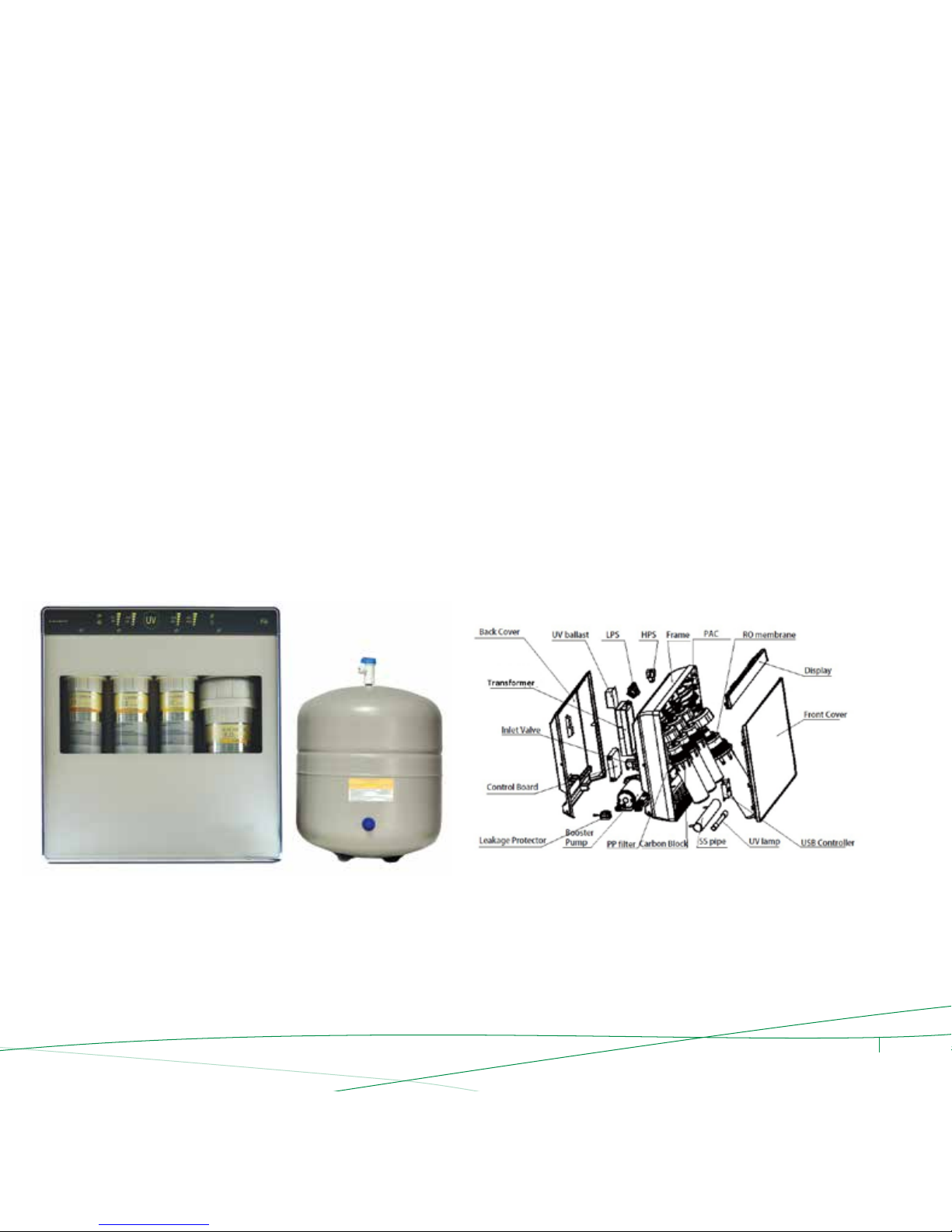

Brief Introduction

This equipment utilizes the current, most advanced international

RO technology. RO technology relies on the articial reversing

of the naturally occurring osmosis phenomena. The RO membranes have

pores with a diameter of 0.0001 micron (0.1 nm), so they can effectively

remove bacteria, viruses, heavy metals, pesticide residue, and other harmful

substances from the water. Produced water is fresh, pure and suitable for

direct use.

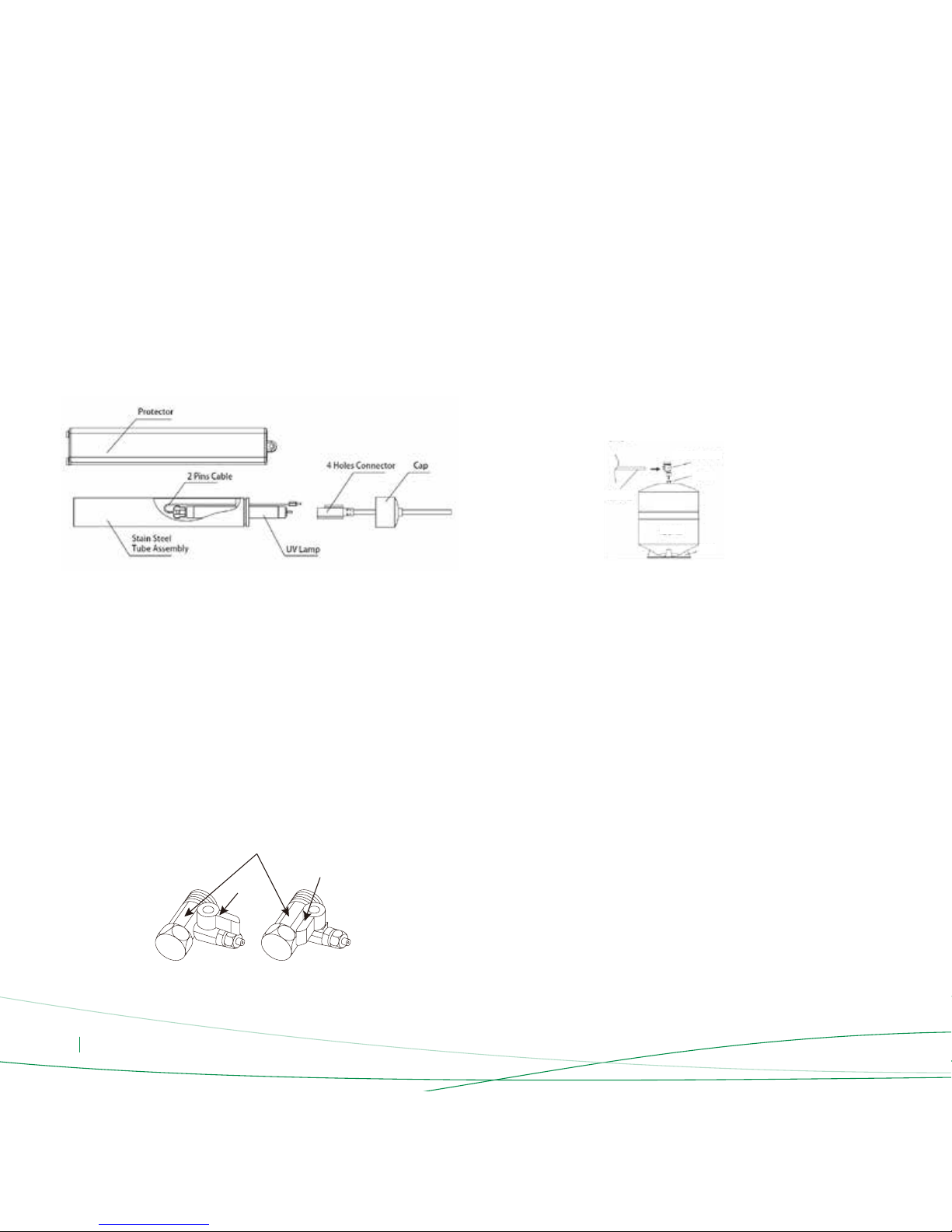

Description of Components

Product Description

Diagram 1

Lily

Page 10

ENG 8

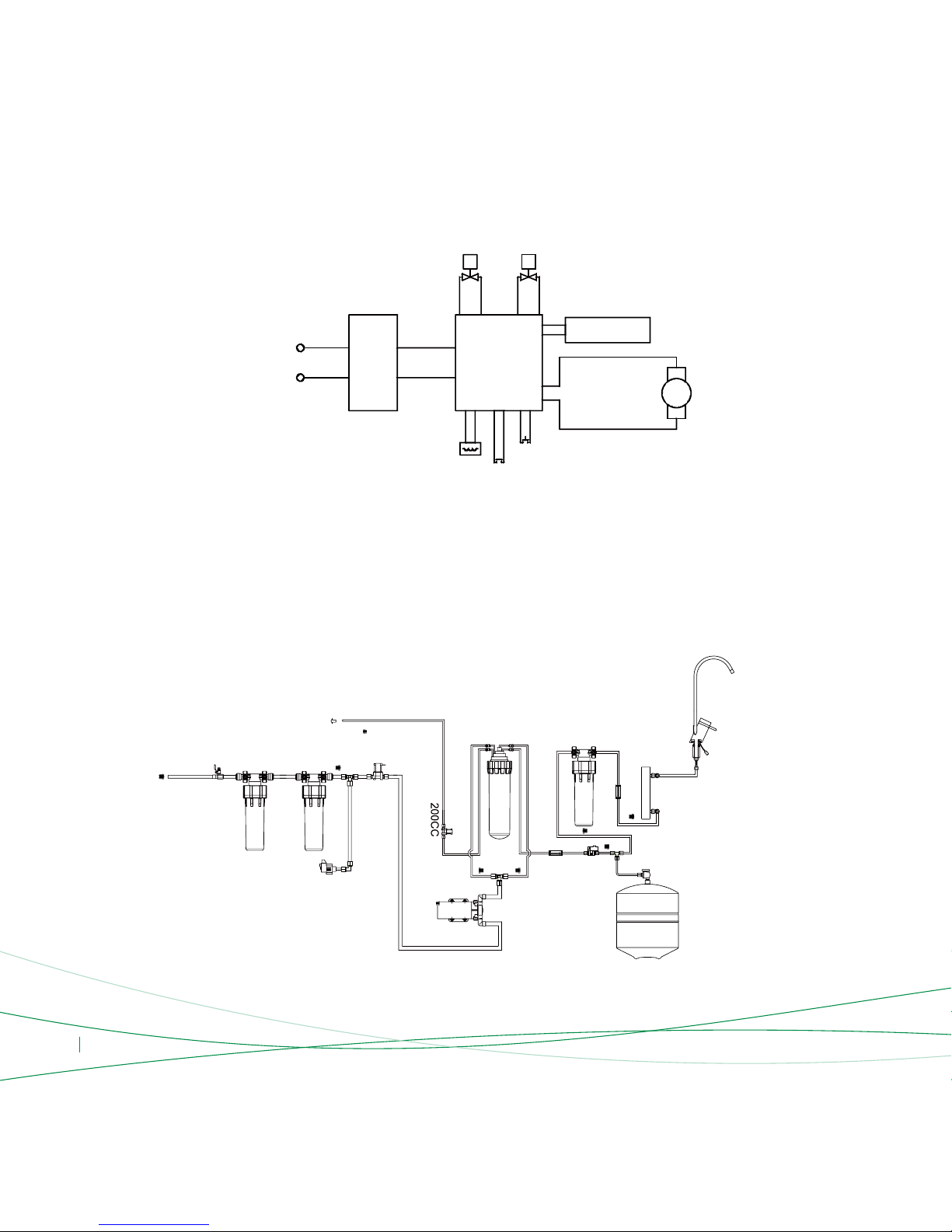

Electrical Diagram

Diagram 2

Diagram 3

Water Route Map

UV ballast LPS HPS Frame

PAC

RO membrane

Display

Front Cover

Switch Mode

Power Supply

Inlet Valve

Booster

Pump

PP filter

SS pipe

UV lamp

USB Controller

Reed Switch

Low Pressure Switch

High Pressure Switch

230V AC

24V DC

Inlet Water Valve

Flushing Valve

UV Lamp

Booster Pump

Power

Control Board

Carbon Block

3 way joint

Municipal

Water

Low Pressure Switch

Inlet Water Valve

Booster

Pump

High

Pressure

Switch

Tank

UV Lamp

Electronic

Faucet

Waste Water

Flushing Vavle

PP

RO

PAC

Check Valve

Tank Valve

Carbon Block

Check

Valve

Page 11

ENG 9

Functions of the Main Components

The standard conguration of the water purier that utilizes the current,

most advanced international RO technology is as follows:

• The rst stage is a 5-micron PP (Sediment) Filter:

The pores on the aperture within the PP lter is 5 microns wide so it

can effectively lter rust, sand, other larger particles and solid impurities

suspended in the water.

• The second stage is a Carbon Block Filter:

The lter effectively absorbs chlorine, mould, disinfection by-products,

odors, discolorations and other materials suspended in the water.

• The third stage is the RO membrane:

The RO membrane with a pore size of 0.0001 micron (0.1 nm), it can

effectively remove bacteria, viruses, heavy metals, pesticide residue, and

other harmful substances. Produced water is fresh, pure and suitable

for direct use.

• The fourth-stage is a Post Active Carbon (PAC) Filter:

This lter regulates the taste of water, keeps the water fresh.

• The fth-stage is a UV Disinfection:

This unit effectively restrains the water pipe and tank etc to breed the

bacteria after long time without use.

Note: the parameters above may change due to product improvements, but the product name plate shall remain the same. TDS refers to inuent total dissolved solids.

Note:

0.1 MPa = 1.02 Kg/cm

2

= 14.5Psi

1 Psi = 0.07 Kg/cm

2

1 Gallon = 3.785 Liters

75 GPD = 75 Gallons/Day = 284 Liters/Day = 197 Milliliters/Minute

Technical Specications

Model No.

Frequency

Voltage

Suitable Water Pressure

Inlet Temperature

Maximum Daily Water TDS Value

Flushing Method

Electric Shock Protection Type

Product Dimensions

Tank Dimensions

Weight

Suitable Water Quality

Power Rating

Daily Water Production Volume

Tank Volume

230V AC

50 Hz

38 W

0.1-0.35 MPa (1 Bar to 3,5 Bars)

5 ~38˚C

≤1000 PPM

Auto Flushing

75 Gallons, approximately 284 Liters

3.2 Gallons, approximately 12.1 Liters

Class II

Municipal tap water meeting the TS-266 standarts

LILY

460x488x161 mm

335x280 mm

14 kg

Page 12

ENG 10

Functions of Accessories

• Storage Tank: Used to store water ltered by the water purier.

• High Pressure Pump: Boosts pressure to create a stable environment

for the RO membrane.

• Flushing (Solenoid) Valve: Control the waste water ow and

automatically ush the RO membrane.

• Low Pressure Switch: Prevents pump idling. When the inlet water

pressure is less than 1 Bars or when the inlet water stops,

the low-voltage switch automatically shuts off the power source

so the machine comes to a halt.

• High Pressure Switch: Prevents pump from overdrive. When the pressure

tank is full or has reached the set pressure level, power supply is

automatically cut off to stop the operation of the machine.

• Inlet Water (Solenoid) Valve: Connects or cuts off incoming water.

• Check Valve: Also known as a one-way valve, controls the direction

of water ow.

• Transformer: Converts 230V AC to 24V DC (the machine's safe

operating voltage).

• Power Control Board: Control the whole process of water production.

• Leakage Alarm: Detect malfunction of water leakage timely to protect

user's safety and avoid the loss of user's property.

• E-Faucet: Controls the water output status of drinking water. Electronic

faucet indicates the lter life while it is on by changing the logo color.

• UV Disinfection Unit: Sterilizes the outlet of pure water.

Water Purier Features

• Side Stream Membrane: The Side Stream R.O. membrane increases

the recovery rate to around 50%, compared to 25% for the regular

residential R.O. membrane, and waste water volume is reduced by 56%.

• Automatic Control System: The system controls the whole water

production process, such as stopping automatically when there is no

inlet water or when the tank is full;

• Auto Flush Function: The system can automatically control the water

auto ush process for the RO membrane to ensure more reliable

and safe operation.

• Remind on Filter Replacement: While the lters are close to the service

life, system can remind the customers with sound and red colors to

replace the lters.

• Leakage Protection: While inspect there has water leakage, it will

automatically stop working, and power off the booster pump, inlet

valve to avoid risk on water leakage. And “Leakage” light ashing on

the display with buzzer warning. Only can be recovered after defect

solved and re-power on.

• UV Lamp Protection: Use the powerful radiation of short-wave

ultraviolet ray to effect on microorganism in water, so as to achieve the

bacteriostatic action of water

• Stock up on top of each other more than 6 pieces.

• Before lifting the packages be sure that xing tapes below the package

are intact.

• Lift the packages holding from bottom.

• Persons, who are vulnarable to heavy lifting shoud not carry the packages

to prevent any health issues.

Transportation

Please take into consideration the following points while transporting the device.

Page 13

ENG 11

Pre-Installation Preparations

• Choose the location where the water purier will be installed

• Conrm the availability of the various tools required

for installation

• Conrm that you have all the connectors required for installation

• Make sure to turn off the water supply and electricity before

commencing installation

Warning: In places where inlet water pressure is more than 0.35 MPa(3,5

Bars), it is recommended to use a pressure reducer before the unit.

Installation Methods

Our company recommends that your water purier is installed by trained professionals as the installation process is somewhat complex and requires the

use of various tools. However, if you decide to install the purier yourself, please refer to the following steps and diagrams:

Adjustable Spanner

Drill

6.2 mm Drilling Bit

Hole Saw φ16-35 mm

T10 Cross and Flathead Screwdrivers

Scissors

14 - 16 mm Wrench

19 - 21 mm Wrench

Needle Nose Pliers

1

1

1 (Waste water hole)

1

1 of each

1 pair

1

1

1

Instructions for Proper Installation

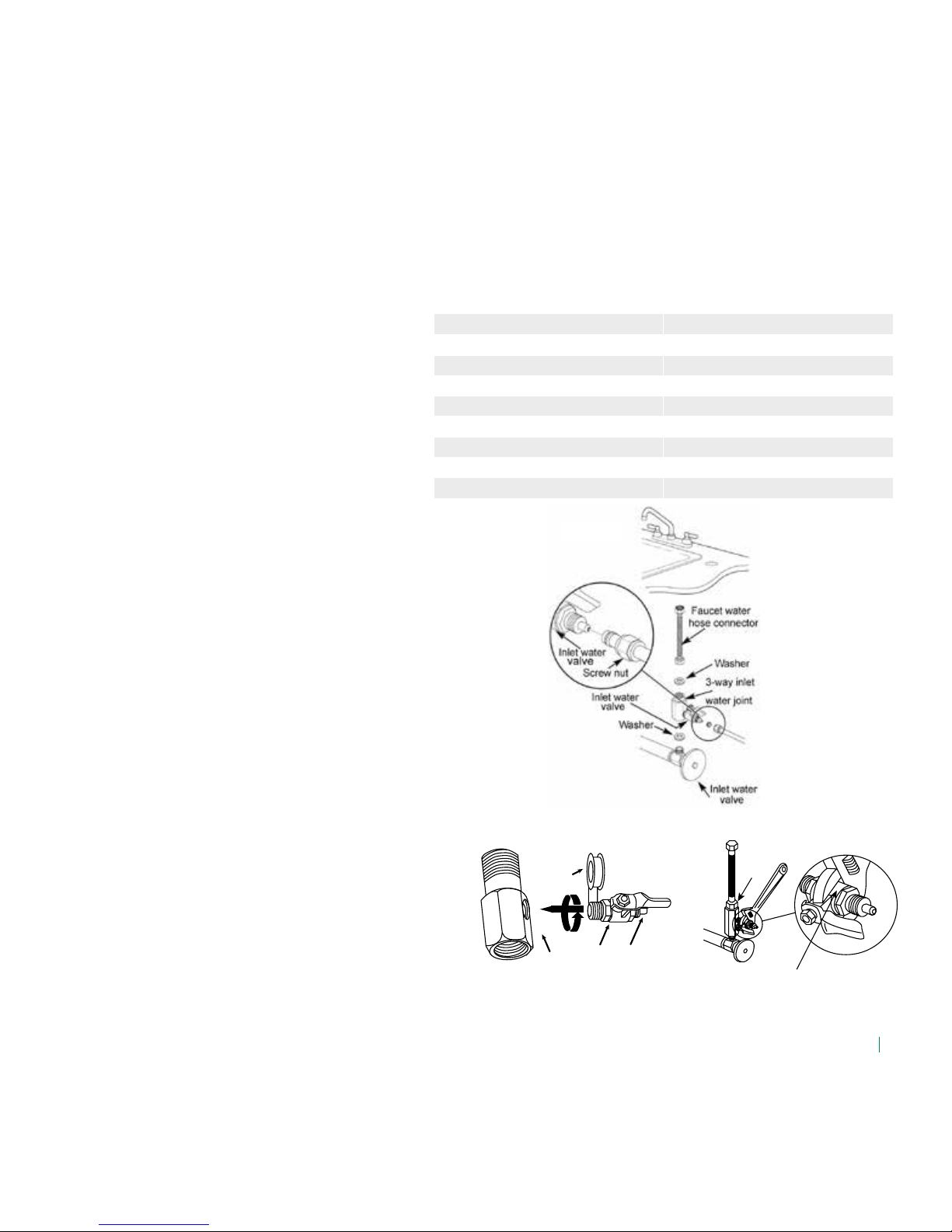

• Installation of the inlet water metal hose and 3-way inlet water joint:

(If the metal hose diameter is equal or less than 9 mm, the 3 - way inlet

water joint should be connected to the unit) First, close the inlet water

valve. Screw off the metal hose. Remove the 3-way inlet water joint

from the water purier accessories box, screw one end of the inlet water

3-way joint onto the inlet water valve outlet. One end of the unscrewed

metal hose should be screwed into the 3-way inlet water joint using the

screw nut (See Diagram 4)

• Installation of the 3-way inlet water joint and inlet water ball valve:

Take out the inlet water ball valve from the water purier accessories

box, wrap one end of the external threads on the ball valve with appro

priate teon tape (See Diagram 5). If you have silica gel, spread a little

over the thread and then screw the ball valve into the corresponding hole

of the 3-way inlet water joint (See Diagram 5). Take out the Ø 9mm

water pipe from the accessories box. Using a pair of scissors, cut

a suitable length of pipe and connect one end of the pipe to

the inlet water ball valve (See Diagram 6). Finally screw the nut in place.

Diagram 4

Diagram 5

3-Way inlet

water joint

Inlet water

ball valve

Teon tape

Water pipe

connection

Diagram 6

9mm Ball valve

Inlet water

3-way

joint

Diagram 6

Page 14

ENG 12

• Installation of inlet tube:

Take out the 1/4” tube from the accessory box, and cut to suitable

length with scissors, connect one end of the inlet tube to the inlet end of

the 3-way joint (See Diagram 4), then screw the nut tightly. The other

end of inlet tube connect to the “Source” of the unit connector.

Note to x the tube and quick connector to avoid water leakage issues.

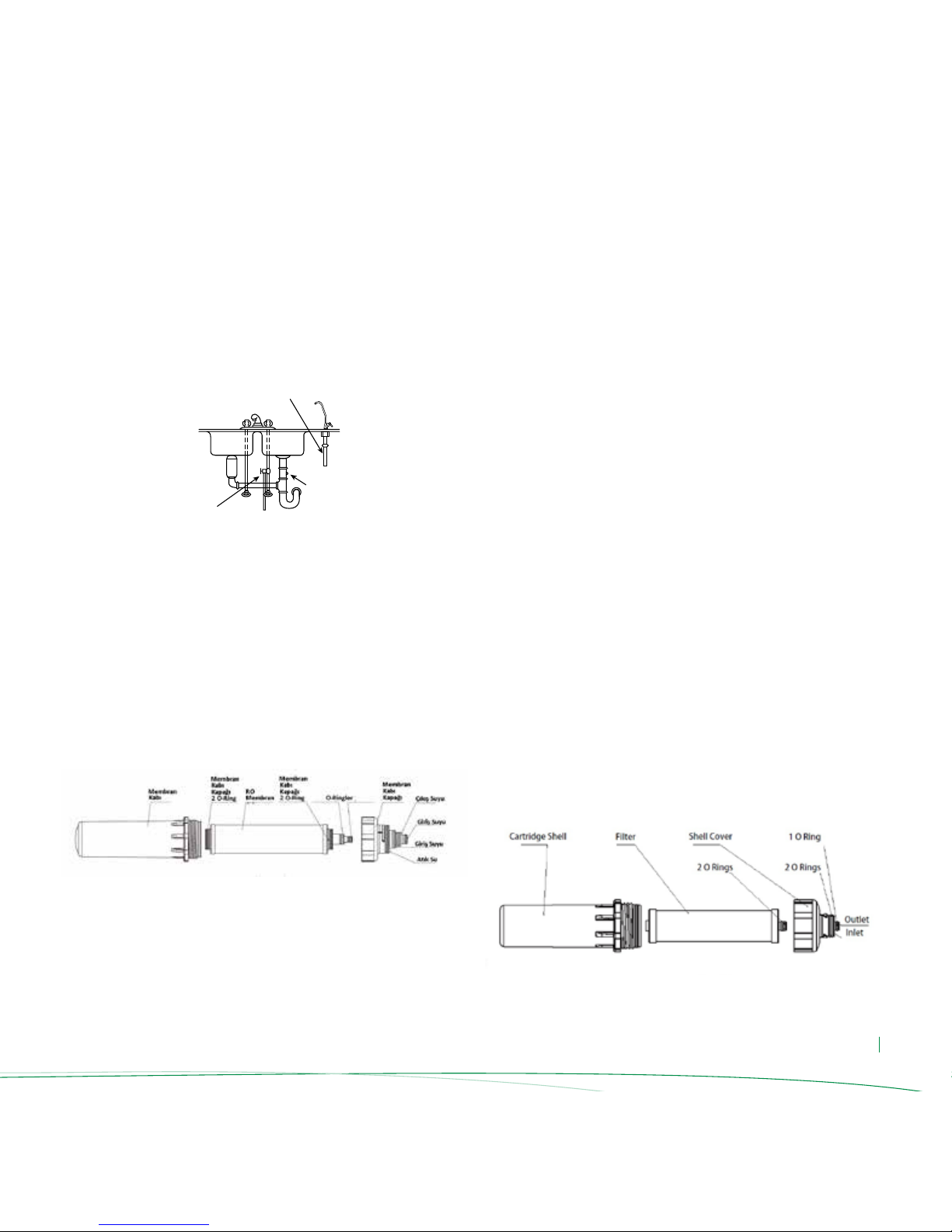

• Installation of the electronic faucet:

Drill a φ20-35 mm hole in an appropriate position on the counter where

the faucet is to be installed. Then take out the faucet from the water

purier accessory bag. Begin the installation of the faucet. In the

counter where the faucet is to be installed, drill a 20-35mm hole in an

appropriate position, then take out the faucet from the water purier

accessory bag, start the faucet installation (See Diagram 7):

A) Basement Installation: install the rubber cushion into the metal cushion,

take out 2 pieces M4mm screw, and x the screw on the metal cushion

through the basement hole, then pull the connectors of faucet through

the basement Pull the faucet cable through the plastic basement, rubber

cushion and the metal cushion in series, and combine the rubber cushion

and metal cushion together, then take out the M4mm screws and x one

screw to metal cushion started from plastic basement. Then put the plastic

basement through the sink hole and insert the cushions, then install

another screw and x tight 2 screws.

NOTE: don’t x the screw to tight once, it should be xed in steps, and

don’t use strong force.

B) Main Part Installation:

Cut a suitable length 1/4” tube and insert one end into the bottom quick

snap of main part, and connect another end to the “Source” connector

of the unit, then press down the main part on the basement.

C) Gooseneck Installation

Make sure all 3 O rings are in the O ring slot of gooseneck tube, then dip

some water on the end with O rings, then insert into the output nozzle of

main part.

• Installation of the Second Faucet Outlet Converter

Lily water treatment system can be connected to outlet connection with

the converter that comes as standard feature inside the package. With

this converter, it possible to connect the system to your refrigerator or to a

second faucet.

Water System Connection:

Connect the pure water pipe to the converter IN end then connect the

OUT end to the one end of three-way connector, after that connect other

two ends of the three-way connector to the E-faucet and M-faucet.

Electrical System Connection:

Connect the one wire connector on the converter to the E-faucet and the

other one connect to the wire from the units. These wire are apple to

apple connection.

Diagram 7

Page 15

ENG 13

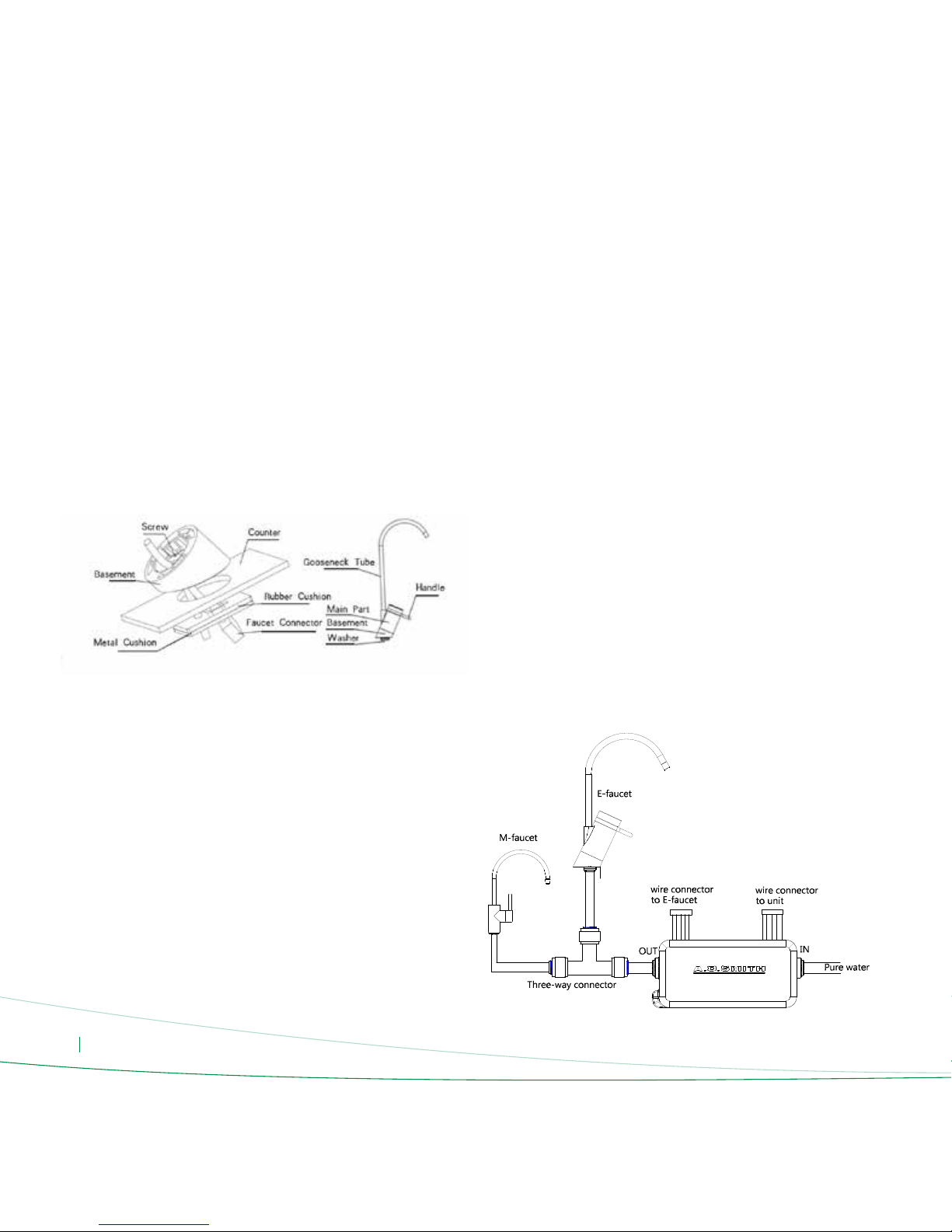

• Installation of the waste water pipe:

Drill a small hole into the sink drain pipe using a φ 6mm drill. Take

a suitable length of the 6mm water pipe and lay one end just inside

the drilled hole (See Diagram 8), put some silica gel where the 6mm

pipe and the drain pipe connect to prevent leakage. Use a cable tie to x

the waste water pipe to the drain pipe (for large ow water puriers;

you will need to insert a waste water clip into the drilled drain pipe hole).

The other end connect to the ''Waste'' at the back of the machine.

• Installation of the Side-Stream RO Membrane:

Open the front cover, pull up and out the RO lter assembly about 15°,

then rotate anticlockwise to take out, then use wrench to remove

the shell cover; then take out the RO membrane from the vacuum

bag, keep all O ring installed (See Diagram 9), put the at end of RO

membrane intothe shell and xed, then rotate the shell cover and tighten

with wrench,after that install the RO lter assembly into the front cover

in clockwise, and push inside until in originally vertical.

• Membrane Installation Warnings:

• The package of the reverse osmosis membrane contains a small amount

of protective solution in order to prevent microbiological contamination

of membrane components during storage and transportation.

• You should pay attention to the direction of the RO membrane during

installation.

• When installing the RO membrane, rst make sure that one end of the

membrane has 2 large O-rings and the other end has two large and

four small O-rings.

• When installing, be sure to put the end with 2 O-rings into the

membrane shell RO outlet water connection. Be sure when installing

to only use a little force to put the RO membrane into the membrane

shell. If you encounter too much resistance, please do not force the

reverse osmosis membrane into the membrane shell, doing so may cause

permanent damage to the membrane shell or membrane components.

A.O. Smith does not assume responsibility for returned components due

to damage during installation.

• Check the grey rubber bracket whether under the RO membrane

assembly, can not missing.

• Do not cut or try to disassemble the replaced membrane. RO membrane

can lter microorganisms and cutting or harming RO membrane may risk

on you and your environments health

• Installation of the Pre-Filters:

Open the front cover, pull up and out the RO lter cartridge assembly

about 15°, then rotate anticlockwise to take out, then use wrench to

remove the shell cover;Then take out the lters from package, keep 2 o

rings installed (See Diagram 10), put the end without O ring of lters into

the cartridge shell and xed, then rotate the shell cover and tighten with

wrench,after that install the RO lter cartridge assembly into the front

cover in clockwise, and push inside until in originally vertical.

The 1st stage lter is PP lter, 2nd stage is carbon block lter, and 4th stage

is PAC lter.

Diagram 8

Pure water pipe

Hot

Cold

Inlet water ball valve

Waste water hole

Diagram 10

Diagram 9

Page 16

ENG 14

• Open the tap water inlet valve and the water purier inlet water ball

valve (See Diagram 13) and plug the unit in the power outlet. Close

the storage tank ball valve, then automatically start a 120 second

ushing process, water will start to drain through the discharge outlet.

• Wait for the water purier to operate stably (for about 5-10 minutes).

Check each connection to make sure they are secure. Check to see if

there is any leakage from the membrane shell, lters, etc.

• Close the pure water osmosis faucet and storage tank ball valve. Wait

approximately 30 seconds. Check to see whether or not the water

purier waste water and high pressure pump have stopped working.

• Open the osmosis faucet. Check to see if the water is owing through

the faucet. If not, check to see whether the tap water pressure is too low

or whether or not the high pressure switch can be reset automatically.

• Wait until the machine is operating properly, then close the inlet water

ball valve. After a short period of time, check to see if the machine stops

working, if it does not stop working, check to see whether or not

the low-pressure switch can be reset.

• Perform a second check to make sure everything is ok. Now your water

purier is ready for use.

• Installation of UV Lamp:

First be sure that the water inlet and electricity connections are cut off from

the unit. Open the front cover, remove the UV lamp protector, and take

out the UV lamp and 2 pin cables from package, put one end 2 pins of UV

lamp into the hole end of cable connector, then put another end 2 pins of

UV lamp and 2 pins plug of cable together into the 4 holes end connector

and tight. Then install the cables and UV lamp into the stain steel tube

assembly, and make sure the 4 holes connector also inside, then cover the

end with cap and x the cover (See Diagram 11).

• RO Unit Placement:

Lily RO unit is not wall hung type, and need put on the ground or solid at

surface directly. If choice to hung on the wall, need to purchase additional

expand bolts and screws for xation.

• Installation of the Storage Tank:

Wrap 4-5 rounds thread seal tape on the tank nozzle, then x the tank

valve into the tank nozzle, then cut out a suitable length 1/4” tube, put one

end of tube on the tank valve, and another end connected to the “Tank”

joint of the unit (See Diagram 12). After that, nd a suitable place to locate

the tank in the cabinet.

Diagram 11

Diagram 12

Diagram 13

Adjustment Methods

Make sure that the water route connections are correct, proper power supply is used and water supply is suitable.

Then, follow these steps to adjust the purier:

3-Way Joint

Close

Open

Tank Valve

Nozzle

1/4”

Tube

Tank

Base

Page 17

ENG 15

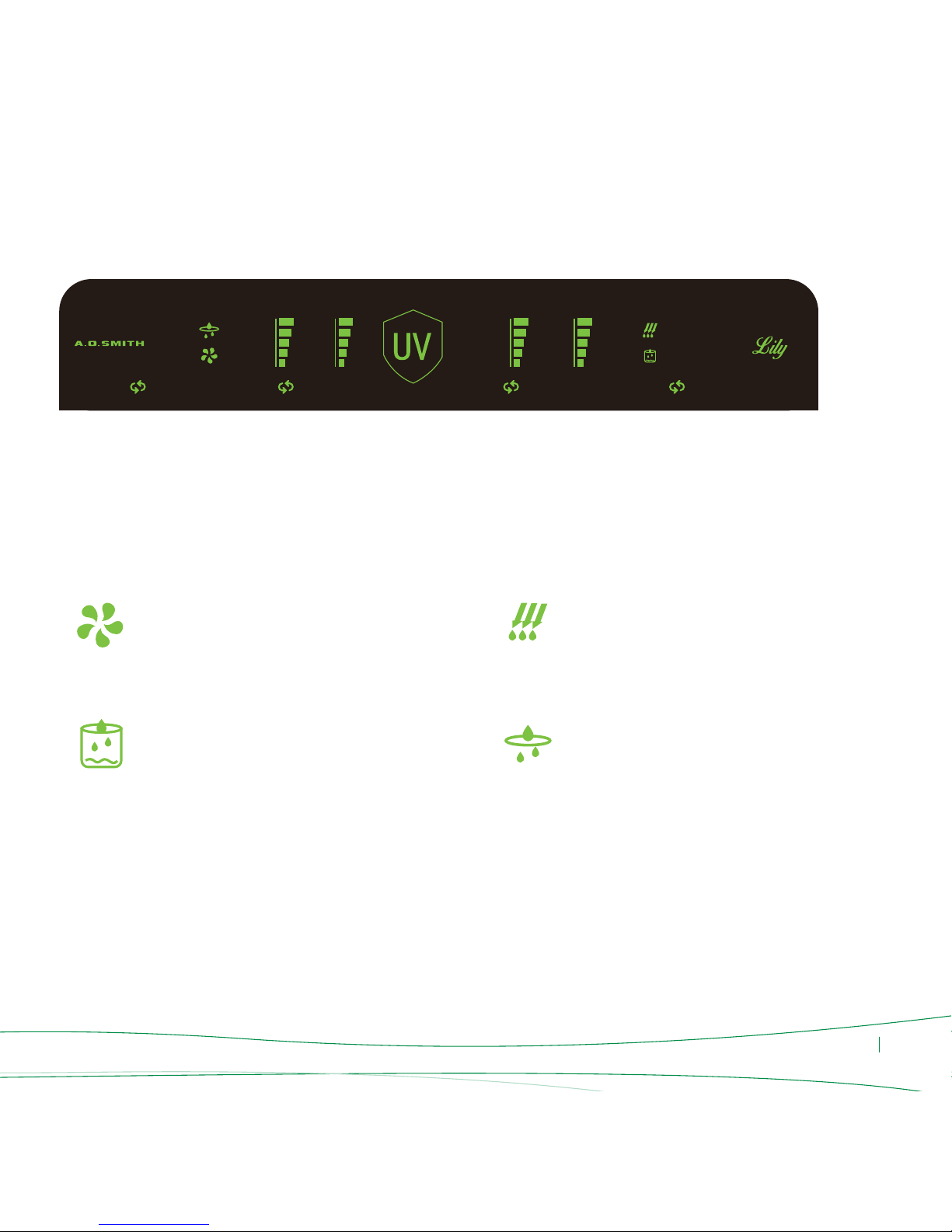

LED Display Functions

1st

PP

2nd

CB

3rd

RO

4th

PAC

Work: When the machine is producing water, this icon will lit up.

Source: When the machine has no inlet water or the inlet water is not

enough, this icon will lit up and the alarm will buzz.

Flush: When the unit is flushing the membrane, this icon will lit up.

Leakage: When there is a water leakage, this icon will lit up and the alarm

will buzz.

UV: This icon indicates the remaining life of UV Lamp.

Replace: These icons will be lit when one of the filters need to be replaced.

1st PP: This icon indicates the remaining life of 1st stage Sediment Filter.

2nd CB: This icon indicates the remaining life of 2nd stage Carbon Block

Filter.

3rd RO: This icon indicates the remaining life of 3rd stage RO Membrane

Filter.

4th PAC: This icon indicates the remaining life of 4th stage Post Active

Carbon Filter.

Work

• This icon will lit up only when the unit is producing

water.

• When the unit is in standby mode, this icon will be off.

Flush

• This icon will lit up only when the unit is flushing the RO

membrane.

• When the unit is in standby mode, this icon will be off.

Source

• When the machine has no inlet water or the inlet water

is not enough, this icon will lit up in red color and the

alarm will buzz..

• Alarm will buzz 7 times, after the buzzing, alarm will be

off and this icon will blink on the display.

• Alarm will buzz 7 times only once but everytime when

the water cut, the alarm will buzz again.

• This function and alarm will be activated when water is

cut no matter the unit is treating water or in standby.

Leakage Sensor and Alarm

• When there is a water leakage inside the unit, solenoid

valve will cut the water and leakage alarm will be

activated. .

• When Leakage Alarm is activated this icon will be

blinking in red color and alarm will buzz in each 2

seconds continuously.

• Alarm can be off only when the power source is the

unit is cut and reconnected to power again.

• Leakage alarm will be activated and the inlet water

will be automatically cut off no matter the unit is

treating water or in standby.

Page 18

ENG 16

1/2/3/4 Filter Life Status and Replace:

•These numbers indicates the remaining life of four

different filters. When the remaining of filter life changes,

the color of these icons will change.

• Number 1 indicates 5 µm Sediment Filter, Number

2 indicates Carbon Block Filter, Number 3 indicates RO

Membrane Filter and Number 4 indicates Post Active

Carbon Filter.

• When the related icon is Green, the filter can be used

normally.

• When the related icon turns to Orange and alarm is

buzzing 4 times, it means the filter should be replaced

soon.

After the icon turns orange on the display, the alarm will

buzz 4 times evertime the unit is treating water, this icon

willl remain until the related filter is replaced.

• When the icon turns Red and Replace icon is blinking

in Red color with alarm is buzzing 8 times, it means

the related filter can not be used and needs replacing

immediately. The unit should be stopped functioning and

call the After Sales Service for filter replacement

After the icon starts blinking on the display, the alarm will

buzz 8 times evertime the unit is treating water. This icon

willl remain blinking until the filter is replaced.

• This function and alarm will be activated no matter the

unit is treating water or in standby.

• Select and Reset Buttons:

When the filters’ life up to the it’s rated service life,

customer should contact the after-sale staff to change the

filter. after changing the filter should reset the filter life

through Select and Reset buttons.

Select and Reset Buttons are located next to UV unit.

Take off the USB cover to control the “Select” and

“Reset” manually (See Diagram 14).

Press the ''Select'' button to select the corresponding

filter icon, the corresponding filter icon will blinking,

then press the ''Reset'' button 3 seconds to reset

thecorresponding filter life, the color of the filter icon

will from red to green. if reset any filter life, related filter

icon will extinguish. if want to reset all the five stages

filter, press the select and reset button at the same time

about 5 seconds.It will exit if no operation in 10 seconds.

CAUTION: “Reset” button can be operated only after

replace the filter, otherwise not allowed to press the

“Reset” button.

THESE RESET/SELECT BUTTONS SHOULD BE

OPERATED BY ONLY AFTER SALES SERVICES.c

UV Lamp Status:

• This icon indicates the remaining life UV lamp. When the

remaining of UV lamp changes, the color of this icon will

change.

• When the icon is Green, UV lamp can be used normally

• When the icon turns to Orange, it means UV lamp

should be replaced soon.

• When the icon turns Red, it means UV lamp can not

be used and needs replacing immediately. The unit should

be stopped functioning and call the After Sales Service for

replacement

• When the icon turns Red and the alarm is buzzing, it

means the unit should be stopped functioning and UV unit

should be checked and UV lamp should be replaced. In this

case, call the After Sales Service for replacement

• This function and alarm will be activated no matter the

unit is treating water or in standby.

Diagram 14

Select Reset

USB Box

Cover

Select Reset

USB Box

Page 19

ENG 17

• Faucet display function:

While the unit power on, open the faucet, the logo “AO SMITH” and

symbol “ ” will be lighted up,the logo shows in white, and symbols color

depends on the service life of filters. During the usage interval, while the

symbol shows in orange or red, please check the unit display and

notice which stage filter, then contact the authorized professionals to

remind and preparation for the maintenance. While close the faucet, both

logo and symbol are also lighted off (See Diagram 15).

Diagram 15

Side Stream R.O. Membrane Technology is a special innovation by

A.O.Smith. Side Stream R.O. Membrane use patented MLSB Screw-type

Technology.

MLSB (multi-leaves single-bag) membrane has vertical inow and

concentrate water direction; longer and narrower inow passage thus

app. 2,8 times higher surface ow rate. Higher ow rate can reinforce the

effect of surface ush, of R.O. membrane, reduce the rate of concentration

polarization, blockage, scale formation, waste water discharge, and

increase the salt rejection rate.

The Side Stream R.O. membrane increases the recovery rate to around

50%, compared to 25% for the regular residential R.O. membrane, and

waste water volume is reduced by 56%.

Combined with MLSB Screw-type Technology, Side Stream R.O. Membrane

creates the world’s highest utilization rate for residential membranes,

reaching 85-90% compared to only 70% for traditional membranes.

With patented full ush function, it completely solves the traditional water

purier problem of having no way for the concentrate water to ush out

of the membrane when the tank is full, leading to membrane scale and

pollution problems. The optimal ushing design reduces ushing discharge

by 50% and extends the service life of the membrane by 1,5 times.

Advantages

• Less Waste Water: It can reduce 56% waste water, energy saving,

en vironmental protection, enjoy low carbon living;

• More Pure Water: It can increase 66% pure water, more efcient and

highest utilization;

• High Salt Rejection: Its salt rejection can be more than 95%, which is the

top level of residential membrane;

• Long Life: By less concentration polarization, it has a low risk

contamination and long life span app. ;

• Reliable Structure: It has water hammer and attack protection, mistake-

proof design to prevent wrong installation;

• Better Sealing: Two o-ring design, completely leak tight, insure pure

water quality;

• Compact Size: 10% smaller, more compact, lighter design.

Side Stream R.O. Membrane

More pure water

waste water

of RO filter

Less

Prolong

66%

56%

1.5

times

Page 20

ENG 18

• During the rst operation of the unit, before activating RO membrane,

pre-lters should be ushed. Follow the below steps to ush the

pre-lters:

- Turn off the inlet water solenoid valve.

- Take out third stage RO membrane housing.

- Place a storage cup to next to the Second Stage Carbon Block housing to

drain the dark color water coming from the Second Stage Filter.

- Turn on the inlet water solenoid valve and wait until the color of the

water returns to normal.

- Turn off the inlet water solenoid valve and reassemble third stage RO

membrane housing.

- Before using Fourth Stage PAC, ush the cartridge for 1-2 minutes also.

• The major components of this product are manufactured using plastic.

When using the water purier, always observe the integrity

of the equipment in order to ensure safe operation.

• The package of the reverse osmosis membrane contains a small amount

of protective solution in order to prevent microbiological contamination

of membrane components during storage and transportation. The

PAC lter may emit activated carbon powder the rst time it is used.

So do not open the water storage tank during the rst hour when the

water purier is put into operation. It is recommended that the water

produced during this period is disposed of. Otherwise, the taste of the

pure water may be unusual.

• When you rst use the storage tank it is recommended that you discard

the rst tank of water; otherwise it may result in abnormal tasting pure

water.

• When you rst operate the water purier, the pure water TDS value may

be a little high. After operating for some time, the TDS value of the pure

water produced will gradually decrease until it is stable.

• When you are using the water purier, the inlet water ball valve should

be opened and the pure water faucet needs to be turned on. When

you are not using water turn off the water faucet, the high pressure

switch will automatically cut off the water supply.

• When the unit is not operated for long periods of time, occurance of

microbiological contamination is possible.

To prevent any microbiological contamination, it is recommended to

operate the unit at least twice a week. Otherwise, the water can have a

smell.

• When any of the following situations occur, immediately disconnect

the water purier water source (close the inlet water ball valve) and/or

the power source and carry out repairs.

- If the water purier pipes or related components are leaking.

- If the water purier and/or components stop working.

- If any components leak electricity.

- If there are any other anomalies or failures.

• When you go out or do not use the machine, disconnect the water

purier's water source (close the inlet water ball valve) and/or power

source.

• If the water purier parts are damaged, it is recommended that the water

purier be entrusted to the manufacturer or distributor, service center,

or specialized technical personnel for replacement to prevent loss caused

by improperly performed maintenance, the manufacturer assumes

no liability for losses incurred as a result of operation or use that does

not conform with the instructions and reminders specied herein.

Operation Warnings

Page 21

ENG 19

Flushing the RO Membrane

As water passes through the RO membrane, impurities and bacteria are

retained on the membrane surface, so you should regularly ush

the machine to ensure that the RO membrane performance is optimized.

• Flushing Method: Automatic ushing.

• Flushing Conditions: The membrane will be automatically ushed in three

conditions:

1. When the product is on

2. When the tank is full

3. When the product stays in stand-by mode in three consecutive days

• Flushing Model: 18 second ushing, 15 seconds working, 18 seconds

ushing again. Total duration 51 seconds.

Filter Replacement Intervals

• The lter replacement cycles for the various lters used in this purier is

derived from statistical indicators on the estimates of average tap water

usage. If there are considerable discrepancies between the users supply

water quality, utilization rates and average indicators, there will be more

obvious differences between the lters actual replacement intervals

and estimated life-cycles and users may experience premature lter clogging,

premature failure, etc. If this occurs, lter replacement intervals should be

based on actual usage conditions. You should also contact your local

after-sales service department immediately to inform them of the situation.

• This machine’s estimated lter replacement cycle is based on average

household water consumption and is suitable only for residential use,

do not install this machine in places that require large volumes of water.

If the water volume requirements are large, our company offers

appropriate equipment tailored for commercial applications.

• According to economic statistics on municipal tap water, a three person

family on average uses 10L of water a day. According to the water

volume and inlet water quality conditions, approximate ltering

volumes are as follows:

Important Note:

Water quality has a great inuence on the life-cycle of the lters. The

lifespan of the RO membrane is affected by many factors.

The table above represents the lifespan of lters under standard

conditions. In actual usage, due to the fact that water quality may be

different, the lifespan of the lters may exceed or may be lower than the

abovementioned estimates.

The above data is provided for reference only. Under normal circumstances,

if you witness the following indications, you should consider replacing your

lters:

• Poor water quality, taste declines, TDS value of water rises TDS value of

water;

• Water ow is signicantly reduced. Check to see if the lter or

membrane is blocked (determine that it was not caused by a temperature

drop);

• If the lter’s outer surface is covered in mud or the lter has signicantly

changed color;

• If serious lter clogging leads to no pure water ow from the unit.

Maintenance and Repair

PROGRESSION

First: 5-micron PP lter

Second: Carbon Block lter

Third: Reverse Osmosis Membrane

Forth: PAC lter

Fifth: UV Lamp

USAGE PERIOD

6-12 Months

6-12 Months

24-36 Months

6-12 Months

12Months

Page 22

ENG 20

Filter Replacement Methods

This product is equipped with disposalable lter housing and lter. This

means that when the lter life is over, lter and lter housing will be

changed. Follow the same steps in the installation of pre-lters section.

Open the front cover, pull up and out the RO lter cartridge assembly

about 15°, then rotate anticlockwise to take out, then use wrench to

remove the shell cover;Then take out the lters from package, keep 2 o

rings installed (See Diagram 9-10), put the end without O ring of lters

into the cartridge shell and xed, then rotate the shell cover and tighten

with wrench,after that install the RO lter cartridge assembly into the front

cover in clockwise, and push inside until in originally vertical.

IMPORTANT:

It is recommended that lter replacement is carried out by qualied

after-sales staff.

Always use gloves when replacing the lters. Replaced lters should be

disposed in a tightly closed garbage bag.

Filter Replacement Warning

During the rst use, Carbon Cartridges will leave a carbon dust into the

water. To prevent carbon dust owing into RO Membrane cartridge,

Carbon Filters should be ushed before the activation of the unit. If this

ushing will not be done, Carbon Dust will shorten RO membrane,

While changing the pre-lter, Second Stage Carbon Block and Fourth Stage

PAC lters should also be ushed.

Follow the spets on page 18 to ush the pre-lters.

General Information

• RO membrane water production volume

The water output volume of the RO membrane component is inuenced

by inlet water pressure and water temperature. Your equipment’s

declared volume of 75GPD is tested under a net pressure of 0.5MPa

and inlet water temperature of 25C . If net pressure is less than 0.5MPa

or if the inlet water temperature is less than 25C, water output volume

of the RO membrane component will be less than 75GPD.

• Storage tank capacity

The storage tank on your equipment has a stated capacity of 3.2G.

However this gure is its theoretical capacity and its actual storage

capacity is about 70%-80% of the stated value, which is app. 2.0-2.5G

• Disposal of old lters

After replacing old lters, they cannot be cleaned and reused; it is

recommended that you dispose of them with solid waste garbage.

Page 23

ENG 21

After-Sales Service

• If your water purifier exhibits abnormal behavior, please turn off

the water source immediately, cut off the power source and contact

your local vendor.

Notes

• Our company reserves the right to change product design, configuration,

and specifications without prior notice.

• Our company assumes no liability for problems that may occur as a result

of technical or editorial errors, omissions or printing problems contained

herein.

Packing List

Main Machine

3 Stage Filters and RO Membrane Water Pipe

Storage Tank

UV Lamp and 2 Pins Cable

Electronic Faucet

5 pins Faucet Cable

¼” Pipe

Converter for Second Faucet Outlet

User Manual

Standard Installation Kit

-Inlet water ball valve

-Waste water tube clamp

-O-ring

-Tank valve

-Thread seal tape

-Nylon cable ties

1 Unit

1 Set

1

1

1

1

5 m

1

1

1

1

2

2

1 Roll

5

Page 24

ENG 22

FAILURE EXPERIENCED

REASON SOLUTION METHOD

• The power source is not connected.

• Low inlet water pressure or no water.

• Low-pressure switch failure, cannot connect the power

source.

• High-pressure switch cannot be restored.

• Switch Mode Power Supply is burned out.

• High-pressure pump burned out.

• Transformer burned out.

• No output voltage from control PCB

• High-pressure pump has lost pressure.

• A pre-lter is blocked.

• Check valve is blocked. (waste water, no pure water)

• The RO Membrane is plugged.

• Inlet water valve is faulty, no water can get in.

• Control PCB cannot shut off ushing valve.

• Check valve has lost pressure.

• High-pressure switch failure.

• System is exhibiting a loss of pressure.

• Pre-lter is plugged.

• RO membrane is plugged.

• Inlet water solenoid valve failure.

• Check valve is plugged.

• PAC lter is plugged.

• High pressure pump pressure is not enough.

• Storage tank doesn’t have enough pressure.

• PAC lter is plugged.

• High-pressure pump pressure is not reaching 0.3MPa,

the storage tank internal pressure cannot reach the set

high pressure.

• Flush solenoid valve failed, cannot effectively

cut off the water supply.

• Check valve has lost pressure. (small W.W. ow rate)

• High-pressure problem.

• High-pressure pump has lost pressure.

• Inlet water solenoid valve is faulty.

• Check the power source or the power source plug.

• Check the inlet water pressure.

• After connecting the inlet water, measure the resistance,

replace.

• After letting off the pressure, measure the resistance,

replace.

• Measure the output voltage, replace.

• Replace the high-pressure pump.

• Check the transformer input voltage/overload.

• Measure the output voltage, replace.

• Replace the pre-lter.

• Wash or replace the RO membrane.

• Replace the Inlet water solenoid valve.

• Replace the check valve.

• Replace the PAC lter.

• Measure the high pressure pump water pressure, replace.

• Measure the water pump pressure, replace.

• Observe the pure water and waste water, replace the pre-lter.

• Replace the check valve.

• Clean or replace the RO membrane.

• Replace the inlet water valve.

• Measure input voltage for ushing valve, replace control PCB

• Replace the check valve.

• Replace the high pressure switch.

• After checking the check valve, check whether

there is water leakage in the pipelines.

• Inate the storage bucket, empty tank pressure

should be between 0.05 and 0.07MPa.

• Replace the PAC lter.

• Measure the pressure from the water pressure pump,

replace.

• Observe the waste water, replace the Flush solenoid valve.

• Observe the waste water, replace the check valve.

• Measure the pressure.

• Measure the water pump pressure, replace.

• Replace the Inlet water solenoid valve.

The machine will not

start

The high pressure pump

is working properly,

but no water is being

produced

The storage tank is full

but no pure

water is owing out

The machine is turned off

but waste water has not

stopped

The machine produces

continuous pure water

After the machine is

lled with water, the

machine starts repeatedly

The pure water ow is

small or not owing

Troubleshooting Guide

Page 25

ENG 23

FAILURE EXPERIENCED

REASON SOLUTION METHOD

• RO membrane connector o-ring deformed.

• RO membrane ruptured/aperture enlarged.

• Air in the tubing.

• Power input specication error.

• Power source is burned/failed.

• PAC lter is saturated.

• Intermittent usage, water ceases owing.

• Filter housing not locking tightly.

• Filter housing o-ring deformed.

• UV Lamp damaged.

• UV Lamp ballast damaged.

• UV Lamp life due.

• Replace the UV Lamp.

• Replace the UV Lamp ballast.

• Replace the UV Lamp.

• Outlet check valve not blocking water completely.

• Leakage in the tubing.

• Air in the motor.

• Pre-lter is blocked.

• Abnormal frequent start up and overheat.

• Replace o-ring.

• Replace RO membrane.

• Replace PAC lter.

• Drain tank water/replace PAC lter

cartridge.

• Lock housing tightly.

• Replace housing o-ring.

• Vent the air in the tubing.

• Check if power input complies with standard specs.

• Check the power source, replace if necessary.

• Replace check valve.

• Lock tightly/replace tubing.

• Vent the air.

• Replace pre-lter.

• Replace booster pump.

No or little decrease in

TDS value in product

water

Machine not treating

water after replacing

lter cartridge

Pressurized motor

continues to restart

frequently

Motor does not pump up

the pressure

Booster pump motor

burned out

Transformer smell

RO water smells or

tastes strange

Filter cartridge junction

leakage

UV Lamp can’t light

up

Page 26

TR 24

Page 27

TR 25

Değerli müşterimiz,

"A.O. Smith" markalı su arıtma cihazlarını tercih ettiğiniz için teşekkür ederiz!

Artık, dünyanın lider su arıtma sistemleri üreticisi tarafından imal edilen su arıtma

ekipmanlarına sahipsiniz. Bu ekipman doğrudan içilebilen, saf su üreterek size daha temiz

ve sağlıklı su elde etme imkanı sunar.

Lütfen, "A.O. Smith" markalı su arıtma cihazınızın kurulumunu gerçekleştirmeden ve

cihazınızı çalıştırmadan evvel bu kullanım kılavuzunu dikkatlice okuyun. Bu kullanım kılavuzu

su arıtma cihazınızın kurulumu ve ayrıca cihazınızdan azami oranda verim almanızı sağlamak

için cihazın doğru şekilde çalıştırılması ve bakımı hakkında detaylı bilgiler içermektedir.

Kurulum işlemleri yalnızca A.O. Smith Su Teknolojileri A.Ş. tarafından yetkilendirilmiş

profesyonel servisler tarafından gerçekleştirilmelidir.

Bakım amaçlı kullanılan yedek parçalar ve cihaza takılacak yedek ltreler cihaza monte

edilmeden evvel A.O. Smith Su Teknolojileri A.Ş. tarafından onaylanmalıdır.

A.O. Smith Su Teknolojileri A.Ş. tarafından onaylanmamış yedek parça veya ltrelerin

kullanımından kaynaklanan herhangi bir performans kaybı garanti kapsamı dışında

kalacaktır.

Kurulum veya işletim esnasında herhangi bir sıkıntı yaşarsanız, cihazınız üzerinde bakım

ve onarım işlemlerini gerçekleştirmeleri için lütfen yerel dağıtımcınızla irtibata geçin.

Page 28

TR 26

Güvenlik Uyarıları

(Güvenlik uyarılarını mutlaka okuyun ve bu uyarılara uygun hareket edin)

Aşağıda belirtilen güvenlik önlemlerini dikkate almanız, maddi hasara uğrama riskinizi, size ve diğer insanlara gelebilecek potansiyel zararları önlemenizi

sağlayacaktır.

•Aşağıda belirtilen güvenlik uyarılarına uymamak riskli durumların oluşmasına yol açabilir:

Uyarılar

Bu bölümün içeriğini göz ardı etmek su arıtma cihazınızın ciddi şekilde zarar görmesine veya ciddi boyutta maddi hasar oluşmasına neden olabilir.

Su arıtma cihazını kendi başınıza parçalara

ayırmayın veya değiştirmeye çalışmayın!

Cihazınızı yetkisiz bir şekilde parçalara

ayırmak ya da cihazınızda değişiklik yapmak,

mekanik ve elektronik arızalara veya sızıntıdan

kaynaklanan kazalara neden olabilir. Ürünle

ilgili sorularınız veya tamirat amaçlı randevu

ayarlamak için lütfen ürünü satın aldığınız

distribütör ile irtibat kurun.

Su arıtma cihazınızı açık alev yakınına

koymayın!

Su arıtma cihazınızı bir alev kaynağı veya ısının

çok yüksek olduğu yerlere koymayın. Aksi

halde, cihazda deformasyon veya erime

olabilir. Bu durum, cihazın arızalanmasına

veya sızıntı yapmasına ve hatta ciddi ziksel

ve maddi zararların oluşmasına neden olabilir.

Cihazın üzerine ağır cisimler koymayın!

Su arıtma cihazınızın üzerine ağır cisimler

koyulması arıtma cihazının dış kabına

veya iç bileşenlerine zarar verebilir. Bu durum,

sızıntıların oluşmasına, ekipman arızalarına

ve ciddi maddi hasarların oluşmasına neden

olabilir.

Cihazın üzerine herhangi bir cisim koymayın!

Isı dağılımını engellemek mekanik ve

elektronik arızalara veya yangın çıkmasına

neden olabilir.

Bu cihazın kullanımı, 8 yaş ve üzeri çocuklar

ile herhangi bir ziksel veya duyusal engeli

bulunan kişiler tarafından ancak bu kişilere

cihazın güvenli bir şekilde kullanılmasıyla

ilgili gözetim veya talimat verilmişse ve

içermiş olduğu tehlikeler kendileri tarafından

anlaşılmışsa yapılabilir.

Bu cihaz, elektrik ve su ile çalıştığından

zihinsel engelli kişilerce kullanılmaması

önerilmektedir.

Çocuklar cihaz ile oynamamalıdır.

Cihazın yakınındaki çocuklar mutlaka gözetim

altında tutulmalıdır. Cihazın temizleme

ve kullanıcı bakımı, gözetimsiz çocuklar

tarafından yapılmamalıdır.

Page 29

TR 27

Su arıtma cihazınızı yüksek su basıncı altında

kullanmayın!

Cihazı yüksek basınç altında kullanmak su

arıtma cihazının borularının delinmesine

ve dolayısı ile sızıntı oluşmasına, cihazın

düzgün çalışmamasına veya ciddi maddi

hasarların oluşmasına neden olabilir.

Tavsiye edilen giriş basıncı:

0.1-0.35 MPa (1-3,5 Bar).

Giriş suyu basıncının 0.35 MPa’yı (3.5

barı) geçtiği yerlerde cihazın önüne

mutlaka bir basınç düşürücü

takılması tavsiye edilir.

Güç kablosuna ıslak elle dokunmayın!

Güç kablosuna ıslak elle dokunmak

elektrik çarpmasına neden olabilir.

Cihaz, ürün kolisinde ürünle birlikte verilen

yeni hortum takımları ile kullanılmalıdır.

Eski hortum takımları tekrar kullanılmamalıdır.

Aksi halde su sızıntıları meydana gelebilir veya

ürün performansı olumsuz etkilenebilir.

Güç kablosuna veya prize hasar vermeyin!

Güç kablosuna veya prize hasar vermek

elektrik çarpmasına, kısa devre olmasına

veya yangın çıkmasına neden olabilir.

Kurulum veya tamirat esnasında cihaz prizden

çekilmelidir!

Kurulum veya tamirat esnasında cihazın

prizden çekilmemesi elektrik çarpmasına

neden olabilir.

Cihaz üzerinde belirtilen güç kaynağı

değerinden daha yüksek değerli güç kaynağı

kullanmayın. Sadece 230V AC güç kullanın!

Cihazın akımını sağlayan priz cihaz üzerinde

belirtilen değerden yüksek akım

sağlamamalıdır; aksi halde aşırı ısınma veya

yangın çıkmasına neden olabilir.

230 V

Cihazınız, sadece bu cihazla sağlanan güç

besleme birimi ile kullanılmalıdır!

Cihazın orijinal olmayan güç besleme birimiyle

kullanımı cihazın performansının olumsuz

etkilenmesine ve uygun olmayan parçalarla

kullanımı sonucu cihazın zarar görmesine

neden olabilir.

Cihazın, besleme kordonu hasar görürse,

A.O.Smith satış temsilcisinden veya yetkili

A.O.Smith servisinden tedarik edilen özel

hazırlanmış bir kordon veya kordon takımı ile

değiştirilmelidir!

Cihazın orijinal olmayan besleme kordonuyla

kullanımı cihazın performansının olumsuz

etkilenmesine ve uygun olmayan parçalarla

kullanımı sonucu cihazın zarar görmesine

neden olabilir.

Su arıtma cihazınızı kanalizasyonun tıkalı

olduğu durumlarda kullanmayın!

Eğer cihazınızı kanalizasyon tıkalıyken

kullanırsanız, atık su cihazın içine geri kaçabilir

ve cihazın içinin kirlenmesine yol açabilir.

Page 30

TR 28

Su arıtma cihazınızı doğrudan güneş ışığının

altına koymayın!

Su arıtma cihazı belirli bir süre güneş ışığında

kalırsa, mikroorganizmalar için uygun

bir üreme alanı oluşturur, arıtma cihazından

elde edilen suyun kalitesi azalır

ve mikroorganizmalar cihazın bileşenlerinin

kirlenmesine yol açabilir.

Atık su tahliye borusu ve atık debi kısıtlayıcı

tıkanık olmamalıdır!

Atık su tahliye boruları veya atık debi kısıtlayıcı

tıkanırsa, yüksek oranda Toplam

Çözünmüş katı TDS madde oluşmasına

ve RO membranının tıkanmasına veya su

arıtma cihazının çalışmamasına neden olabilir.

Cihazı ortam ısısının 5°C'nin altına düştüğü

durumlarda kullanmayın!

Eğer ortam sıcaklığı 5°C’nin altındaysa, lütfen

donmayı engellemek için gerekli önlemleri

alın. Örneğin, cihazın içerisindeki suyun

donmasına bağlı olarak çatlayan Borulardan

sızıntı olmasını engellemek için ısıtıcıyı veya

klimayı çalıştırın.

Su arıtma cihazına beslenen suyun sıcaklığı

38°C'yi aşmamalıdır!

Eğer cihaza beslenen suyun ısısı 38°C'nin,

üzerindeyse, ısı RO membranına zarar verir

ve bu durum membranın işlevini yitirmesine

yol açar.

Su arıtma cihazınızı dış mekanlarda kullanmayın!

Eğer bu su arıtma cihazı dış mekânda

kullanılırsa bu durum cihazın borularının

ve diğer bileşenlerinin eskimesini

hızlandıracaktır. Bu durum, cihazın sızıntı

yapmasına veya mekanik arızalara neden

olabilir.

Cihazınızın aşındırıcı maddelerle temas

etmesinden kaçının!

Bu tür maddeler cihazın dış kapağını eritebilir,

su ile temas eden parçaları etkileyebilir veya

bazı zehirli ve tehlikeli bileşenler su arıtma

cihazının borularına sızabilir. Bu durum,

cihazın kirli su üretmesine, sızıntı yapmasına

ve bu doğrultuda ciddi ziksel ve maddi

zararların oluşmasına neden olabilir.

Cihazın ön cam paneli üzerine güç

uygulamayınız ve cihazı düz zemine

yerleştiriniz!

Cam panele kuvvet uygulanması ve

cihazın öne doğru yatırılması, cihazın eğik

yerleştirilmesi cam panelin zarar görmesine

neden olabilir.

UV ünitesine A.O. Smith yetkili servisi

olmadan müdahale etmeyiniz!

• UV ünitesi ile ilgili bir işlem yapılırken

mutlaka gözlük ve eldiven kullanılmalıdır.

• UV lambaları yanıyorken doğrudan

çıplak göz ile bakmayınız

• UV ünitesinin bakımı esnasında UV

lambalarının aktif olmadığına emin

olunuz.

UV lamba ışını çıplak göze ve cilde zarar verebilir.

Page 31

TR 29

Kontrol Paneli

Ürün Tanıtımı

Diyagram 1Lily

Kısa Tanıtım

Bu cihaz günümüzde mevcut olan en gelişmiş Ters Osmoz (RO)

teknolojisini kullanmaktadır. RO teknolojisi, tabiatta gerçekleşen osmoz

olayının yapay olarak tersine çevrilmesine dayanır. RO membranlarının

aparatlarındaki gözeneklerin ebatları 0.0001 mikron (0.1 nm) çapına kadar

iner ve membranlar bu sayede bakteriler, virüsler, ağır metaller, böcek ilacı

kalıntıları ve suda bulunan diğer zararlı maddeleri etkin bir şekilde

uzaklaştırırlar. Üretilen su taze ve saftır ve doğrudan kullanıma uygundur.

Su Arıtma Cihazının Ayrıntılı Proli

Page 32

TR 30

Kontrol Paneli

Elektrik Şeması

Su Akış Şeması

Diyagram 2

Diyagram 3

Solenoid

Page 33

TR 31

Teknik Bilgiler

Model No.

Voltaj

Frekans

Uygun Giriş Suyu Basıncı

Giriş Suyu Sıcaklığı

Azami Besleme Suyu TDS Değeri

Yıkama Yöntemi

Elektrik Çarpmasına Karşı Koruma Yöntemi

Ürün Ölçüleri

Tank Ölçüleri

Net Ağırlık

Uygun Su Kalitesi

Güç

Azami Günlük Su Üretim Hacmi

Tank Hacmi

Ana Bileşenlerin İşlevleri

Mevcut olan en gelişmiş uluslararası RO teknolojisini kullanan su arıtma

cihazınızın standart kongürasyonu aşağıdaki gibidir:

• Birinci aşamada 5-mikron PP (Sediment) Filtresi bulunur:

PP ltresinin aparatında bulunan gözenekler 5 mikron genişliğindedir

ve pas, kum, diğer büyük parçacıklar ve suda bulunan diğer yabancı

maddeleri etkin bir şekilde süzer.

• İkinci aşamada Blok Karbon Filtresi bulunur:

Bu ltre klor, küf, dezenfeksiyon yan ürünleri, koku, renklenme ve diğer

yabancı maddeleri etkin bir şekilde absorbe eder.

• Üçüncü aşamada Ters Ozmos (RO) membranı bulunur:

RO membranı, 0.0001 mikron (0.1 nm) gözenek çaplarına sahiptir ve

bu sayede suda bulunan bakteri, virüs, ağır metal, böcek ilacı kalıntıları

ile suda bulunan diğer zararlı maddeleri etkin bir şekilde uzaklaştırır.

• Dördüncü aşamada Son Aktif Karbon (PAC) Filtredir:

Bu ltre suyun tadını dengeler ve suyu taze tutar.

• Beşinci aşamada UV dezenfeksiyon ünitesi bulunur.

Bu ünite, özellikle cihazın uzun süre kullanılmadığı durumlarda, su

borularında ve depolama tankında bakterilerin oluşumunu engeller.

Not: Ürünler sürekli olarak geliştirildiğinden yukarıda belirtilen parametrelerde değişiklikler olabilir, ancak ürünlerin etiketleri aynı kalacaktır. TDS, suda çözülmüş toplam

katı atık anlamına gelmektedir.

Not:

0.1 MPa = 1.02 Kg/cm

2

= 14.5Psi

1 Psi = 0.07 Kg/cm

2

1 Galon = 3.785 Litre

75 GPD = 75 Galon/Gün = 284 Litre/Gün = 197 Millilitre/Dakika

230V AC

50 Hz

38 W

0.1-0.35 MPa (1-3,5 Bar)

5 ~38˚C

≤1000 PPM

460x488x161 mm

335x280 mm

14 kg

Otomatik Yıkama

75 Galon, yaklaşık 284 Litre

3.2 Galon, yaklaşık 12.1 Litre

Class II

TS-266 standartlarını karşılayan belediye şebeke suyu

LILY

Page 34

TR 32

Aksesuarların İşlevleri

• Depolama Tankı: Su arıtma cihazının süzdüğü suları depolamak için

kullanılır.

• Yüksek Basınç Pompası: RO membranı için uygun ortamı yaratmak amacı

ile basıncı arttırır.

• Flush (Solenoid) Vana: Atık su akışını kontrol eder ve otomatik olarak

RO membranı yıkar.

• Düşük Basınç Anahtarı: Pompanın rölantide çalışmasını engeller. Giriş su

basıncı 1 Bar’dan düşükse veya su girişi durursa, düşük basınç

anahtarı otomatik olarak devreye girerek güç kaynağını keser

ve cihaz durur.

• Yüksek Basınç Anahtarı: Pompanın aşırı çalışmasını engeller. Basınç tankı

doluysa veya belirlenen basınca ulaşmışsa, güç kaynağı otomatik olarak

kesilir ve cihaz durur.

• Su Girişi (Solenoid) Vanası: Cihaza beslenen suyu açar/kapar.

• Çek Valf: Suyun akış yönünü kontrol eder.

• Transformatör: 230V AC güç değerini cihazın güvenli çalışma voltajı olan

24V DC'ye dönüştürür. .

• Kumanda Panosu: Cihazın tüm çalışma prosesini kontrol eder.

• Kaçak Sensörü: Cihazda su kaçağı olması durumunda kaçağı algılayarak

kullanıcılara ya da eşyalara zarar gelmemesi için alarm verir ve giriş

suyunu keser.

• Elektronik Musluk: Cihazdan gelen suyun çıkışını kontrol eder. Elektronik

özelliği ile cihazın içindeki ltrelerden birinin ömrü azaldığında logo rengi

değişerek uyarı verir.

• UV Dezenfeksiyon Ünitesi: Cihazdan çıkan suyu son aşamada sterilize

eder.

Su Arıtma Cihazının Özellikleri

• Side Stream Membran: Side Stream R.O. Membrane, diğer evsel

membranlara nazaran geri dönüşüm oranını yaklaşık %50 oranında arttırır

ve atık su oranını 56% oranında azaltır.

• Otomatik Kumanda Sistemi: Sistem, su üretim sürecinin tamamını

kumanda eder. Örneğin, su girişi kesintiye uğrayınca veya tank dolunca

otomatik olarak durur;

• Otomatik Yıkama İşlevi: Sistem RO membranının otomatik yıkama

sürecini el değmeden kontrol ederek daha güvenilir ve güvenli bir işletim

ortamı sağlar.

• Filtre Değişim Uyarıları: Filtre kartuşları ömürlerinin sonuna yaklaşırken

sistem, kullanıcılara alarm sesi ve gösterge ekranı renk değişimleri ile

ltre kartuşlarının değiştirilmesi gerektiğini gösterir.

• Kaçak Koruması: Sistem su sızıntısı olduğunu algılarsa pompayı ve giriş

valni durdurarak otomatik olarak çalışmayı keser. Gösterge ekranında

''Su Kaçağı'' ikonu yanmaya başlar ve alarm çalmaya başlar. Sistem

ancak su sızıntısı kesilip cihaz tekrar çalıştırıldığında normale döner.

• UV Dezenfeksiyon Koruması: Bu sistem güçlü ultraviyole ışınlarını

kullanarak suyun içindeki mikroorganizmaları uzaklaştırarak

dezenfeksiyon sağlar.

• Altı (6) adetten fazla koliyi üst üste istiemeyiniz.

• Kolileri kaldırmadan önce alt kapağı tutan bantların mevcut ve zarar

görmemiş olduğundan emin olun.

• Kolileri alt kapaklarından kavrayarak tutunuz.

• Ağır yük kaldırmaya karşı çeşitli rahatsızlıkları bulunan kişiler taşıma

ve müdahalelerde yardım almalıdır.

Nakliye

Cihazı taşırken ve başka bir yere naklederken, lütfen aşağıda bulunan uyarıları dikkate alınız.

Page 35

TR 33

Kurulum İçin Ön-hazırlık

• Su arıtma cihazınızı nereye yerleştireceğinize karar verin.

• Kurulum için ihtiyaç duyacağınız aletlere sahip olduğunuzdan

emin olun.

• Kurulum için ihtiyaç duyacağınız bağlantı elemanlarına sahip

olduğunuzdan emin olun.

• Kurulum işlemlerine başlamadan evvel suyu ve elektriği

kestiğinizden emin olun.

Ayarlanabilir İngiliz Anahtarı

Matkap

6.2 mm Matkap Ucu

Delik Testeresi φ16-35 mm (Panç)

T10 Düz ve Yıldız Vida

Makas

14 - 16 mm İngiliz Anahtarı

19 - 21 mm İngiliz Anahtarı

Karga Burun Pense

1

1

1 (Atık su gideri)

1

1'er adet

1

1

1

1

Kurulum Talimatları

Şirketimiz, kurulum sürecinin karmaşık olması ve çeşitli özel aletlerin kullanılmasını gerektirdiği için cihazınızın kurulumunun eğitimli profesyoneller

tarafından yapılmasını tavsiye eder. Ancak, cihazınızın kurulumunu kendiniz yapmak isterseniz aşağıdaki talimatlardan ve şemalardan faydalanabilirsiniz:

Uyarı: Giriş suyu basıncının 0.35 MPa(3.5 barı) geçtiği yerlerde

cihazın önüne mutlaka bir basınç düşürücü takılması tavsiye

edilir.

Doğru Kurulum için Uyulması Gereken Talimatlar

• Metal su girişi hortumu ve şebeke suyu hat alma bağlantı elemanının

kurulumu:

(Eğer metal borunun yarıçapı 9mm' ye eşit veya daha küçük ise şebeke suyu hattı

cihaza ayrı olarak çekilmelidir.)

İlk olarak, su girişi solenoid vanasını kapatın. Metal hortumun vidasını

sökerek çıkartın. şebeke suyu hat alma bağlantı elemanını su arıtma

cihazınızın aksesuar kutusundan çıkartın ve şebeke suyu hat alma bağlantı

elemanının bir kenarını su girişi solenoid vanasının çıkışına vidalayın. Metal

borunun açıkta kalan kenarını da vidalı somun yardımı ile şebeke suyu

hat alma bağlantı elemanına bağlayın. (bkz. Diyagram 4)

• Şebeke suyu hat alma bağlantı elemanı ve su girişi küresel vanasının

kurulum yöntemi:

Su girişi küresel vanasını su arıtma cihazınızın aksesuar kutusundan

çıkartın. Su girişi küresel vanasınınbir ucunuuygun bir teon bantla sarın

(bkz. Diyagram 5) Eğer elinizde sıvı conta bulunuyorsa, yivlerin üzerine bir

miktar serpin ve küresel vanayı şebeke suyu hat alma bağlantı elemanının

ilgili boşluğuna vidalayın (bkz. Diyagram 5). Ø 9mm su borusunu

aksesuar kutusundan çıkartın. Makas yardımı ile uygun bir uzunlukta

boruyu kesip borunun bir ucunu su girişi küresel vanasına vidalayın (bkz.

Diyagram 6). Son olarak somunu sıkın.

Diyagram 4

Diyagram 5

Şebeke suyu

hat alma

bağlantı elemanı

Su girişi

küresel

vanası

Teon

bant

Su borusu

bağlantısı

Diyagram 6

9mm Küresel

vana

Şebeke suyu hat alma

bağlantı

elemanı

Page 36

TR 34

• Su Giriş Hortumu Kurulum Yöntemi :

Ürün kolisinden ¼” boyutundaki hortumu çıkarın ve uygun uzunlukta

makas ile kesin. Hortumun bir ucunu şebeke suyu hat alma bağlantı

elemanının giriş suyu kısmına takın (Diyagram 4) ve iyice vidalayın.

Giriş suyu hortumunun diğer ucunu da cihazın üstündeki “Giriş Suyu”

bağlantısına takın. Su sızıntılarının engellenmesi için hortumun sıkı bir

şekilde bağlantısının yapıldığına emin olun.

• Elektronik Musluk Kurulumu:

Elektronik musluğun kurulumunun yapılacağı tezgâh üzerinde uygun bir

noktaya φ20-35mm çapında bir delik delin. Daha sonra, musluğu su

arıtma cihazının aksesuar kutusundan çıkartın. Musluğun kurulumuna

başlayın (bkz. Diyagram 7).

A) Musluk Tabanı’nın Kurulumu: Kauçuk yastığı, metal yastığın içine

yerleştirin. 2 adet M4mm vidayı çıkarın. Metal yastık üzerindeki vida ile

metal yastığı musluk tabanına sabitleyin. Son olarak musluk bağlantısını,

musluk tabanının içinden geçirerek yukarı doğru çekin.

Musluk kablosunu plastik musluk tabanından, kauçuk yastıktan ve metal

yastıktan geçirerek çekin. Kauçuk yastığı ve metal yastığı bir arada tutun ve

M4mm vidaları çıkarın ve bir vidayı plastik musluk tabanından başlayarak

metal yastığa takın. Sonrasında plastik musluk tabanını musluk deliğine

yerleştirin ve yastıkları koyun. Diğer vidayı da yerleştirin ve her iki vidayı da

sabitleyerek sıkın.

Not: Vidaları birden çok sıkı sabitlemeyin, kurulum adım adım yapılmalıdır.

Kurulum esnasında aşırı güç uygulamayın.

B) Ana Gövde’nin Kurulumu: Uygun uzunlukta ¼” hortumu kesin.

Hortumun bir ucunu ana gövdenin altında yer alan yuvaya yerleştirin.

Hortumun diğer ucunu cihazın “Su Girişi” bağlantısına takın ve ana

gövdeyi, musluk tabanının üstüne yerleştirin.

C) Musluk Üst Borusu Kurulumu: Her üç O-ringin de musluk üst borusu

içinde yer alan O-ring yuvalarına yerleştiğinden emin olun.

• İkinci Su Çıkışı için Kurulum Yöntemi:

Lily su arıtma cihazı, elektronik musluğuna ek olarak ikinci bir su çıkışına

bağlanabilir. Bu işlem için standart ürün özelliği olan ve ürün kolisinde

bulunan “Dönüştürücü”nün bağlantısının yapılması gerekmektedir.

Bu şekilde cihaz, buzdolabı su çıkışına veya ikinci bir musluk çıkışına

bağlanabilecektir.

Su Çıkış Bağlantısı:

Cihazın arkasındaki “İçme suyu” çıkışına bağlanan hortumu Dönüştücü’nün

“IN” yazan çıkışına takın. Dönüştücü’nün “OUT” yazan çıkışına ise 3 yollu

bir Te takın. 3 Yollu Te çıkışının bir ucunu elektronik musluğa, diğer ucunu

ise diğer su çıkış bağlantısına takın (ikinci bir musluk veya buzdolabı çıkışı).

Elektrik Bağlantısı:

Dönüştürücü üstündeki 2 kablo soketinden birini elektronik musluğa,

diğerini ise cihazın bağlantısına takın.

Diyagram 7

Page 37

ENG 35

• Atık su tahliye borusunun kurulumu:

φ 6mm Matkap ucu kullanarak lavabo tahliye borusuna ufak bir delik

delin. Uygun ebatta 6mm su borusu alıp bir ucunu deldiğiniz deliğe

yerleştirin (bkz. Diyagram 8). Sızıntı olmasını engellemek için

6mm borunun ve tahliye borusunun birleştiği yere biraz sıvı conta sürün.

Tahliye borusunu atık su borusuna bağlamak için kablo kelepçesi

kullanın.Büyük su arıtma cihazları için; deldiğiniz tahliye borusu deliğinin

içerisine atık su kelepçesi takmanız gerekir. Su borusunun diğer ucunu

cihazın arkasındaki ''Atık Su'' yazan bağlantıya takın.

• Side-Stream RO Membran Kurulumu:

Kabinetin camlı ön kapağını açın. 3. Aşama RO Membran kabını 15°

eğip saatin tersi yönünde çevirerek yerinden çıkarın. Filtre kabı anahtarını

kullanarak membran kabı kapağını çıkarın. Kolinin içindeki RO membranı

paketinden çıkartın. Aşağıdaki şekildeki gibi (bkz. Diyagram 9) membranın

bir ucunda 2 adet büyük O-ring ve diğer ucunda da 2 adet büyük ve 4 adet

küçük O-ring bulunduğuna emin olun. Membranın düz tarafı aşağıya gelecek şekilde membran kabına yerleştirin, membran kabı kapağını yerine takın

ve ltre anahtarı ile kapağı sıkın. Membranı taktıktan sonra memran kabını

saat yönüne doğru çevirerek yerine takın ve 15° eğerek yerine oturtun.

• Membran Kurulum Uyarıları:

• Ters osmoz membranının paketinin içerisinde depolama ve nakliyat

sırasında mikrobiyolojik kirlenme olmasını engellemek için az miktarda

koruyucu solüsyon bulunmaktadır.

• Kurulum esnasında RO membranın yönüne dikkat etmelisiniz.

• RO membranın kurulumu esnasında membranın bir ucunda 2 adet

büyük O-ring ve diğer ucunda da 2 adet büyük ve 4 adet küçük O-ring

bulunduğuna emin olmalısınız.

• Kurulum esnasında ucunda 2 O-ring bulunan tarafı membran kabının

RO içme suyu bağlantısı bulunan tarafına yerleştiğinden emin olunuz.

Membranı, membran kabına yerleştirirken haf bir kuvvet uygulamanız

yeterli olacaktır. Eğer çok fazla dirençe karşılaşırsanız, lütfen membranı,

membran kabının içine girmesi için zorlamayın. Aksi halde membran

kabına veya membran bileşenlerine kalıcı zarar verebilirsiniz. A.O.Smith

Su Teknolojileri A.Ş. kurulum esnasında gerçekleşen hasarlar için

sorumluluk kabul etmemektedir.

• Yukarıda belirtilen sebeplerden dolayı membran kabına veya membran

bileşenlerine verilecek hasarlar su arıtma cihazınızın garantisi kapsamında

değildir.

• RO Membran kurulumu esnasında membran kabının altında bulunan gri

kauçuk braketin yerinde olduğuna emin olunuz.

• RO Membran mikroorganizmaları da ltre etme yeteneğine sahip

olduğundan, değiştirdiğiniz membran ltrelere kesici aletlerle müdahale

etmeyiniz ve açmayınız.

• Ön Filtrelerin Kurulumu:

1.aşama olan Sediment Filtre, 2. aşama olan Blok Karbon Filtre ve 4. aşama

olan Post Aktif Karbon Filtrelerin kurulumu için aşağıdaki adımları izleyiniz.

Kabinetin camlı ön kapağını açın. 1. 2. ve 4. aşama ltre kaplarını 15° eğip