A. O. Smith LB-500 Installation Manual

MODELS:

LB/LW-500, 750 AND 1000

SERIES 400/401

GAS-FIRED POWER BURNER COPPER BOILERS

FOR HYDRONIC HEATING AND HOT WATER SUPPLY

• INSTALLATION • OPERATION • MAINTENANCE • LIMITED WARRANTY

H

WARNING: If the information in this

manual is not followed exactly, a fire or

explosion may result causing property

damage, personal injury or loss of life.

— Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your

building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas

supplier, call the fire dep artment.

— Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

CAUTION

TEXT IN BLACK BOLD TYPE OR UNDERLINED CONT AINS

INFORMA TION RELATIVE T O YOUR SAFETY. PLEASE

READ THOROUGHL Y BEFORE INST ALLING AND USING

THIS APPLIANCE.

A DIVISION OF A.O. SMITH CORPORA TION

McBEE, SC RENTON, WA STRA TFORD, ONT ARIO

VELDHOVEN, THE NETHERLANDS

www.aosmithwaterheaters.com

PRINTED IN U.S.A. 1004

PLACE THESE INSTRUCTIONS ADJACENT TO BOILER AND

NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE

1

PART NO. 212107-000 REV. 00

Minimum clearances to combustibles:

• 4” (102 mm) rear

• 0” (0 mm) top & sides

• 6” (152 mm) vent

ROUGH-IN DIMENSIONS

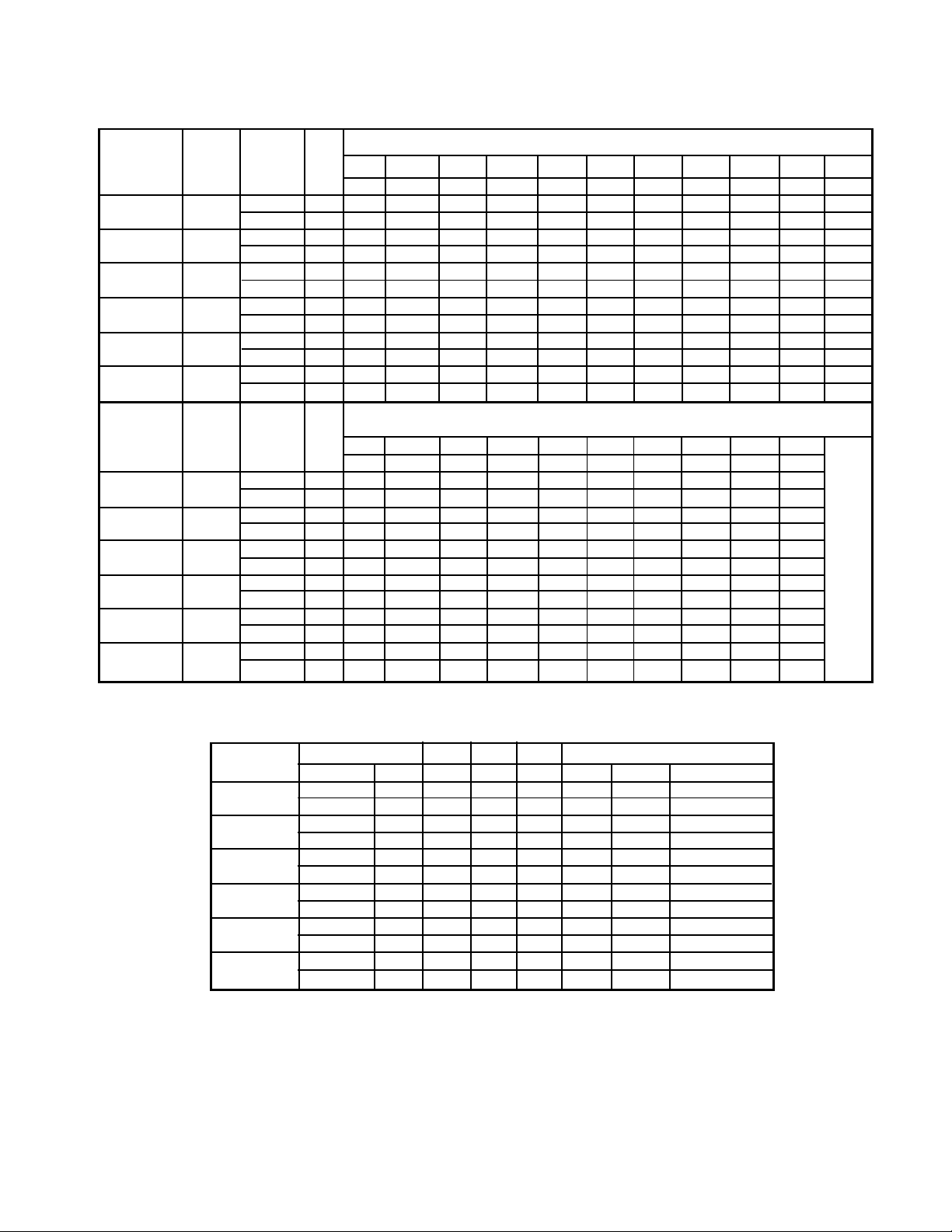

T ABLE 1, GAS AND ELECTRICAL CHARACTERISTICS

Manifold Pressure Maximum Supply Pressure Electrical Characteristics

Model Type of Gas Inches W.C. kP a Inches W.C. kPa Volts/Hz Amperes

LB/LW-500, 750, 1000 NATURAL 3.5 0.87 13.8 3.44 120/60 30

LB/LW-500, 750, 1000 PROP ANE 10 2.49 13.8 3.44 120/60 30

Minimum Supply Pressure, Natural Gas: 7.0 inches W.C. (1.74 kPa)

Minimum Supply Pressure, Propane Gas: 11.0 inches W.C. (2.74 kPa)

Minimum Pressures must be maintained under both load and no load (static and dynamic) conditions.

TABLE 2, ROUGH-IN DIMENSIONS

Models LB/LW-500 LB/LW-500 LB/LW-750 LB/LW-750 LB/LW-1000 LB/LW-1000

Gas Type Natural Gas Propane Gas Natural Gas Propane Gas Natural Gas Propane Gas

Dimensions inches m m inches m m inches m m inches mm inches m m inches m m

Exhaust Vent Diam. 6 152 6 152 6 152 6 152 7 178 7 178

Blower Inlet Diam. 4 102 4 102 4 102 4 102 6 152 6 152

A 53 1346 53 1346 53 1346 53 1346 60 1/2 1537 60 1/2 1537

B 23 584 23 584 23 584 2 3 584 27 1/8 689 27 1/8 689

C 32 813 32 813 32 8 13 32 813 38 3/16 9 70 38 3/16 970

D 13 1/2 343 13 1/2 343 13 1/2 343 13 1/2 343 13 3/4 349 13 3/4 349

E 4 3/8 111 4 3/8 111 4 3/8 111 - - 15 1/2 394 - F 3 1/4 83 3 1/4 8 3 3 1/4 83 - - 3 1/4 83 - -

G 6 3/8 162 6 3/8 162 6 3/8 16 2 6 3/8 162 8 1/8 206 8 1/8 206

H 7 1/2 191 7 1/2 191 7 1/2 1 91 7 1/2 191 8 1/4 210 8 1/4 210

J 3 1/2 89 3 1/2 89 3 1/2 89 3 1/2 89 3 1/2 89 3 1/2 89

K 19 483 19 483 19 483 19 483 36 914 36 914

L 14 1/2 359 14 1/2 359 11 1/4 286 11 1/4 286 12 318 12 318

M 5 127 5 127 5 127 5 127 6 3/4 171 6 3/4 171

N 5 1/4 133 5 1/4 133 5 1/4 1 33 5 1/4 133 4 1/8 105 4 1/8 105

P 11 1/2 292 11 1/2 292 11 1/2 292 11 1/2 292 13 3/8 340 13 3/8 340

Q 2 5 1 2 5 1 2 51 2 51 2 1/4 57 2 1/4 57

R 1 NPT 1 NPT 1 NPT - - 1 1/4 NPT - S ------11 3/4298--11 7/8302

T ------6 1/2165--7 5/8194

U ----- - 1NPT--1 1/4NPT

Approx. Shipping 425 lbs 193 Kg. 425 lbs 193 Kg. 528 lbs 240 Kg. 528 lbs 240 Kg. 934 lbs 424 Kg. 934 lbs 424 Kg.

Weight

2

ROUGH-IN DIMENSIONS (Continued)

TABLE 3, RECOVER Y CAP ACITIES

U.S. Gallons/Hr and Litres/Hr at TEMPERATURE RISE INDICATED

GAS INPUT F° 18F° 20F° 30F° 36F° 40F° 50F° 54F° 60F° 70F° 72F°

MODEL TYPE BTUH KW C° 10C° 11C° 17C° 20C° 22C° 28C° 30C° 33C° 39C° 40C°

LB/LW-500 Natural 500,000 GPH 3030 2727 1818 1515 1364 1091 1010 909 779 758

146 LPH 11471 10324 6882 5735 5162 4129 3824 3441 2950 2868

LB/LW-500 Propane 450,000 GPH 2727 2455 1636 1364 1227 982 909 818 701 682

132 LPH 10324 9291 6194 5162 4646 3716 3441 3097 2655 2581

LB/LW-750 Natural 750,000 GPH 4545 4091 2727 2273 2045 1636 1515 1364 1169 1136

220 LPH 17206 15485 10324 8603 7743 6194 5735 5162 4424 4301

LB/LW-750 Propane 675,000 GPH 4091 3682 2455 2045 1841 1473 1364 1227 1052 1023

198 LPH 15485 13937 9291 7743 6968 5575 5162 4646 3982 3871

LB/LW-1000 Natural 1,000,000 GPH 6061 5455 3636 3030 2727 2182 2020 1818 1558 1515

293 LPH 22941 20647 13765 11471 10324 8259 7647 6882 5899 5735

LB/LW-1000 Propane 860,000 GPH 5212 4691 3127 2606 2345 1876 1737 1564 1340 1303

252 LPH 19729 17757 11838 9865 8878 7103 6576 5919 5073 4932

U.S. Gallons/Hr and Litres/Hr at TEMPERATURE RISE INDICATED

GAS INPUT F° 80F° 90F° 100F° 108F° 110F° 120F° 126F° 130F° 140F°

MODEL TYPE BTUH KW C° 44C° 50C° 56C° 60C° 61C° 67C° 70C° 72C° 78C°

LB/LW-500 Natural 500,000 GPH 682 606 545 505 496 455 433 420 390

146 LPH 2581 2294 2065 1912 1877 1721 1639 1588 1475

LB/LW-500 Propane 450,000 GPH 614 545 491 455 446 409 390 378 351

132 LPH 2323 2065 1858 1721 1689 1549 1475 1429 1327

LB/LW-750 Natural 750,000 GPH 1023 909 818 758 744 682 649 629 584

220 LPH 3871 3441 3097 2868 2816 2581 2458 2382 2212

LB/LW-750 Propane 675,000 GPH 920 818 736 682 669 614 584 566 526

198 LPH 3484 3097 2787 2581 2534 2323 2212 2144 1991

LB/LW-1000 Natural 1,000,000 GPH 1364 1212 1091 1010 992 909 866 839 779

293 LPH 5162 4588 4129 3824 3754 3441 3277 3176 2950

LB/LW-1000 Propane 860,000 GPH 1173 1042 938 869 853 782 745 722 670

252 LPH 4439 3946 3551 3288 3228 2959 2818 2732 2537

TABLE 4, HEAD LOSS at FLOW RA TES/MINUTE and TEMPERA TURE RISE SHOWN

INPUT F° 18F° 20F° HEAD LOSS Boiler

MODEL BTUH KW C° 10C° 11.1C° Feet Metres Inlet & Outlet

LB/L W-500 500,000 G P M 50 45 10 2” N PT

Natural 146 LPM 189 172 3.0

LB/L W-500 450,000 G P M 45 41 8.4 2” N PT

Propane 132 LPM 170 155 2.6

LB/L W-750 750,000 G P M 75 68 10.1 2” N PT

Natural 220 LPM 284 258 3.1

LB/L W-750 675,000 G P M 67 61 8.7 2” N PT

Propane 198 LPM 255 232 2.7

LB/LW -1000 1,000,000 G P M 100 91 8.9 2” NPT

Natural 293 LPM 378 344 2.7

LB/LW -1000 860,000 G P M 86 78 6.7 2” NPT

Propane 252 LPM 325 296 2.0

The ideal flow rate through the Legend models is considered to be the flow rate that results in

a 20 F° temperature rise across the unit. Table 4, shows head loss through units at

flow rate resulting in 20 F° rise. For head loss at other flow rates see sheet E202.2 in

A.O. Smith Architect’s & Engineer’s Manual.

3

CONTENTS

Page

ROUGH-IN DIMENSIONS .............................................................. 2-3

FOREWORD .................................................................................. 4

Grounding Instructions ............................................................. 5

Inlet Water Considerations ........................................................5

Correct Gas ............................................................................. 5

Precautions .............................................................................. 5

Liquid Petroleum Models............................................................ 5

HIGH ALTITUDE INSTALLATIONS.................................................... 5

Field Installed Components ........................................................ 6

Panels and Covers ................................................................... 6

FEATURES / CONTROLS

Electronic Ignition Control .......................................................... 6

Hot Surface Ignitor.................................................................... 6

Blocked Flue Switch ................................................................. 6

Blower Prover Switch .............................................................. 7

Low Gas Switch ...................................................................... 7

Water Flow Switch................................................................... 7

Air Shutter................................................................................ 7

Blower Speed Control............................................................... 7

Combination Gas Control........................................................... 7

Manual Reset Limit (E.C.O.) ....................................................... 7

Automatic Reset Limit ............................................................... 7

On / Off Switch ........................................................................ 7

Circulating Pump ....................................................................... 8

T ank T emperature Control ......................................................... 8

Low Water Cutoff (not supplied) .............................................. 8

Drain V alve............................................................................... 8

Relief Valves ............................................................................ 8

INST ALLATION INSTRUCTIONS

Required Ability ........................................................................ 9

Location ................................................................................... 9

Chemical Vapor Corrosion ........................................................ 9

Installation Clearances .............................................................. 9

Leveling.................................................................................... 9

Air Requirements ...................................................................... 9

VENTING ..................................................................................... 10

Special Installation Considerations . ........................................ 11

Venting System Using AL 29-4C®........................................... 11

General Installation Requirements ........................................... 11

General Exhaust Vent Installation Procedure........................... 11

Connecting Vent to Boiler................................................... 11-13

Venting Supports.................................................................... 13

Vertical Installation Requirements............................................ 13

Horizontal Installation Requirements ...................................13-16

Direct Vent Installation Requirements ...................................... 16

SYSTEM INST ALLATION

General .................................................................................. 16

Page

Hot Water Heating (Hydronic) Equipment................................. 16

Internal Contaminants ............................................................. 17

Hot Water Supply System General Water Line Connections .... 17

Hard Water Conditions ............................................................ 19

Thermal Expansion (Closed System). ...................................... 19

T ank Probe Installation Procedure............................................ 19

T ank Probe Set-Point Adjustment ............................................ 19

GAS CONNECTIONS .................................................................... 19

Gas Supply Line Sizing ........................................................... 20

WIRING ........................................................................................ 20

SUGGESTED PIPE SIZING TABLES ............................................... 21

WIRING CONNECTION DIAGRAM .................................................. 22

SCHEMATIC DIAGRAM................................................................. 23

OPERATION ................................................................................. 24

General .................................................................................. 24

Filling and Purging for Heating Boiler Installation ...................... 24

Filling for Hot Water Supply Boiler Installation .......................... 24

Purging Gas Line .................................................................... 24

LIGHTING & OPERA TING INSTRUCTIONS ................................. 25-26

Inlet Gas Pressure .................................................................. 27

Manifold Pressure Connections .............................................. 27

Gas Pressure Regulators ....................................................... 27

Safety Checks........................................................................ 27

Water T emperature Regulation ................................................ 28

Sequence of Operation........................................................... 28

MAINTENANCE

Venting Maintenance .............................................................. 29

Burner and Flame Pattern ....................................................... 29

Burner Maintenance ............................................................... 30

Condensate Removal System ................................................. 30

DIA-SCAN II SELF-DIAGNOSTIC SYSTEM..................................... 30

Line Polarity Indicator.............................................................. 31

Fuse Protection ...................................................................... 31

Dia-Scan II Display Board

Operating Procedures ............................................................ 31

T emperature Set-Point Adjustment Procedure ......................... 32

Switching Differential Adjustment Procedure .......................... 32

Circulating Pump Adjustment Procedure .................................. 32

Display Current Mode ............................................................. 33

Display T otal Cycle Count........................................................ 33

T ank Probe T emp. Set-Point Adjustment Procedure.................. 33

Display Board LED Indicators .................................................. 34

TROUBLESHOOTING

Short Cycling .......................................................................... 34

Hard Starts............................................................................. 34

Troubleshooting Error Codes .................................................. 34

LIMITED WARRANTY ................................................................... 36

FOREWORD

This design complies with the latest edition of the ANSI Z21.13 CSA 4.9 low-pressure boiler standard.

Compliance under this standard implies that when the boiler

underwent test, the gas manifold and control assembly provided

on the boiler met safe lighting and other performance criteria.

Detailed installation diagrams are found in this manual. These

diagrams will serve to provide the installer a reference for the

materials and methods of piping necessary. It is essential that

all water, gas piping and wiring be installed as shown on the

diagrams. You should thoroughly read and understand this

manual before installation and/or operation of this boiler.

The factory warranty will be

improperly installed or operated.

®AL 29-4C is a registered trademark of Allegheny Ludlum Corporation.

void if the boiler(s) have been

In addition to these instructions, the boiler(s) shall be installed in

accordance with those installation regulations in force in the local

area where the installation is to be made. These shall be carefully

followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

In the absence of local codes, the installation must comply with

the latest editions, as follows:

In the United States:

The National Fuel Gas Code, ANSI Z223.1/NFPA 54and the

National Electric Code, NFPA 70.

In Canada:

The installation Code CAN/CSA B149.1-00 and the Canadian

Electric Code, CSA C22.2.

4

These are available from the Canadian Standards Association,

8501 East Pleasant Valley Road, Cleveland, OH 44131, USA, or,

Canadian Gas Association Laboratories, 55 Scarsdale Road,

Don Mills, Ontario M3B 2R3, Canada.

GROUNDING INSTRUCTIONS

This boiler must be grounded in accordance with the National

Electrical Code and/or local codes. Boiler is polarity sensitive,

correct wiring is imperative for proper operation.

with age. For these reasons, the use of a propane gas detector

is recommended.

IF YOU EXPERIENCE AN OUT OF GAS SITUA TION, DO NOT TRY

TO RELIGHT APPLIANCES YOURSELF. Call your local service

agent. Only trained LP professionals should conduct the required

safety checks in accordance with industry standards.

HIGH AL TITUDE INST ALLATIONS

This boiler must be connected to a grounded metal, permanent

wiring system, or an equipment grounding conductor must be

run with the circuit conductors and connected to the equipment

grounding terminal or lead on the boiler.

INLET WATER CONSIDERATIONS

T o minimize the amount of condensate, a minimum inlet water

temperature to the heat exchanger of 140°F (60°C) shall be

maintained. This temperature can be acquired by returning 140°F

(60°C) water from the remote storage tank to the boiler or by

incorporating a by-pass loop between the boiler’s inlet and outlet

connections.

Circulating water through the boiler and to the remote storage

tank (if applicable) is accomplished by a built-in pump on LW

models only. For hot water heating systems using the LB model,

the circulating pump is NOT provided and must be field installed.

CORRECT GAS

MAKE SURE THE GAS ON WHICH THE BOILER WILL OPERA TE

IS THE SAME AS THAT SPECIFIED ON THE BOILER RATING

PLATE. DO NOT INSTALL THE BOILER IF EQUIPPED FOR A

DIFFERENT TYPE OF GAS — CONSUL T YOUR SUPPLIER.

PRECAUTIONS

IF THE UNIT IS EXPOSED TO THE FOLLOWING , DO NOT OPERA TE

UNTIL ALL CORRECTIVE STEPS HAVE BEEN MADE BY A

QUALIFIED SERVICEMAN:

1. EXPOSURE TO FIRE.

2. IF DAMAGED.

3. FIRING WITHOUT WA TER.

4. SOOTING.

IF THE BOILER HAS BEEN EXPOSED TO FLOODING , IT MUST BE

REPLACED.

LIQUID PETROLEUM MODELS

Boilers for propane or liquefied petroleum gas (LPG) are different

from natural gas models. A natural gas boiler will not function

safely on LP gas and no attempt should be made to convert a

boiler from natural gas to LP gas.

LP gas must be used with great caution. It is highly explosive

and heavier than air. It collects first in the low areas making its

odor difficult to detect at nose level. If LP gas is present or even

suspected, do not attempt to find the cause yourself. Leave the

building, leaving doors open to ventilate, then call your gas

supplier or service agent. Keep area clear until a service call has

been made.

At times you may not be able to smell an LP gas leak. One cause

is odor fade, which is a loss of the chemical odorant that gives LP

gas its distinctive smell. Another cause can be your physical

condition, such as having a cold or diminishing sense of smell

WARNING

INSTALLATIONS ABOVE 2000 FEET (600 M) REQUIRE

REPLACEMENT OF THE BURNER ORIFICE IN ACCORDANCE

WITH SECTION 8.2.1 OF THE NATIONAL FUEL GAS CODE (ANSI

Z223.1). FAILURE TO REPLACE THE ORIFICE WILL RESUL T IN

IMPROPER AND INEFFICIENT OPERA TION OF THE APPLIANCE

RESUL TING IN THE PRODUCTION OF INCREASED LEVELS OF

CARBON MONOXIDE GAS IN EXCESS OF SAFE LIMITS WHICH

COULD RESULT IN SERIOUS PERSONAL INJURY OR DEA TH.

Ratings specified by manufacturers for most appliances apply

for elevations up to 2000 feet (600 m). For elevations above 2000

feet (600 m), ratings must be reduced at the rate of 4% for each

1000 feet (300 m) above sea level. For example, if a boiler is

rated at 500,000 Btu/hr. at sea level, to rate the boiler at 4000 feet

(1200 m), the original rating is reduced by 16 percent (4 x 4%) to

a rating of 420,000 Btu/hr.

The input reduction is primarily achieved by reducing the size of

the main burner orifice. T o do this, the main burner orifices require

replacement with an orifice sized for the particular installation

elevation. Part number for gas orifices for altitudes up to 4000

feet (1220 m) are given in Table 5. Orifices for higher altitudes

are special order and may be obtained from A. O. Smith Water

Products Company. When ordering, be sure to state the model

number and the altitude of the location where the boiler is installed.

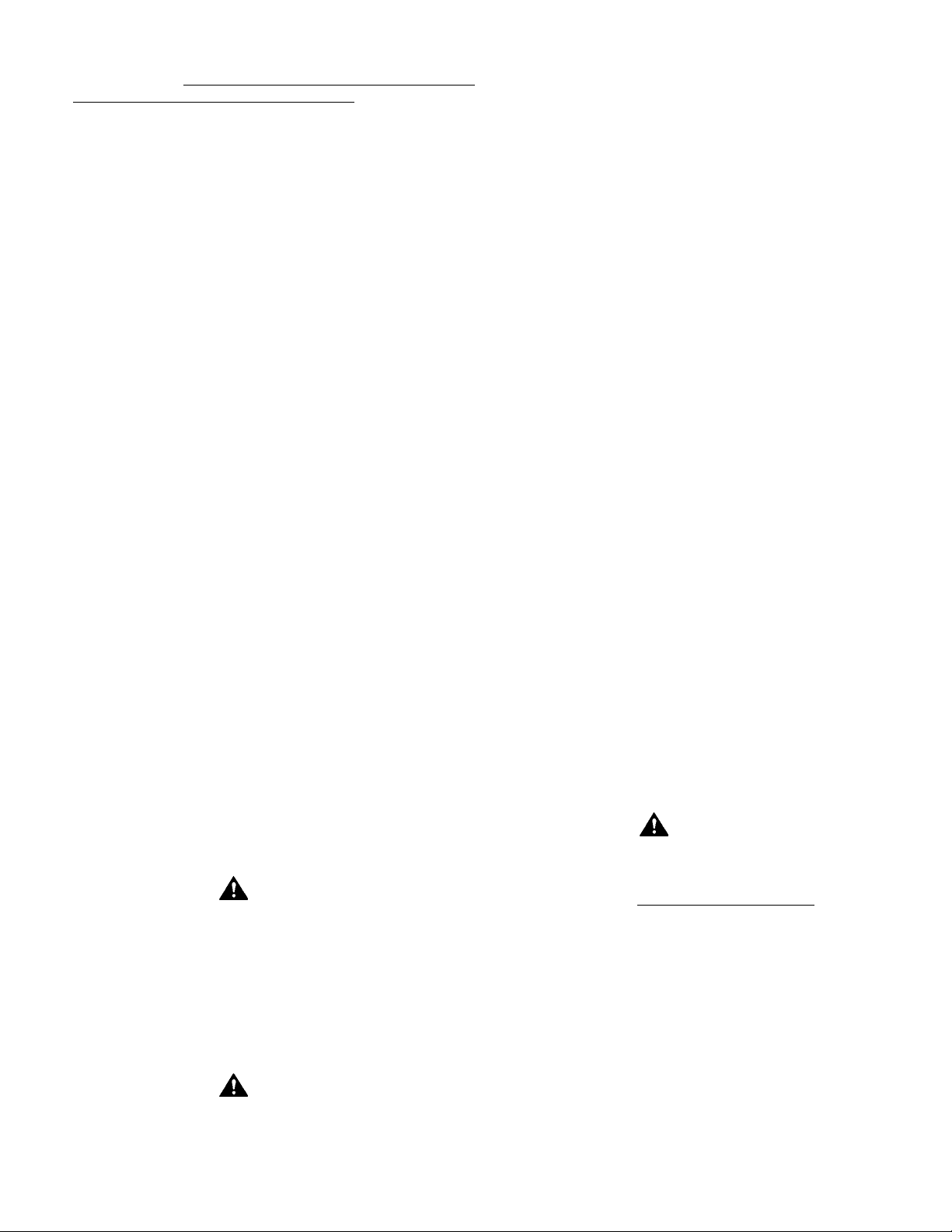

TABLE 5. LEGEND 2000 ORIFICE T ABLE

Natural Gas Propane Size Elevation

Model Part No. Part No. (In.) (Ft.)

LB/LW-500 *191884-0 — 0.391 0-2000

LB/LW-500 191884-1 — 0.384 2001-3000

LB/LW-500 191884-2 — 0.374 3001-4000

LB/LW-500 — 192741-0 0.229 0-2000

LB/LW-500 -- 192741-1 0.226 2001-3000

LB/LW-500 -- 192741-2 0.223 3001-4000

LB/LW-750(USA) *191884-3 -- 0.484 0-2000

LB/LW-750(USA) 191884-5 -- 0.469 2001-3000

LB/LW-750 USA 191884-7 -- 0.461 3001-4000

LB/LW-750 CAN *191884-11 -- 0.464 0-2000

LB/LW-750 CAN 191884-12 -- 0.450 2001-3000

LB/LW-750 CAN 191884-13 -- 0.443 3001-4000

LB/LW-750 -- 192741-3 0.286 0-2000

LB/LW-750 -- 192741-4 0.282 2001-3000

LB/LW-750 -- 192741-6 0.278 3001-4000

LB/LW-1000 *192222-0 -- 0.555 0-2000

LB/LW-1000 192222-1 -- 0.537 2001-3000

LB/LW-1000 192222-2 -- 0.533 3001-4000

LB/LW-1000 -- *192739-0 0.333 0-2000

LB/LW-1000 -- 192739-1 0.329 2001-3000

LB/LW-1000 -- 192739-2 0.325 3001-4000

*Factory installed orifice.

Upon completion of derating of the boiler, adjustment to the gas

pressure regulator may be required. See GAS PRESSURE

REGULATORS in this manual for inlet and manifold pressure

requirements.

Also, due to the input rating reduction required at high altitudes,

the output rating of the appliance is also reduced and should be

compensated for in the sizing of the equipment for applications.

5

NOTE: Some gas utility companies derate their gas for altitude,

making it unnecessary to install high altitude orifices. Call the

local gas utility company to verify BTU content.

FIELD INSTALLED COMPONENTS

When installing the boiler, the following components MUST be

used, if applicable:

1) Circulating Pump (Hydronic)

2) Tank Temperature Control (Hot Water Supply)

3) Loop Temperature Control (Hydronic)

4) Low Water Cutoff Device

5) Relief Valve

6) Pressure Gauge

7) Manual Gas Shutoff Valve (Supply)

Check the FEATURES AND CONTROLS section for further

information.

system monitors the burner flame through the principle of flame

rectification. If a flame is not verified, the gas valve is immediately

closed.

FIGURE 2. FIGURE 3.

FIGURE 1.

P ANELS AND COVERS

All panels and covers (e.g. control and junction box covers; front,

side and rear panels of boiler) MUST be in place after service

and/or before operation of the boiler. This will ensure that all gas

ignition components will be protected from water.

NOTE: Remove the two (2) sheet metal screws from the rear of

the top cover and discard them, see fig 1. This will allow removal

of the top cover without the use of tools. Also, remove the sheet

metal screw from the bottom of the front panel.

FEATURES/CONTROLS

The Legend 2000® is a low-pressure boiler (Category IV) to be

used as either hot water supply (domestic/commercial water

heating) or hot water heating (hydronic) application. Category IV

boilers operate with a positive vent pressure and with a vent gas

temperature less than 140°F (60°C) above its dew point. Category

IV appliances are often termed “High Efficiency” appliances.

The control board provides a pre-purge period of twenty (20)

seconds and a post-purge period of twenty-five (25) seconds.

The flame establishing period is four (4) seconds.

This control is non-adjustable. Any attempts to modify the

performance, other than those listed in this manual, voids the

control warranty.

The 24 VAC circuitry of the ignition control system is protected

with a 3-amp fuse. If the fuse opens, a red LED located near the

fuse will light.

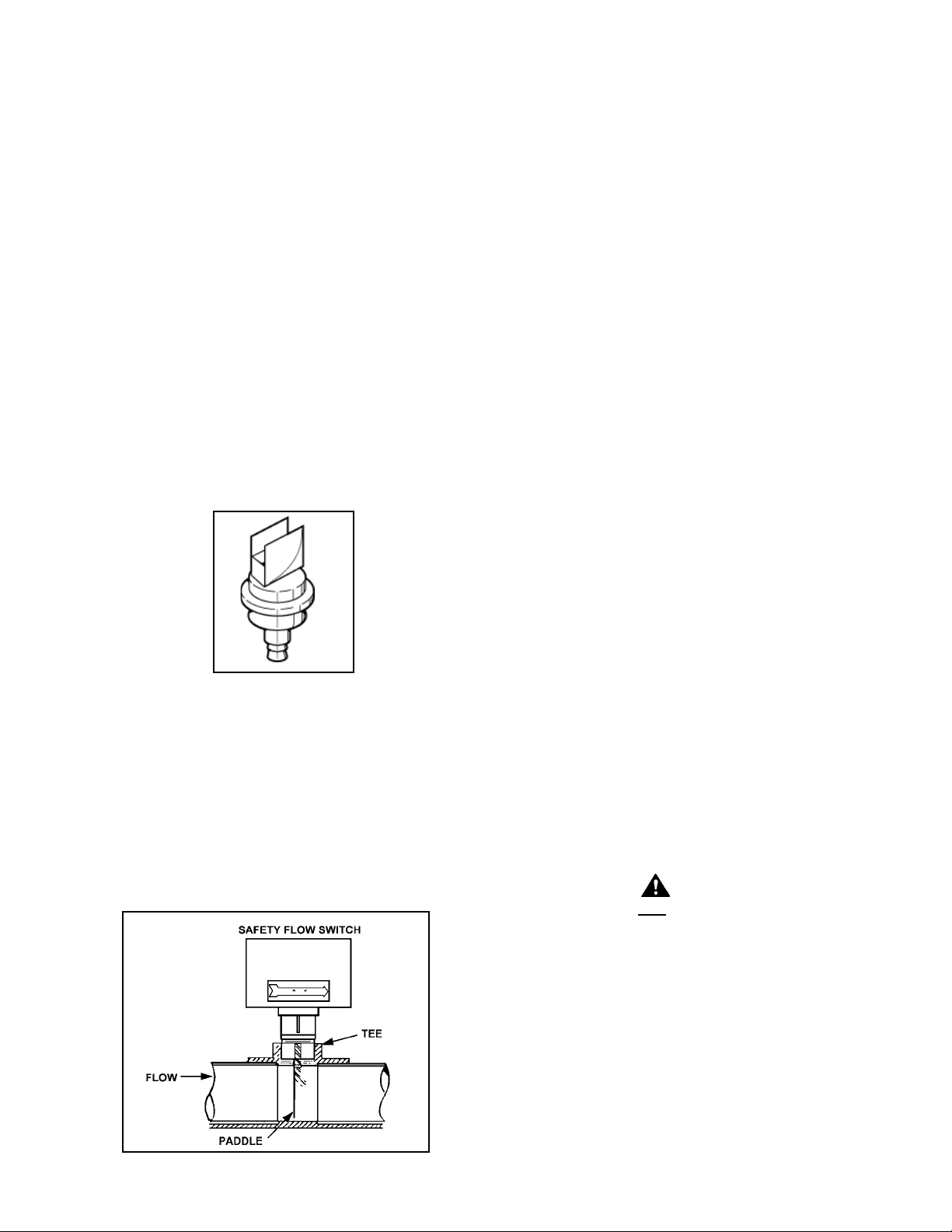

HOT SURFACE IGNITOR

The Hot Surface Igniter, fig. 3, is a device that ignites the main

burner by high temperature (>1800°F) [982°C]. The igniter is

made of recrystallized silicon carbide, and when 120 VAC is

applied to the igniter, sufficient heat is generated to ignite the

main burner. Although improvements have been made to

strengthen the igniter, it is still fragile and care must be taken in

handling the igniter to prevent breakage.

This high efficiency is obtained from a unique heat exchanger

design consisting of multiple integral high-finned copper tubes

brazed in parallel into two brass manifolds. The condensate

from the heat exchanger flows downward into the vent collector

housing then into the plastic condensate drain and through the

attached flexible hose which must terminate at a suitable floor

drain.

ELECTRONIC IGNITION CONTROL

The Legend 2000® is controlled by the WHC 1502 ignition system,

fig. 2. The WHC 1502 is a solid-state ignition control that ignites

the main burner by energizing the Hot Surface Ignitor, fig. 3. The

ignition control system continuously monitors the current of the

ignitor and will not allow gas to enter the main burner until current

flow reaches the preset ignition temperature threshold. Once

the ignition threshold has been reached, the control system will

open the gas valve(s). After the main burner ignites, the control

FIGURE 4.

BLOCKED FLUE SWITCH

The Blocked Flue Switch (BFS) fig. 4, is a single-pole, normally

closed pressure switch that will open its contacts when a rising

positive pressure of 1.0 in. w.c. (0.25 kPa) is encountered. The

contacts will close when the pressure falls below the fixed set

point of 1.0 in. w.c. (0.25 kPa) The BFS monitors the pressure

inside the venting system. If the venting system is blocked in

such a way that the build up in pressure exceeds the setting of

6

the BFS, the main burner is extinguished (if boiler is running) or

the boiler will not start up.

BLOWER PROVER SWITCH

The Blower Prover Switch (BPS) fig. 4, is similar in construction

to the BFS. It is a single-pole, normally open pressure switch

that will close its contacts when a rising positive pressure of

1.0 in. w.c. (0.25 kPa) is encountered. The contacts will open

when the pressure falls below the fixed set point of 1.0 in. w.c.

(0.25 kPa) The BPS monitors the pressure inside the blower

elbow. If the blower is not operating at a sufficient blowing cap acity ,

the main burner is extinguished (if boiler is running) or the boiler

will not start up.

LOW GAS SWITCH

The Low Gas Switch (LGS) fig. 5, is a single-pole, normally open

pressure switch that will close its contacts when a rising pressure

of 5.0 in. w.c. (1.24 kPa) is encountered. The contacts will open

when the pressure falls below the fixed set point of 5.0 in. w.c.

(1.24 kPa) The LGS monitors the gas supply pressure to the

boiler. If the gas supply falls below 5.0 in. w.c. (1.24 kPa), the

main burner is extinguished (if boiler is running) or the boiler will

not start up.

AIR SHUTTER

The blower is equipped with an air shutter assembly for fine

adjustment of the air to gas ratio The assembly consists of a

shutter flange and the air shutter. The shutter may require

adjustment to achieve ideal start-up characteristics when fine tuning

the boiler for correct combustion specifications. Refer to the

Start-Up Procedures, part number 192077 Rev. 1, for the proper

combustion specifications and limits. If necessary, the shutter

may be adjusted by loosening the two nuts used to hold the shutter

and blower adapter assembly in place on the inlet of the blower.

Once the unit is set to the specifications called for in the Start-Up

Procedures, tighten the nuts to lock the shutter in place.

BLOWER SPEED CONTROL

The Blower Speed Control (BSC) permits variation of speed of

the blower during boiler (LB/LW-500 only) start-up. When the

1502 Control Board energizes the igniter, the BSC will lower the

speed (RPM) of the blower to a preset level. This lower speed

will be maintained until the igniter is de-energized by the Control

Board. Then, the blower will return to its normal operating speed.

COMBINATION GAS CONTROL

The Combination Gas Control (CGC) is a gas valve or valves that

controls the supply of gas to the main burner during operation of

the boiler. The CGC includes a manual main shutoff valve, two

(2) automatic valves and a pressure regulator, see figure 15.

FIGURE 5. LOW GAS SWITCH (LGS)

WATER FLOW SWITCH

The Water Flow Switch (WFS) fig. 6, is installed at the boiler water

outlet to prevent main burner operation in the event of inadequate

water flow through the boiler. The WFS is a single-pole, normally

open switch that will close its contacts when an increasing water

flow rate of approximately 25 GPM (1.61 lps) is encountered. The

contacts will open when the flow rate drops below this setting,

extinguishing the main burner flames (if boiler is running) or the

boiler will not start up .

The two-position gas control knob has “ON” and “OFF” positions

that allows or prevents the flow of gas to the main burner,

respectively. The first automatic valve is solenoid operated and

opens and closes when the main valve terminal on the Control

Board is energized or de-energized, respectively. The second

automatic valve is diaphragm operated and opens under control

of the pressure regulator and closes if gas or power supply is

interrupted. The pressure regulator is adjustable and maintains

an almost constant gas outlet pressure under wide fluctuations

in gas supply pressure.

MANUAL RESET LIMIT (E.C.O)

This device prevents the water temperature from exceeding 250°F

(121°C). It is located in the outlet waterway within the outlet

temperature sensing device and is monitored by the Control

Board. Commonly referred to as the “emergency cut out”, it is a

manually resettable control. The “ADJUST”, “SELECT” or

“ENTER/RESET” button on the display board must be depressed

to reset the unit if the water temperature reaches this limit. See

figure 20.

CAUTION

LIMIT CONTROLS ARE NOT TO BE USED AS A THERMOST A T OR

OPERA TING CONTROL.

AUTOMATIC RESET LIMIT

This limit is a safety device in series with the ignition system. Set

the limit control to a minimum of 30°F (16°C) above the maximum

designed system temperature. If the boiler outlet water

temperature should exceed the automatic reset limit setting, the

main gas valves will close. The automatic reset limit control is

factory set at 180°F (82°C) and has an adjustable range from

110 to 240°F (43° to 116°C). The operating differential is also

adjustable from 5 to 50°F (3° to 28°C).

FIGURE 6. WA TER FLOW SWITCH (WFS)

ON/OFF SWITCH

The ON/OFF Switch is a single-pole, single-throw rocker switch.

This switch provides 120V from the line source to the boiler.

7

CIRCULATING PUMP

DRAIN V AL VE

HOT WA TER SUPPLY SYSTEMS, the circulating pump is integral

to the LW models. This pump has been lubricated at the factory,

and future lubrication should be in accordance with the motor

manufacturer’s instructions provided as a supplement to this

manual.

FOR HOT WA TER HEA TING SYSTEMS-LB MODELS, the circulating

pump is NOT provided and must be obtained and installed in the

field.

NOTE: I f a system pump is to be installed on a Legend LB

model, the maximum rating of the pump motor must

not exceed 1 hp.

TANK TEMPERATURE CONTROL

A tank probe is provided with LW models to be used for tank

temperature regulations. The temperature setting for the tank is

set through the display.

Refer to figs. 7, 13, 14 and 16 for connecting the tank probe to the

boiler.

See TEMPERATURE SET POINT ADJUSTMENT PROCEDURE

for further instructions.

FOR HOT WA TER SUPPLY SYSTEMS, the boiler is supplied with

a Tank Probe to be field installed in the storage tank. Alternate

methods of temperature control, if desired, must be supplied by

the installer.

A change in water temperature in the storage tank lower than the

Tank Temperature Control setting will cause the sensor to close

its contacts and consequently, energize the boiler.

If the Tank Probe or Temperature Control is out of calibration,

replace it with a new one; do not attempt to fix this control.

A drain valve is factory installed in the heat exchanger manifold.

This will help to drain the heat exchanger.

Additional drain valves must be obtained and installed on each

boiler and tank for draining purposes, see figures 12, 13 and 14.

SAFETY RELIEF V AL VE

Your local code authority may have other specific safety relief

valve requirements not covered below.

WARNING

THE PURPOSE OF A SAFETY RELIEF VALVE IS TO AVOID

EXCESSIVE PRESSURE OR TEMPERA TURE INTO THE STEAM

RANGE WHICH MA Y CAUSE SCALDING AT FIXTURES, TANK

EXPLOSION, SYSTEM OR BOILER DAMAGE.

TO A VOID SCALDING OR W ATER DAMAGE, A DRAIN LINE MUST

BE CONNECTED TO A SAFETY RELIEF VALVE TO DIRECT

DISCHARGE TO A SAFE LOCATION. A DRAIN LINE MUST NOT BE

REDUCED FROM THE SIZE OF THE VAL VE OUTLET AND IT MUST

NOT CONTAIN ANY V AL VES BETWEEN THE BOILER AND THE

RELIEF VA LVE OR THE RELIEF V AL VE AND THE DRAIN EXIT . IN

ADDITION, THERE SHOULD NOT BE ANY RESTRICTIONS IN A

DRAIN LINE NOR SHOULD IT BE ROUTED THROUGH AREAS

WHERE FREEZING CONDITIONS MIGHT OCCUR. DO NOT THREAD

OR CAP THE DRAIN LINE EXIT . RESTRICTING OR BLOCKING A

DRAIN LINE WILL DEFEAT THE PURPOSE OF THE SAFETY RELIEF

V ALVE AND MA Y CREA TE AN UNSAFE CONDITION. INST ALL A

DRAIN LINE WITH A DOWNWARD SLOPE SUCH THA T IT WILL

NATURALL Y DRAIN ITSELF .

If any pressure relief valve is replaced, the replacement valve

must comply with the latest version of the ASME Boiler and

Pressure Vessel Code, Section IV (“HEATING BOILERS”).

NOTE: If you are using an L W model in a hydronic (space heating)

application, do not use the tank probe as a loop temperature

regulation device. The tank probe’s maximum setting is

190°F (88°C). Therefore, 24 VAC connections (red/green wires)

are provided in the rear junction box for an alternate device. The

J33 board jumper must be removed to use a 24 VAC temperature

regulation device (See figures 21 and 22).

LOW WATER CUTOFF (Not Supplied)

If low water protection is required by the authorities having

jurisdiction, a low water cutoff switch should be installed next to

the boiler in the outlet water line as shown in figure 12. The

switch should receive periodic (every six months) inspection to

assure proper operation. A Low Water Cutoff device of the float

type should be flushed every six months.

Encase field-supplied wires

between tank probe and junction

box with 1/2" field supplied

conduit. "Pigtails" of fieldsupplied wires should be spliced

to "pigtails" of tank probe and

connected to 24V AC junction box.

This conduit and wiring should be

separate from any other conduit/

wiring to guard against EMI

(electromagnetic interference).

FIGURE 7. TANK PROBE INST ALLA TION

Select a relief valve with a discharge rating NOT LESS than the

boiler input, and a set pressure NOT EXCEEDING the working

pressure of any component in the system.

FOR HOT WATER SUPPLY SYSTEMS, the boilers are shipped

with a 125 psi (860 kPa) pressure relief valve that must be installed

in the water outlet as near to the boiler as possible.

This ASME-rated valve has a discharge capacity that exceeds the

maximum boiler input rating and a pressure rating that does not

exceed the maximum working pressure shown on the boiler rating

plate.

In addition, a CSA design-certified and ASME-rated temperature

and pressure (T & P) relief valve must be installed on each and

every water storage tank in the hot water supply system.

8

The T & P relief valve must comply with the applicable construction

provisions of the

Shutoff Devices for Hot Water Supply Systems, ANSI Z21.22-1999

or CAN/CSA-B149.1-00, or most recent edition. The T & P relief

valve must be of the automatic reset type and not embody a singleuse type fusible plug, cartridge or linkage.

The T & P relief valve should have a temperature rating of 210°F

(99°C), a pressure rating NOT exceeding the lowest rated working

pressure of any system component, and a discharge capacity

exceeding the total input of the water boilers supplying water to

the storage tank.

Locate the T & P relief valve (a) in the top of the tank, or (b) in the

side of the tank on a centerline within the upper 6 inches (152

mm) of the top of the tank. See figures 13 and 14. The tapping

shall be threaded in accordance with the latest edition of the

Standard for Pipe Threads, General Purpose (inch), ANSI/ASME

B1.20.1. The location of, or intended location for, the T & P relief

valve shall be readily accessible for servicing or replacement.

Standard for Relief Valves and Automatic Gas

If the boiler is installed above radiation level, a Low Water Cutoff

Device must be installed in the boiler outlet at the time of

installation.

CHEMICAL VAPOR CORROSION

Water boiler corrosion and component failure can be caused by

the heating and breakdown of airborne chemical vapors. Spray

can propellants, cleaning solvents, refrigerator and air

conditioning refrigerants, swimming pool chemicals, calcium and

sodium chloride (water softener salt), waxes, and process

chemicals are typical compounds which are potentially corrosive.

These materials are corrosive at very low concentration levels

with little or no odor to reveal their presence.

Products of this sort should not be stored near the boiler. Also,

air which is brought in contact with the water boiler should not

contain any of these chemicals. If necessary, uncontaminated

air should be obtained from remote or outside sources. Failure

to observe this requirement will void the warranty.

FOR HOT WATER HEATING SYSTEMS, the boilers are shipped

with a 50 psi (345 kPa) pressure relief valve. This relief valve

must be installed in the water outlet as near to the boiler as

possible.

INST ALLA TION INSTRUCTIONS

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS BOILER REQUIRES

ABILITY EQUIV ALENT T O THAT OF A LICENSED TRADESMAN

IN THE FIELD INVOL VED. PLUMBING, AIR SUPPLY, VENTING,

GAS SUPPLY AND ELECTRICAL WORK ARE REQUIRED.

LOCATION

When installing the boiler, consideration must be given to proper

location. The location selected should provide adequate air

supply and be as centralized with the piping system as possible.

THE BOILER MUST NOT BE INSTALLED ON CARPETING.

THE BOILER SHOULD NOT BE LOCATED IN AN AREA WHERE IT

WILL BE SUBJECT TO FREEZING .

LOCATE IT NEAR A FLOOR DRAIN. THE BOILER SHOULD BE

LOCATED IN AN AREA WHERE LEAKAGE FROM THE BOILER OR

CONNECTIONS WILL NOT RESULT IN DAMAGE TO THE

ADJACENT AREA OR TO LOWER FLOORS OF THE STRUCTURE.

WARNING

THERE IS A RISK IN USING FUEL BURNING APPLIANCES SUCH

AS BOILERS IN ROOMS OR AREAS WHERE GASOLINE, OTHER

FLAMMABLE LIQUIDS OR ENGINE DRIVEN EQUIPMENT OR

VEHICLES ARE STORED, OPERATED OR REPAIRED.

FLAMMABLE VAPORS ARE HEAVY AND TRA VEL ALONG THE

FLOOR AND MA Y BE IGNITED BY SP ARKS CAUSING FIRE OR

EXPLOSION. SOME LOCAL CODES PERMIT OPERA TION OF GAS

APPLIANCES IF INSTALLED 18 INCHES (457 MM) OR MORE

ABOVE THE FLOOR. THIS MA Y REDUCE THE RISK IF LOCATION

IN SUCH AN AREA CANNOT BE A VOIDED.

WARNING

FLAMMABLE ITEMS, PRESSURIZED CONTAINERS OR ANY

OTHER POTENTIAL FIRE HAZARDOUS ARTICLES MUST NEVER

BE PLACED ON OR ADJACENT TO THE BOILER. OPEN

CONTAINERS OR FLAMMABLE MATERIAL SHOULD NOT BE

STORED OR USED IN THE SAME ROOM WITH THE BOILER.

INST ALLATION CLEARANCES

This boiler is approved for installation on combustible flooring in

an alcove with minimum clearances to combustibles of:

4" (102 mm) Rear; 0" (0 mm) Top and Sides; 6" (152 mm) Vent.

Two inch (51 mm) clearance is allowable from combustible

construction for hot water pipes.

Sufficient area should be provided at the front and rear of the unit

for proper servicing. Service clearances of 24" (610 mm) in front,

rear, top and left side are recommended. In a utility room

installation, the door opening shall be wide enough to allow the

boiler to enter or to permit the replacement of another appliance

such as a water heater.

LEVELING

Each unit should be checked after installation to be certain that it

is level.

If the unit is not level, obtain and insert shims under the nylon

protective feet at the frame base to correct this condition.

AIR REQUIREMENTS

WARNING

FOR SAFE OPERA TION, AN AMPLE SUPPL Y OF AIR MUST BE

PROVIDED FOR PROPER COMBUSTION AND VENTILA TION IN

ACCORDANCE WITH SECTION 8.3, AIR FOR COMBUSTION AND

VENTILA TION, OF THE

OR SECTION 7.4 OF CSA-B149.1-00 OR APPLICABLE

PROVISIONS OF THE LOCAL BUILDING CODES. AN INSUFFICIENT

SUPPL Y OF AIR WILL RESULT IN A YELLOW , LUMINOUS BURNER

FLAME, CAUSING CARBONING OR SOOTING OF THE FINNED HEAT

EXCHANGER AND CREA TING A RISK OF ASPHYXIATION. DO NOT

OBSTRUCT THE FLOW OF COMBUSTION AND VENTILA TION AIR.

UNCONFINED SPACE

In buildings of conventional frame, brick or stone construction,

unconfined spaces may provide adequate air for combustion.

If the unconfined space is within a building of tight construction

(buildings using the following construction: weather stripping,

heavy insulation, caulking, vapor barrier, etc.), air for combustion,

ventilation and draft hood dilution must be obtained from outdoors

9

NATIONAL FUEL GAS CODE, ANSI Z223.1

or spaces freely communicating with the outdoors. The

installation instructions for confined spaces in tightly constructed

buildings must be followed to ensure adequate air supply.

CONFINED SPACE

Where power vented equipment is used in the same room as the

boiler, sufficient air openings must be supplied.

UNDERSIZED OPENINGS MAY RESULT IN INSUFFICIENT AIR

FOR COMBUSTION.

A. U.S. INSTALLA TIONS

When drawing combustion and dilution air from inside a

conventionally constructed building to a confined space, such a

space shall be provided with two permanent openings, ONE IN

OR WITHIN 12 INCHES (305 MM) OF THE ENCLOSURE TOP

AND ONE IN OR WITHIN 12 INCHES (305 MM) OF THE

ENCLOSURE BOTTOM. Each opening shall have a free area of

at least one square inch per 1000 Btu/hr (2,225 mm

the total input of all appliances in the enclosure, but not less than

100 square inches (645 cm

2

).

2

per kw) of

If the confined space is within a building of tight construction, air

for combustion, ventilation and draft hood dilution must be

obtained from outdoors. When directly communicating with the

outdoors or communicating with the outdoors through vertical

ducts, two permanent openings, located in the aforementioned

manner, shall be provided. Each opening shall have a free area

of not less than one square inch per 4000 Btu/hr (551 mm

2

per

kw) of the total input of all appliances in the enclosure. If horizontal

ducts are used, each opening shall have a free area of not less

than one square inch per 2000 Btu/hr (1,101 mm

2

per kw) of the

total input of all appliances in the enclosure.

B. CANADIAN INST ALLATIONS

Ventilation of the sp ace occupied by the boiler(s) shall be provided

by an opening for ventilation air at the highest practical point

communicating with outdoors. The total cross-sectional area

shall be at least 10% of the area of the combustion air opening

but in no case shall the cross-sectional area be less than

10 square inches (6500 mm

2

).

In addition to the above, there shall be permanent air supply

opening(s) having a cross-sectional area of not less than 1 square

inch per 7,000 BTUH (315 mm

BTUH

plus 1 square inch per 14,000 BTU (158 mm2/kW) in

2

/KW) up to and including 1,000,000

excess of 1,000,000 BTUH. This opening(s) shall be located at,

or ducted to, a point neither more than 18” (457 mm) nor less

than 6 inches (152 mm) above the floor level.

Where an exhaust fan is installed in the same room with the

boiler, sufficient openings for air must be provided in the walls.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRA WN INTO

THE ROOM THROUGH THE CHIMNEY OR OTHER OPENINGS,

CAUSING POOR COMBUSTION. SOOTING MA Y RESUL T WITH

AN INCREASED RISK OF ASPHYXIA TION.

VENTING

WARNING

THE INSTRUCTIONS IN THIS SECTION ON VENTING THE BOILER

MUST BE FOLLOWED TO AVOID CHOKED COMBUSTION OR

RECIRCULATION OF FLUE GASES. SUCH CONDITIONS CAUSE

SOOTING OR RISKS OF FIRE AND ASPHYXIATION.

VENT SIZING , INST ALLA TION AND TERMINA TION SHALL BE IN

ACCORDANCE WITH THIS INST ALLA TION MANUAL.

ALL ELECTRICAL POWER AND GAS MUST BE TURNED OFF

PRIOR TO ANY INSTALLA TION OF THE VENTING SYSTEM.

SPECIAL INST ALLATION CONSIDERA TIONS

The Legend 2000® is listed as a Category IV appliance and utilizes

a mechanical forced draft system. The vent system shall be

designed to prevent leakage of flue gases and condensate. The

condensate must be allowed to flow to a suitable drain. Since

the condensate is known to be detrimental to conventional vent

materials (galvanized steel, some stainless steels), the vent

material for the boiler’s exhaust shall be approved and certified

for the venting of low temperature condensing flue gasses. AL

®

is one such material.

29-4C

The exhaust gases of this boiler are generally only 15°-20°F (8°C

to 11°C) higher than the boiler’s operating temperature, much

lower than a standard boiler. In cold climates any water vapor

remaining in the flue gases will condense into a cloud of vapor at

the point where the vent system exits the building. Special

FIGURE 8. SIDEWALL EXHAUST VENTING

10

consideration is recommended, before locating the vent

termination near walkways, windows and building entrances.

Direct venting into dead spaces such as; alleys, atriums and

inside corners can cause recirculation of flue gases. Recirculation

of flue gases will cause sooting, premature failure of the heat

exchanger and icing of the combustion air intake during severe

cold weather. To prevent the recirculation of flue gases, maintain

as much distance as possible between the combustion air intake

and the exhaust vent terminal. Due to large volumes of flue gases,

multiple boiler applications also require additional distance

between the intake and exhaust terminals.

VENTING SYSTEM USING AL 29-4C

®

The LEGEND 2000® may be installed in four separate orientations

depending on the requirements of the building and the appliance.

The installer must decide which method is most appropriate for

each installation. These orientations are:

1. Vertical Termination — vertical vent termination through un-

enclosed or enclosed areas with roof penetration, see fig. 9.

2. Through-the-Wall Termination (TWT) — horizontal vent

termination directly through an outside wall, see figure 9A.

3. Direct Vent — using TWT to exhaust flue products and PVC

piping to bring combustion air to the boiler from the outside,

see figures 11 and 11C.

4. Vertical Direct Vent — using a vertical vent termination to

exhaust flue products and PVC piping to bring combustion air

to the boiler from outside, see figures 11A and 11B.

GENERAL INST ALLA TION REQUIREMENTS

COMMOM VENTING LEGEND BOILERS.

Common venting of multiple Legend boilers are not allowed

except with either a U.L. or CSA approved power venter.

• All the vent pipe(s) and power venter must be sized by and

installed as per the recommendations of the power venter

manufacturer. Please see boiler’s wiring label for electrical

hook-up of power venter to the ignition control.

• When multiple Legend boilers are connected using a common power venter and common power venter and common

vent pipe; the power venter and vent piping should be sized to

maintain a -0.0 IWC to -0.04 IWC draft in the common vent

downstream of the boilers, when any one of or all boilers are

firing. A positive pressure of +.02 IWC to =.05 IWC should be

seen 12" above the boot tee of each unit when the unit is firing.

• All Venting material must be AL29-4C venting material.

• A factory start-up of the engineered power venting system must

be preformed by an authorized factory start-up agent of the

power venter system manufacturer.

• To assure proper boiler and power venter operation, both the

power venter start-up and A.O. Smith Authorized boiler start-up

must be performed simultaneously.

1. Failure to conform with any of these requirements may violate

local, state/provincial or federal codes as well as create

conditions which may cause catastrophic property damage or

personal injury . The vent system must terminate so that proper

clearances are maintained as cited in local codes or the latest

edition of the National Fuel Gas Code, ANSI Z223.1 or

CSA-B149.1-00 and latest addenda. The vent system must

not have external runs greater than that allowed by local codes

or the National Fuel Gas Code.

2. AL 29-4C® sections and fittings MUST be used for the entire

length of the exhaust system; alternatives such as galvanized

pipe, PVC, CPVC or Type B Vent sections must

3. Install a AL 29-4C

®

drain fitting as close as possible to the

not be used.

boiler vent connector outlet. See “CONNECTING VENT TO

BOILER” on the installation of this drain fitting.

4. Horizontal runs of vent pipe shall be securely supported by

adequately placed (approximately every 6 feet [2 m])

non-combustible hangers and/or slip joints suitable for the

weight and design of the material employed to prevent sagging

and to maintain a minimum upward slope of 1/4" per foot (21

mm) from the boiler to the vent terminal (see “VENTING

SUPPORTS” and figures 9A and 11).

The upward slope allows any build up of condensate to flow

back towards the boiler and drain fitting preventing the

accumulation of condensate. See “CONNECTING VENT TO

BOILER.”

EXCEPTION: The vent connector on the boiler is sloped

downward to direct condensate towards the “field-installed”

drain fitting.

5. All joints in the venting system MUST be sealed with RTV 106

or equivalent sealant.

6. NO other appliances may be interconnected to any part of this

venting system, including vent connectors which serve

appliances vented by NATURAL DRAFT.

7. The venting system must be planned so as to avoid possible

contact with concealed plumbing or electrical wiring inside

walls.

8. The venting system must be planned to maintain an airspace

clearance from combustibles of at least 6 inches (152 mm)

®

for any conduit and fittings of single wall AL 29-4C

vent and at

least 4 inches (102 mm) for any conduit and fittings of double

wall AL 29-4C® vent. Double wall AL 29-4C® vent must be

used when penetrating any floors, walls or ceilings and any

penetration must be properly fire stopped. All insulation

material must be removed from any wall, floor or ceiling cavity

for at least 4 inches (102 mm) from the conduit.

9. The venting system in a multi-family structure must be planned

to be enclosed when passing through occupied or unoccupied

spaces above the connected boiler. This enclosure is to be of

materials no less fire resistant than surrounding floors and

walls. It is recommended that the system be enclosed

whenever passing through occupied spaces.

GENERAL EXHAUST VENT INST ALLA TION PROCEDURE

Prior to beginning the installation of the vent system, determine

and obtain all parts required for the installation. Refer to the

DIRECT VENT KIT PAR TS LIST (p art no. 192109), for a list of the

vent sections and fittings.

Proper operation of the boiler and venting system is dependent

upon use of all specified parts and installation techniques; both

safety and proper performance of the system may suffer if

instructions are not followed.

CONNECTING VENT TO BOILER

At the outlet of the boiler vent, see figure 10, the AL 29-4C® Vent

Boot-T ee and Boot-Tee Drain Cover must be used as the transition

from the horizontal to vertical run. This is where the bottom most

support bracket should be located.

11

Loading...

Loading...