A. O. Smith GDVH-40 Installation Manual

GAS W A TER HEA TERS

OWNER'S MANUALRESIDENTIAL

DIRECT VENT

Thank you for buying this energy efficient water heater from

A.O. Smith Water Products Comp any. We appreciate your

confidence in our products.

You should thoroughly read this manual before installation

and/or operation of this water heater . Please pay particular

attention to the important safety and operating instructions

as well as the WARNINGS and CAUTIONS.

GAS MODELS

GDVH/GDVS/XDVS

TABLE OF CONTENTS

............................................................................. PAGE

GET TO KNOW YOUR W A TER HEA TER ......................2

GENERAL SAFETY INFORMA TION .............................3

INSTALLATION ......................................................... 3-19

OPERATION ............................................................. 19-21

MAINTENANCE AND

TROUBLESHOOTING .............................................. 21-23

WARRANTY................................................................. 24

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS

INFORMA TION RELATIVE TO YOUR SAFETY. PLEASE READ

THOROUGHLY BEFORE INSTALLING AND USING THIS

APPLIANCE.

A DIVISION OF A.O. SMITH CORPORATION

www.aosmithwaterheaters.com

KEEP THIS MANUAL IN THE POCKET ON HEA TER FOR FUTURE REFERENCE

WHENEVER MAINTENANCE ADJUSTMENT OR SERVICE IS REQUIRED.

PRINTED IN U.S.A. 0106 P ART NO. 184961-001

1

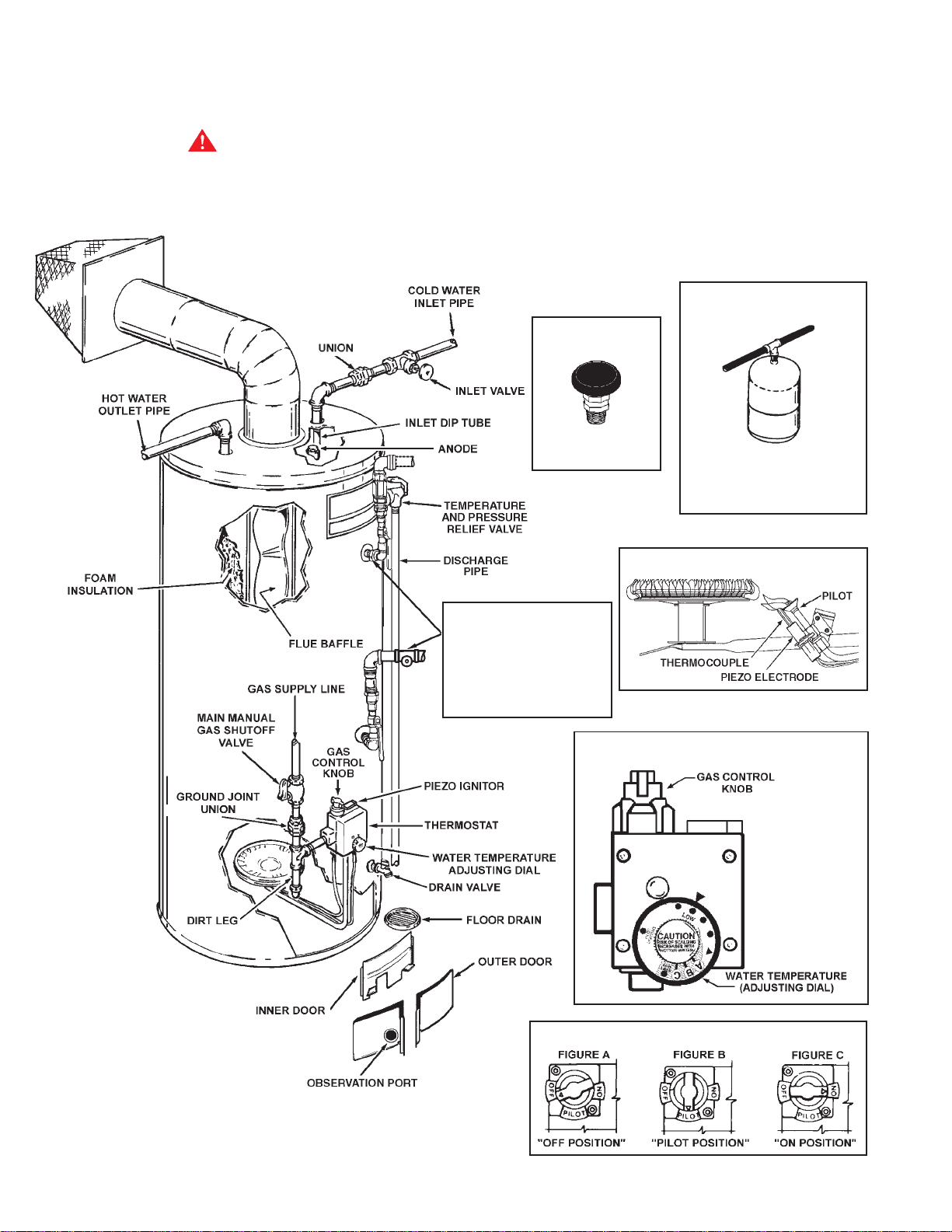

GET TO KNOW YOUR WATER HEATER

TYPICAL INST ALLATION

WARNING

DO NOT A TTEMPT TO OPERA TE W A TER HEATER WITH COLD

WA TER INLET VAL VE CLOSED.

REPLACEMENT P ARTS

Replacement parts may be ordered through authorized

servicers or distributors. Refer to the Yellow Pages for where to

call or contact A. O. Smith Water Products Company, 500

Tennessee Waltz Parkway, Ashland City, TN 37015,

1-800-433-2545. When ordering parts, provide complete

model and serial numbers (see rating plate), quantity and

name of part desired (as listed in Figure 1). Standard

hardware items may be purchased locally.

THERMAL

EXPANSION T ANK

V ACUUM RELIEF

VALVE

INSTALL PER LOCAL

CODES.

INSTALL THERMAL EXP ANSION

TANK IF WATER HEATER IS

INSTALLED IN A CLOSED

SYSTEM.

(DO NOT CAP OR PLUG)

CERTAIN MODELS ARE

EQUIPPED WITH SIDE

PLUMBING CONNECTIONS

FOR SPACE HEA TING. THE

HOT AND COLD FITTING

ASSEMBLIES (PART #900126-2)

CAN BE ORDERED THROUGH

THE MANUFACTURER.

GAS PILOT & MAIN BURNER

THERMOST AT

ALL PIPING MATERIALS TO BE

SUPPLIED BY CUSTOMER.

GAS CONTROL

FIGURE 1

2

GENERAL SAFETY

INFORMATION

EXTERNAL DAMAGE

Do not operate the water heater until it has been fully checked out

by a qualified technician, if the water heater:

• Has been exposed to fire or damage.

• Displays evidence of sooting.

• Produces steam or unusually hot water.

combustion, resulting in fire, asphyxiation, serious personal

injury or death.

•

Do not cover the outer door, thermostat or temperature &

pressure relief valve.

•

Do not cover the instruction manual. Keep it on the side of the

water heater or nearby for future reference.

•

Do obtain new warning and instruction labels from A.O. Smith

for placement on the blanket directly over the existing labels.

INST ALLATION

If the water heater has been flooded it must be replaced.

CHEMICAL V APOR CORROSION

WARNING

CORROSION OF THE FLUEWAYS AND VENT SYSTEM MAY

OCCUR IF AIR FOR COMBUSTION CONTAINS CERTAIN

CHEMICAL VAPORS. SUCH CORROSION MAY RESULT IN

FAILURE AND RISK OF ASPHYXIA TION.

Spray can propellants, cleaning solvents, refrigerator and air

conditioning refrigerants, swimming pool chemicals, calcium

and sodium chloride (water softener salt), waxes and process

chemicals are typical compounds which are potentially corrosive.

Do not store products of this sort near the heater. Also, air which is

brought in contact with the heater should not contain any of these

chemicals. If necessary, uncontaminated air should be obtained

from remote or outside sources. The limited warranty is voided

when failure of water heater is due to a corrosive atmosphere.

(Refer to the limited warranty for complete terms and conditions).

EXTENDED NON-USE PERIODS

WARNING

HYDROGEN GAS CAN BE PRODUCED IN A HOT WATER

SYSTEM SERVED BY THIS HEA TER THA T HAS NOT BEEN USED

FOR A LONG PERIOD OF TIME (GENERALLY TWO WEEKS OR

MORE).

reduce the risk of injury under these conditions, it is

recommended that the hot water faucet be opened for several

minutes at the kitchen sink before using any electrical appliance

connected to the hot water system. If hydrogen is present, there

will probably be an unusual sound such as air escaping through

the pipe as the water begins to flow.

SMOKING OR OPEN FLAME NEAR THE F AUCET A T THE TIME IT

IS OPEN.

HYDROGEN GAS IS EXTREMELY FLAMMABLE. To

THERE SHOULD BE NO

INSULA TION BLANKETS

Insulation blankets available to the general public for external use

on gas water heaters are not necessary with A. O. Smith product s.

The purpose of an insulation blanket is to reduce the standby

heat loss encountered with storage tank water heaters. Your

A. O. Smith water heater meets or exceeds the National Appliance

Energy Conservation Act standards with respect to insulation and

standby loss requirements, making an insulation blanket

unnecessary.

WARNING

Should you choose to apply an insulation blanket to this heater,

you should follow these instructions (See Figure 1 for

identification of components mentioned below). Failure to follow

these instructions can restrict the air flow required for proper

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS WATER HEATER

REQUIRES ABILITY EQUIVALENT TO THAT OF A LICENSED

TRADESMAN IN THE FIELD INVOLVED. PLUMBING, AIR

SUPPL Y, VENTING AND GAS SUPPLY ARE REQUIRED.

INSPECT SHIPMENT

There may be hidden damage caused in transit. Check to be

certain all parts of the venting system, as listed below, are present.

CAUTION!!! IF THERE ARE ANY DAMAGED PARTS, DO NOT

INSTALL THIS W A TER HEA TER. REPORT ANY SHORT AGE TO

YOUR DISTRIBUTOR OR DAMAGE TO YOUR CARRIER.

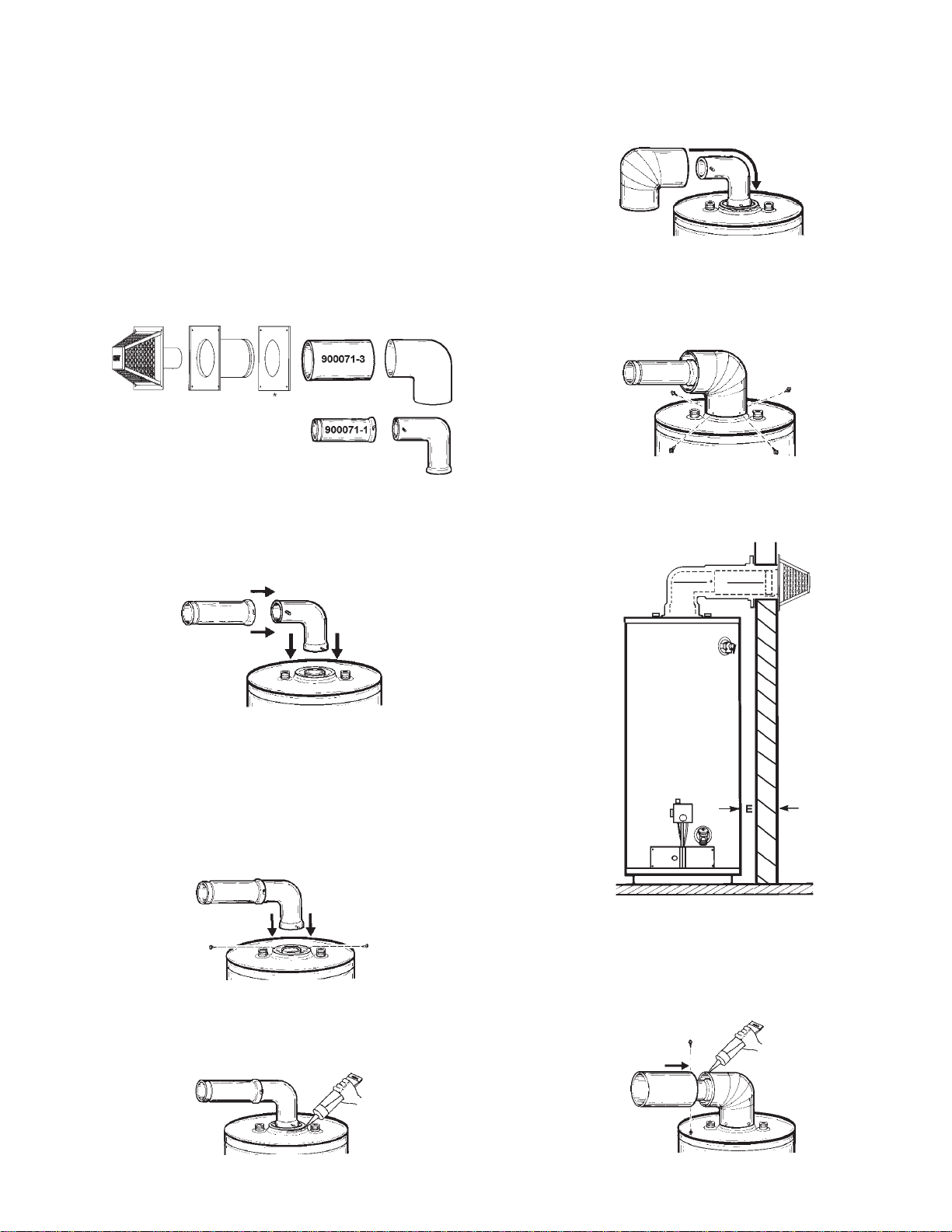

VENT KIT ASSEMBL Y COMPONENTS

1 3” 90° elbow 1 Finishing collar (inside)

1 6” 90° elbow 1 Finishing collar (outside)

1 3” tube 1 Terminal Vent Cap Assembly

1 6” tube 1 Tube silicone sealant

GENERAL

The installation must conform to these instructions and the local

code authority having jurisdiction. In the absence of local codes,

the installation must comply with the current editions of the

National Fuel Gas Code, ANSI Z223.1/NFPA 54. The code is

available from the Canadian Standards Association, 8501 East

Pleasant Valley Road, Cleveland, OH 44131.

FACTS T O CONSIDER ABOUT THE LOCA TION

You should carefully choose an indoor location for the new water

heater, because the placement is a very important consideration

for the safety of the occupants in the building and for the most

economical use of the appliance. This water heater is not for use

in manufactured (mobile) homes or outdoor installation.

Whether replacing an old water heater or putting the water heater

in a new location, the following critical points must be observed.

When installing the heater, consideration must be given to proper

location. The water heater should be located as close to or

centralized to the water piping system as possible. The water

heater should be located in an area not subject to freezing

temperatures.

THE HEATER SHOULD BE LOCATED IN AN AREA WHERE

LEAKAGE OF THE T ANK OR CONNECTIONS WILL NOT RESUL T IN

DAMAGE TO THE AREA ADJACENT TO THE HEA TER OR TO LOWER

FLOORS OF THE STRUCTURE. When such locations cannot be

avoided, a suitable drain pan should be installed under the heater.

Such pans should have a minimum length and width of at least 2

3

inches greater than the diameter of the heater and should be piped to

an adequate drain. Drain pans suitable for these heaters are

available from your dealer or A. O. Smith Water Products Company,

500 Tennessee Waltz Parkway, Ashland City, TN 37055. Contact us at

our website: www.aosmithwaterheaters.com,phone: 800.433.2545,

or fax: 1.800.433.2515.

Water heater life depends upon water quality, water pressure

and the environment in which the water heater is installed.

Water heaters are sometimes installed in locations where

leakage may result in property damage, even with the use of a

drain pan piped to a drain. However, unanticipated damage

can be reduced or prevented by a leak detector or water shut-off

device used in conjunction with a piped drain pan. These

devices are available from some plumbing supply

wholesalers and retailers, and detect and react to leakage in

various ways:

• Sensors mounted in the drain pan that trigger an alarm or

turn off the incoming water to the water heater when leakage

is detected.

• Sensors mounted in the drain pan that turn off the water

supply to the entire home when water is detected in the

drain pan.

• Water supply shut-off devices that activate based on the

water pressure differential between the cold water and hot

water pipes connected to the water heater.

WARNING

DO NOT INSTALL THIS WATER HEATER DIRECTLY ON A

CARPETED FLOOR. A FIRE HAZARD MA Y RESUL T.

Instead the

water heater must be placed on a metal or wood panel extending

beyond the full width and depth by at least 3 inches (76.2mm) in

any direction. If the heater is installed in a carpeted alcove or

closet, the entire floor shall be covered by the panel.

Refer to Figure 1 for typical installation. A suitable pipe thread

sealant must be used to prevent leakage.

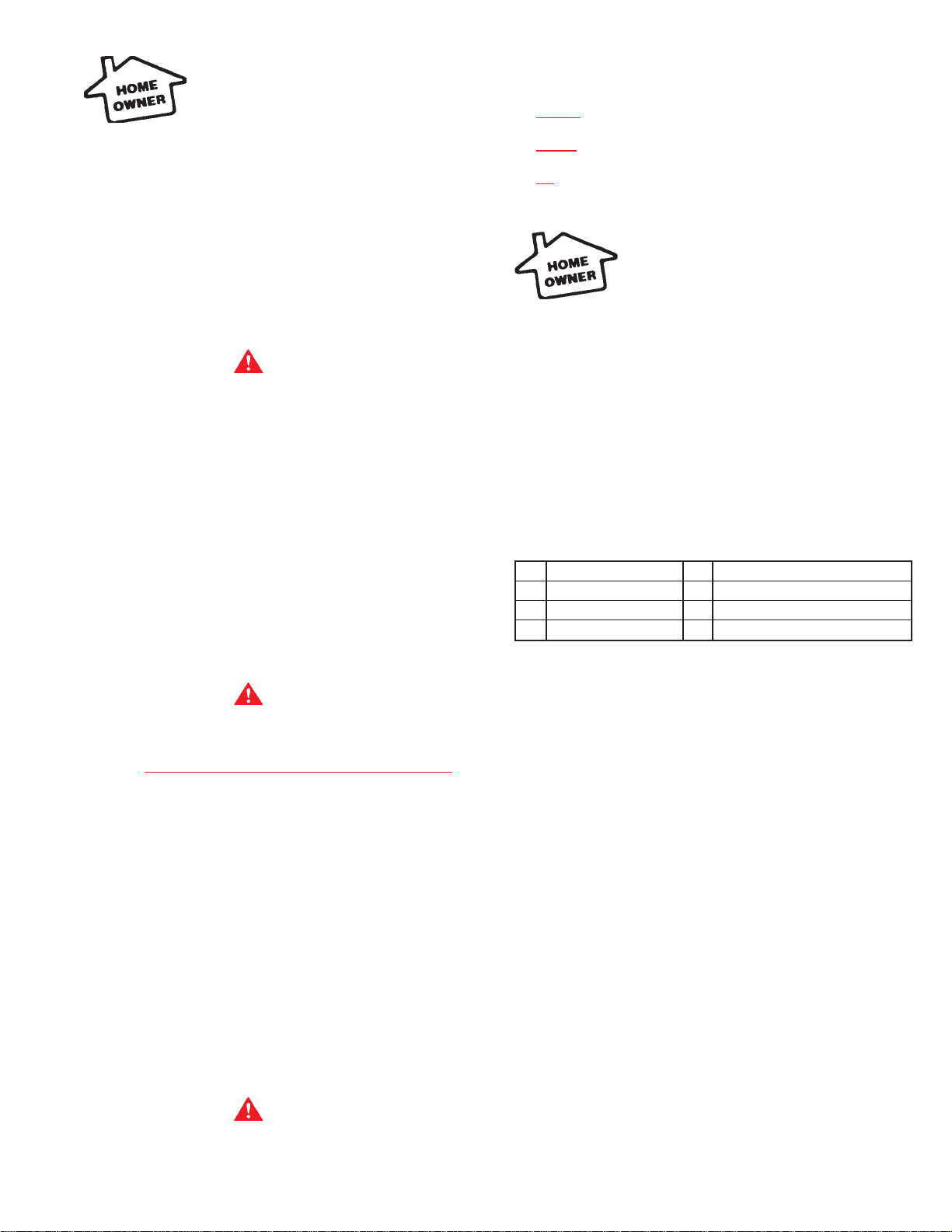

WA TER (POT ABLE) HEA TING AND SP ACE HEA TING

1. All piping components connected to this unit for space heating

applications shall be suitable for use with potable water.

2. Toxic chemicals, such as those used for boiler treatment, shall

NEVER be introduced into this system.

3. This unit may NEVER be connected to any existing heating

system or component(s) previously used with a non-potable

water heating appliance.

4. When the system requires water for space heating at

temperatures higher than required for domestic water

purposes, a tempering valve must be installed, see Figure 2

for suggested piping arrangement.

• Devices that will turn off the gas supply to a gas water heater

while at the same time shutting off its water supply.

Under no circumstances is the manufacturer to be held liable for

any water damage in connection with this water heater.

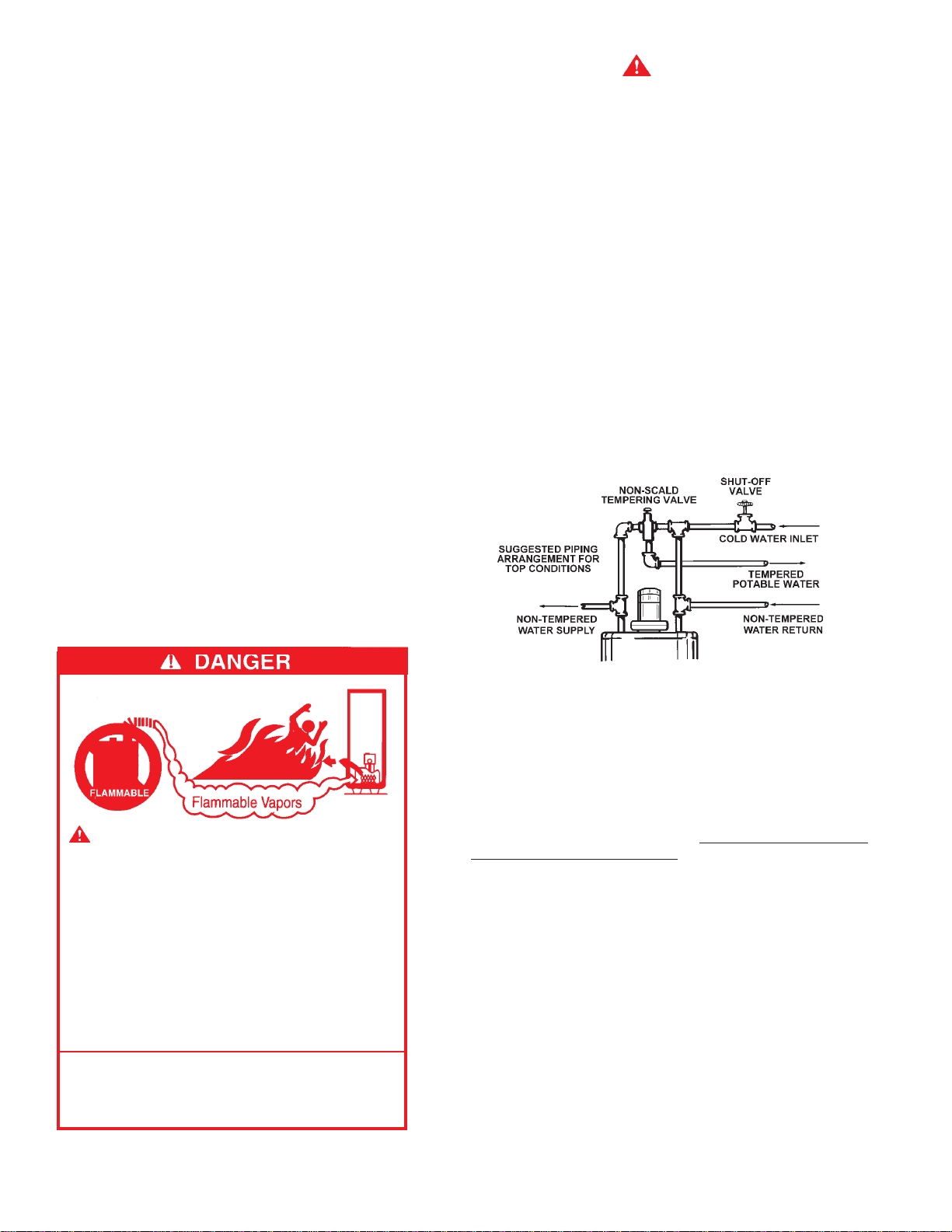

Vapors from flammable

liquids may explode and catch

fire causing death or severe

burns.

Do not use or store flammable

products such as gasoline,

solvents or adhesives in the same

room or area near the water heater.

Keep flammable products:

1. far away from heater,

2. in approved containers,

3. tightly closed and

4. out of children’s reach.

Installation:

Do not install water heater where

flammable products will be stored

or used unless the main burner

and pilot flames are at least 18”

Water heater has a main burner

and pilot flame. The pilot flame:

1. is on all the time and

2. will ignite flammable vapors.

Vapors:

1. cannot be seen,

2. are heavier than air,

3. go a long way on the floor

and

4. can be carried from other

rooms to the pilot flame by

air currents.

above the floor. This will

reduce, but not eliminate the

risk of vapors being ignited by

the main burner or pilot flame.

The location selection must provide adequate clearances for

servicing and proper operation of the water heater.

FIGURE 2

CLOSED WATER SYSTEM

A closed system will exist if a back-flow preventer (check valve),

pressure reducing valve, or other similar device is installed in the

cold water line between the water heater and the street main (or

well). Excessive pressure may develop due to the thermal

expansion of heated water causing premature tank failure or

intermittent relief valve operation.

This type of failure is not

covered by the limited warranty. An expansion tank may be

necessary in the cold water supply to alleviate this situation, see

Figure 1. Contact the local plumbing authority.

If the temperature and pressure relief valve on the appliance

discharges periodically, this may be due to thermal expansion in a

closed water supply system. Contact the water supplier or local

plumbing inspector on how to correct this situation.

DO NOT

PLUG THE TEMPERA TURE AND PRESSURE RELIEF V AL VE.

GAS CONNECTIONS

The minimum gas supply pressure for input adjustment is 5.0”

W.C. (1.2 kPa) for natural gas and 11.0” W.C. for propane gas.

THE HEATER IS NOT INTENDED FOR OPERA TION AT HIGHER

THAN 10.5” WATER COLUMN (2.6 kPa) SUPPLY PRESSURE.

EXPOSURE TO HIGHER GAS SUPPL Y PRESSURE MA Y CAUSE

DAMAGE TO THE CONTROL WHICH COULD RESULT IN FIRE

OR EXPLOSION.

improper testing of gas lines or emergency malfunction of the

supply system, the control must be checked for safe operation.

4

If over-pressure has occurred such as through

Make sure that the outside vents on the supply regulators and the

safety vent valves are protected against blockage. These are

parts of the gas supply system not the heater. Vent blockage may

occur during ice storms.

IT IS IMPORTANT TO GUARD AGAINST CONTROL FOULING

FROM CONTAMINANTS IN THE GAS WAYS. SUCH FOULING

MAY CAUSE IMPROPER OPERA TION, FIRE OR EXPLOSION.

All piping must comply with local codes and ordinances or with

the current edition of National Fuel Gas Code (ANSI Z223.1/

NFPA-54) whichever applies.

REFER TO FIGURE 1 FOR CONNECTION DETAILS. BEFORE

ATTACHING THE GAS LINE BE SURE THAT ALL GAS PIPE IS

CLEAN ON THE INSIDE.

TO TRAP ANY DIRT OR FOREIGN MATERIAL IN THE GAS

SUPPLY LINE, A DIRT LEG (SOMETIMES CALLED DRIP LEG)

MUST BE INCORPORA TED IN THE PIPING, FIGURE 1. The dirt

leg must be readily accessible. Install in accordance with

recommendations of serving gas supplier. Refer to the latest

edition of the National Fuel Gas Code ANSI Z223.1.

To prevent damage, care must be taken not to apply too much

torque when attaching gas supply pipe to thermostat gas inlet.

The thermostat inlet has a pad for use with a backup wrench.

Apply joint compounds (pipe dope) sparingly and only to the male

threads of pipe joints. Do not apply compound to the first two

threads. Use compounds resistant to the action of liquefied

petroleum gases. Do not use teflon tape on thermostat fittings.

DISCONNECT THE APPLIANCE FROM THE GAS SUPPLY

PIPING SYSTEM DURING ANY SUPPLY PRESSURE TESTING

EXCEEDING 1/2 PSI (3.5 kPa). GAS SUPPLY LINE MUST BE

CAPPED WHEN DISCONNECTED FROM THE HEATER. FOR

TEST PRESSURES AT 1/2 PSI (3.5 kPa) OR LESS, THE

APPLIANCE NEED NOT BE DISCONNECTED, BUT MUST BE

ISOLATED FROM THE SUPPLY PRESSURE TEST BY CLOSING

THE MAIN MANUAL GAS V AL VE.

not exceed the working pressure shown on the rating plate of the

heater. In addition, the hourly BTU rated temperature steam

discharge capacity of the relief valve shall not be less than the

input rating of the heater.

THE RELIEF VALVE AND TANK. DO NOT PLUG THE RELIEF

VALVE.

The drain line connected to this valve must not contain a reducing

coupling or other restriction and must terminate near a suitable

drain to prevent water damage during valve operation. The

discharge line shall be installed in a manner to allow complete

drainage of both the valve and line. DO NOT THREAD, PLUG OR

CAP THE END OF THE DRAIN LINE.

NO VAL VE IS TO BE PLACED BETWEEN

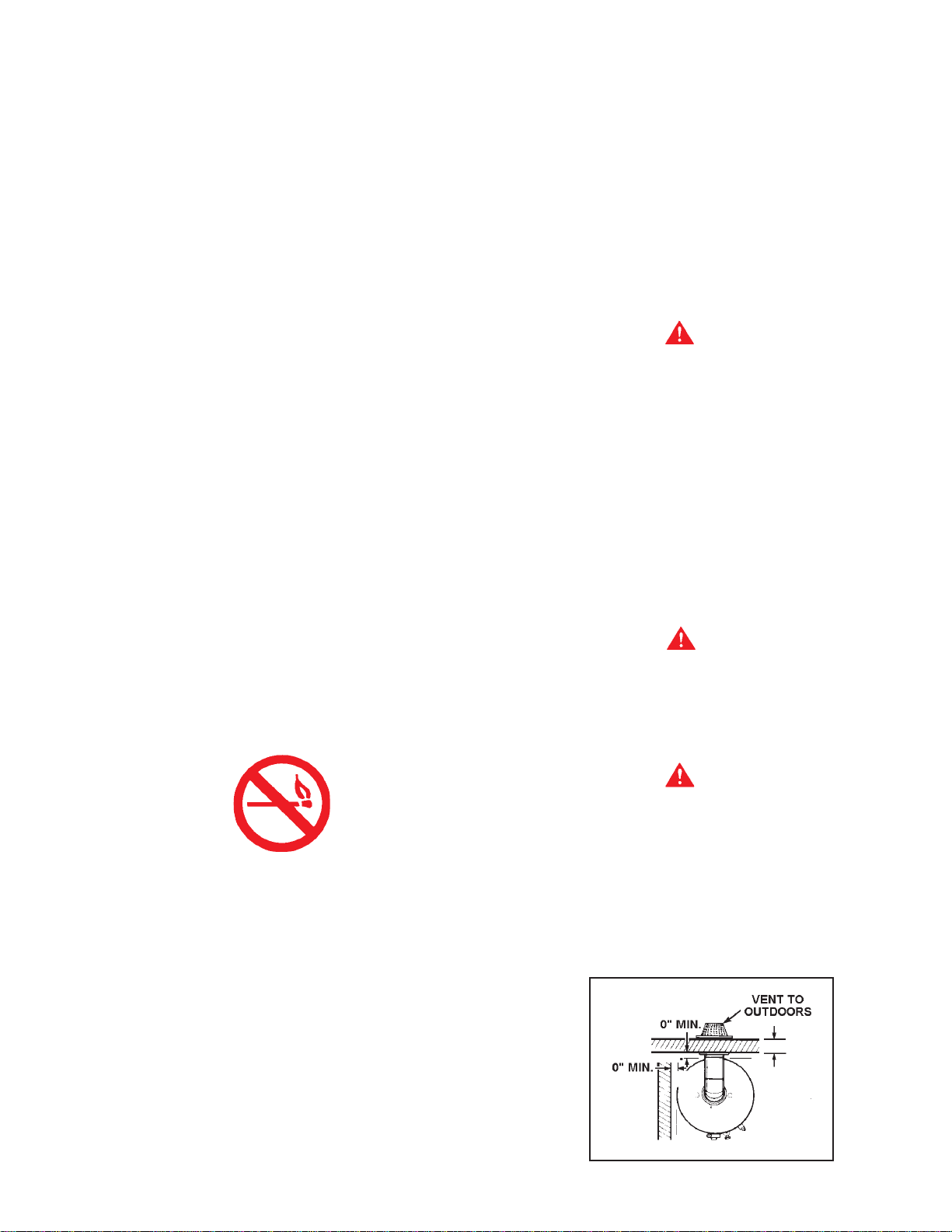

VENTING

WARNING

NEVER OPERATE THE HEATER UNLESS IT IS VENTED TO THE

OUTDOORS AND HAS ADEQUATE AIR SUPPLY TO AVOID

RISKS OF IMPROPER OPERATION, FIRE, EXPLOSION OR

ASPHYXIATION.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND

VENTILATING AIR. ADEQUATE AIR FOR COMBUSTION AND

VENTILA TION MUST BE PROVIDED FOR SAFE OPERA TION.

VENT PIPE TERMINA TION

Before installing water heater determine placement of vent pipe

termination.

MAKE CERTAIN TO OBSERVE VENT LOCATION LIMITATION,

SEE FIGURES 4 & 5.

CAUTION

Use only the vent kit assembly supplied with this water heater or if

needed one of the three listed optional flue extensions. See

Figure 10 for possible combinations. VENTING OR

TERMINATION WITH ANY OTHER KIT NOT LISTED IS NOT

RECOMMENDED AND COULD AFFECT THE SYSTEMS

PERFORMANCE AND RESULT IN A SAFETY HAZARD.

BEFORE PLACING THE HEATER IN OPERATION, CHECK

FOR GAS LEAKAGE. USE SOAP AND WATER SOLUTION OR

OTHER MATERIAL ACCEPTABLE FOR THIS PURPOSE. DO

NOT USE MATCHES, CANDLES, FLAME OR OTHER

SOURCES OF IGNITION TO LOCA TE GAS LEAKS.

RELIEF V AL VE

A NEW TEMPERATURE AND PRESSURE RELIEF VALVE

COMPL YING WITH THE ST ANDARD FOR RELIEF VALVES AND

AUTOMATIC GAS SHUT OFF DEVICES FOR HOT WATER

SUPPL Y SYSTEMS, ANSI Z21.22 (CURRENT EDITION) MUST

BE INSTALLED IN THE HEATER IN THE MARKED OPENING

PROVIDED, SEE FIGURE 1. THE V ALVE MUST BE OF A SIZE

(INPUT RATING) THA T WILL BE ADEQUATE FOR YOUR SIZE

HEATER.

Check the metal tag on the relief valve and compare it to the

heater’s rating plate. The pressure rating of the relief valve must

WARNING

MINIMUM CLEARANCES BETWEEN THE WATER HEATER AND

COMBUSTIBLE AND NONCOMBUSTIBLE CONSTRUCTION

ARE: 0 INCHES FROM SIDES, 0 INCHES FROM BACK, 4 INCHES

FROM FRONT OF JACKET TO CLOSET DOOR AND 3 INCHES

FROM TOP OF JACKET TO COMBUSTIBLE AND

NONCOMBUSTIBLE MATERIAL. MINIMUM VENT CLEARANCE: 0

INCHES. PROVIDE 24 INCHES FRONT CLEARANCE FOR

SERVICING AND ADEQUATE CLEARANCE BETWEEN THE

JACKET TO P & CEILING FOR SERVICING THE FLUE AREA , SEE

FIGURES 3 AND 3A.

FIGURE 3

5

FIGURE 3A

COMBUSTION AIR AND VENTILA TION

When determining the installation location for a direct vent

water heater, snow accumulation and drifting should be

considered in areas where applicable.

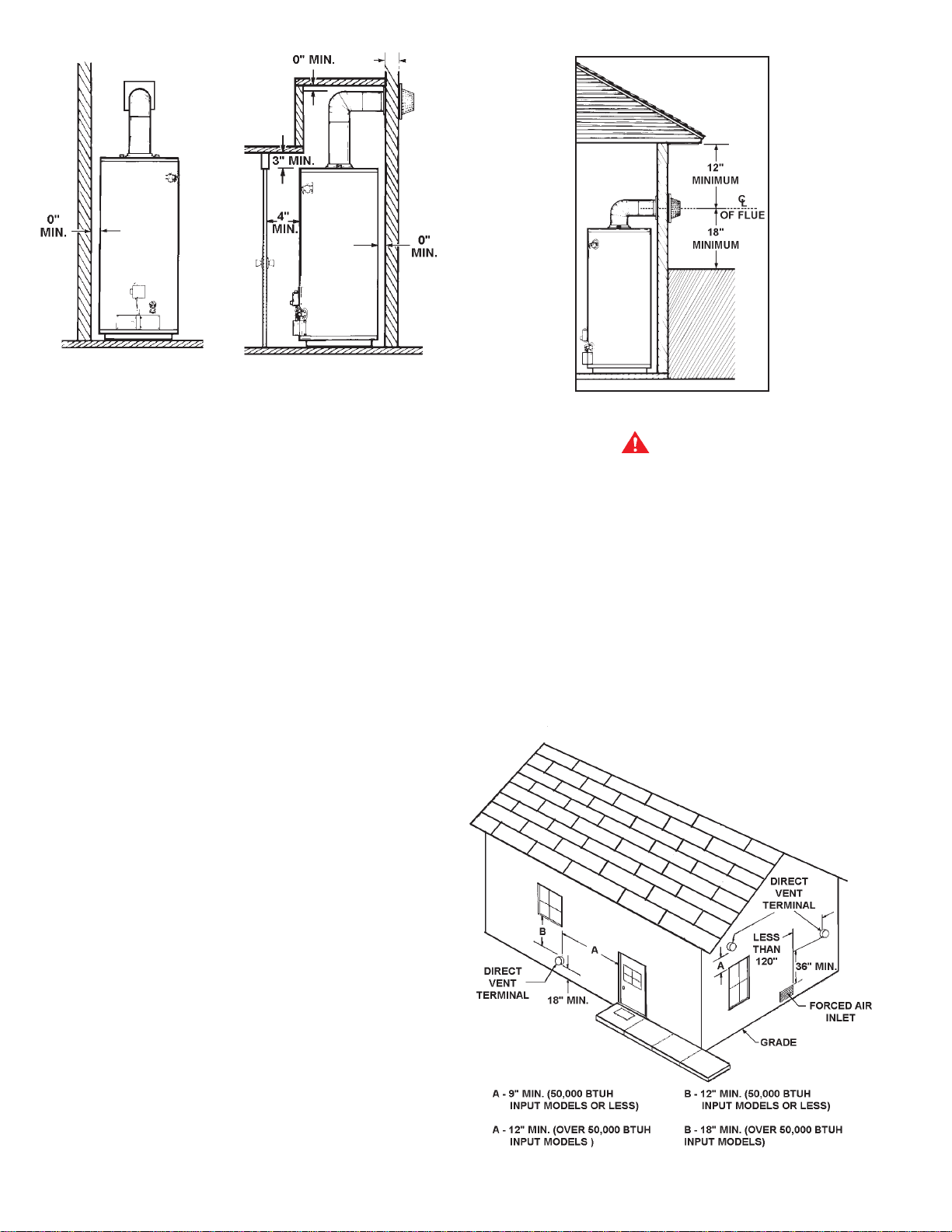

VENTING CLEARANCES

• 18” minimum in all directions from any obstruction that may

interfere.

• 18” minimum from the ground and 12” from ceiling

overhangs, see Figure 4.

• The direct vent terminal shall terminate at least 3 feet above

any forced air inlet located within 10 feet, see Figure 5.

• 9” minimum horizontally from or above any door, window or

gravity air inlet into the building (50,000 BtuH input or less.)

FIGURE 4

WARNING

Vent termination must not be within 4 feet of any items such as

gas meters, gas valves or other gas regulating equipment.

OPTIONAL WIRE GRILL

When the water heater vent cap is low enough to be touched

accidentally, or is accessible to small children, installation of a

protective vent cover is recommended. Some local codes may

require a vent cap cover. Figure 9 shows the optional wire vent

cap protector available from the water heater manufacturer.

A wire mesh chain link fence (as shown in Figure 9) may be

used instead of the factory cover. Care should be taken to

maintain adequate ventilation around the vent cap. If a chain

link fence is installed, it must not be used as a storage area for

items that may block proper ventilation.

• 12” minimum horizontally from or above any door, window or

gravity air inlet into the building (over 50,000 BtuH input).

• 12” minimum below any door, window or gravity air inlet into

the building (50,000 BtuH input or less).

• 18” minimum below any door, window or gravity air inlet into

the building (over 50,000 BtuH input).

• 18” minimum from other gravity or natural appliance outlet

vents when directly above or 135° to either side of center

line, see Figure 6.

• 36” minimum from any outlet vents when directly below or

45° to either side of center line, see Figure 7.

• 36” minimum in all directions from any other forced air

appliance outlet vent, see Figure 7.

• The location selection must provide clearances for

servicing and proper operation of the water heater, see

Figure 8.

• Vent termination must not be within 4 feet of any items such

as gas meters, gas valves or other gas regulating

equipment.

FIGURE 5

6

FLUE EXTENSIONS

There are three optional extension kits available. Any

combination of the three kits can be chosen; however, only one

kit can be used vertically and/or horizontally, see Figures 10

and 11.

WARNING

At no time can more than one Vertical and/or one Horizontal

Vent Kit be used.

Unless otherwise specified at the time of ordering, a standard

extension kit is individually packaged and shipped within the

water heater carton.

FIGURE 6

FIGURE 7

POSSIBLE EXTENSION COMBINA TIONS

FIGURE 10

FIGURE 8

FIGURE 9

FIGURE 11

7

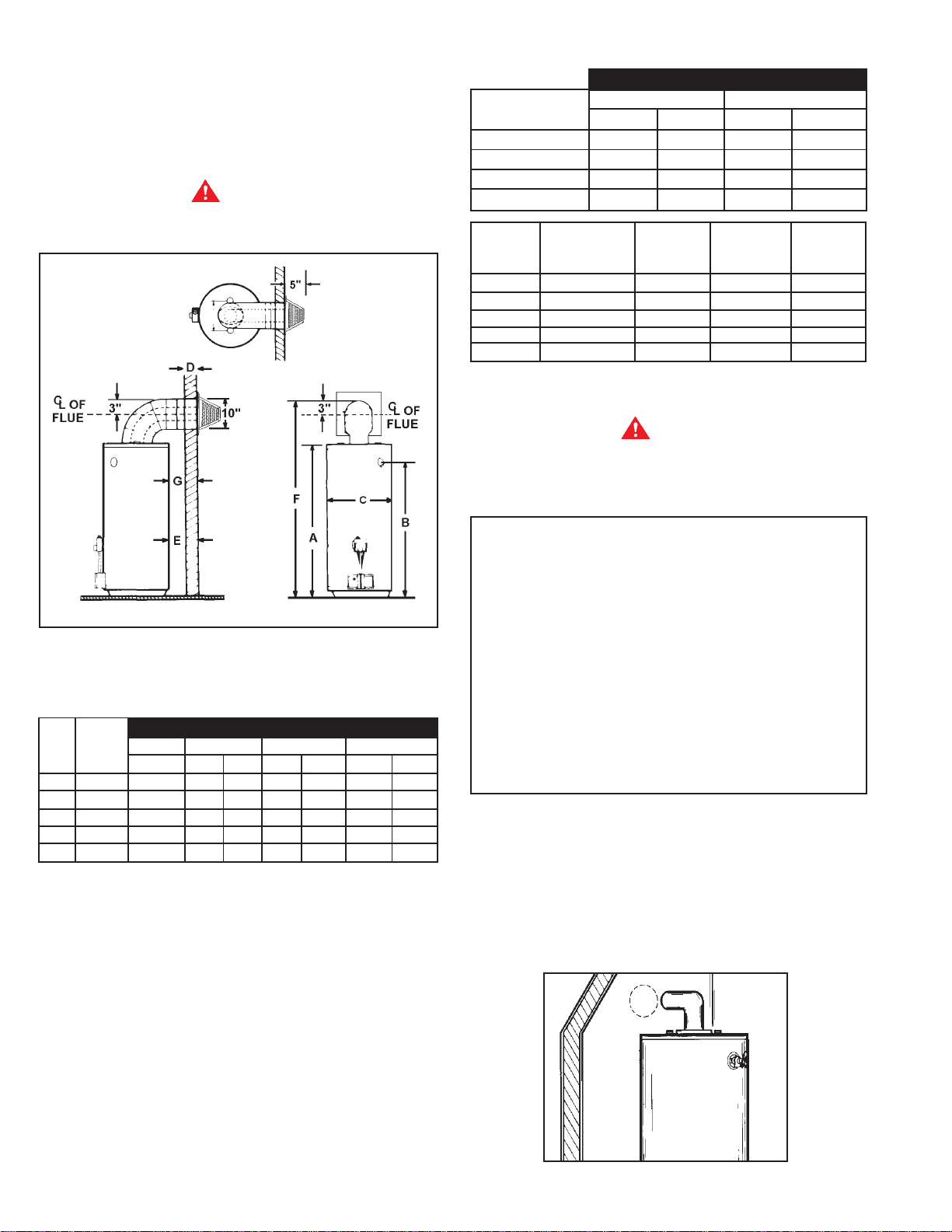

VERTICAL (EXTENSION KIT) HEIGHT

It is simple to determine which kit is needed for vertical height.

Take the total height (to the top of the flue) required and

comparing that to “F DIMENSION” in TABLE 1, it can be

determined which kit needs to be used vertically.

WARNING

Obstructions and deteriorated vent systems may present

serious health risk or asphyxiation.

T ABLE 2.

E DIMENSIONS

40-50 Gal. 75 Gal.

VENT KITS MIN. MAX. MIN. MAX.

900068-7-STD. 3-1/2 10 7/8 7-3/8

900124-6 10 15-1/2 7-3/8 12-7/8

900124-7 15-1/2 26-1/2 12-7/8 23-7/8

900124-8 26-1/2 48 23-7/8 45-3/8

*BTU’S in

*GAL. 1000’s

CAP. NAT/L.P. A B C

40 36/36 48-3/4 41-3/4 21

50 38/38 57-1/2 50-1/2 21

40 40/40 48-3/4 41-3/4 21

50 48/44 61 54 21

75 55 NA T. 63 54-3/4 26-1/4

*See models and rating plate attached to the water heater for

specific model number and other detailed information.

WARNING

Be sure vent pipe is properly connected to prevent escape of

dangerous flue gases which could cause deadly asphyxiation.

ALL INST ALLA TIONS

FIGURE 12

T ABLE 1.

BTU’s F DIMENSION

*GAL. in 1000’s900068-7 900124-6 900124-7 900124-8

CAP . NAT/L.P. STD. MIN. MAX. MIN. MAX. MIN. MAX.

40 36/36 63-3/4 72 77 77 88 88 110

50 38/38 72 80-3/4 86 86-1/4 97-1/4 97-1/4 118-3/4

40 40/40 63-3/4 72 77 77 88 88 110

50 48/44 76 84-1/4 89-3/4 89-3/4 100-3/4 100-3/4 122-3/4

75 55 NAT. 76-1/4 84-1/2 89-1/2 89-1/2 100-1/2 100-1/2 122-1/2

* See models and rating plate attached to the water heater for

specific model number and other detailed information.

HORIZONTAL (EXTENSION KIT)

To determine the horizontal length and extension kit needed,

simply plug the dimensions “D” and “G” into the equation

below. The answer “E” should then be located in TABLE 2. The

size range in which “E” dimension falls indicates the kit that

should be used horizontally to obtain the desired length.

For ease of assembly the installation of the various kit

combinations has been broken into individual sections.

The two steps below are common to all installations. Once

these have been performed, you need only to refer to the

type installation that pertains to you.

Installation Using V ent Kits:

1. Standard V ent Kit..................................... Page 8

2. Optional Vertical V ent Kit ....................... Page 10

with Standard V ent Kit

3. Optional Horizontal Vent Kit ................... Page 13

4. Optional Horizontal and .......................... Page 15

Vertical Vent Kits

CUTTING THE OPENING THROUGH

THE OUTSIDE WALL

After thoroughly reading the “Locating the New Water Heater”

section of this manual and you have chosen a suitable water

heater installation site, use the chart below to determine

dimensions for the opening in the wall.

Cut a 6

1

/4” diameter hole completely through the outside wall.

EQUATION: D + G = E

“D” = The wall thickness

“G” = The distance wanted between the edge of the water

heater and the inside edge of the wall

“E” = The distance the extension kit must be able to extend

FIGURE 13

8

WATER HEATER ATTITUDE

There is a certain amount of variation permissible with regard

to the direction the water heater faces.

Standing in front of the water heater (gas control facing you), set

the 3” diameter elbow (slotted end) on the flue. This will give

you a better understanding of the relation of the vent assembly

to the opening in the wall and more importantly any possibly of

interference of venting and water piping.

The direction of the water heater can now be made. Also

consider the gas control valve to insure installation, lighting,

and maintenance accessibility are retained.

STANDARD VENT KIT INSTALLATION #1

4. First remove the 3” horizontal extension from the elbow.

Starting with the long end (with four securing holes), place

the 6” diameter vent elbow over the 3” diameter elbow.

Bend the round end “oval” to fit the flared oval end of the

jacket top.

FIGURE 18

5. Making sure the 6” diameter elbow is centered around the

3” diameter flue, secure the 6” diameter vent pipe using

four sheet metal screws at the connection of the jacket top.

* Each part is stamped with a

part number.

FIGURE 14

The opening through the wall should be cut at this time. If it

hasn’t been, refer back to that section.

1. Lock the elbow to the straight 3” flue pipe. Set this assembly

in place on the end of the water heater’sflue collar.

FIGURE 15

2. Mark the flue collar at the slots in the elbow. Using a #22 drill

bit, drill holes into the flue collar at the two

slots and secure the elbow to the flue collar using the

screws provided.

NOTE: Make sure elbow is properly aligned to opening in

the outside wall.

FIGURE 19

V

6. The standard vent kit includes a 6” diameter extension pipe

which is used when “E” dimension is over 6 1/2”.

FIGURE 16

3. Using the tube of sealant supplied, run an ample amount

around the oval flare of the jacket.

FIGURE 17

FIGURE 20

7. If “E” is less than 6 1/2” move to next step.

If “E” dimension is over 6 1/2”, assemble the 6” diameter

extension pipe (crimped end) to the 6” diameter vent elbow

and secure using two sheet metal screws.

FIGURE 21

9

Loading...

Loading...