A.O. Smith DW-1810 User Manual

Commercial Gas Boilers

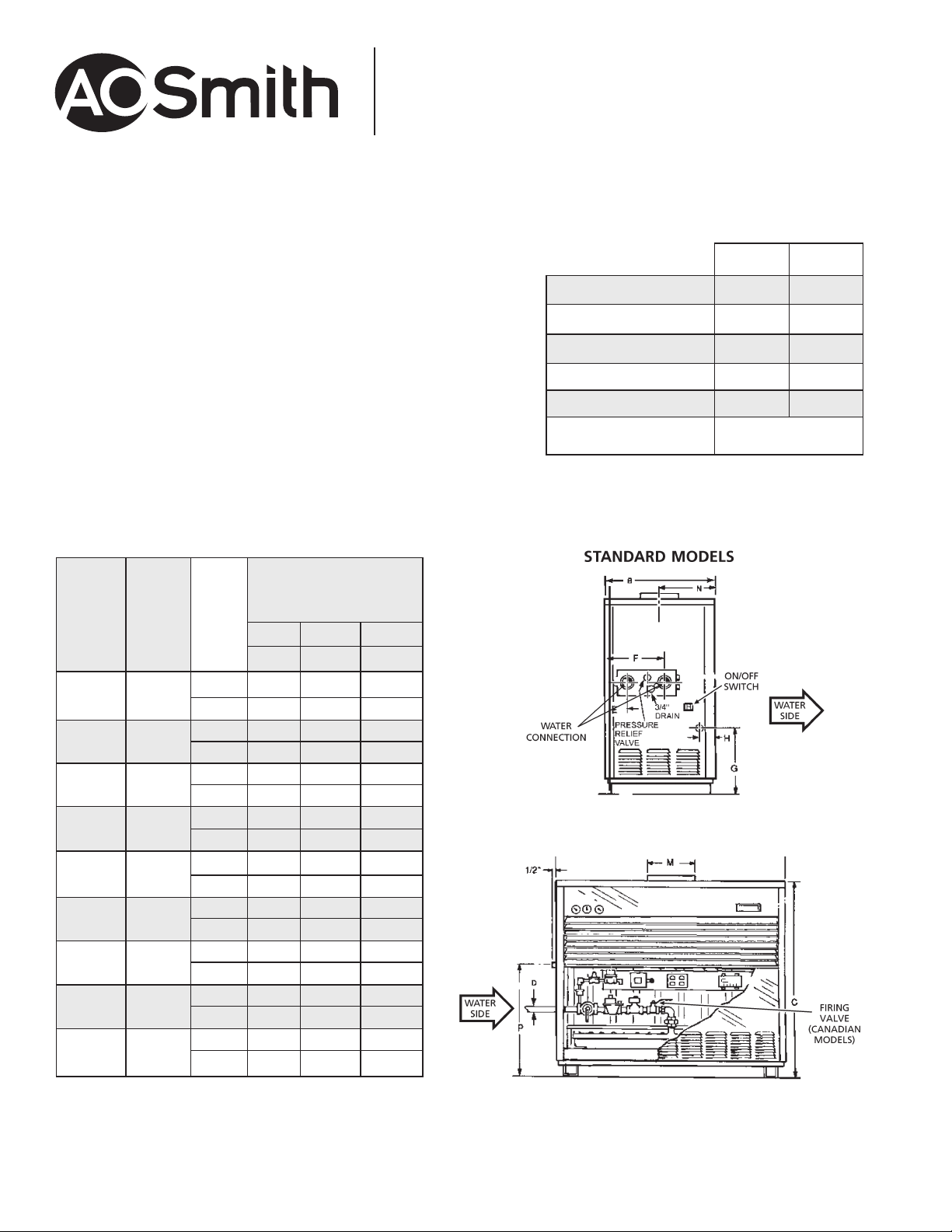

MODELS

DW -720

UP TO 82% EFFICIENT HOT WATER SUPPLY BOILERS

The Dura-Max® series offers excellent performance and low-profile design flexibility for both

new construction and retrofit applications. A double-row, integral-finned copper tube heat

exchanger provides exceptional heat transfer efficiency. Each unit features a small footprint

with a built-in draft diverter for extra clearance to simplify installation. Reliable, quiet, drawermounted stainless steel burners resist corrosion, improve access for easy maintenance.

FEATURES

100% ALL NON-FERROUS HEAT EXCHANGER WATERWAYS

• All waterways 100% copper, brass or bronze

• Won’t rust, resists thermal shock

• Heavy-duty bronze castings and copper heat exchange tubes

• Bronze removable return bends for easy access and inspection

of individual tubes

GASKETLESS WET SECTION

• Unique “O”-ring design compresses to form water-tight seal

positioned away from and outside the combustion chamber

• Isolated location offers optimum protection and years of service

DRAWER-MOUNTED, STAINLESS STEEL DURA-MAX® BURNERS

• Quiet operation and efcient, reliable design

• Protects against corrosion and condensation deterioration

• Easy slide-out burner tray simplies cleaning and maintenance

through

DW- 1810

COMPACT, LOW-PROFILE DESIGN

• Built-in draft diverter provides extra clearance in tight, retrot installations

• Clean, compact jacket design for easy access and assembly

• Cool to touch and approved for combustible oors

INTERMITTENT ELECTRONIC IGNITION

• Eliminates standing pilot, saves energy

• Includes power ON/OFF switch

FACTORY-MOUNTED BRONZE-FITTED PUMP

• Ensures proper ow rates and efcient heat transfer

• Thermal Balancer Pump Delay Switch cycles pump,

reduces standby heat loss

MAXIMUM HYDROSTATIC WORKING PRESSURE: 160 PSI

MEETS ASHRAE/IESNA 90.1-2004

FIVE-YEAR HEAT EXCHANGER LIMITED WARRANTY

• For complete information, consult written warranty or contact A. O. Smith

Revised November 2009

Page 1 of 4

AOSDG25300

OTHER DURA-MAX® FEATURES

l

MANUAL RESET, HIGH LIMIT

l

SAFETY FLOW

l

SWITCH

ASME-RATED PRESSURE RELIEF VALVE

l

REDUNDANT GAS VALVE

DURA-MAX® OPTIONS

q CSD-1

q NEW YORK CODE

q CALIFORNIA CODE

q PANEL MOUNTED INLET/OUTLET DIAL

q THERMOMETERS AND PRESSURE GAUGE

q MOTORIZED MODULATING FIRE

q DUAL STAGE FIRING

q RIGHT HAND GAS AND/OR WATER CONNECTIONS

q CUPRO-NICKEL HEAT EXCHANGER

q SIDEWALL VENT KITSALL-BRONZE PUMP

q HIGH VELOCITY HARD WATER PUMP

q LOW WATER CUTOFF

INPUT AND RECOVERY

Commercial Gas Boilers

l

125#

MINIMUM CLEARANCES TO COMBUSTIBLES ALL MODELS

Inches CM

TOP 12

WATERSIDE

BLANK SIDE

REAR

VENT

FRONT

18

6

6

6

30.5

45.7

15.5

15.5

15.5

Alcove

MODEL

NUMBER

DW-720

DW-840

DW-960

DW-1080

DW-1210

DW-1350

DW-1480

DW-1610

DW-1810

BTU

INPUT

PER

HOUR*

720,000

840,000

960,000

1,080,000

1,210,000

1,350,000

1,480,000

1,610,000

1,810,000

GPH

OR

LPH

GPH

LPH

GPH

LPH

GPH

LPH

GPH

LPH

GPH

LPH

GPH

LPH

GPH

LPH

GPH

LPH

GPH

LPH

RECOVERY -GALLONS OR

LITRES PER HOUR AT

DEGREE RISE

40°F

22°C

1767

6690 2676

2062

7805 3122

2356

8920 3568 2548

2684

10,158

3007

11,381

3355

12,698

3588

13,581

3903

14,774

4388

16,609

100°F

56°C 78°C

707 505

825 589

943 673

1073

4063

1203

4552

1342

5079 3628

1435 1025

5432

1561

5910

1755

6644 4746

140°F

1911

2230

767

2902

859

3252

958

3880

1115

4221

1254

* Natural gas only

Gas supply pressure: 13:8” w.c. maximum, 5.5” w.c. minimum

Electrical requirements: 120 VAC, 15 Amps

Revised November 2009

www.hotwater.com

Page 2 of 4

AOSDG25300

Loading...

Loading...