Page 1

Instruction Manual

COMMERCIAL ELECTRIC WATER HEATERS

MODELS DRE-52/80/120 SERIES 100

& DVE-52/80/120 SERIES 100

INSTALLATION - OPERATION - SERVICE

- MAINTENANCE - LIMITED WARRANTY

500 Tennessee Waltz Parkway

Ashland City, TN 37015

ASME

(OPTIONAL)

Thank you for buying this energy efcient water heater.

We appreciate your condence in our products.

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

PRINTED IN THE U.S.A 0908 196674-002

1

Page 2

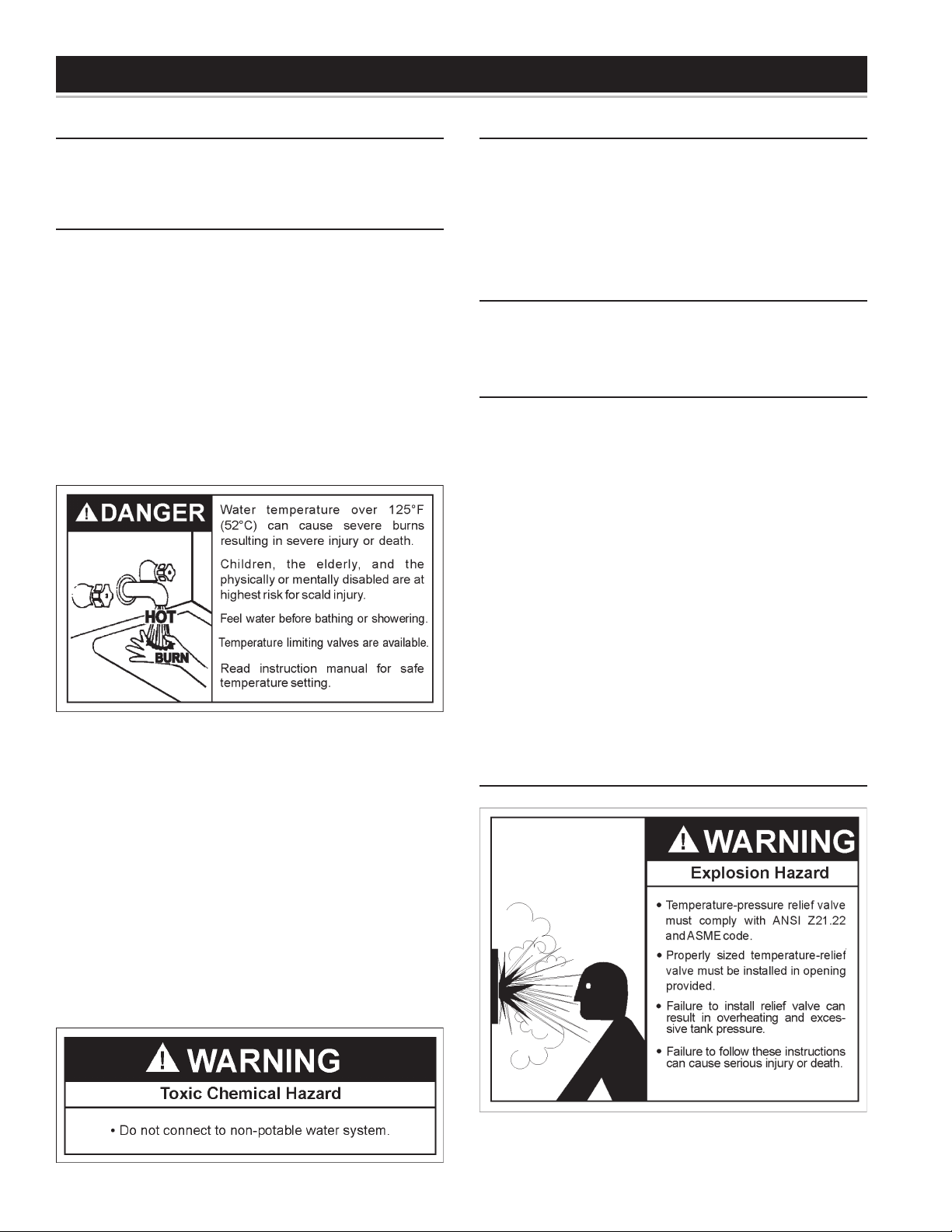

SAFE INSTALLATION, USE, AND SERVICE

The proper installation, use and servicing of this water heater is extremely important to your safety and the safety of others.

Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and

others of a potential injury hazard. Read and obey all safety messages and instructions throughout this manual. It is very important

that the meaning of each safety message is understood by you and others who install, use, or service this water heater.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently hazardous

DANGER

WARNING

CAUTION

situation which, if not avoided, could result

in death or injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result

in death or injury.

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result

in minor or moderate injury.

CAUTION used without the safety alert

CAUTION

All safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety message, and

how to avoid the risk of injury.

The California Safe Drinking Water and Toxic Enforcement Act requires the Governor of California to publish a list of substances

known to the State of California to cause cancer, birth defects, or other reproductive harm, and requires businesses to warn of

potential exposure to such substances.

This product contains a chemical known to the State of California to cause cancer, birth defects, or other reproductive harm. This

appliance can cause low level exposure to some of the substances listed, including formaldehyde.

symbol indicates a potentially hazardous

situation which, if not avoided, could result

in property damage.

IMPORTANT DEFINITIONS

• QualiedInstallerorServiceAgency:

Installation and service of this water heater requires ability equivalent to that of a Qualied Agency (as dened by ANSI below) in the

eld involved. Installation skills such as plumbing, electrical supply are required in addition to electrical testing skills when performing

service.

• ANSIZ223.12006Sec.3.3.83:

“Qualied Agency” - “Any individual, rm, corporation or company that either in person or through a representative is engaged in and is

responsible for (a) the installation, testing or replacement of gas piping or (b) the connection, installation, testing, repair or servicing of

appliances and equipment; that is experienced in such work; that is familiar with all precautions required; and that has complied with all

the requirements of the authority having jurisdiction.”

2

Page 3

GENERAL SAFETY INFORMATION

PRECAUTIONS

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN UNDER

WATER. Immediately call a qualied service technician to inspect

the appliance and to replace any part of the control system which

has been under water.

If the unit is exposed to the following, do not operate heater until all

corrective steps have been made by a qualied service agency.

1. External re.

2. Damage.

3. Firing without water.

GROUNDING INSTRUCTIONS

This water heater must be grounded in accordance with the

National Electrical Code and/or local codes. These must be

followed in all cases. Failure to ground this water heater properly

may also cause erratic control system operation on ELECTRONIC

CONTROL models.

This water heater must be connected to a grounded metal, permanent

wiring system; or an equipment grounding conductor must be run with

the circuit conductors and connected to the equipment grounding

terminal or lead on the water heater.

When servicing this unit, verify the power to the unit is turned off prior to opening the control cabinet door.

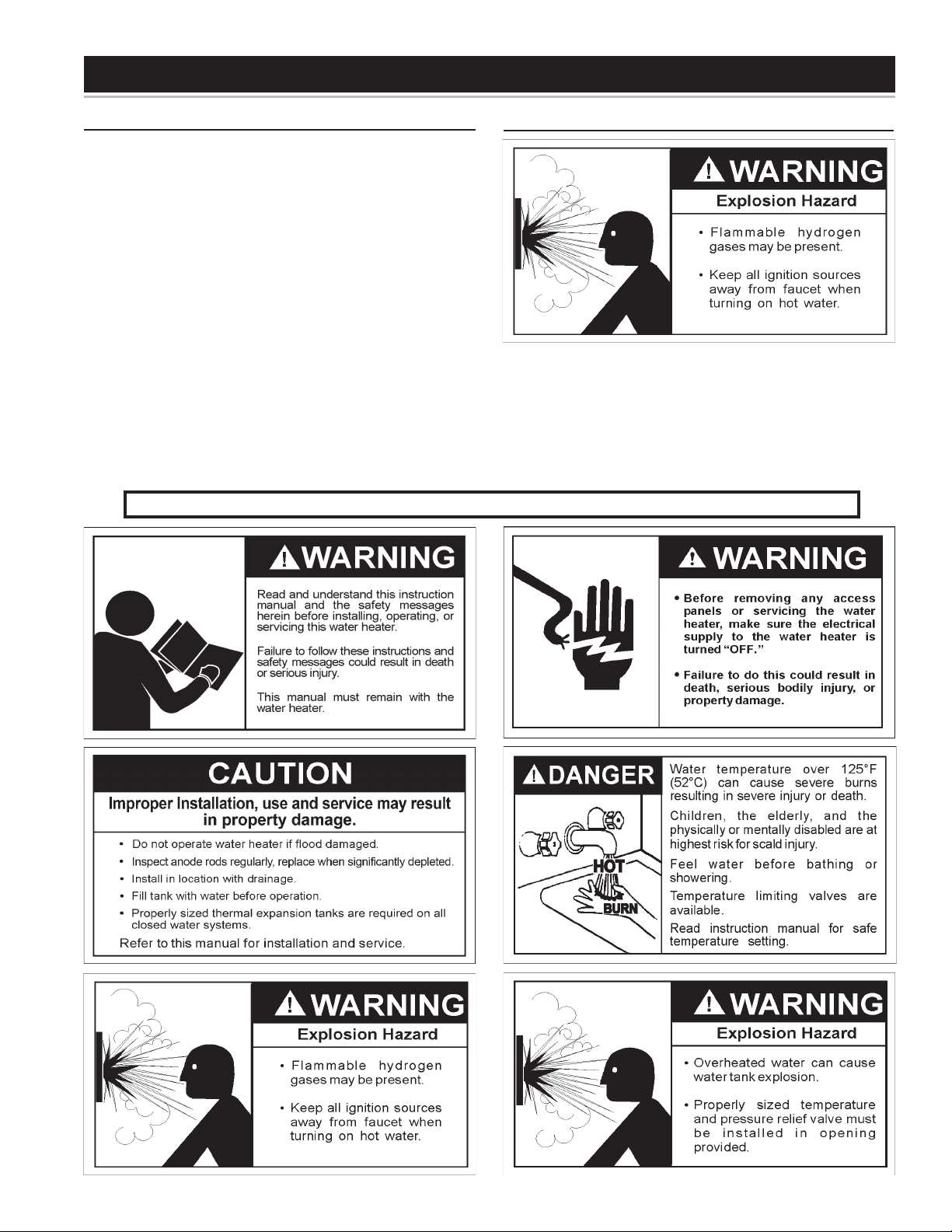

HYDROGEN GAS (FLAMMABLE)

Hydrogen gas can be produced in a hot water system served by this

heater that has not been used for a long period of time (generally two

weeks or more). Hydrogen gas is extremely ammable.

risk of injury under these conditions, it is recommended that the hot water

faucet be opened for several minutes at the kitchen sink before using any

electrical appliance connected to the hot water system. If hydrogen is present

there will probably be an unusual sound such as air escaping through the pipe

as the water begins to ow.

OPEN FLAME NEAR THE FAUCET AT THE TIME IT IS OPEN.

THERE SHOULD BE NO SMOKING OR

To reduce the

3

Page 4

TABLE OF CONTENTS

SAFE INSTALLATION, USE AND SERVICE..................................... 2

GENERAL SAFETY INFORMATION .................................................3

TABLE OF CONTENTS ..................................................................... 4

INTRODUCTION ...............................................................................4

Preparing for the New Installation .............................................4

DIMENSIONS AND CAPACITIES DATA ...........................................5

APPROVALS ..................................................................................... 6

FEATURES AND COMPONENTS .................................................7-8

LOCATING THE NEW WATER HEATER .......................................... 9

INSTALLATION ...............................................................................10

Required Ability ........................................................................10

General .................................................................................... 10

Mixing Valve Usage ................................................................. 10

Chemical Vapor Corrosion .......................................................10

Circulating Pump .....................................................................10

Insulation Blankets ..................................................................10

Temperature-Pressure Relief Valve .................................... 10-11

Water Line Connection ............................................................ 11

Closed Water System .............................................................. 11

Thermal Expansion .................................................................. 11

ELECTRICAL ..................................................................................12

OPERATION .................................................................................... 19

General .................................................................................... 19

Filling the Water Heater ........................................................... 19

Start Up ...................................................................................19

Draining the Water Heater ....................................................... 19

TEMPERATURE REGULATION .....................................................20

High Temperature Devices ......................................................20

Thermostat Controls ................................................................ 20

Thermostat Settings – Surface Mount Control Models ............ 20

Thermostat Settings – Electronic Control Models ................... 21

ELECTRONIC CONTROL MODELS OPERATION ......................... 21

Control System Features ......................................................... 21

Control System Navigation ...................................................... 21

Desktop Screen ..................................................................21-23

Temperatures Menu ............................................................23-24

Temperature Settings ..............................................................24

Heater Status Menu ................................................................. 25

Economy Mode Setup Menu ..............................................25-26

Economy Mode Settings .....................................................26-28

Alarm Output Setup Menu .......................................................29

Display Settings Menu ............................................................. 29

Heater Information Menu .................................................... 29-30

Current Fault / Alert Menu .......................................................30

Fault Occurrence Menu ........................................................... 30

Restore Factory Defaults Menu .......................................... 30-31

MAINTENANCE ..............................................................................31

General ............................................................................... 31-32

Flushing ...................................................................................32

Sediment Removal ..................................................................32

Water and Lime Scale Removal .............................................. 32

TROUBLESHOOTING CHECKLIST ............................................... 33

Not Enough or No Water .........................................................33

Water Heater Makes Strange Sounds ..................................... 33

If You Cannot Identify or Correct the Source of Malfunction

Leakage Checkpoints ..............................................................34

PIPING DIAGRAMS ...................................................................35-42

WARRANTY ....................................................................................43

............17

INTRODUCTION

Thank You for purchasing this water heater. Properly installed and

maintained, it should give you years of trouble free service.

Abbreviations Found In This Instruction Manual:

• ANSI - American National Standards Institute

• ASME - American Society of Mechanical Engineers

• GAMA - Gas Appliance Manufacturer’s Association

• NEC - National Electrical Code

• NFPA - National Fire Protection Association

• UL - Underwriters Laboratory

PREPARING FOR THE INSTALLATION

1. Read the “General Safety Information” section of this manual rst and

then the entire manual carefully. If you don’t follow the safety rules, the

water heater may not operate safely. It could cause DEATH, SERIOUS

BODILY INJURY AND/OR PROPERTY DAMAGE.

This manual contains instructions for the installation, operation,

and maintenance of the electric water heater. It also contains

warnings throughout the manual that you must read and be

aware of. All warnings and all instructions are essential to the

proper operation of the water heater and your safety. READ

THE ENTIRE MANUAL BEFORE ATTEMPTING TO INSTALL

OR OPERATE THE WATER HEATER.

Detailed installation diagrams are in this manual. These diagrams will

serve to provide the installer with a reference for the materials and

method of piping suggested. IT IS NECESSARY THAT ALL WATER

PIPING AND THE ELECTRICAL WIRING BE INSTALLED AND

CONNECTED AS SHOWN IN THE DIAGRAMS.

Particular attention should be given to the installation of thermometers

at the locations indicated in the diagrams as these are necessary for

checking the operation of the heater.

Be sure to turn off power when working on or near the electrical

system of the heater. Never touch electrical components with wet

hands or when standing in water. When replacing fuses always use

the correct size for the circuit. see page 13.

The principal components of the heater are identied on pages 7 & 8.

The model and rating plate on page 6 interprets certain markings into

useful information. Both of these references should be used to identify

the heater, its components and optional equipment.

2. The installation must conform with these instructions and the local

code authority having jurisdiction and the requirements of the power

company. In the absence of code requirements, follow NFPA-70

(current edition). In the absence of local codes, the installation

must comply with the latest editions of the National Electrical Code,

NFPA 70 or the Canadian Electrical Code CSA C22.1. The National

Electrical Code may be ordered from: National Fire Protection

Association, 1 Batterymarch Park, Quincy, MA 02269. The Canadian

Electrical Code is available from the Canadian Standards Association,

8501 East Pleasant Valley Road, Cleveland, OH 44131.

3. If after reading this manual you have any questions or do not

understand any portion of the instructions, call the toll free number

listed on the back cover of this manual for technical assistance.

A sample rating plate is shown on page 6 of this manual. In order

to expedite your request, please have full model and serial number

available for the technician.

4. Carefully plan your intended placement of the water heater. Examine

the location to ensure the water heater complies with the “Locating

the New Water Heater” section in this manual.

Installation and service of this water heater requires ability equivalent

to that of a licensed tradesman or qualied agency (page 2) in the

eld involved. Plumbing and electrical work are required.

5. For installation in California this water heater must be braced or

anchored to avoid falling or moving during an earthquake. See

instructions for correct installation procedures. Instructions may be

obtained from California Ofce of the State Architect, 1102 Q Street,

Suite 5100, Sacramento, CA 95811.

6. Massachusetts Code requires this water heater to be installed in

accordance with Massachusetts 248-CMR 2.00: State Plumbing Code

and 248-CMR 5.00.

4

Page 5

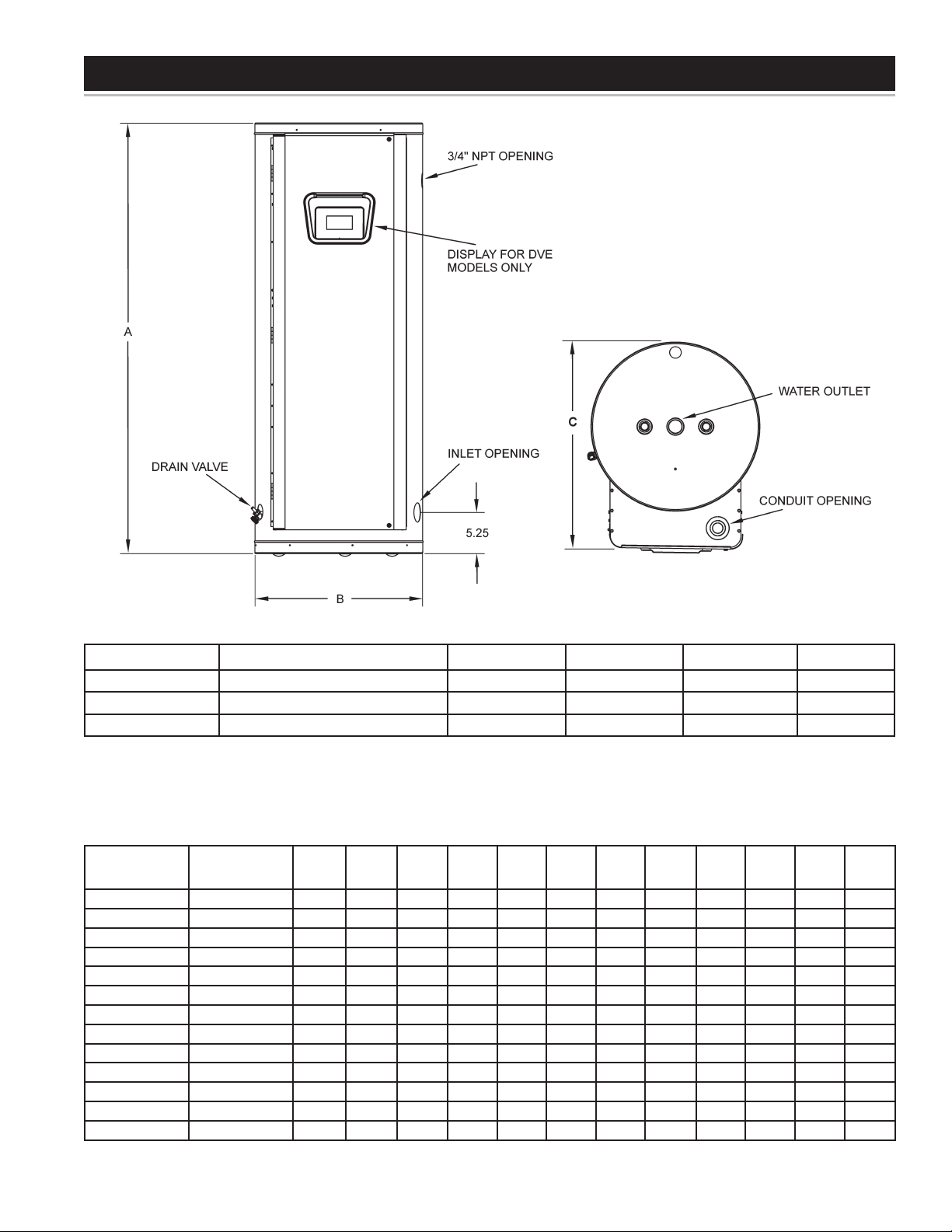

DIMENSIONS AND CAPACITIES DATA

DRE/DVE MODEL DIFFERENCES

This Instruction Manual covers two models of

commercial electric water heaters; DRE models and

DVE models. These two models are equipped from the

factory with different controls.

DRE models are factory equipped with surface mounted

thermostat/ECO combination controls. DVE models are

factory equipped with an electronic control system.

In this Instruction Manual “DRE” models are referred to

as: “Surface Mount Control” models.

In this Instruction Manual “DVE” models are referred to

as: “Electronic Control” models.

Model Number Tank Capacity in Gallons (Liters) A - Inches (mm) B - Inches (mm) C - Inches (mm) Inlet/Outlet

DRE/DVE-52 50 (189.3) 55 3/4 (1416) 21 3/4 (552) 27 (685) 1 1/4

DRE/DVE-80 80 (302.8) 60 1/4 (1350) 25 1/2 (648) 31 (787) 1 1/4

DRE/DVE-120 119 (450.5) 62 1/4 (1581) 29 1/2 (749) 35 (889) 1 1/4

RECOVERY RATE IN GALLONS PER HOUR*

Temperature Rise °F

Standard

KW Input

BTU/

Hour 30° 40° 50° 60° 70° 80° 90° 100° 110° 120° 130° 140°

6 20,478 82 62 49 41 35 31 27 25 22 21 19 18

9 30,717 123 92 74 62 53 46 41 37 34 31 28 26

12 40,956 164 123 98 82 70 61 55 49 45 41 38 35

13.5 46,075 184 138 111 92 79 69 62 55 50 46 43 40

15 51,195 205 154 123 102 88 77 68 61 56 51 47 44

18 61,434 246 184 148 123 105 92 82 74 67 61 57 53

24 81,912 328 246 197 164 140 123 109 98 89 82 76 70

27 92,151 369 276 221 184 158 138 123 111 101 92 85 79

30 102,390 410 307 246 205 176 154 137 123 112 102 95 88

36 122,868 492 369 295 246 211 184 164 148 134 123 113 105

40.5 138,226 554 418 3332 277 237 208 1185 166 151 138 128 119

45 153,585 615 461 369 307 263 230 205 184 168 154 142 132

54 184,302 738 553 443 369 316 277 246 221 201 184 170 158

*Figured at 1 KW (3413 Btu) = 4.1 gallons at 100°F temperature rise.

To determine recovery rate per minute, divide recovery rate per hour by 60.

5

Page 6

APPROVALS

All models meet

National Sanitation

Foundation NSF-5

requirements.

All models are listed

by Underwriters

Laboratories Inc.

MODEL AND RATING

6

Page 7

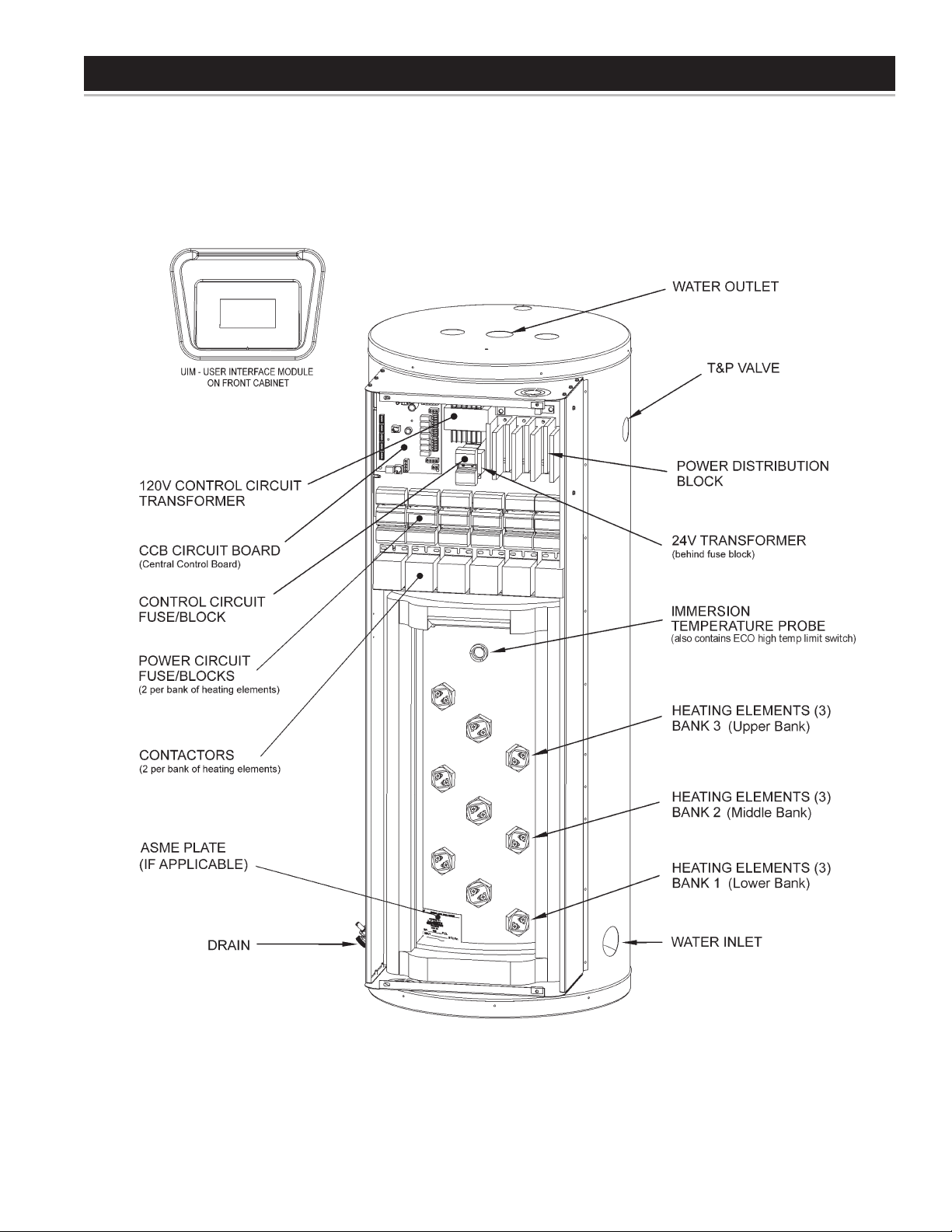

FEATURES AND COMPONENTS

ELECTRONIC CONTROL MODELS

FIGURE 1

7

Page 8

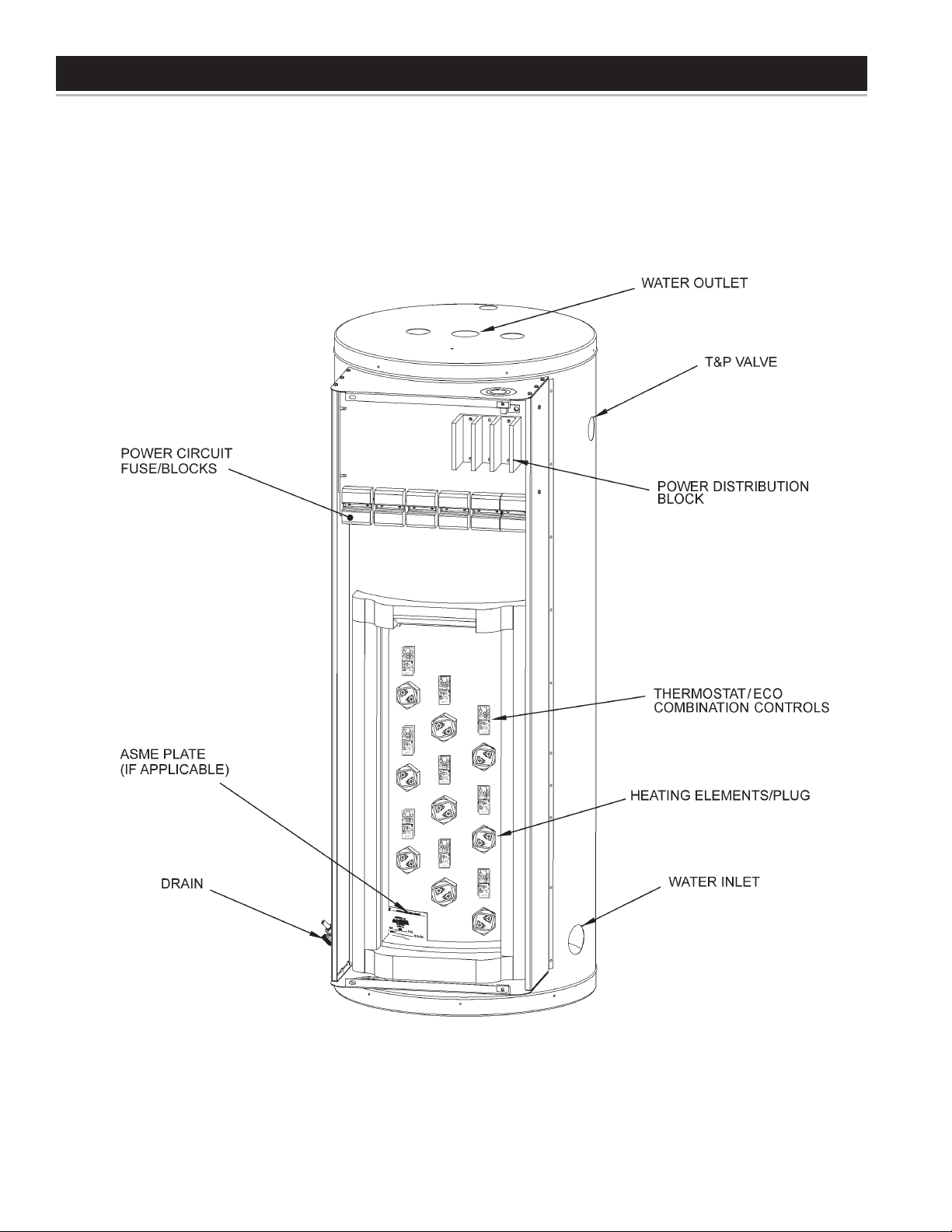

FEATURES AND COMPONENTS

SURFACE MOUNT CONTROL MODELS

FIGURE 2

8

Page 9

LOCATING THE NEW WATER HEATER

FACTS TO CONSIDER ABOUT THE LOCATION

Carefully choose a location for the new water heater. The placement

is a very important consideration for the safety of the occupants in

the building and for the most economical use of the appliance.

Whether replacing an old water heater or putting the water heater in

a new location, the following critical points must be observed. The

water heater must be located:

1. On a level surface. Shim the channel type skid base as necessary

if levelling is required.

2. Near a oor drain. The heater should be located in an area where

leakage of the tank or connections will not result in damage to the

area adjacent to the heater or to lower oors of the structure.

3. Close to the point of major hot water usage and the power

supply.

Hot water piping and branch circuit wiring should be as short as

possible.

Insulate hot and cold water piping where heat loss and condensation

may be a problem.

Heater construc ti on p er mits i nstallation , maint enance, and

service work to be performed through the front control panel.

Suggested clearances from adjacent surfaces are 12 inches on

top, 30 inches in front for access to the unit.

The heater may be installed on or against combustible surfaces. The

left side and back may be placed ush against adjacent surfaces.

The temperature of the space in which the water heater is installed

must not go below 32°F or above 122°F.

9

Page 10

INSTALLATION

REQUIRED ABILITY

Installation and service of this water heater requires ability equivalent

to that of a qualied agency (page 2) in the eld involved. Plumbing

and electrical work is required.

GENERAL

The installation must conform with these instructions and the

local code authority having jurisdiction and the requirements of the

power company. In the absence of code requirements, follow NFPA70 (current edition). In the absence of local codes, the installation

must comply with the latest editions of the National Electrical Code,

NFPA 70 or the Canadian Electrical Code CSA C22.1. The National

Electrical Code may be ordered from: National Fire Protection

Association, 1 Batterymarch Park, Quincy, MA 02269. The Canadian

Electrical Code is available from the Canadian Standards Association,

8501 East Pleasant Valley Road, Cleveland, OH 44131.

Do NOT test electrical system before heater is lled with water, follow

the START UP procedure in the OPERATION section of this manual.

The principal components of the heater are identified in the

Features and Components illustrations on pages 6 and 7.

CONTAMINATED WATER

Th is water he at er shal l no t be connec ted to any heat ing

system(s) or c om ponent(s) u se d with a n on- potable water

heating appliance.

Toxic chemicals, such as those used for boiler treatment shall not

be introduced into this system.

CIRCULATING PUMP

Field installed circulating pumps should be of all bronze

construction.

INSULATION BLANKETS

Insulation blankets are available t o the gen er al public for

external use on electric water heaters but are not necessary with

this product. The purpose of an insulation blanket is to reduce

the standby heat loss encountered with storage tank heaters.

Your water heater meets or exceeds the EPACT and ASHRAE/

IES 90.1 standards with respect to insulation and standby loss

requirements, making an insulation blanket unnecessary.

Should you choose to apply an insulation blanket to this heater,

you should follow these instructions below. Failure to follow

these instructions can result in f ire, serious personal injury,

or death.

MIXINGVALVEUSAGE:

Water heaters are intended to produce hot water. Water heated to

a temperature which will satisfy space heating, clothes washing,

dish washing, cleaning and other sanitizing needs can scald and

permanently injure you upon contact. Some people are more likely

to be permanently injured by hot water than others. These include

the elderly, children, the infirm, or physically/developmentally

disabled. If anyone using hot water in your home ts into one of these

groups or if there is a local code or state law requiring a maximum

water temperature at the hot water tap, then you must take special

precautions. In addition to using the lowest possible temperature

setting that satises your hot water needs, a means such as a

MIXING VALVE, should be used at the hot water taps used by these

people or at the water heater.

MIXING VALVES for reducing point of use temperature are

available. Consult a qualied installer or service agency. Follow all

manufacturer’s Instructions for installation of these valves. Before

changing the factory setting on the thermostat, read the “Temperature

Regulation” section in this manual.

• Do not cover the temperature and pressure relief (T & P) valve

with an insulation blanket.

• Do not cover the instruction manual. Keep it on the side of the

water heater or nearby for future reference.

• Do obtain new warning and instruction labels for placement on

the blanket directly over the existing labels.

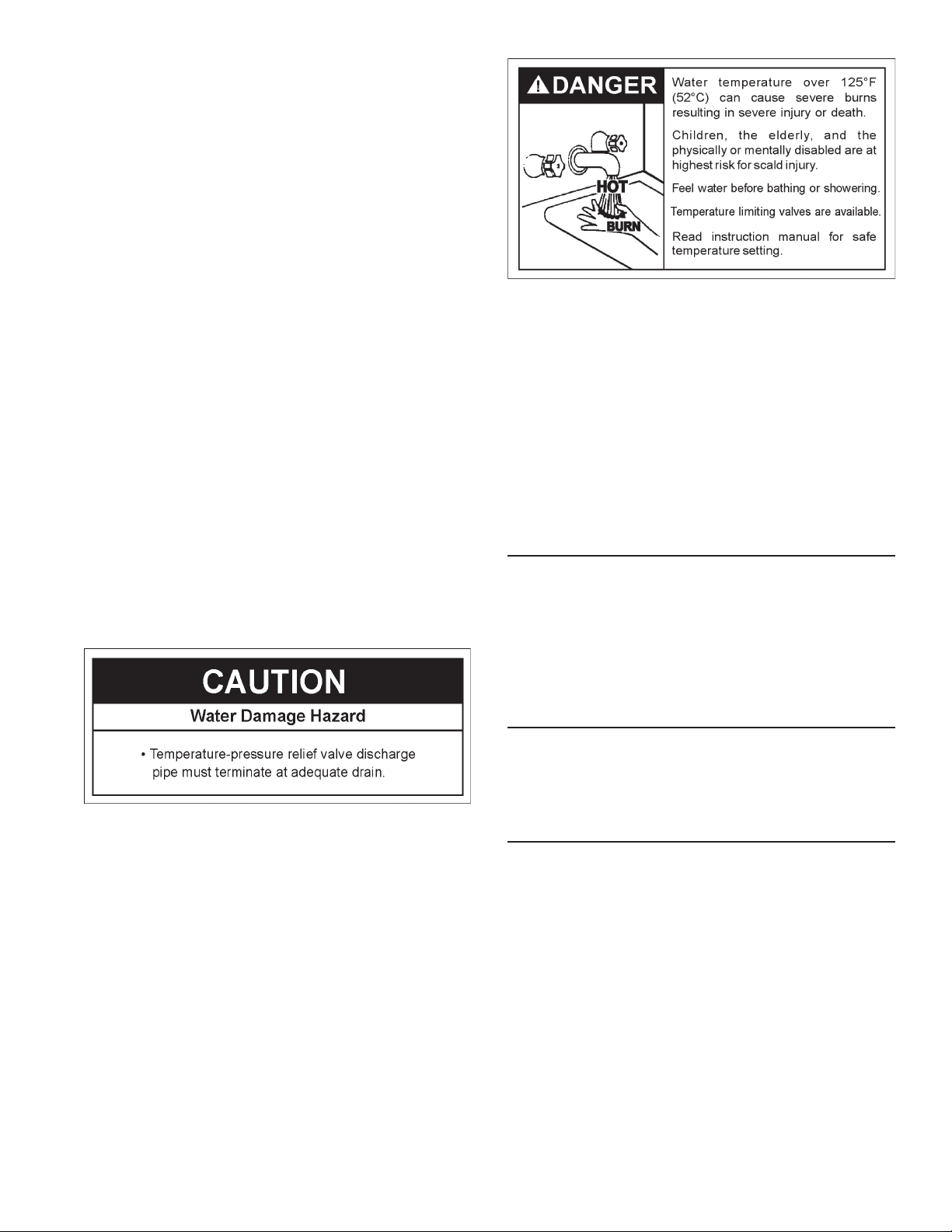

TEMPERATURE-PRESSURE RELIEF VALVE

This water heater is provided with a properly rated/sized and

certified combination temperature - pressure relief valve by the

10

Page 11

manufacturer. The valve is cer tified by a nationally recognized

testing laboratory that maintains periodic inspection of production

of listed equipment of materials as meeting the requirements

for Relief Valves for Hot Water Supply Systems, ANSI Z 21.22 •

CSA 4.4, and the code requirements of ASME.

If replaced, the new valve must meet the requirements of local

cod es, b ut n ot l ess tha n a c ombin ati on t empe rat ure and p res sure

relief valve rated/sized and certified as indicated in the above

paragraph. The new valve must be marked with a maximum set

pre ssu re n ot t o excee d th e ma r ke d hy dro sta t ic work ing p res sur e

of the water heater (150 psi = 1,035 kPa) and a discharge

capacity not less than the water heater Btu/hr or K W input rate

as shown on the water heater’s model rating plate.

For safe operation of the water heater, the temperature and

pressure relief valve must not be removed from its designated

opening nor plugged. The temperature- pressure relief valve

must b e installed directly into the fitting of the water heater

de sign ed f or t he r e lie f valve. I nst a ll disc har g e p ipin g so tha t any

di scha rge w ill ex it o nly w ith in 6 inc hes (15. 2 cm) ab ove, o r at any

distance below the structural floor. Be certain that no contact is

made with any live electrical part. The discharge opening must

not be blocked or reduced in size under any circumstances.

Excessive length, over 30 feet (9.14 m), or use of more than

four elb ows can cause restriction and reduce the discharge

capacity of the valve.

No valve or other obstruction is to be placed between the relief

valve and the tank. Do not connect discharge piping directly to

the drain unless a 6” (15.2 cm) air gap is provided. To prevent

bo dily i nj ury, haz ard to li fe, or pr op erty damag e, the reli ef valve

must be allowed to discharge water in adequate quantities should

circumstances demand. If the discharge pipe is not c onnected

to a drain or other suitable means, the water flow may cause

property damage.

The temperature-pressure relief valve must be manually

operated at least once a year. Caution should be taken to

ensure that (1) no one is in front of or around the outlet of the

temperature-pressure relief valve discharge line, and (2) the

water manually discharged will not cause any bodily injury or

proper ty damage because the water may be extremely hot. If

after manually operating the valve, it fails to completely reset

and continues to release water, immediately close the cold water

inlet to the water heater, follow the draining instructions in this

manual, and replace the temperature-pressure relief valve with

a properly rated/sized new one.

If you do not understand these instructions or have any questions

regarding the temperature -pressure relief valve call the toll free

number listed on the back cover of this manual for technical

assistance.

WATER LINE CONNECTIONS

This manual provides detailed piping installation diagrams (see

back section of this manual) for typical methods of application.

For the heater inlet and outlet connections, di-electric unions are

recommended. The water heater may be installed by itself, or with a

separate storage tank, on both single and two-temperature systems.

When used with a separate storage tank, the circulation may be either

by gravity or by means of a circulating pump. When a circulating

pump is used it is important to note that the ow rate should be slow

so that there will be a minimum of turbulence inside the heater.

The Discharge Pipe:

• Shall not be smaller in size than the outlet pipe size

of the valve, or have any reducing couplings or other

restrictions.

• Shall not be plugged or blocked.

• Shall be of material listed for hot water distribution.

• Shall be installed so as to allow complete drainage of both the

temperature-pressure relief valve and the discharge pipe.

• Shall terminate at an adequate drain.

• Shall not have any valve or other obstruction between the relief

valve and the drain.

CLOSED WATER SYSTEMS

Water supply systems may, because of code requirements or

such conditions as high line pressure, among others, have

installed devices such as pressure reducing valves, check valves,

and back flow preventers. Devices such as these cause the water

system to be a closed system.

THERMAL EXPANSION

As water is heated, it expands (thermal expansion). In a closed

system the volume of water will grow when it is heated. As the volume

of water grows there will be a corresponding increase in water pressure

due to thermal expansion. Thermal expansion can cause premature

tank failure (leakage). This type of failure is not covered under the limited

warranty. Thermal expansion can also cause intermittent temperaturepressure relief valve operation: water discharged from the valve due to

excessive pressure build up. This condition is not covered under the

limited warranty. The temperature-pressure relief valve is not intended

for the constant relief of thermal expansion.

A properly sized thermal expansion tank should be installed

on all closed systems to control the harmful effects of thermal

expansion. Contact a local plumbing service agency to have a

thermal expansion tank installed.

11

Page 12

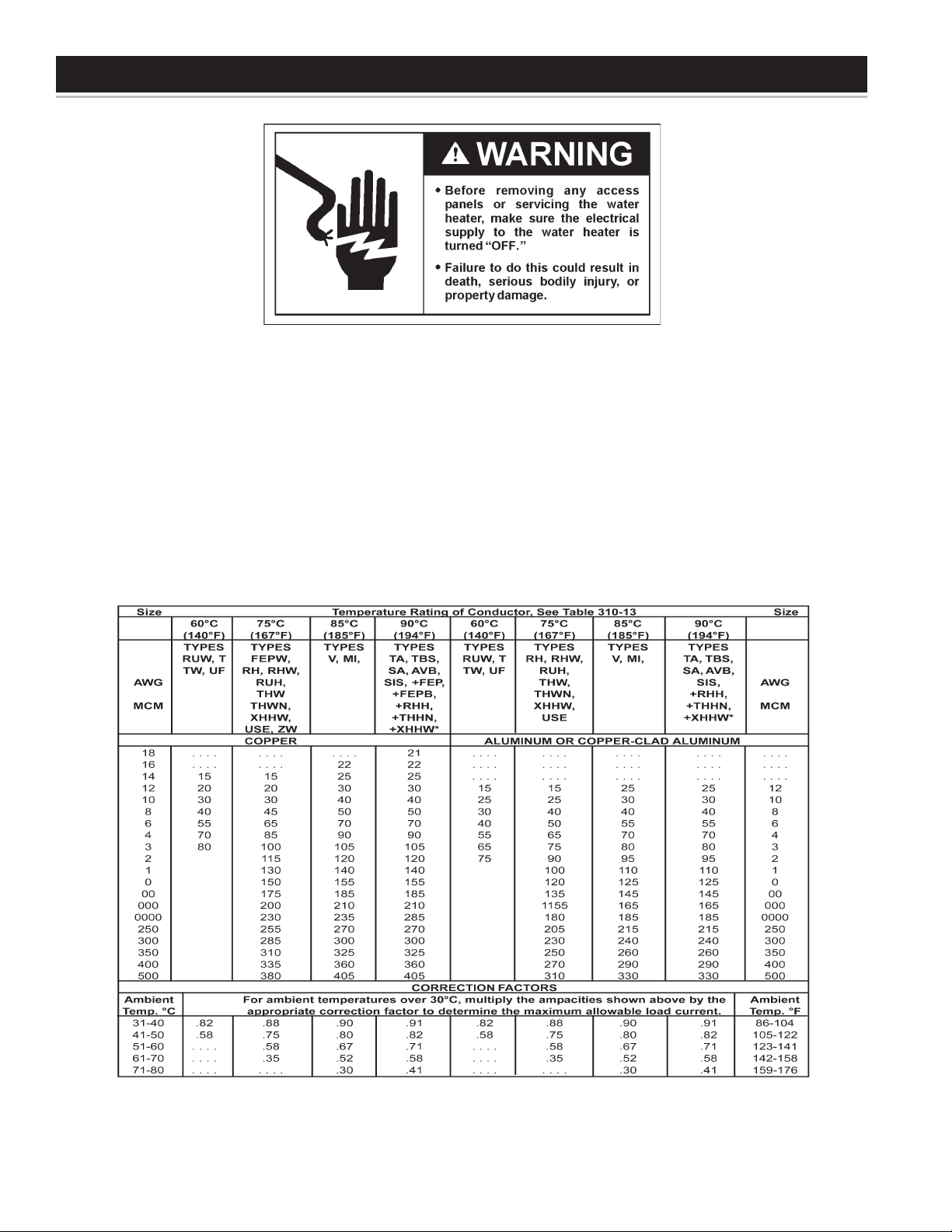

ELECTRICAL

GENERAL

The installation must conform with these instructions and the local code authority having jurisdiction and the requirements of the power

company. In the absence of local codes, the installation must comply with the current editions of the National Electrical Code, NFPA 70 or

the Canadian Electrical Code CSA C22.1.

An electrical ground is required to reduce risk of electrical shock or possible electrocution. The water heater should be connected to a

separate grounded branch circuit with over-current protection and disconnect switch. The water heater should be grounded in accordance

with national and local codes.

Voltage applied to the heater should not vary more than +5% to -10% of the model and rating plate marking for satisfactory operation.

TABLE 310-16. Allowable Ampacities of Insulated Conductors

Not more than three conductors in raceway, cable, or earth (directly buried), based

on ambient temperature of 30°C (86°F)

+The load current rating and the overcurrent protection for these conductors shall not exceed 15 amperes for 14 AWG. 20 amperes for 12 AWG.

and 30 amperes for 10 AWG copper; or 15 amperes for 12 AWG and 25 amperes for 10 AWG aluminum and copper-clad aluminum.

*For dry locations only. See 75°C column for wet locations.

12

Page 13

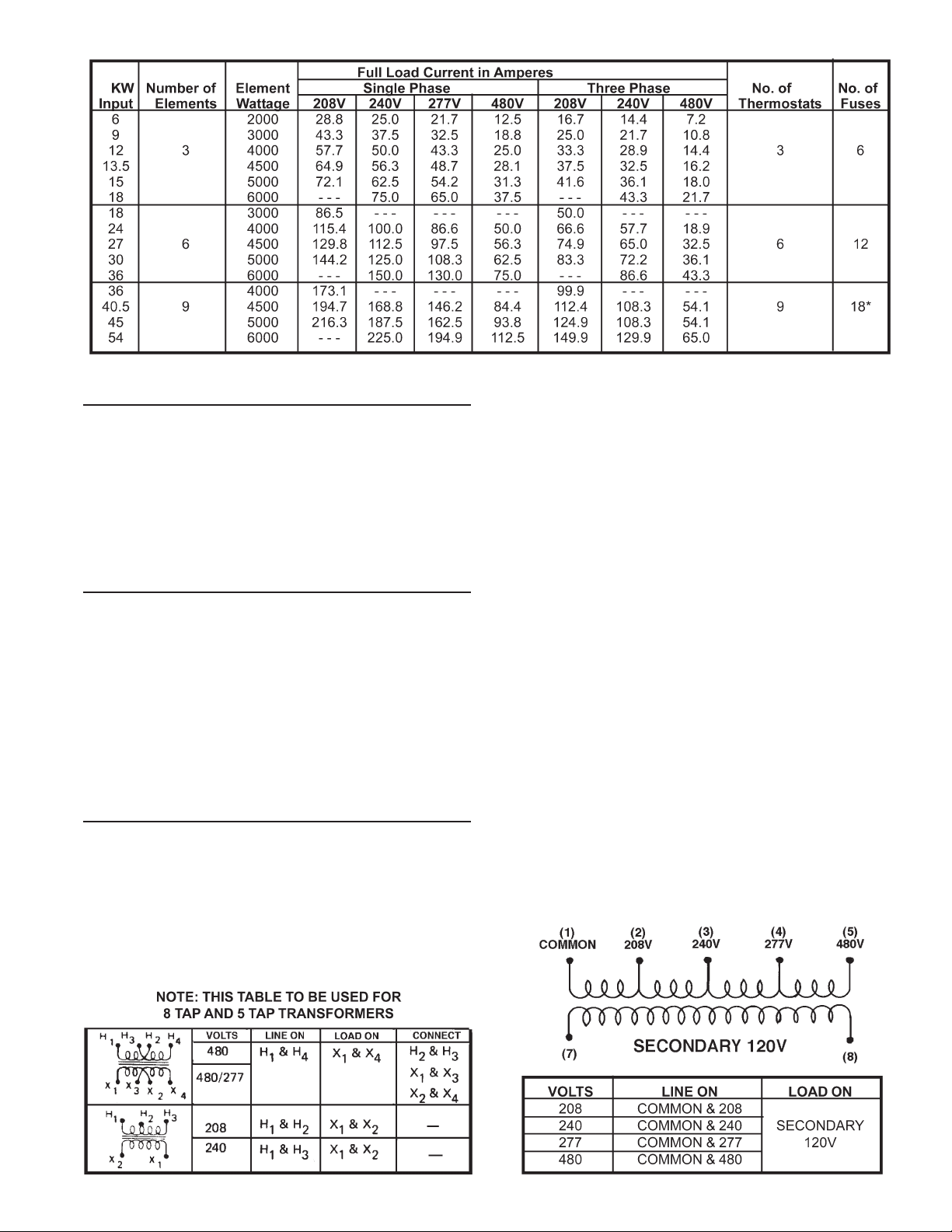

AMPERAGE TABLE/OVERCURRENT PROTECTION

The tables above provides the total connected heating element load

in amperes for branch circuit conductor and overcurrent protection

sizing. Single-phase heaters are two wire circuits. Three-phase

heaters are three wire circuits. In addition to the foregoing, a

grounded conductor is required.

The rating of the overcurrent protection must be computed on the basis

of 125% of the total connected load amperage. Where the standard

ratings and settings do not correspond with this computation, the next

higher standard rating or setting should be selected.

HEATER CIRCUITS - ELECTRONIC CONTROL MODELS

The water heater’s electrical components are pictured and identied

in Figures 1 and 2. The model and rating plate illustration on page 4

identies heater circuit ratings. The ELECTRONIC CONTROL model

has two electrical circuits.

• The control circuit, which controls the electrical power to heating

elements, referring the following control circuit diagram Figure 3.

• The power circuit, which is operated by the control circuit carries

the electrical load of the heating elements. The following

describes the heater circuits and includes wiring diagrams for

Delta conguration, refer to the “WYE Conguration Insert” for

water heaters operating at 380V/400V/416V/575V. All heater

circuits are designed for 50/60 cycle alternating current.

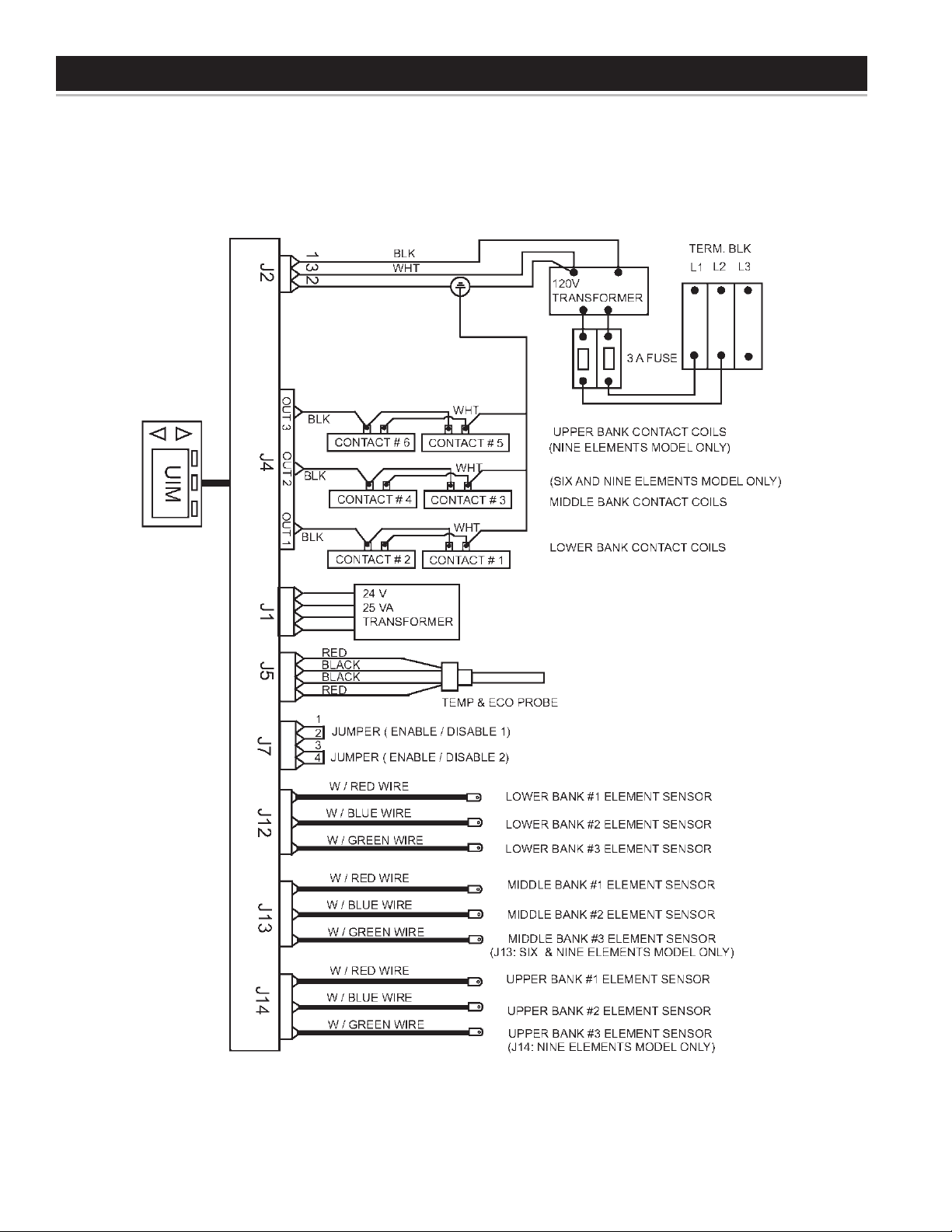

CONTROL CIRCUIT - ELECTRONIC CONTROL MODELS

These models are equipped with an electronic control system. The

system includes a CCB (Central Control Board) circuit board, an

immersion temperature probe with ECO for temperature sensing and

limiting, a UIM (User Interface Module) for user interface & information

display and element current sensors for monitoring the power circuits.

Refer to the control circuit label on the water heater for details. The CCB

is powered by a small 120V/24V transformer. The control circuit operates

on 120V supplied by a larger 100VA transformer. Standard equipment

includes control circuit fusing using two, 3 amp, class G fuses with 600

volt rating. Do not substitute fuses of a different rating.

Sequence of Operation

1. When the control is powered, the UIM should display model

information, water temperature, Operating Set Point, heating

status and operating mode.

2. If the control determines that the actual water temperature inside

the tank is below the programmed Operating Setpoint minus the (1st)

differential, a call for heat is activated.

3. After all safety checks are veried, the CCB will energize contactor

coils starting with the lower bank of heating elements (each

diagonal row of three heating elements is considered a “bank” - see

Figure 1) then energize the middle bank (if so equipped) and top bank

(if so equipped). The middle and top banks (if so equipped) are

energized according to programmed 2nd and 3rd differential

set points.

4. The control remains in the heating mode until the water temperature

reaches the programmed Operating Setpoint. At this point the

contactors will be de-energized in the reverse order.

5. The control system now enters the standby operating mode while

continuing to monitor the water temperature and the state of other

system devices. If the water temperature drops below the

programmed Operating Setpoint minus the (1st) differential, the control

will automatically return to step 2 and repeat the heating cycle.

NOTE: See the Electronic Control Models Operation section for more

detailed information on temperature settings mentioned above.

120 VAC CONTROL CIRCUIT TRANSFORMER CONNECTIONS - ELECTRONIC CONTROL MODELS

13

Page 14

WIRING DIAGRAMS

CCB (CENTRAL CONTROL BOARD) CIRCUIT BOARD

CONTROL CIRCUIT DIAGRAM - ELECTRONIC CONTROL MODELS

FIGURE 3.

14

Page 15

WIRING DIAGRAMS

POWER CIRCUIT DIAGRAMS - ELECTRONIC CONTROL MODELS

The water heater’s electrical components are pictured and identied on page 7. The following describes the heater circuits and includes wiring

diagrams. All heater circuits are designed for 60/50 hertz alternating current. The water heater circuit wiring is 12 AWG, AWM, or TEW type,

rated 600 volts, 105°C. Fusing consists of three 30 amp fuses for each contactor. Fusing is an optional feature for Canadian models.

THREE ELEMENTS - SINGLE AND THREE PHASE

SIX ELEMENTS - SINGLE AND THREE PHASE

DIAGRAM 1.

15

Page 16

WIRING DIAGRAMS

NINE ELEMENT - SINGLE AND THREE PHASE

DIAGRAM 2.

CONVERSION TO SINGLE PHASE

When the heater is shipped for connection to a three-phase electrical

service, it may be connected to a single-phase electrical service of

the same voltage by:

1. Disconnect blue wires and yellow wires from terminal L3.

2. Reconnect all blue wires to terminal L1 (with black wires).

3. Reconnect all yellow wires to terminal L2 (with red wires).

4. Connect incoming power to terminals L1 and L2.

CONVERSION TO THREE PHASE

When heater is shipped for connection to a single-phase electrical

service, it may be connected to a three-phase electrical service of

the same voltage by:

1. Disconnect blue wires from terminal L1.

2. Disconnect yellow wires from terminal L2.

3. Reconnect all blue wires and yellow wires to terminal L3.

4. Connect incoming power to terminals L1, L2, and L3.

16

Page 17

WIRING DIAGRAMS

POWER CIRCUIT DIAGRAMS - SURFACE MOUNT CONTROL MODELS

The water heater’s electrical components are pictured and identied on page 8. The following describes the heater circuits and includes

wiring diagrams. All heater circuits are designed for 60/50 hertz alternating current. The water heater circuit wiring is 12 AWG, AWM, or TEW

type, rated 600 volts, 105°C. Fusing consist of two 30 amp fuses for each element. Fusing is an optional feature for Canadian models.

DIAGRAM 3.

17

Page 18

WIRING DIAGRAMS

NINE ELEMENTS - SINGLE AND THREE PHASE

DIAGRAM 4.

CONVERSION TO SINGLE PHASE

When the heater is shipped for connection to a three-phase electrical

service, it may be connected to a single-phase electrical service of

the same voltage by:

1. Disconnect blue wires from terminal L2.

2. Connect all blue wires to terminal L1 (with black wires).

3. Disconnect all red wires from terminal L3.

4. Connect all red wires to terminal L-2 (with yellow wires).

5. Connect incoming power to terminals L1 and L2.

CONVERSION TO THREE PHASE

When heater is shipped for connection to a single-phase electrical

service, it may be connected to a three-phase electrical service of

the same voltage by:

1. Disconnect blue wires from terminal L1

2. Disconnect red wires from terminal L2.

3. Connect all blue wires to terminal L2 (with yellow wires).

4. Connect red wires to terminal L3.

5. Connect incoming power to terminals L1, L2 and L3.

18

Page 19

OPERATION

GENERAL

Refer to the Features and Components section of this manual

(pages 7 & 8) for the location of components mentioned in the

instructions that follow.

NEVER turn on power to the water heater without being certain the

water heater is lled with water and a temperature and pressure

relief valve is installed in the relief valve opening.

DO NOT TEST ELECTRICAL SYSTEM BEFORE HEATER IS

FILLED WITH WATER. FOLLOW FILLING AND START-UP

INSTRUCTIONS IN OPERATION SECTION.

FILLING THE WATER HEATER

INITIAL START UP

The following checks should be made by the installer when the

heater is placed into operation for the rst time.

1. Turn off the electrical disconnect switch.

2. Open the front panel, check all water and electrical connections for

tightness. Also check connections on top and side of heater. Repair

water leaks and tighten electrical connections as necessary.

3. Depress the red manual reset button on each Thermostat/ECO

combination control (Surface Mount Control Models only).

4. Turn on the electrical disconnect switch.

5. Observe the operation of the electrical components during the rst

heating cycle. Use care as the electrical circuits are energized.

6. Close the front panel.

Temperature control and contactor operation should be checked

by al l owi ng hea ter to co me u p to temp e rat ure an d shut

off automatically. Use care as the electrical circuits are

energized.

DRAINING THE WATER HEATER

The water heater must be drained if it is to be shut down and

exposed to freezing temperatures. Maintenance and service

procedures may also require draining the heater.

1. Turn off the electrical disconnect switch.

2. Close the supply water inlet valve to heater.

3. Attach hose to outlet opening of drain valve and direct end

to drain.

4. Open a nearby hot water faucet and the heater drain valve.

5. If the heater is being drained for an extended shutdown, it is

suggested the drain valve be left open during this period. The

hose may be removed.

1. Turn off the electrical disconnect switch.

2. Close the water heater drain valve.

3. Open a nearby hot water faucet to permit the air in the system

to escape.

4. Fully open the cold water inlet pipe valve allowing the heater

and piping to be lled.

5. Close the hot water faucet as water starts to ow. The heater is

now ready for STARTUP and TEMPERATURE REGULATION.

Follow FILLING instructions when restoring hot water service.

19

Page 20

TEMPERATURE REGULATION

HIGH TEMPERATURE LIMIT CONTROLS (ECO)

Both the ELECTRONIC CONTROL and SURFACE MOUNT

CONTROL model water heaters are equipped with one or more ECO

(energy cut off) non adjustable high temperature limit control(s). An

ECO is a normally closed switch that opens (activates) on a rise

in temperature. If the ECO switch contacts open (activate) due to

abnormally high water temperatures it will lock-out and disable further

heating element operation. It is important that a qualied service

agent be contacted to determine the reason for the ECO activation

before resetting the ECO. Once the reason has been determined

and corrected the ECO(s) can be reset as follows:

Surface Mount Control Models

Surface Mount Control models have multiple surface mounted

Thermostat/ECO combination controls. One for each installed heating

element - see the Surface Mount Control wiring diagrams in this manual.

The ECO high temperature limit switch contacts on each control will

open when the tank temperature reaches approximately 200°F/93°C.

When the ECO switch contacts open (activate) voltage to ONE heating

element ONLY is terminated to prevent further heating operation of

that element. Voltage may still be present at other heating elements

and they may still be heating the water.

The ECO is a manual reset switch. Should one or more ECO

activate, the tank temperature must drop below 120°F/49°C before

an ECO can be reset. To manually reset an ECO:

1. Disconnect the power supply to the water heater.

2. Allow the tank temperature to cool below 120°F/49°C.

3. Remove the front control cover from the effected control(s).

4. Press the manual reset button on each of the effected controls.

Once the control(s) has been reset the control cover should be

replaced prior to restoring power to the water heater.

Setting the water heater temperatures at 120°f will reduce the

risk of scalds. Some States require settings at specific lower

temperatures.

THERMOSTAT SETTINGS - SURFACE MOUNT CONTROL

These models have multiple thermostat/ECO combination controls

one for each heating element installed. These thermostats are set from

the factory at 140°F/60°C. Set the thermostat dial at the lowest setting

which produces an acceptable hot water supply. This will always give

the most energy efcient operation.

Electronic Control Models

The ECO high temperature limit switch is located inside the

immersion Temperature Probe (two red wires) on ELECTRONIC

CONTROL models. The ECO switch contacts will open when the

water temperature reaches approximately 202°F/94°C. When

the ECO switch contacts open (activate) the electronic control

system locks out and displays a Fault message. Voltage to the

contactor coils and heating elements is terminated to prevent

further heating operation.

Should the ECO activate, the water temperature must drop below

140°F/60°C before the control system can be reset. Once the water

temperature has cooled below this point the power supply to the water

heater must be turned off and on again to reset the control system.

THERMOSTAT CONTROLS

The water heaters covered in this instruction manual are equipped

with adjustable thermostat controls to control water temperature.

Hot water temperatures required for automatic dishwasher and

laundry use can cause scald burns resulting in serious personal

injury and/or death. The temperature at which injury occurs

varies with the persons age and duration of exposure. The

slower response time of children, the elderly or disabled persons

increases the hazards to them. Never allow small children to use

a hot water tap or draw their own bath water. Never leave a child

or disabled person unattended in a bathtub or shower.

The water heater should be located in an area where the general

public does not have access to set temperatures.

Figure 4 shows the approximate time-to-burn relationship for normal

adult skin.

Temperature

Settings

180°F (82°C)

160°F (71°C)

150°F (66°C)

140°F (60°C)

130°F (54°C)

120°F (49°C)

80°F (27°C)

Time to Produce 2nd & 3rd

Degree Burns on Adult Skin

Nearly Instantaneous

About 1/2 second

About 1-1/2 seconds

Less than 5 seconds

About 30 seconds

More than 5 minutes

- - - - - - - - - - - - - - - -

FIGURE 4

20

Page 21

THERMOSTAT SETTINGS - ELECTRONIC CONTROLS

These models are equipped with an electronic control system. The

control system senses temperature from a factory installed Immersion

Temperature Probe (see Figure 1). The “Operating Set Point” is

adjusted to control water temperature. This is an adjustable user setting

in the control system’s “Temperatures Menu.” This and all control

system menus are accessed through the UIM (User Interface Module

- see Figure 5) located on the front panel of the water heater.

ELECTRONIC CONTROL MODELS OPERATION

The Operating Set Point is adjustable from 90°F/42°C to 190°F/88°C.

The factory setting is 120°F/49°C. See the Electronic Control Models

Operation section of this manual for instructions on how to adjust

the Operating Set Point and other user settings.

UIM (User Interface Module)

FIGURE 5

Set the Operating Set Point at the lowest setting which produces

an acceptable hot water supply. This will always give the most

energy efficient operation.

CONTROL SYSTEM FEATURES

AdvancedDiagnostics:Plain English text and animated icons display

detailed operational and diagnostic information. LCD screen on the

front of the water heater displays the Sequence of Operation in real

time. Fault or Alert messages are displayed when operational problems

occur. Advanced Service menu displays a list of possible causes for

current Fault and Alert conditions to aid in servicing.

EconomyMode Operation: Control system automatically lowers

the Operating Set Point by a programmed value during user dened

time periods. Helps reduce operating costs during unoccupied or

peak demand periods.

LinearSequencing: Banks of heating elements (3 elements per

bank) are energized according to adjustable (1 to 20°) differential

set points for each bank. First bank on is the last bank off. Helps

reduce operating costs during low/moderate loads.

CONTROL SYSTEM NAVIGATION

The UIM (User Interface Module) is located on the front cabinet of the

Electronic Control Model water heaters. All operational information

and user settings are displayed and accessed using the UIM. The

UIM includes ve snap acting (momentary) user input buttons; an

Up, Down and 3 Operational Buttons.

Up & Down Buttons

Used to navigate (up and down) and to select (highlight) menu items.

Also used to adjust or change (increase/decrease, on/off, set time)

various user settings.

Operational Buttons

The 3 Operational Buttons are multifunctional. Their current function is

dened by the text that appears above each button on the LCD screen.

The function will change depending on what menu is currently displayed

or what menu item is selected. When no text appears on the LCD

screen above an Operational Button there is no function assigned.

THE DESKTOP SCREEN

Figure 7 below shows the control system “Desktop Screen.” This

is the default screen. If there are no active Fault or Alert conditions

and no user input for approximately 10 minutes the control system

will return to this screen automatically.

Model Information

Model information and menu titles are shown in the black bar at the

top of the Desktop Screen.

Tank Temperature

Current water tem pe ra tu re as sen se d from t he immersion

Temperature Probe.

OperatingSetPoint:Temperature at which the control system will

maintain tank (water) temperature in the Normal Mode. This line of

text will read Economy Set Point whenever the control system is

operating in the Economy Mode.

Status: The Operating State of the control system is displayed

beneath the Operating Set Point.

UIM - USER INTERFACE MODULE

FIGURE 6.

FIGURE 7.

21

Page 22

Menu: The left Operational Button is pressed to enter the Main Menu

where all control system menus are accessed. See Table 3 for a list

of control system menus.

Help:The right Operational Button is pressed to access instructions

and explanations for user settings, Operating States, Status Icons,

manufacturer’s web address, technical support phone number and

service agent contact information.

Day/Time/Operating Mode: T he c urrent time and day a re

also displayed on the Desktop Screen. “Clock Not Set” will be

displayed until the time clock has been initially set. Day and Time

TABLE 1 STATUS ICONS.

ICON DESCRIPTION

Water temperature in the tank has fallen. Shaded area of the animated thermometer icon will rise and fall in

response to water temperature in the storage tank as sensed from the immersion Temperature Probe.

Water temperature in the tank has reached the Operating Set Point. Shaded area of the animated thermometer

icon will rise and fall in response to water temperature in the storage tank as sensed from the immersion

Temperature Probe.

are adjusted in the Economy Mode Setup menu. The current

Operating Mode, either Normal Mode or Economy Mode, is

displayed beneath the day and time.

DiscreetMenuContactInformation: From the Desktop Screen

press and hold down the middle (unmarked) Operational Button for

30 seconds and then release it. This will launch a discreet menu

where personalized contact information can be entered. Installing

contractors and/or service agents can enter their company name

and telephone number. This contact information will be displayed

with all Fault and Alert messages.

The control is unable to initiate a heating cycle. This will happen whenever a Fault condition is detected by the

control system or when either of the two Enable/Disable circuits are open circuits.

The control system is in Heating Mode and has energized the electromagnetic contactor coils for at least one bank

of heating elements. This animated icon DOES NOT indicate current has been sensed from the heating elements,

only that there is a call for heat present and the control system has initiated heating operation.

Heating elements icon for a water heater equipped with 1 Bank of heating elements. Each circle represents one

heating element. Each diagonal row of 3 elements = 1 Bank of elements. Open circles represent heating elements

the control system has not energized and is not sensing electrical current from.

Heating elements icon for a water heater equipped with 2 Banks of heating elements. Each circle represents one

heating element. Each diagonal row of 3 elements = 1 Bank of elements. Open circles represent heating elements

the control system has not energized and is not sensing electrical current from.

Heating elements icon for a water heater equipped with 3 Banks of heating elements. Each circle represents one

heating element. Each diagonal row of 3 elements = 1 Bank of elements. Open circles represent heating elements

the control system has not energized and is not sensing electrical current from.

Heating elements icon for a water heater equipped with 3 Banks of heating elements. Each circle represents one

heating element. Each diagonal row of 3 elements = 1 Bank of elements. Filled circles represent heating elements

the control system has energized AND is sensing electrical current from.

Heating elements icon for a water heater equipped with 3 Banks of heating elements. Each circle represents one

heating element. Each diagonal row of 3 elements = 1 Bank of elements. Open circles with an X represent heating

elements the control system has energized that it IS NOT sensing electrical current from.

The control has detected/declared a Fault Condition. Fault message details can be viewed in the Current Fault

menu. Heating operation is discontinued (locked out) until the condition that caused the fault is corrected. Power to

the water heater must be cycled off and on to reset the control system. Note; cycling power will not reset the control

system if the condition that caused the fault has not been corrected.

The control has detected/declared an Alert Condition. The water heater will continue to operate during an Alert

Condition but there is an operational condition that requires the attention of a Qualied Service Agent. Alert message

details can be viewed in the Current Alert menu.

22

Page 23

TABLE 2 OPERATING STATES.

STATE DESCRIPTION

Standby

Heating The control system is in the Heating Mode. At least one bank of heating elements has been energized.

Alert

Fault

MENUS DESCRIPTION

Temperatures

Heater Status

Economy Mode

Setup

Alarm Output

Setup

The water heater is not in an active heating cycle. This usually indicates the temperature in the tank has reached

the Operating Set Point and the control system has terminated the heating cycle.

The control system has detected/declared an Alert Condition. The controls system will continue heating operation.

However, a Qualied Service Agent should be contacted to check/service the water heater.

The control system has detected/declared a Fault Condition. The control system will discontinue heating operation

and “lock out.” Power to the water heater must be cycled off and on to reset the control system. Note; cycling power

will not reset the control system until the condition that caused the fault has been corrected.

TABLE 3 CONTROL SYSTEM MENUS.

Most commonly accessed menu. Operating Set Point, Differential settings, Tank Temperature and Tank Probe

Offset are located in this menu.

Current Operating State/Mode (heating/standby etc) and status (open/closed - on/off - yes/no) of monitored water

heater functions and components are displayed in this menu.

Seven day 24 hour time clock with temperature set back capability to reduce operating costs during unoccupied

or reduced demand periods.

The control system’s CCB (Central Control Board) features on board SPDT (single pole double throw) relay contacts

for building EMS (Energy Management System) notication of operational conditions such as Fault Conditions and

heating mode status. This menu features a list of user denable conditions for relay activation.

Display Settings

Heater Information

Current Fault/Alert Displays any current Alert or Fault messages.

Fault History

Fault Occurrence

Restore Factory

Defaults

Help Menu

Temperature units (°F or °C), appearance (brightness contrast) and backlight delay user adjustable settings are

located in this menu.

Elapsed time of operation, total heating cycle time, heating cycle count, heating element bank(s) cycle count and

heating bank on time along with UIM and CCB software revisions can be viewed in this menu.

Retains 9 event history of Fault/Alert messages with time stamp. The Fault History is useful when dealing with intermittent

operational problems or when the customer has reset the control system prior to a service agent’s arrival.

Running total of all Fault and Alert Conditions that have occurred are displayed in this menu. Can help determine

potential root cause(s) of related operational problems.

This control system feature allows the user to restore control system user settings to their factory default settings.

Alarm Output Setup and Display Settings menu items ARE NOT changed when factory defaults are restored.

Accessible by pressing the corresponding Operational Button from most menus and screen displays. This menu

provides access to instructions and explanations for user settings, Operating States, Status Icons, manufacturer’s

web address, technical support phone number and service agent contact information.

TEMPERATURES MENU

Operating Set Point

User adjustable setting 90°F to 190°F range; factory default is

120°F. When the water temperature sensed by the control system

from the immersion Temperature Probe reaches the Operating Set

Point the control system will end the heating cycle. A call for heat

will be activated again when the water temperature drops below the

Operating Set Point minus the 1st Differential Setting.

Example: Operating Set Point is 120°F, the 1st Differential Setting is

2°F (factory default). A call for heat will be activated when the sensed

water temperature drops to 118°F.

23

Page 24

Differential Settings

Adjustable user setting(s) 1°F to 20° range; factory default is 2°F.

The water heaters covered in this Instruction Manual will have 3, 6 or

9 heating elements. Each group of 3 heating elements is one “Bank” of

heating elements. Heating elements are energized in Banks of 3. Each

Bank of heating elements will have a Differential Setting associated

with it. Differential Settings are located in the Temperatures Menu.

There is a 1st Differential Setting on all models. There will be one

additional Differential Setting visible/adjustable for each additional

Bank of (3) heating elements.

Operating Sequence

With an Operating Set Point of 120°F and all Differential settings at 2°F

the On/Off sequencing of heating element Banks would be as follows:

BANK NUMBER

DIFFERENTIAL

SETTING

TURN ON

TEMP

TURN OFF

TEMP

Bank 1 2°F 118°F 120°F

Bank 2 2°F 116°F 118°F

Bank 3 2°F 114°F 116°F

ACTION DISPLAY

From the Desktop Screen, press the Operational Button underneath “MENU”

to enter the Main Menu.

Notice how the text above the Operational Buttons on the display changes

as you navigate through the various menus and screens.

Tank Temperature

Non adjustable information display. Current water temperature as sensed

by the control system from the immersion Temperature Probe.

Tank Probe Offset

User adjustable setting -5°F to +5°F range; factory default is 0°F. If the

current Tank Temperature is sensed (from the immersion Temperature

Probe) at 120°F and the offset is adjusted to -5°F the control system

would calibrate or “offset” the Tank Temperature to 115°F. Heating cycles

would then start/stop based on the calibrated Tank Temperature.

Used to calibrate for slight differences in control system temperature

sensing. This can improve the precision of temperature control in

the storage tank and at points of use. This feature can also be

used to compensate for building recirculation loops (hot water

returning to the storage tank) that may cause the heating cycle to

terminate prematurely.

TEMPERATURE SETTINGS

The Operating Set Point and the Differential Settings are adjusted

in the Temperatures Menu. The following instructions explain how to

adjust these user settings and navigate the control system menus.

With Temperatures selected (highlight in black) in the Main Menu, press

the Operational Button underneath “SELECT” to enter the Temperatures

Menu.

If Temperatures is not selected use the Up and Down buttons to select this

menu item.

With the Operating Set Point selected in the Temperatures Menu, press

the Operational Button underneath “CHANGE” to activate the adjustment

mode for this menu item.

Press the Up and Down buttons to adjust the Operating Set Point to the

desired setting.

Press the Operational Button underneath “UPDATE” to conrm the new

setting. Press the Operational Button underneath “CANCEL” to discard the

new setting and retain the previous setting.

The new Operating Set Point value should now be displayed as the current

value.

NOTE: Use this same procedure to adjust the Differential settings and the

Tank Probe Offset in the Temperatures Menu.

This same procedure is used to change user settings in other control system

menus.

24

Page 25

HEATER STATUS MENU

This menu displays non adjustable operational information. This

menu contains more information that can be displayed on one screen

of the LCD display. Use the Up & Down Buttons to navigate to the

bottom of this menu.

Top of Menu

Bottom of Menu

Alarm Condition

Displays the status of the user denable Alarm Output function - see

Alarm Output Setup Menu. Yes = alarm condition has been met, No

= alarm condition has not been met.

Alarm Relay Output

Displays the state of the normally open contacts of the Alarm Output

relay. This relay (J3 contacts on the CCB) is used for building EMS

(Energy Management System) notication of operational conditions

such as Fault conditions.

ECONOMY MODE SETUP MENU

This menu contains settings used to establish an “Economy Set

Point” and “Economy Mode” operating periods. This control system

feature can help reduce operating costs during unoccupied, low load,

or peak demand periods.

Desktop Screen During Economy Mode

Status

Displays the current Operating State of the control system. IE:

Heating, Standby, Fault see Table 2.

Element Banks On

Displays the current number of heating element Banks the control

system has energized. Each Bank of elements contains 3 heating

elements.

ECO Contact

Displays the current state of the ECO high temperature limit

switch contacts. The ECO switch is located inside the immersion

Temperature Probe (two red wires).

Enable / Disable 1 & 2

Displays the current state, open or closed, of the two Enable/Disable

circuits (J7 socket on the CCB - see wiring diagrams) provided

for external supervisory controls such as building EMS (Energy

Management System). Both of these Enable/Disable circuits must be

closed to “enable” heating operation. If either Enable/Disable circuit is

open for any reason heating operation will be “disabled.” There is a plug

with two jumper wires installed from the factory in the CCB J7 socket to

enable heating operation when external controls are not in use.

Service Note: If a supervisory control(s) is used to enable/disable

heating operation, install eld wiring between the J7 socket on the CCB

and a set of “dry contacts” on the external control per all applicable

building codes. This is a switching circuit only: DO NOT apply any

external voltage or connect any load (IE: relay coil) to either circuit.

Economy Mode Setup Menu

Setpoint Adjustment

Adjustable user setting (2°F to 50°F - factory default is 20°F) the

control system uses to calculate the “Economy Set Point.” The Economy

Set Point = normal Operating Set Point minus the programmed Setpoint

Adjustment value. The Economy Set Point is the water temperature

the control system maintains during programmed Economy Mode time

periods. “Economy Set Point” is displayed instead of “Operating Set

Point” and “Economy Mode” appears beneath the current time on the

Desktop Screen during Economy Mode time periods.

Current Time

Seven Day 24 hr clock. Use this menu item to set the current time

and day of the week. Current day and time are not set from the

factory. “Clock Not Set” will be displayed on the Desktop until the

time/day has been initially set.

Heater In Economy Mode

Displays whether the control system is currently operating in

Economy Mode or not.

Element Bank On

Displays the on/off status of each Bank of heating elements. Yes =

On, No = Off.

Daily Operating Mode (Sun - Mon - Tue - Wed - Thu - Fri - Sat)

Seven daily sub menus are listed at the bottom of the Economy Mode

Setup menu. There are 3 Operating Modes in each sub menu;

25

Page 26

“Normal Operation All Day” - “Economy Mode All Day” and “Normal

Operation Between.” Only one Operating Mode can be active, the

factory default is Normal Operation All Day.

NormalOperationAllDay:When this operating mode is active the

normal Operating Set Point is used for the entire day.

EconomyModeAllDay:When this operating mode is active the

Economy Set Point is used for the entire day.

ACTION DISPLAY

From the Desktop Screen, press the Operational Button underneath “MENU”

to enter the Main Menu.

Notice how the text above the Operational Buttons on the display changes

as you navigate through the various menus and screens.

Use the Up/Down buttons to select (highlight in black) the Economy Mode

Setup menu from the Main Menu. Press the Operational Button underneath

“SELECT” to enter the Economy Mode Setup menu.

NormalOperationBetween: When this operating mode is active

there will also be start and stop times to program. The normal

Operating Set Point is used between the programmed start and stop

times and the Economy Set Point will be in effect during the rest of

the day. There is one start time and one stop time event per day.

ECONOMY MODE SETTINGS

Setpoint Adjustment Value

Use the Up/Down buttons to select (highlight in black) Setpoint Adjustment.

Press the Operational Button underneath “CHANGE” to activate the

adjustment mode for the Setpoint Adjustment value.

Use the Up/Down buttons to change the Setpoint Adjustment to the desired

value. The Setpoint Adjustment value is adjustable from 2°F to 50°F. The

factory default is 20°F.

Notice how the text above the Operational Buttons on the display changes

to “UPDATE” & “CANCEL” when the adjustment mode is activated and how

the current value is outlined rather than highlighted in black.

Press the Operational Button underneath “UPDATE” to enter and conrm

the new value. Pressing the Operational Button underneath “CANCEL”

would discard the new value and retain the previous value.

The new Setpoint Adjustment value should now be displayed as the

current value.

26

Page 27

ECONOMY MODE SETTINGS

Time Clock Settings

ACTION DISPLAY

From the Desktop Screen navigate to the Economy Mode Setup menu.

Use the Up/Down buttons to select (highlight in black) Current Time sub

menu. Press the Operational Button underneath “CHANGE” to enter the

Current Time sub menu.

Use the Up/Down buttons to select the “Weekday” setting.

Press the Operational Button underneath “CHANGE” to activate the

adjustment mode for this setting.

Press the Up and Down buttons to adjust the Weekday setting to the

current day.

Notice how the text above the Operational Buttons on the display changes

to “ACCEPT” & “CANCEL” when the adjustment mode is activated and how

the current setting is outlined rather than highlighted in black.

Press the Operational Button underneath “ACCEPT” to enter and conrm

the new setting. Pressing the Operational Button underneath “CANCEL”

would discard the new setting and retain the previous setting.

Use the Up/Down and the CHANGE/ACCEPT Operational Buttons to

individually select and change the remaining time settings (Hour, Minutes,

AM/PM) to the current time in the same way as outlined above.

When nished making changes press the Operational Button underneath

“BACK” to conrm all new settings and update the control system. The

display will automatically return to the Economy Mode Setup menu.

The new settings should be displayed as the Current Time.

27

Page 28

ECONOMY MODE SETTINGS

Daily Operating Mode Settings

ACTION DISPLAY

Economy Mode All Day:

From the Economy Mode Setup menu use the Up/Down buttons to select

(highlight in black) the Daily sub menu for “Sun.” Press the Operational

Button underneath “CHANGE” to enter this menu.

Use the Up/Down buttons to select (highlight in black) the “Economy Mode

All Day” setting.

Press the Operational Button underneath “SELECT” to change from the

factory default Normal Operation All Day setting to the Economy Mode All

Day setting.

Press the Operational Button underneath “BACK” to conrm the new setting

and update the control system. You will be returned to the Economy Mode

Setup menu. The new setting should now be displayed for Sun.

Normal Operation Between:

From the Economy Mode Setup menu Use the Up/Down and CHANGE

buttons to enter the Mon sub menu.

Use the Up/Down buttons to select (highlight in black) the “Normal Operation

Between” setting. Press the Operational Button underneath “SELECT” to

change the operating mode for Monday to Normal Operation Between.

Note that when this setting is selected Start and Stop time user settings

appear on the display.

Use the Up/Down buttons to navigate between the Start and Stop time Hour,

Minutes and AM/PM settings.

With each item selected press the Operational Button underneath “SELECT”

to activate the adjustment mode for each setting. Use the Up/Down buttons

to change the value to the desired setting.

Press the Operational Button underneath “ACCEPT” to enter the new setting

or “CANCEL” to discard the new setting and retain the previous setting.

Press the Operational Button underneath “BACK” to conrm the settings

and update the control system. You will be returned to the Economy Mode

Setup menu. The new settings should be shown for Mon.

28

Page 29

ALARM OUTPUT SETUP MENU

Permits user to set the condition (from a list of options) for when

the CCB’s integral alarm output relay will be energized. Alarm relay

connections (common, normally open, normally closed) are located

on the J3 terminal strip on the CCB. Alarm output relay contacts are

capable of switching 1 amp maximum at 120 VAC.

The alarm relay operates in the background according to the settings

in this menu and is not capable of disabling water heater operation.

The alarm relay is used for external notication/verication of

various operational conditions such as fault conditions and heating

mode status. This relay can be used with building EMS (Energy

Management System) and other external supervisory controls.

DISPLAY SETTINGS MENU

Permits user to set display options for viewing information on the

UIM’s LCD screen.

Temperature Units

Adjustable user setting that changes temperature units display to

Celsius °C or Fahrenheit °F.

Backlight Delay

Adjustable user setting that determines how long the UIM’s LCD

backlight remains illuminated after a key has been pressed. Available

settings are; Always Off, 10, 30 or 60 seconds and Always On.

Contrast

Adjustable user setting to adjust the UIM’s LCD screen contrast

between text and background.

Display Settings

Changing the user settings in this menu is done using the same

methods for changing the Operating Set Point.

Service Note

Adjustable user settings in the Display Settings menu are unaffected

by Restore Factory Defaults.

Output Function

Adjustable user setting. Available options for the Alarm Output

Function setting are:

HeatingMode: Used for heating mode on/off status notication.

Enable/DisableClosed:Used for notication and/or verication of

the enable/disable circuits open/closed status. There are two enable/

disable circuits available for external supervisory control(s) at the J7

socket on the CCB - see wiring diagrams. Enable/disable circuit(s)

status can be viewed in the Heater Status Menu.

Temp<HeaterSP: Used for external notication when current tank

temperature drops below Operating Set Point.

Temp<AlarmSP:Used for external notication when current tank

temperature drops below programmable Alarm SP.

FaultorAlert: Used for external notication whenever a Fault or

Alert condition is active.

Fault:Used for notication whenever a Fault condition is active.

Disabled: Disables the Alarm Relay Output Function.

AlarmSP:Adjustable user setting (90°F to 190°F) the control system

uses for the “Temp < Alarm SP” function described above. This setting

has no effect with any other Alarm Output functions.

AlarmOutputSettings: Changing the user settings in this menu is

done using the same methods for changing the Operating Set Point.

HEATER INFORMATION MENU

This menu displays non adjustable operational information.

TOP OF MENU

ServiceNote: Adjustable user settings in the Alarm Output Setup

menu are unaffected by Restore Factory Defaults.

BOTTOM OF MENU

29

Page 30

Elapsed Time

Total accumulated time the control system (water heater) has been

energized.

Total Heating Time

Total accumulated time the control system has been in the heating

mode. IE: any heating elements have been energized.

Bank # Cycles

Total accumulated count of heating cycles for each Bank of heating elements.

Bank # On Time

Total accumulated heating on time for each Bank of heating

elements.

CCB Version

Software version for Central Control Board.

UIM Version

Software version for User Interface Module.

CURRENT FAULT / ALERT MENU

This menu displays non adjustable operational information. With the

Fault History sub menu selected in Main Menu; press the Operational

Button underneath “SELECT” to display the current Fault or Alert

message. If there is not a Fault or Alert condition currently active

“(none)” is displayed to the right of this menu.

Main Menu - Current Fault Selected

This menu displays non adjustable operational information. The

control system records and stores the last 9 Fault and Alert

messages in chronological order in this menu. The most recent

will be at the top of the list. A time stamp is displayed below each

listed Fault and Alert message showing when the Fault or Alert

condition occurred.

The Fault History is useful when dealing with intermittent operational

problems or when the customer has reset the control system prior

to a service agent’s arrival.

With a Fault or Alert item selected press the Operational Button

underneath “VIEW” to display the details for the Fault or Alert

message. The Fault/Alert mess age screen disp lays a b rief

description of the condition, contact information and access to the

Advanced service information sub menu.

Current / History Fault Message

FAULT HISTORY MENU

Fault History Menu

FAULT OCCURRENCE MENU

Total accumulated number each individual Fault condition has

occurred is displayed in this menu. This running total of Fault

Occurrences can be useful in determining which (if any) operational

problems have been persistent.

Fault Occurrence Menu

RESTORE FACTORY DEFAULTS MENU

This control system menu allows the user to restore most of the

control system’s user settings to their factory default settings. User

settings in the Alarm Output Setup and Display Settings menus are

unaffected by executing Restore Factory Defaults.

30

Page 31

Restore Factory Defaults

ACTION DISPLAY

From the Main Menu use the Up/Down buttons to select (highlight in black)

the “Restore Factory Defaults” menu.

Press the Operational Button underneath “SELECT.” The Restore Factory

Defaults menu will be displayed.

From the Restore Factory Defaults menu press the Operational Button

underneath “YES.” The display will show text conrming the factory default

settings have been restored.

Press the Operational Button underneath “BACK” to exit the Restore Factory

Defaults menu.

GENERAL

MAINTENANCE

Periodically the drain valve should be opened and the water

allowed to run until it flows clean. This will help to prevent

sediment buildup in the tank bottom.

Periodically check the temperature and pressure relief valve to ensure

that it is in operating condition. Lift the lever at the top of the valve

several times until the valve seats properly and operates freely.

Water heater maintenance includes periodic tank flushing and

cleaning, and removal of lime scale from the heating element.

The heater tank is equipped with an anode rod to aid in corrosion control.

ANODE INSPECTION AND REPLACEMENT

Inspection of the sacricial anode every 6 to 12 months allows you

to identify a spent anode and replace it. Replace the anode when

31

Page 32

its diameter is 3/8” (1 cm) of an inch, or annually which ever is rst.

Aggressive, very hot and softened water causes rapid consumption

of the anode requiring frequent inspections. Call the toll free number

on the back cover of this manual for information on obtaining

replacement anode rods.

MAINTENANCE SCHEDULE

Component Operation Interval Required