Page 1

DURA-POWER™ XI

COMMERCIAL ELECTRIC

COMMERCIAL

ELECTRIC WATER HEATERS

ADVANCED ELECTRONIC CONTROL

A. O. Smith’s new propriety electronic water

heater control, provides precise + or - 1ºF

temperature control, that is ideal for industrial

and food service applications where accurate

hot water temperatures are needed.

EASY-TO-READ TEXT

• Animated icons display detailed operational

and diagnostic information. Fault or alert

messages appear if an operational issue

occurs.

LOW WATER CUT OFF

• Factory standard on board low water cut-off

uses a remote electronic immersion type

probe to prevent energizing of the elements

in the event of low water condition and

eliminates accidental dry firing.

PROGRESSIVE MODULATING

• Matches number of elements to current

load conditions. Rotates and lead lags

element loads to provide long life and equal

wear.

ECONOMY MODE OPERATION

• Control system automatically lowers the

operating set point by a programmed value

during user defined time periods. Seven-day

clock may be programmed for night set

back and or weekend shutdown to reduce

operating cost and save money.

BMS COMPATIBLE

• Modbus/BACnet compatible with optional

Gateway interface. Call 888 WATER02 for

more information.

PERMAGLAS® GLASS LINING IS

STANDARD

• Exclusive process provides superior

protection against corrosion in varying

water conditions. Cement and Epoxy linings

are optional.

ASME CODE CONSTRUCTION

• All models are constructed to the

requirements of ASME and are available in

125, 150 and 160 psi working pressures

(125 psi working pressure - standard).

Consult factory for ASME code tanks with

greater or lesser working pressures and

special configurations or materials.

INCOLOY IMMERSION HEATERS

• Heavy-duty elements have incoloy

sheathing: provide excellent protection

against oxidation and scaling. The input

ranges from 15kW to 900kW (see

accompanying chart).

FUSING

• Control and power circuit fusing to meet

N.E.C.

COMPLIANCE

• Meets the standby loss requirements of

the U.S. Department of Energy, NRCan and

current edition of ASHRAE/IES 90.1.

MAGNETIC CONTACTOR(S)

• Heavy duty UL rated for 100,000 cycles.

OTHER STANDARD FEATURES

• Color-coded circuitry for easier servicing

• Anode rods for maximum corrosion

protection

• Standard voltages include 208, 240, 380,

400, 415, 480, 600 volt single or threephase

• International voltages available (consult

factory)

• Factory-installed terminal block(s)

• Temperature and pressure relief valve,

supplied but not installed

OPTIONAL DUAL-ENERGY SOURCE

CAPABILITY

• Provides emergency back up energy source

or winter/summer boiler operation. Can

be specified with optional water to water

or steam to water heat exchangers. Both

single and double-wall heat exchangers are

available. Complete control packages can

be factory-installed for hook-up and run

capability.

THREE YEAR LIMITED WARRANTY

• For complete warranty information consult

written warranty or go to hotwater.com

Attention: Significant changes have been made to some

models. Please note that this spec sheet refers specifically

to models manufactured in Lebanon, TN

DVE-150 THRU 2500

DHE-150 THRU 2500

© October 2018 A. O. Smith Corporation. All rights reserved.

www.hotwater.com | 800-527-1953 Toll-Free USA | A. O. Smith Corporation | 500 Tennessee Waltz Parkway | Ashland City, TN 37015

Page 1 of 4

AOSCE15500

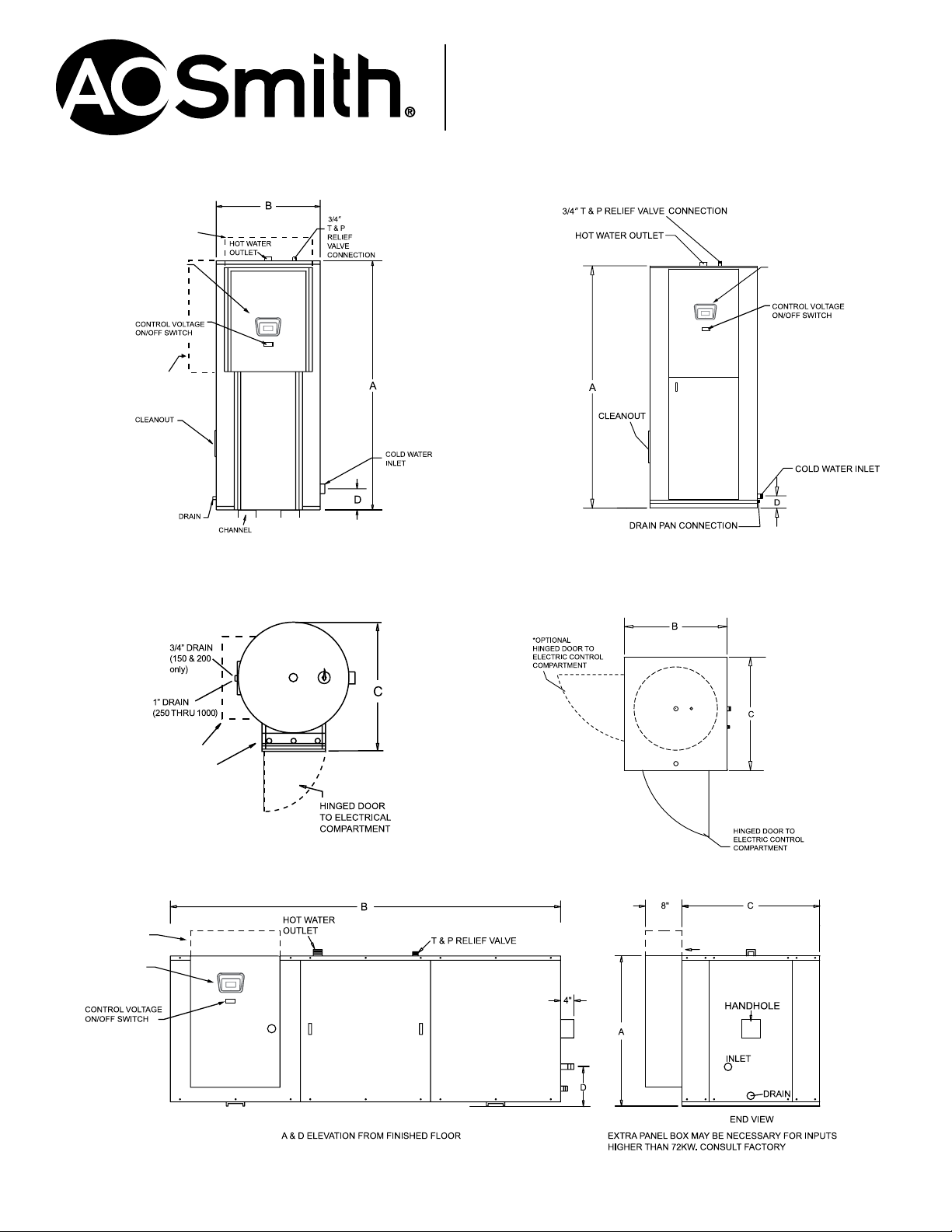

Page 2

COMMERCIAL

ELECTRONIC

CONTROL

LOCATION OF

ADDITIONAL

BOX FOR DUAL

BOX MODELS

ELECTRONIC

CONTROL

ADDITIONAL

HEIGHT IF

REQUIRED

(2" Channel on 150 gallon and higher. Optional on smaller sizes.)

LOCATION OF

ADDITIONAL

CONTROL BOX

IF NEEDED

ELECTRIC WATER HEATERS

Vertical Round Models 150-1000

*An oversized control panel may be required on models with inputs above 72 kW. Consult the

factory for specific details.

Vertical Square Models 1250-2500

TOP VIEWTOP VIEW

Horizontal Models

ADDITIONAL

HEIGHT IF

REQUIRED

ELECTRONIC

CONTROL

*An oversized control panel may be required on models with inputs above 72 kW. An oversized

control panel may increase the width and depth of the square jacket by up to 2”.

ADDITIONAL

HEIGHT IF

REQUIRED

Page 2 of 4

AOSCE15500

Page 3

COMMERCIAL

ELECTRIC WATER HEATERS

Model Number* Max. KW

Vertical Round Electric Storage Heater

DVE-150A 162 150 65-1/2” 32” 38-3/4” 11-3/4” 1-1/2” 1-1/2” 650

DVE-200A 162 200 78” 32” 38-3/4” 11-3/4” 1-1/2” 1-1/2” 750

DVE-250A 198 250 92” 34” 40-3/4” 19-1/4” 1-1/2” 1-1/2” 1,165

DVE-300A 180 300 80” 40” 46-3/4” 20-3/4” 2” 2” 1,350

DVE-400A 162 400 80” 46” 52-3/4” 22-1/4” 2” 2” 1,590

DVE-500A 162 500 92” 46” 52-3/4” 22-1/4” 2” 2” 1,700

DVE-600A 216 600 92” 52” 60-3/4” 24-1/4” 2-1/2” 2-1/2” 2,010

DVE-800A 216 750 104” 52” 60-3/4” 24-1/4” 2-1/2” 2-1/2” 2,450

DVE-1000A 216 950 128” 52” 60-3/4” 24-1/4” 2-1/2” 2-1/2” 3,160

Vertical Square Electric Storage Heater

DVE-150A 162 150 65-1/2” 32 38-3/4” 7-3/4” 1.5 1.5 650

DVE-200A 198 200 78 32 38-3/4” 7-3/4” 1.5 1.5 750

DVE-250A 234 250 92 34 40-3/4” 19-1/2” 1.5 1.5 1165

DVE-300A 288 300 80 40 46-3/4” 21 2 2 1350

DVE-400A 324 400 80 46 52-3/4” 22-1/2” 2 2 1590

DVE-500A 432 500 92 46 52-3/4” 22-1/2” 2 2 1700

DVE-600A 414 600 92 46 60-3/4” 24-1/2” 2.5 2.5 2010

DVE-800A 468 800 104 52 60-3/4” 24-1/2” 2.5 2.5 2450

DVE-1000A 648 1,000 128 52 60-3/4” 24-1/2” 2.5 2.5 3160

DVE-1250A 648 1,250 132-1/2” 52 64-1/2” 23-1/4” 3 3 3,560

DVE-1500A 918 1,500 128-1/2” 70-1/2” 70-1/2” 25-1/4” 3” 3” 4,120

DVE-2000A 918 2,000 124-1/2” 78-1/2” 78-1/2” 27” 3” 3” 4,350

DVE-2500A 918 2,500 146-1/2” 82-1/2” 82-1/2” 29” 3” 3” 5,750

Horizontal Square Electric Storage Heater

DHE-150A 162 150 37” 68-1/2” 34-1/4” 12” 2” 2” 1,180

DHE-200A 198 200 37” 78” 34-1/4” 12” 2” 2” 1,370

DHE-250A 234 250 39” 90-1/4” 36-1/4” 13” 2” 2” 1,450

DHE-300A 288 300 45” 78-1/4” 42-1/4” 14-3/4” 2” 2” 1,530

DHE-400A 324 400 52” 78-1/4” 48-1/4” 16” 2” 2” 1,750

DHE-500A 432 500 52” 90-3/4” 48-1/4” 16” 2” 2” 1,860

DHE-600A 414 600 58” 90-3/4” 54-1/4” 13-1/2” 2-1/2” 2” 2,340

DHE-800A 468 750 58” 102-1/4” 54-1/4” 13-1/2” 2-1/2” 2” 2,850

DHE-1000A 648 950 58” 126-1/4” 54-1/4” 13-1/2” 2-1/2” 2” 3,040

DHE-1250A 648 1,250 64” 130-1/4” 60-1/4” 15” 3” 3” 3,750

DHE-1500A 918 1,500 70” 126-1/4” 66-1/4” 16” 3” 3” 4,340

DHE-2000A 918 2,000 82” 123-1/4” 78-1/4” 14” 3” 3” 4,580

DHE-2500A 918 2,500 82” 144-1/4” 78-1/4” 16-1/2” 3” 3” 6,060

Gallon

Capacity

Dimensions in Inches Water Connection

A B C D Inlet Openings Outlet Openings

Shipping

Weight (lbs)

kW Input

15 62 51,180 1 1 15 2/1 72 63 42 36 18

18 74 61,416 1 1 18 2/1 87 75 50 44 22

30 123 102,360 2 1 15 2/1 144 125 83 72 36

36 148 122,832 2 1 18 4/2 4/2 174 150 100 87 44

45 185 153,540 3 1 15 3/2 3/2 216 188 125 108 54

54 221 184,248 3 1 18 6/2 3/2 260 225 150 130 65

60 246 204,720 4 2 15 12/6 4/3 289 250 167 144 72

72 295 245,664 4 2 18 8/4 4/4

90 369 307,080 5 2 18 6/3 3/3 250 217 109

108 443 368,496 6 2 18 12/4 4/4 300 260 130

120 492 409,440 8 3 15 8/4 4/4 333 289 144

135 554 460,620 9 3 15 9/6 4/4 375 325 162

144 590 491,328 8 3 18 16/8 4/4 400 347 174

162 664 552,744 9 3 18 18/6 8/6 450 389 195

180 738 614,160 10 4 18 20/10 8/8 500 434 217

216 886 736,992 12 4 18 24/8 8/8 600 519 260

234 959 798,408 13 5 18 26/13 8/8 650 563 282

252 1,033 859,824 14 5 18 28/14 8/8 700 607 304

270 1,107 921,240 15 5 18 30/10 12/10 750 649 325

288 1,181 982,656 16 6 18 32/16 12/12 800 692 347

306 1,255 1,044,072 17 6 18 34/17 12/12 850 736 368

324 1,328 1,105,488 18 6 18 36/12 12/12 900 780 390

342 1,402 1,166,904 19 7 18 38/19 12/12 950 822 412

360 1,476 1,228,320 20 7 18 40/20 12/12 1,000 865 435

378 1,550 1,289,736 21 7 18 42/14 14/14 1,050 909 455

396 1,624 1,351,152 22 8 18 44/22 15/16 1,100 952 477

414 1,697 1,412,568 23 8 18 46/23 16/16 1,150 995 498

432 1,771 1,473,984 24 8 18 48/16 16/16 1,200 1,040 520

For higher inputs consult the factory.

GPH

100°F

Rise

Btu/hr

Equivalent

Max.

No. of

Elements

No. of

Control

Steps

kW Per

Element

No. of

Contractors

240/480V

Suggested

Modulating

Control Steps

240/480V

Single Phase Three Phase

208V 240V 208V 240V 480V

Not

Recommended

Amperage Draw

200 174 87

Not

Recommended

Page 3 of 4

AOSCE15500

Page 4

COMMERCIAL

ELECTRIC WATER HEATERS

TANK LININGS OPTIONS

CEMENT

• A special formulation of cement providing excellent corrosion protection.

Available on 250 gallon and larger tanks.

EPOXY

• A solventless two component epoxy lining available on 250 gallon and

larger tanks.

SPECIAL CONSTRUCTION OPTIONS

“12 X 16” MANHOLE – AVAILABLE ON 250 GALLON AND

ABOVE

150 OR 160 PSI WORKING PRESSURE

• Must be specified at time of order.

OTHER OPTIONAL FEATURES

TEMPERATURE AND PRESSURE RELIEF VALVES

• For working pressures other than standard; consult factory.

HORIZONTAL OR VERTICAL

• See specifications, most gallon capacities may be obtained in vertical or

horizontal construction.

CIRCULATING PUMP PACKAGE

• Circulating pump and piping sized to turn over entire storage capacity

of tank once each hour. Recommended to optimize available water at

temperature in horizontal tanks particularly where low draw conditions

are anticipated.

OPTIONAL INTERNATIONAL VOLTAGES

• 380 and 415 volts three-phase.

FACTORY-INSTALLED DIAL-TYPE PRESSURE GAUGE

CONTROL OPTIONS

HOT WATER GENERATING TUBE HEAT EXCHANGERS

• Custom dual energy source units with heating units and control trim and can be

built to design specifications on a special order basis for steam or boiler water

applications. Consult factory or Hot Water Generator specification sheets for

tube bundle sizing information and control options.

• Allows for remote connection to building demand limiter or other functions.

PILOT LIGHTS AND SWITCHES

• Denotes heating stage(s) in operation. Up to one light per contactor is available.

• A simple means of load control allows all or part of unit input to be controlled

manually. Up to one switch per contactor is available.

SAFETY DOOR INTERLOCK

• Prevents opening of control panel door when heater power supply is on. NOTE:

Once door is opened heater may be energized if necessary for service diagnosis.

SHUNT TRIP CIRCUIT BREAKER

• A safety device (circuit breaker) which disconnects power to heater in the event

of over-current, high temperature or low water level, breaker must be manually

reset Field Installed.

FACTORY-INSTALLED DIAL-TYPE TEMPERATURE GAUGE

SAMPLE SPECIFICATIONS

The heater(s) shall be A. O. Smith Commercial Electric Model Number ___________________ or an approved equal. Heater(s) shall be rated at _______ kW, _______

V, _______ phase, 60 cycle AC. The heater shall be for (vertical/horizontal) installation with lifting lug access and channel skid base not on every tank. Vessel shall be constructed

to Section IV of the ASME Code for 125 psi working pressure. Vessel shall be glass-lined with anodic protection. Entire vessel and electrical controls are to be encased in a sheet

metal enclosure with baked enamel finish. Tank to be insulated with fiberglass insulation. Enclosure to have hinged locking door over electric controls. There shall be ____________

individually replaceable heavy duty Incoloy sheathed heating elements each complete with prewired terminal leads. These elements will be switched by magnetic contactors which

are operated by a 120V fused control circuit protected by manual reset high limit. Control circuit is activated by a master pilot switch and electronic low water cutoff. This control shall

prevent the entire electrical load from being switched on instantaneously. The control shall have even load progressive sequencing which utilizes the “first on, first off” principle thereby

equalizing the operating time of heating elements and contactors. Each magnetic contactor and heating element circuit will be protected by a maximum of 60 amp cartridge type fuses

with a minimum of 100,000 amp interrupting capacity. The entire water heating package shall be prewired to solderless terminal lugs, factory tested, complete with a CSA Certified and

ASME Rated T&P relief valve and bear the Underwriters’ Laboratories label. Heater(s) shall have a 3-year limited warranty as outlined in the written warranty. Fully illustrated instruction

manual included. Water heater units(s) shall be compatible with building management systems using Modbus or BACnet with factory supplied gateway.

For technical information call 800-527-1953. A. O. Smith Corporation reserves the right to make product changes or improvements without prior notice.

© October 2018 A. O. Smith Corporation. All rights reserved.

www.hotwater.com | 800-527-1953 Toll-Free USA | A. O. Smith Corporation | 500 Tennessee Waltz Parkway | Ashland City, TN 37015

Page 4 of 4

AOSCE15500

Loading...

Loading...