A.O. Smith DVE-150A, DVE-200A, DVE-250A, DVE-300A, DVE-400A Installation Manual

...

WARNING: If the information in this

manual is not followed exactly, a fire or

explosion may result causing property damage,

personal injury, or loss of life.

100303268_2000556051 Rev A

Commercial Electric

Water Hea ter

Installation & Service

Manual

Models: 0150 - 1000

HLW

WARNING

Save this manual for future reference.

This manual must only be used

by a qualified heating installer

/service technician. Read all

instructions, including this

manual, before installing.

Perform steps in the order given.

Failure to comply could result in

severe personal injury, death, or

substantial property damage.

Contents

HAZARD DEFINITIONS .................................................... 2

PLEASE READ BEFORE PROCEEDING ........................ 3

INTRODUCTION ................................................................ 4

RATINGS ........................................................................... 5

1. FEATURES AND COMPONENTS

Vertical Models ................................................................... 6

Horizontal Models............................................................... 7

Dimensions and Capacities Data ................................... 8-9

2. DETERMINE WATER HEATER LOCATION

Facts to Consider About the Location ......................... 10-11

3. INSTALLATION

Mixing Valve Usage ......................................................... 12

Chemical Vapor Corrosion ............................................... 12

Circulating Pump .............................................................. 12

Insulation Blankets .......................................................... 12

Temperature - Pressure Relief Valve ...........................12-13

Closed Water Systems ......................................................13

Thermal Expansion .......................................................... 13

4. ELECTRICAL

General ............................................................................. 14

Branch Circuit ................................................................... 14

Heater Circuits.................................................................. 14

Power Circuit .................................................................... 14

Amp Chart ................................................................... 15-16

Electrical and Recoveries Data ........................................ 17

208V - 240V Chart ............................................................18

5. OPERATION

General ............................................................................. 19

Filling the Water Heater ................................................... 19

Initial Start-up ................................................................... 19

Draining the Water Heater ............................................... 19

6. TEMPERATURE REGULATION

High Temperature Limit Controls (ECO) .......................... 20

Thermostat Controls ......................................................... 20

Temperature Adjustment .................................................. 20

7. CONTROL SYSTEM OPERATION

Heating Banks Operation ................................................. 21

Control System Features ................................................. 21

Control System Navigation ............................................... 21

The Display Screen .......................................................... 21

Control System Operation Tables ............................... 22-23

Temperatures Menu ......................................................... 24

Temperature Screens ...................................................... 25

Water Heater Status Menu .............................................. 26

Economy Mode Setup Menu ............................................ 27

Economy Mode Settings Tables ................................. 28-30

Alarm Output Setup Menu ............................................... 31

Display Settings Menu ..................................................... 31

Heater Information Menu ................................................. 32

Current Fault / Alert Menu ................................................ 32

Fault History Menu ........................................................... 32

Fault Occurrence Menu .................................................... 33

Restore Factory Defaults Menu ....................................... 34

8. MAINTENANCE

General ............................................................................. 35

Anode Rod Inspection ...................................................... 35

Flushing the Water Heater ............................................... 35

Sediment Removal ........................................................... 36

Lime Scale Removal ........................................................ 36

9. TROUBLESHOOTING

Checklist ........................................................................... 37

10. DIAGRAMS

Wiring Diagram .......................................................... 38-39

Revision Notes .................................................. Back Cover

Hazard definitions

The following defined terms are used throughout this manual to bring attention to the presence of hazards of various risk levels or

to important information concerning the life of the product.

DANGER

WARNING

CAUTION

CAUTION

NOTICE

2

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

NOTICE indicates special instructions on installation, operation, or maintenance that are important but not

related to personal injury or property damage.

Please read before proceeding

WARNING

NOTICE

Installer – Read all instructions before

installing. Perform steps in the order

given.

Have this water heater serviced/inspected

by a qualified service technician, at least

annually.

Failure to comply with the above could

result in severe personal injury, death, or

substantial property damage.

When calling or writing about the water

heater – Please have the water heater

model and serial number from the water

heater rating plate.

Consider piping and installation when

determining water heater location.

Any claims for damage or shortage in

shipment must be filed immediately

against the transportation company by the

consignee.

Factory warranty (shipped with unit) does

not apply to units improperly installed or

improperly operated.

When servicing the water heater –

• To avoid electric shock, disconnect electrical supply

before performing maintenance.

• To avoid severe burns, allow the water heater to cool

before performing maintenance.

• Do not use this water heater if any part has been under

water. The possible damage to a flooded appliance can

be extensive and present numerous safety hazards. Any

appliance that has been under water must be replaced.

Grounding Instructions –

• This water heater must be grounded in accordance

with the National Electrical Code and/or local codes.

These must be followed in all cases. Failure to ground

this water heater properly may also cause erratic

control system operation on ELECTRONIC

CONTROL models.

• This water heater must be connected to a grounded

metal, permanent wiring system, or an equipment

grounding conductor must be run with the circuit

conductors and connected to the equipment grounding

terminal or lead on the water heater.

WARNING

WARNING

WARNING

Failure to adhere to the guidelines on this

page can result in severe personal injury,

death, or substantial property damage.

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury, or loss of life.

The California Safe Drinking Water and

Toxic Enforcement Act requires the

Governor of California to publish a list of

substances known to the State of California

to cause cancer, birth defects, or other

reproductive harm, and requires businesses

to warn of potential exposure to such

substances.

This product contains a chemical known to

the State of California to cause cancer, birth

defects, or other reproductive harm. This

water heater can cause low level exposure

to some of the substances listed in the Act.

Hydrogen Gas (Flammable) –

Hydrogen gas can be produced in a hot water system,

served by this heater, that has not been used for a long

period of time (generally two weeks or more). Hydrogen

gas is extremely flammable. To reduce the risk of injury,

it is recommended that the hot water faucet be opened

for several minutes at the kitchen sink before using any

electrical appliance connected to the hot water system.

If hydrogen is present, there will probably be an unusual

sound, such as air escaping through the pipe as water

begins to flow.

WARNING

WARNING

WARNING

There should be no smoking or open

flame near the faucet at the time it

is open.

Flammable hydrogen gases may be

present.

Keep all ignition sources away from

faucet when turning on hot water.

3

Introduction

ank you for purchasing this water heater. Properly installed

and maintained, it should give you years of trouble-free

service.

Abbreviations Used

Abbreviations found in this instruction manual include:

• ANSI - American National Standards Institute

• ASME - American Society of Mechanical Engineers

• NEC - National Electrical Code

• NFPA - National Fire Protection Association

• UL - Underwriters Laboratory

• CSA - Canadian Standards Association

• AHRI - Air Conditioning, Heating, & Refrigeration

Institute

Preparing for the Installation

WARNING

Read the Please read before proceeding... section of this manual

rst, then read the entire manual carefully. If you don’t follow

the safety rules, the water heater may not operate safely, which

could result in death, serious bodily injury, and/or property

damage.

is manual contains instructions for the installation,

operation, and maintenance of the water heater. It also

contains warnings throughout the manual that you must

read and be aware of. All warnings and all instructions are

essential to the proper operation of the water heater and your

safety. Read the entire manual before attempting to install or

operate the water heater.

General outline diagrams are in this manual. ese diagrams

will serve to provide the installer with a reference for basic

installation of this product. It is necessary that all water piping

and electrical wiring be installed and connected as shown in

the diagrams.

Before removing any access panels

or servicing the water heater, make

sure the electrical supply to the water

heater is turned OFF. Failure to do

this could result in death, serious

bodily injury, or property damage.

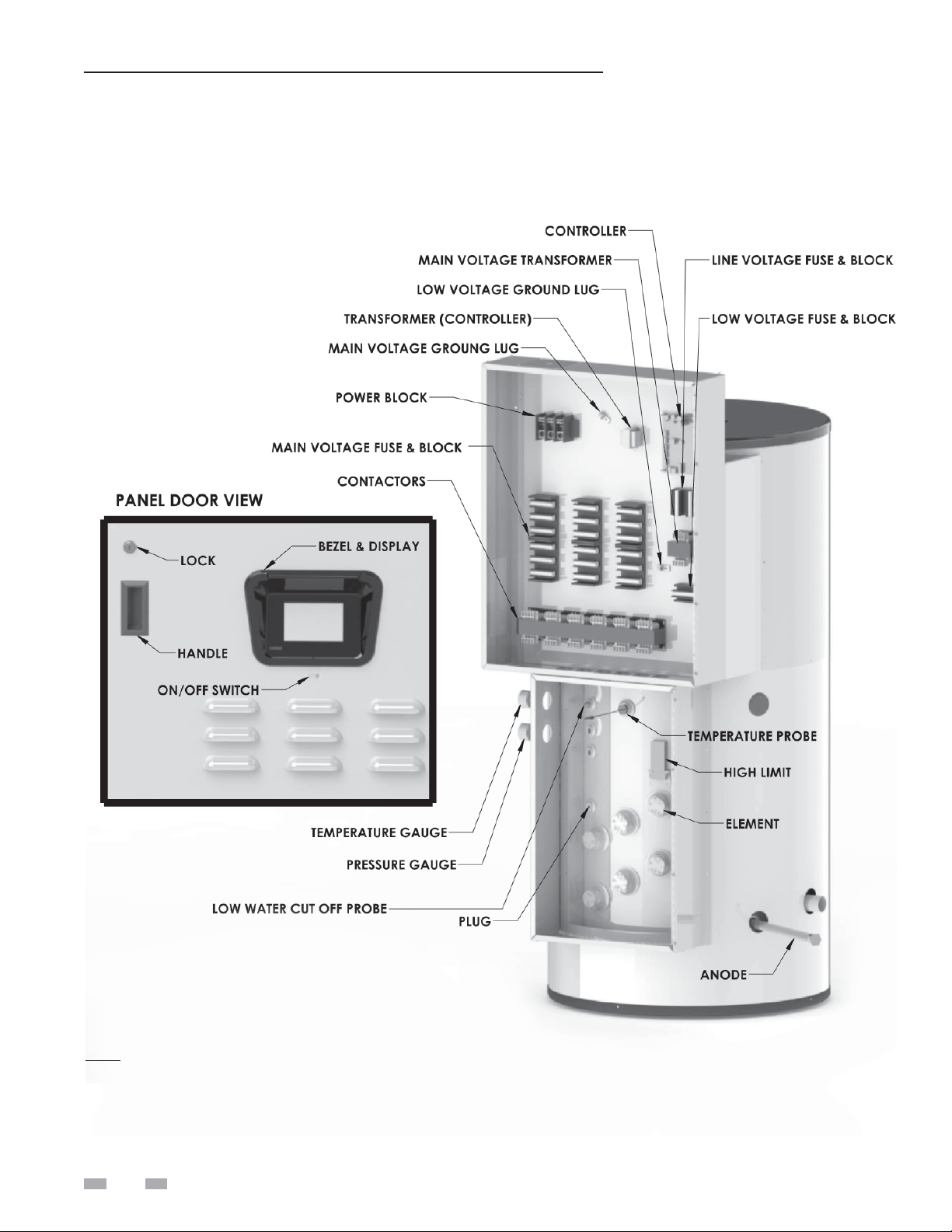

e principle components of the heater are identi ed on pages

6 and 7. e model and rating plate on page 5 interprets certain

markings into useful information. Both of these references

should be used to identify the heater, its components, and

optional equipment.

e installation must conform with these instructions

and the local code authority having jurisdiction and the

requirements of the power company. In the absence of local

codes, the installation must comply with the current editions

of the National Electrical Code, NFPA 70 or the Canadian

Electrical Code, CSA C22.1. e National Electrical Code

may be ordered from: National Fire Protection Association,

1 Batterymarch Park, Quincy, MA 02269. e Canadian

Electrical Code is available from the Canadian Standards

Association, 8501 East Pleasant Valley Road, Cleveland, OH

44131.

If a er reading this manual you have any questions or do not

understand any portion of the instructions, call the telephone

number on the back cover for further assistance. Please have

the model and serial number of the unit available for the

technician.

Carefully plan your intended placement of the water heater.

Examine the location to ensure the water heater complies with

the Determine Water Heater Location section in the manual.

Clearance must be maintained so that the heating elements

may be removed for servicing a er installation.

Installation and service of this water heater requires ability

equivalent to that of a licensed tradesman or quali ed agency

in the eld involved. Plumbing and electrical work are

required.

For installation in California, this water heater must be braced

or anchored to avoid falling or moving during an earthquake.

See instructions for correct installation procedures.

Instructions may be obtained from the California O ce of

the State Architect, 1102 Q Street, Suite 5100, Sacramento,

CA 95811.

Be sure to turn power OFF when working on or near the

electrical system of the water heater. Never touch electrical

components with wet hands or when standing in water. When

replacing fuses always use the correct size for the circuit. Use

the same size and type of fuse when replacing.

Detailed installation diagrams are in this manual. ese

diagrams will serve to provide the installer with a reference for

the materials and method of piping suggested. It is necessary

that all water piping and electrical wiring be installed and

connected as shown in the diagrams.

4

Massachusetts Code requires this water heater to be installed

in accordance with Massachusetts 248-CMR 2.00: State

Plumbing Code and 248-CMR 5.00.

Ratings

Rating & Model Plate

HLW

All models are listed

by Underwriters

Laboratories Inc.

>Kt>KEdEd

PHASEVOLTS, AC UPPER

VOLTS, AC UPPER

MODEL NUMBER

L

KILOWATTS

MODEL NUMBER BARCODE

XXXXXXXX

ELECTRIC STORAGE

TANK WATER HEATER

SERIAL NUMBER ITEM ID/PART NUMBERMODEL NUMBER

KILOWATTS

KILOWATTS

LOWER

KILOWATTS

LOWER

TOTAL kW

CONNECTED

ADDRESS

TOTAL kW

CONNECTED

CAPACITY

US GALLONS

CIRCUIT

SERIAL NUMBER BARCODE

SERIAL NUMB ER

5555

®

,,,,

MAX WORKING

PRESSURE

123456789

LISTED

932N

E

A

S

M

CERTIFIED BYLC

E

MAWPXXXPSI

123456

MAX ALLOWABLE INPUT

HLW

XXXXXXXXX BTU/HR

S/N123456789

YEAR BUILT YYWW

CRN XXXXXXXXXXXXXXXXXXXX

5

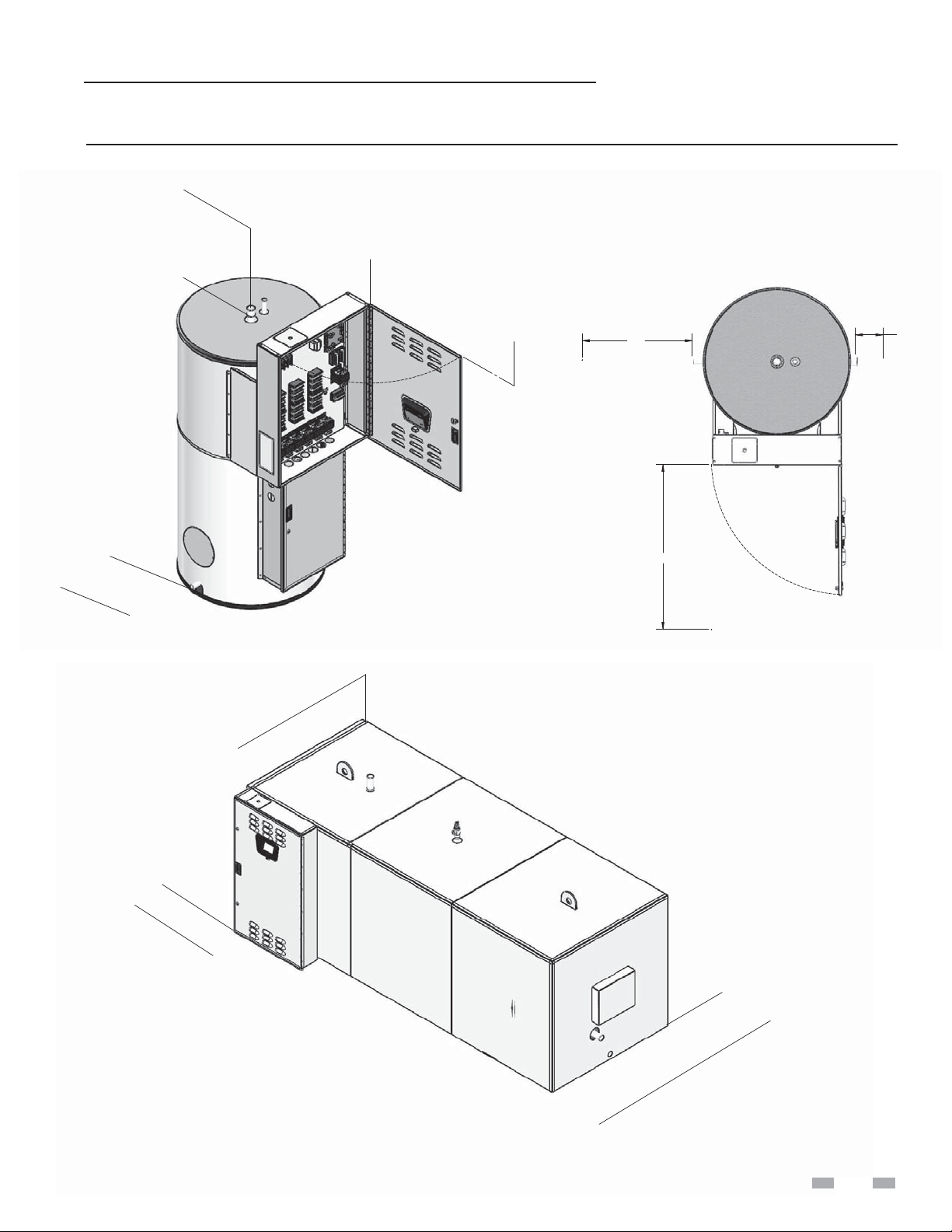

1 Features and Components

Vertical Models

Note: Model shown for illustration purposes only. Actual con gurations may vary.

6

1 Features and Components

Horizontal Models

CONTROLLER

TRANSFORMER (CONTROLLER)

MAIN VOLTAGE GROUND LUG

POWER BLOCK

CONTACTORS

MAIN VOLTAGE FUSE & BLOCK

LOW VOLTAGE FUSE & BLOCK

MAIN VOLTAGE TRANSFORMER

ELEMENTS

HIGH LIMIT

LOW VOLTAGE FUSE & BLOCK

LOW VOLTAGE GROUND LUG

LOW WATER CUT OFF PROBE

TEMPERATURE PROBE

PLUG

RELIEF VALVE

ANODE

HANDHOLE/

MANWAY

ACCESS

Note: Model shown for illustration purposes only. Actual con gurations may vary.

7

1 Features and Components

Specifications Data

ADDITIONAL

HEIGHT IF

REQUIRED

ELECTRONIC

CONTROL

CONTROL VOLTAGE

ON/OFF SWITCH

CLEANOUT

DRAIN

HOT WATER

OUTLET

B

3/4"

T & P

RELIEF

VALVE

CONNECTION

A

COLD WATER

INLET

D

3/4" OR 1" DRAIN

C

HINGED DOOR

TO ELECTRICAL

COMPARTMENT

ELECTRONIC

CONTROL

CONTROL VOLTAGE

ON/OFF SWITCH

CHANNEL (150 & 200 GALLON DO NOT HAVE CHANNELS)

B

HOT WATER

OUTLET

A & D ELEVATION FROM FINISHED FLOOR

T&P RELIEF VALVE

4.000

TOP VIEW

C 6.688

ADDITIONAL

HEIGHT IF

REQUIRED

HANDHOLE

INLET

D

EXTRA PANEL BOX MAY BE NECESSARY FOR INPUTS

HIGHER THAN 72KW. CONSULT FACTORY.

DRAIN

8

1 Features and Components (continued)

Specifications Data (continued)

Model

0150 162 65 1/2" 32" 38 3/4" 11 3/4" 1 1/2" 1 1/2" 650

0200 216 78" 32" 38 3/4" 11 3/4" 1 1/2" 1 1/2" 750

0250 270 91 3/8" 34" 40 3/4" 19 1/4" 1 1/2" 1 1/2" 1,165

0300 162 80" 40" 46 3/4" 20 3/4" 2" 2" 1,350

0400 162 80" 46" 52 3/4" 22 1/4" 2" 2" 1,590

0500 270 91 3/8" 46" 52 3/4" 22 1/4" 2" 2" 1,700

0600 270 92 5/8" 52" 58 3/4" 24 1/4" 2 1/2" 2 1/2" 2,010

0800 432 104" 52" 58 3/4" 24 1/4" 2 1/2" 2 1/2" 2,450

1000 486 128" 52" 58 3/4" 24 1/4" 2 1/2" 2 1/2" 3,160

1250 648 132 1/2" 64 1/2" 64 1/2" 23 1/4" 3" 3" 3,560

1500 918 128 1/2" 70 1/2" 70 1/2" 25 1/4" 3" 3" 4,120

2000 918 140 1/2" 76 1/2" 76 1/2" 27 1/4" 3" 3" 4,350

2500 918 146 1/2" 82 1/2" 82 1/2" 29" 3" 3" 5,750

0150 162 37" 68 1/2" 34 1/4" 12" 2" 2" 1,180

0200 198 37" 78" 34 1/4" 12" 2" 2" 1,370

0250 240 39" 90 1/4" 36 1/4" 13" 2" 2" 1,450

0300 300 45" 78 1/4" 42 1/4" 14 3/4" 2" 2" 1,530

0400 324 52" 78 1/4" 48 1/4" 16" 2" 2" 1,750

0500 432 52" 90 3/4" 48 1/4" 16" 2" 2" 1,860

0600 414 58" 90 3/4" 54 1/4" 13 1/2" 2 1/2" 2" 2,340

0800 468 58" 102 1/4" 54 1/4" 13 1/2" 2 1/2" 2" 2,850

1000 648 58" 126 1/4" 54 1/4" 13 1/2" 2 1/2" 2" 3,040

1250 648 64" 130 1/4" 60 1/4" 15" 3" 3" 3,750

1500 918 70" 126 1/4" 66 1/4" 16" 3" 3" 4,340

2000 918 76" 137 1/4" 72 1/4" 17 1/2" 3" 3" 4,580

2500 918 82" 144 1/4" 78 1/4" 16 1/2" 3" 3" 6,060

Maximum KW

Input

Height

A

Width

(Length)

B

VERTICAL ROUND ELECTRIC STORAGE HEATER

VERTICAL SQUARE ELECTRIC STORAGE HEATER

HORIZONTAL SQUARE ELECTRIC STORAGE HEATER

Depth

C

D

Inlet

Water

Connection

Outlet Water

Connection

Shipping

Weight (lbs)

9

2 Determine Water Heater Location

Determine Water Heater Location

CAUTION

Carefully choose a location for the new water heater. e

placement is a very important consideration for the safety of the

occupants in the building and for the most economical use of

the appliance.

Whether replacing an old water heater or putting the water

heater in a new location, the following critical points must be

observed. e water heater must be located:

1. On a level surface. Shim the channel-type skid base as

necessary if leveling is required.

2. Near a oor drain. e heater should be located in an area

where leakage of the tank or connections will not result in

damage to the area adjacent to the heater or to lower oors

of the structure. When such locations cannot be avoided, a

suitable drain pan should be installed under the heater. e

pan should be at least 2 inches deep, have a minimum length

and width of at least 2 inches greater than the dimensions of

the water heater, and should be piped to an adequate drain.

e discharge opening of the relief valve should always be

piped to an open drain.

3. Close to the point of major hot water usage and the power

supply.

All water heaters eventually leak. Do

not install without adequate drainage.

Hot water piping and branch circuit wiring should be as short as

possible. Insulate hot and cold water piping where heat loss and

condensation may be a problem.

Heater construction permits installation, maintenance, and

service work to be performed through the element box door and

control box door.

Suggested clearances from adjacent surfaces are 12 inches on

top, 30 inches in front of access doors, 24 inches for cleanout/

handhole/manway side, and 6 inches on the inlet water piping

side.

e heater may be installed on or against combustible surfaces.

e back may be placed ush against adjacent surfaces. Be sure

to place the cover plates over the rear crating couplings before

locating vertical model heaters that were shipped laying down.

e heater may be installed in a con ned space if adequate

ventilation is provided.

e temperature of the space in which the water heater is

installed must not go below 32F or above 122F.

10

2 Determine Water Heater Location (continued)

Figure 2-1 Clearances from Combustible Construction

←

TOP

CLEARANCE

12"

←

←

ACCESS DOOR

CLEARANCE

30"

←

MANWAY OR

HANDHOLE

CLEARANCE

24"

REAR

INLET WATER

PIPING

CLEARANCE

6"

RIGHT

MANWAY OR

HANDHOLE

CLEARANCE

←

←

24"

ACCESS DOOR

CLEARANCE

*30"

↓

LEFT

ACCESS DOOR

CLEARANCE

FRONT

CLEARANCE

36"

FRONT

↓

12"

↓

REAR

↓

*DISTANCE FOR DOOR TO OPEN

FRONT

↓

RIGHT

24"

↓

MANWAY OR

HANDHOLE

CLEARANCE

11

3 Installation

e installation must conform to these instructions and local

code authority having jurisdiction. Grounding and electrical

wiring connected to the water heater must also conform to the

National Electrical Code, NFPA 70. is publication is available

from e National Fire Protection Association, 1 Batterymarch

Park, Quincy, MA 02269.

CAUTION

e principle components of the heater are identi ed in the

Features and Components illustration on pages 6 and 7.

DANGER

Do NOT test electrical system before

heater is lled with water. Follow the

Start-up procedure in the Operation

section of this manual.

Water temperature over 125F (52C)

can cause severe burns instantly resulting

in severe injury or death. Children, the

elderly, and the physically or mentally

disabled are at highest risk for scald

injury. Feel water before bathing or

showering. Temperature limiting devices,

such as mixing valves, must be installed

when required by code and to ensure safe

temperatures at fixtures.

Mixing Valve Usage

Water heaters are intended to produce hot water. Water heated to

a temperature which will satisfy clothes washing, dish washing,

cleaning, and other sanitizing needs can scald and permanently

injure you upon contact. Some people are more likely to be

permanently injured by hot water than others. ese include the

elderly, children, the in rm, or the physically or developmentally

disabled. If anyone using hot water in your home ts into one

of these groups, or if there is a local code or state law requiring a

maximum water temperature at the hot water tap, then you must

take special precautions. In addition to using the lowest possible

temperature setting that satis es your hot water needs, a means

such as a mixing valve, should be used at the hot water taps or at

the water heater.

Mixing valves for reducing point-of-use temperature are

available. Consult a quali ed installer or service agency. Follow

all manufacturer’s instructions for installation of mixing valves.

Before changing the factory setting on the thermostat, read the

Temperature Regulation section in this manual.

WARNING

Toxic chemical hazard: Do not connect

to non-potable water system.

Chemical Vapor Corrosion

is water heater shall not be connected to any heating

system(s) or component(s) used with a non-potable water

heating appliance. Toxic chemicals, such as those used for boiler

treatment, shall not be introduced into this system. Water heater

corrosion and component failure can be caused by the heating and

breakdown of airborne chemical vapors. Spray can propellants,

cleaning solvents, refrigerator and air conditioning refrigerants,

swimming pool chemicals, water so ener chemicals, calcium

and sodium chloride, waxes, and process chemicals are typical

compounds which are potentially corrosive. ese materials

are corrosive at very low concentration levels with little or no

odor to reveal their presence. Products of this sort should not

be stored near the heater. Also, air which is brought in contact

with the water heater should not contain any of these chemicals.

If necessary, uncontaminated air should be obtained from

remote or outside sources.

Circulating Pump

Field-installed circulating pumps should be of all bronze

constructions. To optimize the total storage capacity of a

horizontal vessel, particularly under low draw conditions, it is

recommended to utilize a pump and recirculation line sized to

turn the entire storage capacity of the tank once each hour (i.e., a

600 gallon tank would require a 10 gpm pump).

Insulation Blankets

Insulation blankets are available to the general public for

external use on electric water heaters, but are not necessary with

this product. e purpose of an insulation blanket is to reduce

the standby heat loss encountered with storage tank heaters.

Your water heater meets or exceeds the EPACT and ASHRAE/

IES 90.1 standards with respect to insulation and standby loss

requirements, making an insulation blanket unnecessary.

Should you choose to apply an insulation blanket to this heater,

you should follow the instructions below. Failure to follow these

instructions can result in re, serious personal injury, or death.

• Do NOT cover the temperature and pressure relief (T & P)

valve with an insulation blanket.

• Do NOT cover the instruction manual. Keep it on the side

of the water heater or nearby for future reference.

• DO obtain new warning and instruction labels for placement

on the blanket directly over the existing labels.

Temperature - Pressure Relief Valve

WARNING

is water heater is provided with a properly rated/sized and

certi ed combination temperature-pressure relief valve by the

manufacturer. e valve is certi ed by a nationally recognized

testing laboratory that maintains periodic inspection of

production of listed equipment of materials as meeting the

requirements for Relief Valves for Hot Water Supply Systems,

ANSI Z21.22 • CSA 4.4, and the code requirements of ASME.

The temperature and pressure relief

valve must comply with ANSI Z21.22

and ASME code. A properly sized

temperature and pressure relief valve

must be installed in the opening

provided. Failure to install a relief

valve can result in overheating and

excessive tank pressure. Failure to

follow these instructions can cause

serious injury or death.

12

Loading...

Loading...