Page 1

COMMERCIAL

ELECTRIC WATER HEATERS

CUSTOM Xi™ SERIES

HEAVY DUTY COMMERCIAL ELECTRIC WATER HEATERS

ADVANCED ELECTRONIC CONTROL

• A. O. Smith’s new proprietary electronic water

heater control provides precise + or – 1°

temperature control that is ideal for industrial

and food service applications where exact

temperatures are needed.

• The Operating Set Point is adjustable from

90°F/42°C to 190°F/88°C. The factory setting

is 120°F/49°C.

• Approved for 180°F/82°C sanitizing

applications.

PLAIN ENGLISH TEXT

• Animated icons display detailed operational

and diagnostic information. Fault or Alert

messages appear if an operational issue

occurs.

ELEMENT SENSING

• Each element is constantly monitored and

current on/off state is displayed, any element

failure is reported and its exact location is

shown, eliminates a need for field testing of

elements.

LOW WATER CUT OFF

• Factory standard on board low water cutoff

uses a remote electric immersion type probe

to prevent energizing of the elements in the

event of low water condition and eliminates

accidental dry firing.

SEQUENCING

• Units with multiple element contactors

are sequenced on with one-second delay

between stages. Prevents high amp electrical

loads from hitting the electric system all at

once and provides a smoother operating unit.

Adjustable modulating mode is optional see

options.

NIGHT SETBACK OPERATION

• Control system automatically lowers the

operating set point by a user defined value

during setback periods. Seven-day clock may

be programmed for night set back and or

weekend shutdown to reduce operating cost

and save energy.

BUILDING MANAGEMENT SYSTEM

• BACnet or Modbus compatible with optional

ICC Gateway.

• Call 1.888.WATER02 for more information.

POWERED ANODE

• The DSE models use a unique combination

of a conventional sacrificial anode and an

adaptive powered anode. The powered

anode is self-adjusting to water conditions,

does not require maintenance and provides

longer-lasting tank protection in hard to

reach areas. This multi-anode system provides

superior anodic protection to hidden surfaces

of the tank not protected in conventional

commercial electric water heaters.

INCOLOY IMMERSION HEATERS

• Heavy-duty elements provide excellent

protection against oxidation and scaling.

Input ranges from 3kW to 90kW available

(see accompanying chart). Rugged, industrial

grade, elements.

FOAM INSULATED

• All models meet or exceed the thermal

efficiency and/or standby loss requirements

of the U. S. Department of Energy and

current edition ASHRAE/IES 90.1.

GLASSLINED TANK

• A. O. Smith’s PermaGlas® coating provides

truly superior protection against corrosion

and is permanently bonded to all inner tank

surfaces at 1600°F.

ASME TANK CONSTRUCTION

• 160 psi working pressure

THREE YEAR LIMITED WARRANTY

• For complete warranty information consult

written warranty.

Features and benefits continued on the following page.

Attention: Changes have been made to some models.

Please note that this spec sheet refers specifically to models

manufactured in McBee, SC

DSE-5A thru DSE-120A

(DSE-100A Shown)

© August 2018 | A. O. Smith Corporation. All rights reserved.

www.hotwater.com | 800-527-1953 Toll-Free USA | A. O. Smith Corporation | 500 Tennessee Waltz Parkway | Ashland City, TN 37015

Page 1 of 4

AOSCE15100

Page 2

FEATURES AND BENEFITS (CONTINUED)

COMMERCIAL

ELECTRIC WATER HEATERS

STANDARD VOLTAGES

• 208, 240 and 480 volt single and three phase. All 208 and 240 volt at 24kW

and below are supplied phase convertible (single to three and vice versa).

277 volt single phase also available. Consult factory for 120 volt power

circuit availability.

TERMINAL BLOCK

• To accept copper or aluminum leads (on units with more than one

contactor).

120 VOLT CONTROL CIRCUIT

• Powered by fused transformer.

MAGNETIC CONTACTORS

• Heavy-duty UL rated for 100,000 cycles.

POWER CIRCUIT FUSING (120 AMP CURRENT DRAW AND

ABOVE)

• Meets National Electric Code and UL requirements that water heaters must

have internal fusing when current draw exceeds 120 amps.

SIMPLIFIED CIRCUITRY, COLOR-CODED FOR EASE OF SERVICE

HINGED CONTROL COMPARTMENT DOOR

CSA CERTIFIED AND ASME RATED T&P RELIEF VALVE

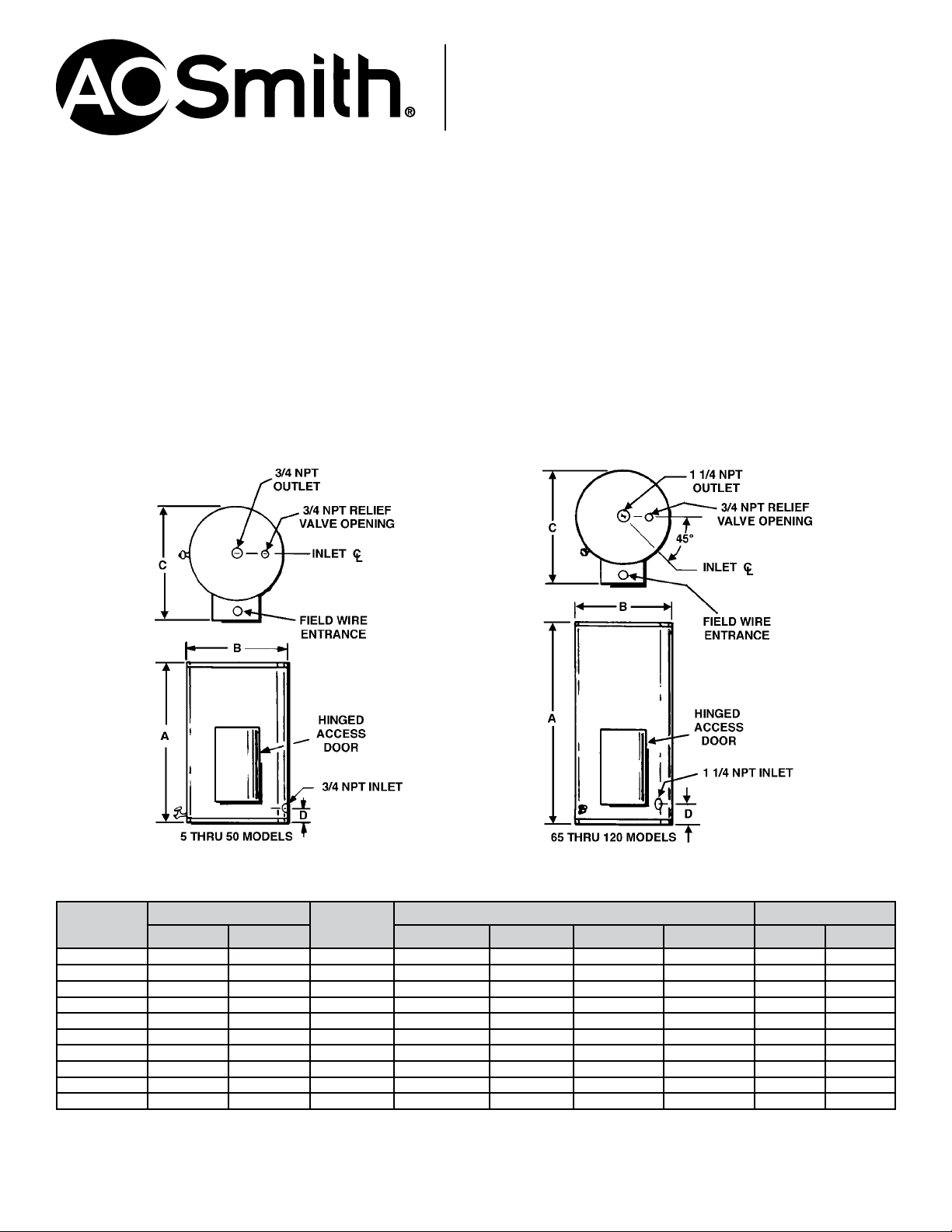

ROUGH-IN DIMENSIONS

Model Number

DSE-5A 5 19 3 22 in 16 in 24 in 4.25 in 82 37.2

DSE-10A 10 38 6 28.13 in 18 in 26 in 5.25 in 116 48.1

DSE-20A 20 76 18 31.75 in 22 in 28 in 5.75 in 145 65.7

DSE-30A 30 114 24 43.25 in 22 in 28 in 5.75 in 218 98.9

DSE-40A 40 151 36 54.75 in 22 in 28 in 5.75 in 245 111.1

DSE-50A 50 189 90 66.19 in 22 in 28 in 5.75 in 291 132.0

DSE-65A 65 246 90 57.25 in 26.5 in 32.5 in 11.38 in 344 156.0

DSE-80A 80 303 90 58.13 in 28 in 35 in 12.5 in 406 184.2

DSE-100A 100 379 90 70.25 in 28 in 35 in 12.5 in 419 190.1

DSE-120A 120 450 90 70.25 in 30.13 in 37 in 12.5 in 453 205.5

* Not available in 208 volt

Tank Capacity

Gallons Litres A B C D lbs. Kg.

Maximum kW

Input

*

Dimensions in Inches (mm) Approx. Shipping Weight

AOSCE15100

Page 2 of 4

Page 3

COMMERCIAL

ELECTRIC WATER HEATERS

RECOVERY CAPACITIES

GPH recoveries at list temperature rise

Standard

kW Input

3 10,239 41 31 24 20 17 15 13 12 11 10 10 9

6 20,478 82 62 49 41 35 31 27 25 22 21 19 18

9 30,717 123 92 74 62 53 46 41 37 34 31 28 26

12 40,956 164 123 98 82 70 61 55 49 45 41 38 35

15 51,195 205 154 123 102 88 88 68 61 56 51 47 44

18 61,434 246 184 148 123 105 92 82 74 67 62 57 53

24 81,912 328 246 197 164 140 123 109 98 90 82 76 70

30 102,390 410 308 246 205 176 154 137 123 112 103 95 88

36 122,868 492 369 295 246 211 184 164 148 134 123 113 105

45 153,585 615 461 369 307 263 230 205 184 168 154 142 132

54 184,302 738 554 443 359 316 277 246 221 201 185 170 158

60 204,780 819 615 492 410 351 307 273 246 223 205 189 176

75 255,975 1025 768 615 512 439 384 341 307 279 256 236 219

90 307,170 1229 922 738 615 527 461 410 369 335 307 284 263

STANDARD kW INPUTS AND AMPERAGE

Standard kW

Ratings

BTU/

30°F Rise 40°F Rise 50°F Rise 60°F Rise 70°F Rise 80°F Rise 90°F Rise 100°F Rise 110°F Rise 120°F Rise 130°F Rise 140°F Rise

Hour

Immersion

Heaters***

Wattage

No. of 208V 240V 480V

Number of 50A

Contactors

Full Load Current in Amperes

Single Phase Three Phase

208V 240V 277V 480V 208V 240V 480V

3 1 3,000

6 1 6,000 28.8 25 21.2 12.5 16.7 14.4 7.2

9 1 9,000 43.3 37.5 32.5 18.8 25 21.7 10.8

12 1 12,000 57.7 50 43.3 25 33.3 28.9 14.4

15 1 15,000 72.1 62.5 54.2 31.3 41.6 36.1 18

18 *1 18,000

24 2 12,000

30 2 15,000 144.2 125 108.3 62.5 83.3 72.2 36.1

36 *2 18,000

45 3 15,000

54 3 18,000 N/A 225 194.9 112.5 149.9 129.9 65

60 4 15,000 4 4 4 N/A 250 216.6 125 166.7 145 72

75 5 15,000

90 5 18,000 N/A N/A N/A 188 250 217 108

* 208V models use one additional immersion heater.

*** Each immersion heater contains three electric elements.

1

1 1

2

2 2

3

3 3

5 5 5

14.4 12.5 10.8 6.3 8.3 7.2 3.6

86.5 75 65 37.5 50 43.3 21.7

115.4 100 86.6 50 66.6 57.7 28.9

173.1 150 130 75 99.9 86.6 43.3

216.3 187.5 162.5 93.8 124.9 108.3 54.1

N/A N/A N/A 156 208.4 181 90

Page 3 of 4

AOSCE15100

Page 4

OPTIONAL EQUIPMENT & CONSTRUCTION

COMMERCIAL

ELECTRIC WATER HEATERS

HANDHOLE CLEANOUT (NOT AVAILABLE ON 5 & 10 GALLON

MODELS.)

DIAL TYPE COMBINATION TEMPERATURE & PRESSURE GAUGE

(SHIPPED LOOSE)

POWER CIRCUIT FUSING (LESS THAN 120 AMPS)

• Sub-divides internal circuitry with maximum of 60 amp fuses. Supplied as

standard when required by NEC and UL.

ALARM HORN

• Horns may be furnished to warn of any condition in the heater for which

sensors have been specified.

NORTH CAROLINA CODE - FACTORY INSTALLED T&P VALVE

CONTROL OPTIONS

MODULATING CONTROL

• The first element on is the first element off.

• Not available on single element, single contactor units.

OPTIONAL INTERNATIONAL VOLTAGES

• 380, 415, 575 and 600 volts three-phase available with Y connected

elements.

SPECIFICATION

The heater shall be a glass-lined Custom Xi™ commercial electric model No.______ with _____gallons storage, as manufactured by A. O. Smith. Heater should

be rated at ____kW, ____volts, ____phase, 50/60 cycle AC and constructed in accordance with ASME Code, shall bear appropriate symbol and be listed with

the National Board as required. Heater shall be listed with Underwriters’ Laboratories and classified to The National Sanitation Foundation Standard No. 5. All

internal surfaces of the tank shall be glass-lined with an alkaline borosilicate composition that has been fused-to-steel by firing at a temperature of 1600°F. Tank

shall be cathodically protected with a combination of sacrificial and powered anodes. The entire vessel is to be enclosed in a round steel enclosure with baked

enamel finish. Water heater shall have an electronic control with large LCD displaying current water heater status; provide real time element status and sensing,

low water cutoff and economy mode operation. Shall have 120 volt control circuit transformer, transformer fusing, magnetic contactor(s), element fusing per

N.E.C., and commercial grade Incoloy elements. Temperature controls include limiting switch which will require resetting manually in the event the temperature

reaches 202°F. Foam insulation shall meet the thermal efficiency and/or standby loss requirements of the U. S. Department of Energy and current edition of

ASHRAE/IES 90.1. Heater shall include a CSA Certified and ASME Rated T&P relief valve and a drain valve. Water heater units(s) shall be compatible with building

management systems using Modbus or BACnet with optional ICC interface.

For technical information, call 800-527-1953. A. O. Smith Corporation reserves the right to make product changes or improvements without prior notice.

© August 2018 | A. O. Smith Corporation. All rights reserved.

www.hotwater.com | 800-527-1953 Toll-Free USA | A. O. Smith Corporation | 500 Tennessee Waltz Parkway | Ashland City, TN 37015

Page 4 of 4

AOSCE15100

Loading...

Loading...